Biaxially oriented polyethylene (BOPE) coating print film

A technology of cloth printing film and functional layer, which is applied in the field of coating film, can solve the problems of poor printing performance, difficulty in UV ink adhesion, corona value can only reach 38 dynes, etc., and achieve the effect of enhanced printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

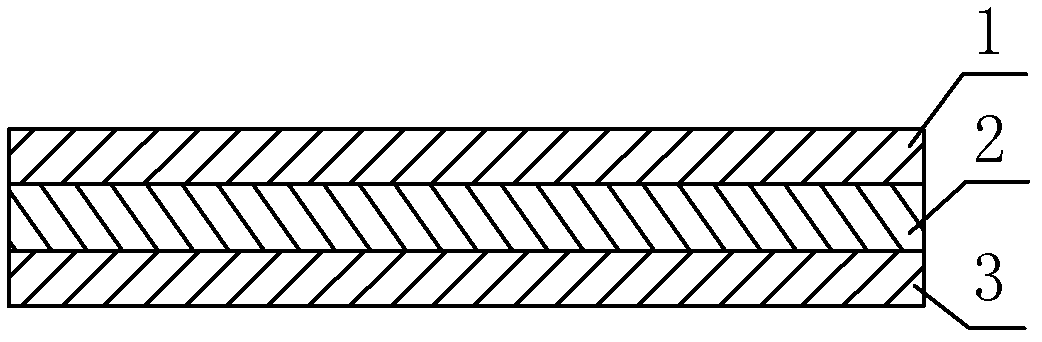

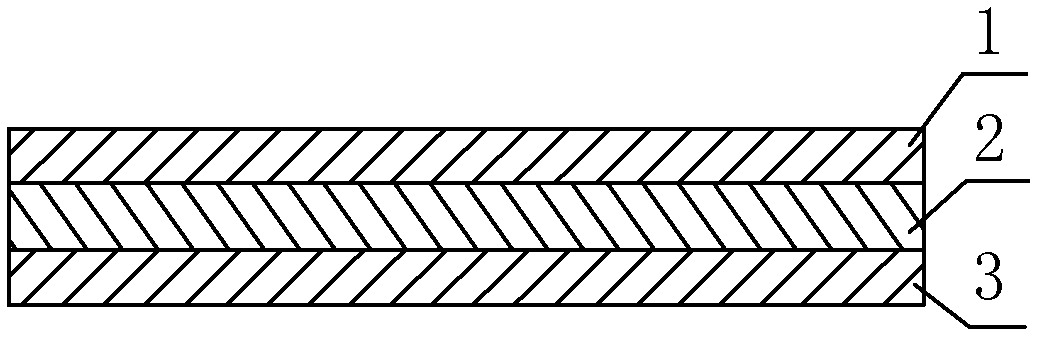

[0017] Such as figure 1 As shown, the BOPE coated printing film includes functional layer 1, core layer 2 and sub-functional layer 3, the core layer is located between the functional layer and the sub-functional layer, and the functional layer, core layer and sub-functional layer are co-extruded It is integrated by two-way stretching; the mass percentages of functional layer, core layer and sub-functional layer are: functional layer 1%, core layer 98%, and sub-functional layer 1%;

[0018] The material of the functional layer is composed of ethyl acetate, C9 hydrogenated petroleum resin (or C9 hydrogenated petroleum resin, hydrogenated C9 petroleum resin), metallocene polyethylene, polyvinyl alcohol, sodium hydroxide, antioxidant, dispersant, each The mass percentage of raw materials is: ethyl acetate 55%, C9 hydrogenated petroleum resin 10%, metallocene polyethylene 18%, polyvinyl alcohol 13%, sodium hydroxide 2%, antioxidant 1%, dispersant 1%;

[0019] The material of the c...

Embodiment 2

[0028] Such as figure 1 As shown, the BOPE coated printing film includes functional layer 1, core layer 2 and sub-functional layer 3, the core layer is located between the functional layer and the sub-functional layer, and the functional layer, core layer and sub-functional layer are co-extruded It is integrated by two-way stretching; the mass percentages of functional layer, core layer and sub-functional layer are: functional layer 5%, core layer 92%, and sub-functional layer 3%;

[0029] The material of the functional layer is composed of ethyl acetate, C9 hydrogenated petroleum resin (or C9 hydrogenated petroleum resin, hydrogenated C9 petroleum resin), metallocene polyethylene, polyvinyl alcohol, sodium hydroxide, antioxidant, dispersant, each The mass percentage of raw materials is: ethyl acetate 55%, C9 hydrogenated petroleum resin 10%, metallocene polyethylene 18%, polyvinyl alcohol 13%, sodium hydroxide 2%, antioxidant 1%, dispersant 1%;

[0030] The material of the c...

Embodiment 3

[0039] Such as figure 1 As shown, the BOPE coated printing film includes functional layer 1, core layer 2 and sub-functional layer 3, the core layer is located between the functional layer and the sub-functional layer, and the functional layer, core layer and sub-functional layer are co-extruded It is integrated by two-way stretching; the mass percentages of functional layer, core layer and sub-functional layer are: functional layer 8%, core layer 91%, and sub-functional layer 1%;

[0040] The material of the functional layer is composed of ethyl acetate, C9 hydrogenated petroleum resin (or C9 hydrogenated petroleum resin, hydrogenated C9 petroleum resin), metallocene polyethylene, polyvinyl alcohol, sodium hydroxide, antioxidant, dispersant, each The mass percentage of raw materials is: ethyl acetate 55%, C9 hydrogenated petroleum resin 10%, metallocene polyethylene 18%, polyvinyl alcohol 13%, sodium hydroxide 2%, antioxidant 1%, dispersant 1%;

[0041] The material of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com