Halogen-free flame retardant mark sheet and preparation method

A technology of marking and sheet materials, applied in the field of materials, to achieve the effect of simple preparation method, little harm to human body, and convenient marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

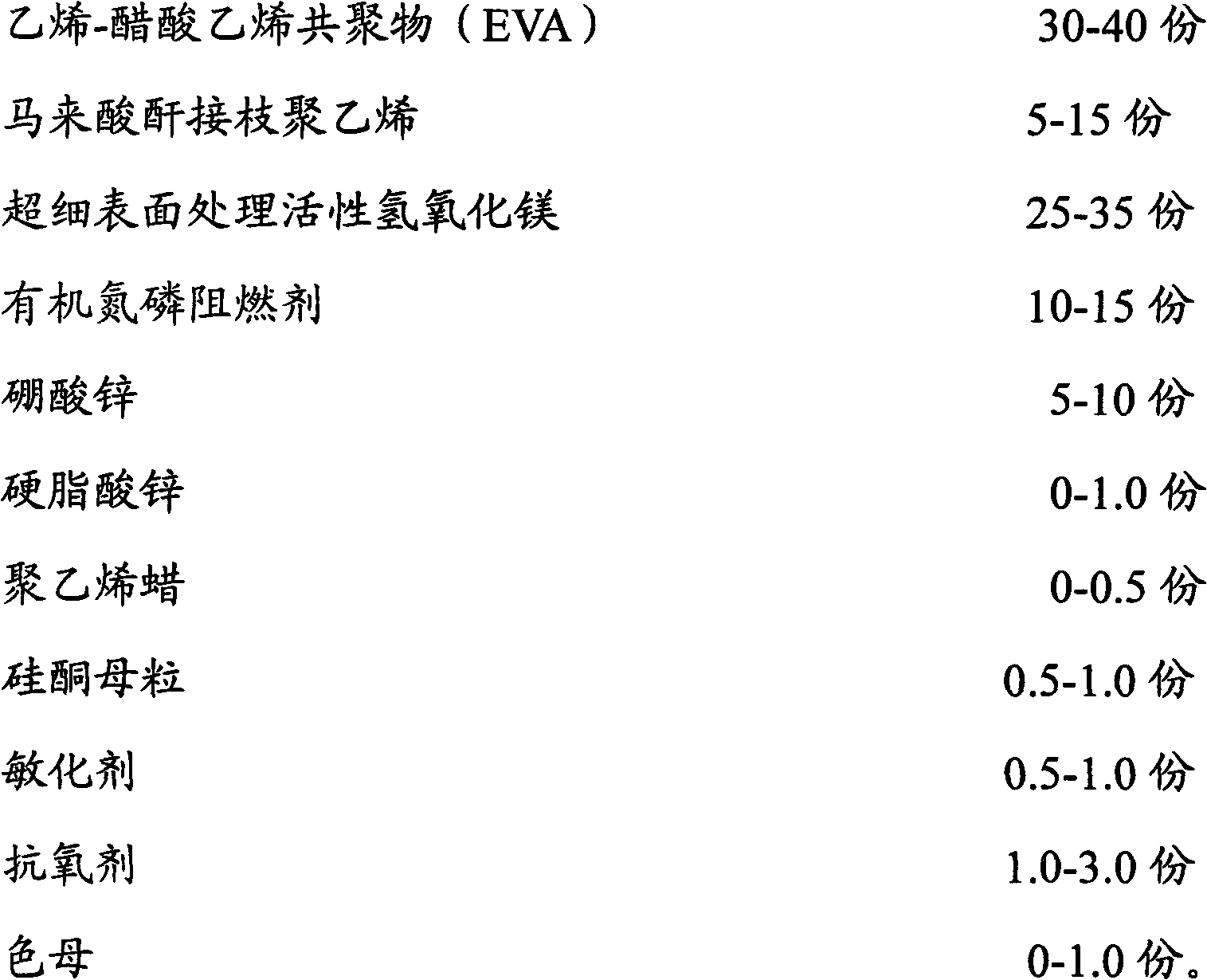

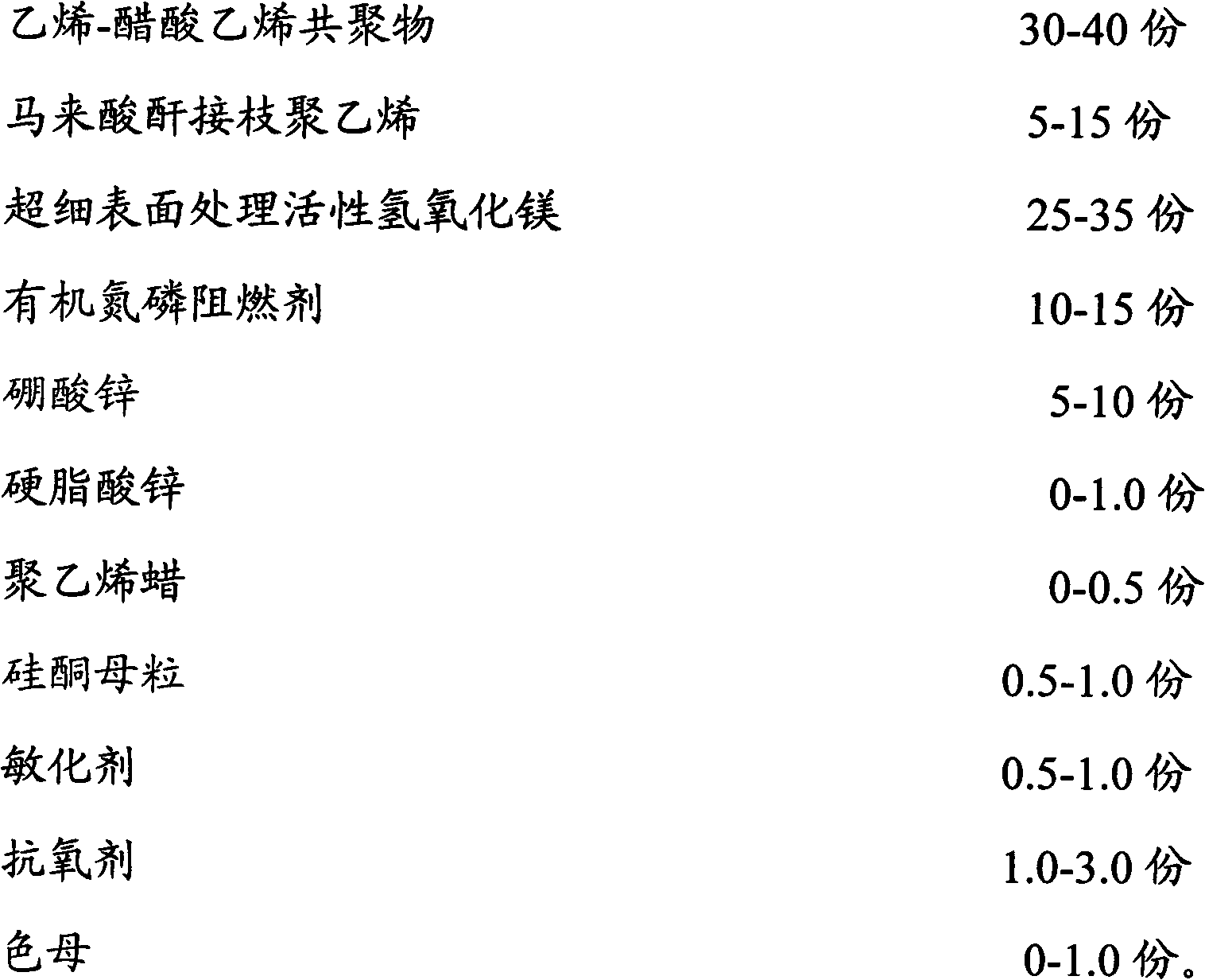

Method used

Image

Examples

Embodiment 1

[0025] Take 35 parts of ethylene-vinyl acetate copolymer (EVA), 15 parts of maleic anhydride grafted polyethylene, 25 parts of ultra-fine surface-treated active magnesium hydroxide, 13 parts of organic nitrogen and phosphorus flame retardants, 8 parts of zinc borate, stearin Zinc acid 0.5 part, polyethylene wax 0.5 part, silicone masterbatch 1.0 part, sensitizer 0.5 part, antioxidant 1.0 part, white masterbatch 0.5 part, add to the mixer in turn, mix at 60℃ for 5-10min, and then use The kneading machine and the screw granulator are mixed, extruded, drawn, cooled, and pelletized at 110-150°C to obtain the masterbatch of the halogen-free flame-retardant marking sheet material.

Embodiment 2

[0027] Take 35 parts of ethylene-vinyl acetate copolymer (EVA), 10 parts of maleic anhydride grafted polyethylene, 30 parts of ultra-fine surface-treated active magnesium hydroxide, 15 parts of organic nitrogen and phosphorus flame retardants, 6 parts of zinc borate, stearin Zinc acid 0.5 part, polyethylene wax 0.5 part, silicone masterbatch 0.5 part, sensitizer 0.5 part, antioxidant 1.5 part, yellow masterbatch 0.5 part, add to the mixer in turn, mix at 60℃ for 5-10min, and then use The kneading machine and the screw granulator are mixed, extruded, drawn, cooled, and pelletized at 110-145°C to obtain the masterbatch of the halogen-free flame-retardant marking sheet material.

Embodiment 3

[0029] Take 40 parts of ethylene-vinyl acetate copolymer (EVA), 5 parts of maleic anhydride grafted polyethylene, 30 parts of ultra-fine surface-treated active magnesium hydroxide, 13 parts of organic nitrogen and phosphorus flame retardants, 7.5 parts of zinc borate, stearin 0.5 parts of zinc acid, 0-0.5 parts of polyethylene wax, 0.5 parts of silicone masterbatch, 1.0 parts of sensitizer, 1.5 parts of antioxidant, 0.5 parts of yellow masterbatch, add to the mixer in turn, mix at 60 ° C for 5-10 minutes, Then kneading, extruding, drawing, cooling, and pelletizing at 100-140° C. with a kneading machine and a screw granulator to obtain the masterbatch of the halogen-free flame-retardant marking sheet material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com