Toner for printer

A technology of toner for printers, applied in electrography, optics, instruments, etc., can solve problems such as uneven chroma, uneven melting temperature of toner, and uneven quality, and achieve improved dispersion performance and excellent gloss degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

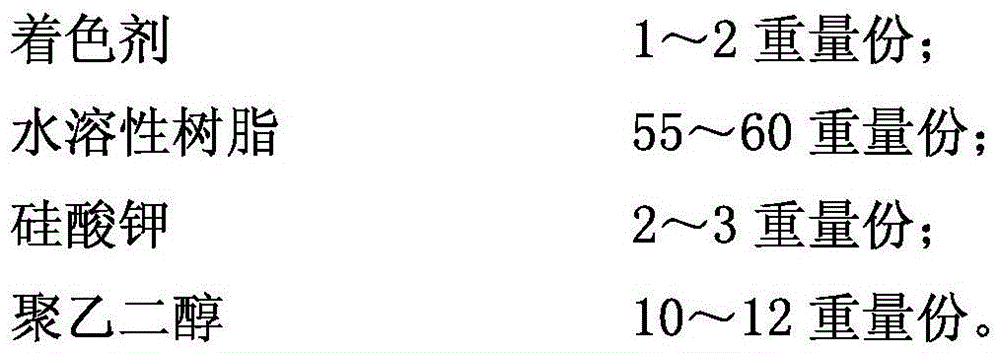

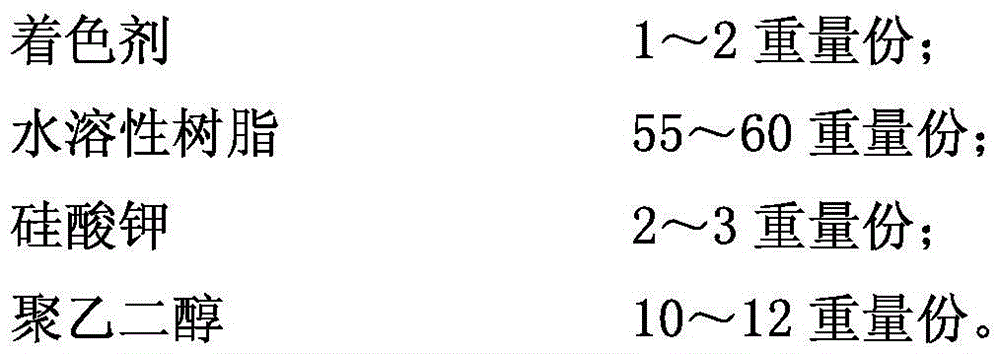

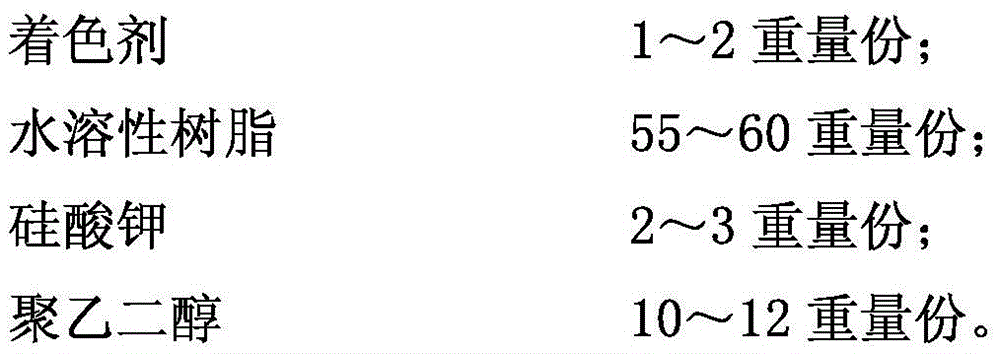

[0015] This case proposes the printer toner of an embodiment, comprises following material:

[0016]

[0017] Colorants generally refer to pigments. In this case, the specific types of colorants are not limited, so the choice of colorants is free to choose according to actual needs. For example, when black toner is required, carbon black is selected for coloring agent, when a color toner is needed, just select the pigment of the corresponding color.

[0018] The role of potassium silicate is to improve the rub resistance of the toner after transfer. Polyethylene glycol improves the dispersibility of the toner.

[0019] In the above embodiments, the number average molecular weight of polyethylene glycol is 1200-1400 g / mol. The study found that the number average molecular weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com