Large-scale non-quenched-and-tempered steel rolling equipment and rolling production method thereof

A non-quenched and tempered steel, rolling equipment technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the process temperature cooling rate is difficult to control, can not guarantee the structure and performance requirements, low toughness and mechanical properties and other problems, to achieve the effect of removing surface iron oxide scale and scratching defects of water tank, effectively controllable structure and performance, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

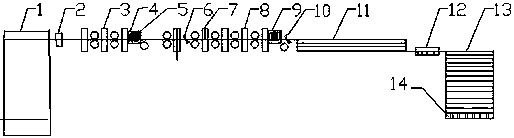

[0049] Such as figure 1 , 2 . As shown in 3, a large-scale non-quenched and tempered steel rolling equipment includes a walking heating furnace 1, a high-pressure water descaling machine 2, a rough rolling unit 3, a 1# simple control cooling device 4, and a hot continuous rolling unit 7 , finishing rolling unit 8, 2# simple control cooling device 9, tail-cutting crank type flying shear 10, traverse mechanism 11, hot saw machine 12, cooling bed 13 and collection device 14; the walking heating furnace 1, high pressure Water descaling machine 2, rough rolling unit 3, 1# simple control cooling device 4, hot continuous rolling unit 7, finishing rolling unit 8, 2# simple control cooling device 9, tail cutting crank type flying shear 10, traverse mechanism 11 , hot sawing machine 12, cooling bed 13 and collecting device 14 are connected successively, and described hot continuous rolling unit 7 is provided with cutting head flying shear 6, and collecting device 14 is located at the o...

Embodiment 2

[0053] Such as figure 1 , 2 . As shown in 3, a large-scale non-quenched and tempered steel rolling equipment includes a walking heating furnace 1, a high-pressure water descaling machine 2, a rough rolling unit 3, a 1# simple control cooling device 4, and a hot continuous rolling unit 7 , finishing rolling unit 8, 2# simple control cooling device 9, tail-cutting crank type flying shear 10, traverse mechanism 11, hot saw machine 12, cooling bed 13 and collection device 14; the walking heating furnace 1, high pressure Water descaling machine 2, rough rolling unit 3, 1# simple control cooling device 4, hot continuous rolling unit 7, finishing rolling unit 8, 2# simple control cooling device 9, tail cutting crank type flying shear 10, traverse mechanism 11 , hot sawing machine 12, cooling bed 13 and collecting device 14 are connected successively, and described hot continuous rolling unit 7 is provided with cutting head flying shear 6, and collecting device 14 is located at the o...

Embodiment 3

[0058] Such as figure 1 , 2. As shown in 3, a large-scale non-quenched and tempered steel rolling equipment includes a walking heating furnace 1, a high-pressure water descaling machine 2, a rough rolling unit 3, a 1# simple control cooling device 4, and a hot continuous rolling unit 7 , finishing rolling unit 8, 2# simple control cooling device 9, tail-cutting crank type flying shear 10, traverse mechanism 11, hot saw machine 12, cooling bed 13 and collection device 14; the walking heating furnace 1, high pressure Water descaling machine 2, rough rolling unit 3, 1# simple control cooling device 4, hot continuous rolling unit 7, finishing rolling unit 8, 2# simple control cooling device 9, tail cutting crank type flying shear 10, traverse mechanism 11 , hot sawing machine 12, cooling bed 13 and collecting device 14 are connected successively, and described hot continuous rolling unit 7 is provided with cutting head flying shear 6, and collecting device 14 is located at the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com