Reinforcing and toughening filling master batch with compatibilization performance and preparation method therefor

A technology of strengthening, toughening and filling masterbatch, which is applied in the field of polymer materials, to achieve the effect of reasonable and controllable process conditions, improved effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

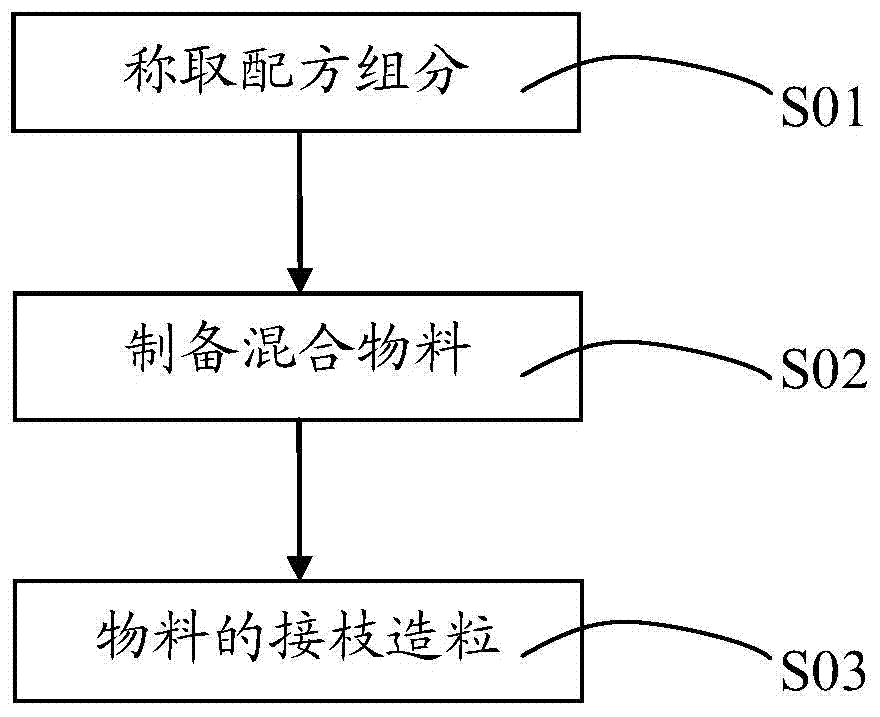

[0027] And, the embodiment of the present invention also provides a method for preparing a reinforced and toughened filler masterbatch with compatibilization properties, including the following steps, such as figure 1 Shown:

[0028] S01. Weighing the formula components: Weighing the formula of the above-mentioned reinforced and toughened filler masterbatch with compatibilizing properties and weighing each component respectively;

[0029] S02. Prepare the mixed material: mix the above-mentioned components to form a mixed material;

[0030] S03. Graft granulation of materials: Add the above mixture into a twin-screw extruder for graft granulation. The processing temperature of the twin-screw extruder is 110-230°C.

[0031] Specifically, in the above step S01, the formula of the filling masterbatch and the preferred content and type of each component in the formula are as described above, and will not be repeated here in order to save space.

[0032] In the above step S02, the...

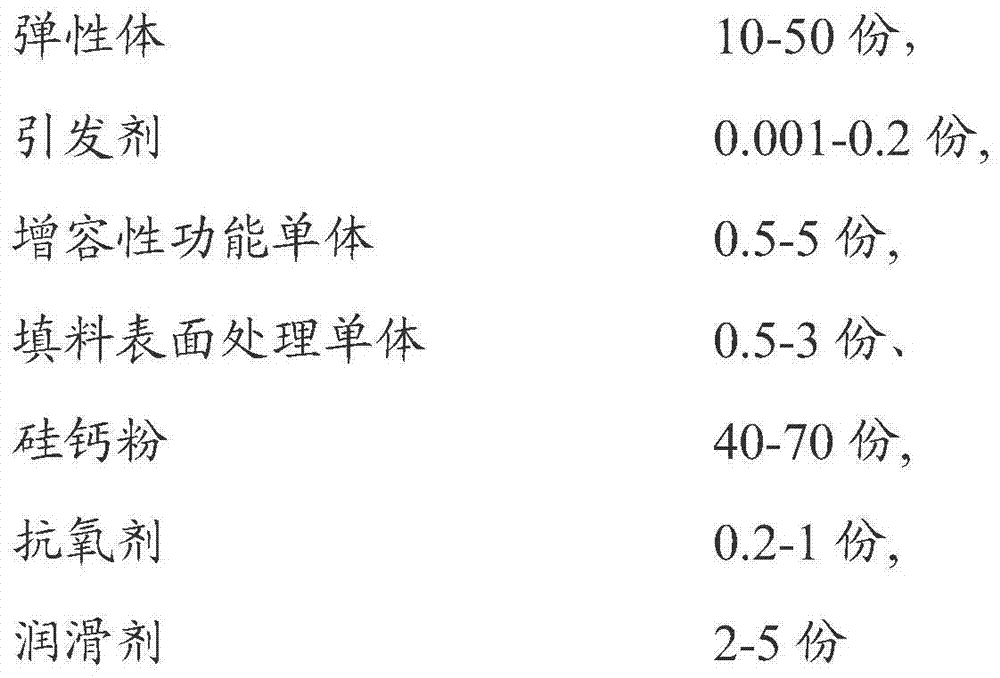

Embodiment 1

[0039] A kind of filler masterbatch, the formula component that it comprises and the content of corresponding component see embodiment 1 in following table 1, wherein, described elastomer is POE8150; Described initiator is dicumyl peroxide; Described The compatibilizing functional monomer is maleic anhydride; the filler surface treatment monomer is vinyltrimethoxysilane; the lubricant is polyethylene wax; silicon calcium powder is 2500 mesh.

[0040] A preparation method for filler masterbatch, comprising the following steps:

[0041] S01. Take the formula components: take each component by the formula of Example 1 in Table 1;

[0042] S02. Prepare the mixed material: mix the above-mentioned components, and stir at 23° C. for 5 minutes to form the mixed material;

[0043] S03. Graft granulation of materials: Add the above mixed material into a co-rotating twin-screw extruder for graft granulation. The processing temperature of the co-rotating twin-screw extruder is 110-230°C....

Embodiment 2

[0045] A kind of filler masterbatch, the formula component that it comprises and the content of corresponding component see embodiment 2 in the following table 1, wherein, described elastomer is POE8150; Described initiator is dicumyl peroxide; Described The compatibilizing functional monomer is maleic anhydride; the filler surface treatment monomer is vinyltrimethoxysilane; the lubricant is polyethylene wax; silicon calcium powder is 2500 mesh.

[0046] A preparation method for filler masterbatch, comprising the following steps:

[0047] S01. Take the formula components: weigh each component by the formula of Example 2 in Table 1;

[0048] S02. Prepare the mixed material: mix the above-mentioned components, and stir at 23° C. for 5 minutes to form the mixed material;

[0049] S03. Graft granulation of materials: Add the above mixed material into a co-rotating twin-screw extruder for graft granulation. The processing temperature of the co-rotating twin-screw extruder is 110-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com