B0PP (biaxially-oriented polypropylene) extrusion coating membrane

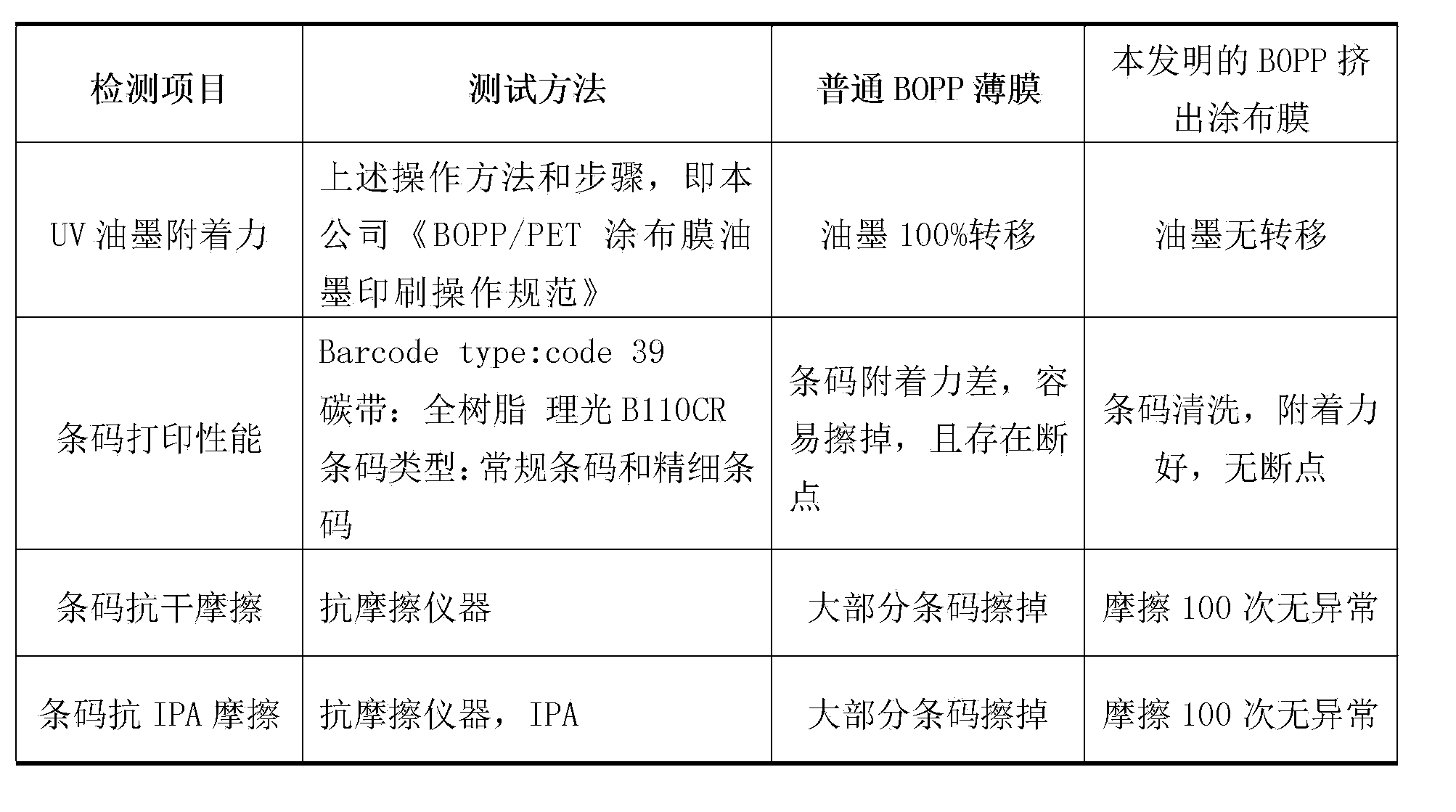

A 1. B0PP, coating film technology, applied in the field of label materials, can solve the problems of poor wipe resistance, poor printing fastness, poor printing quality, etc., and achieve good printing fastness, good wipe resistance and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

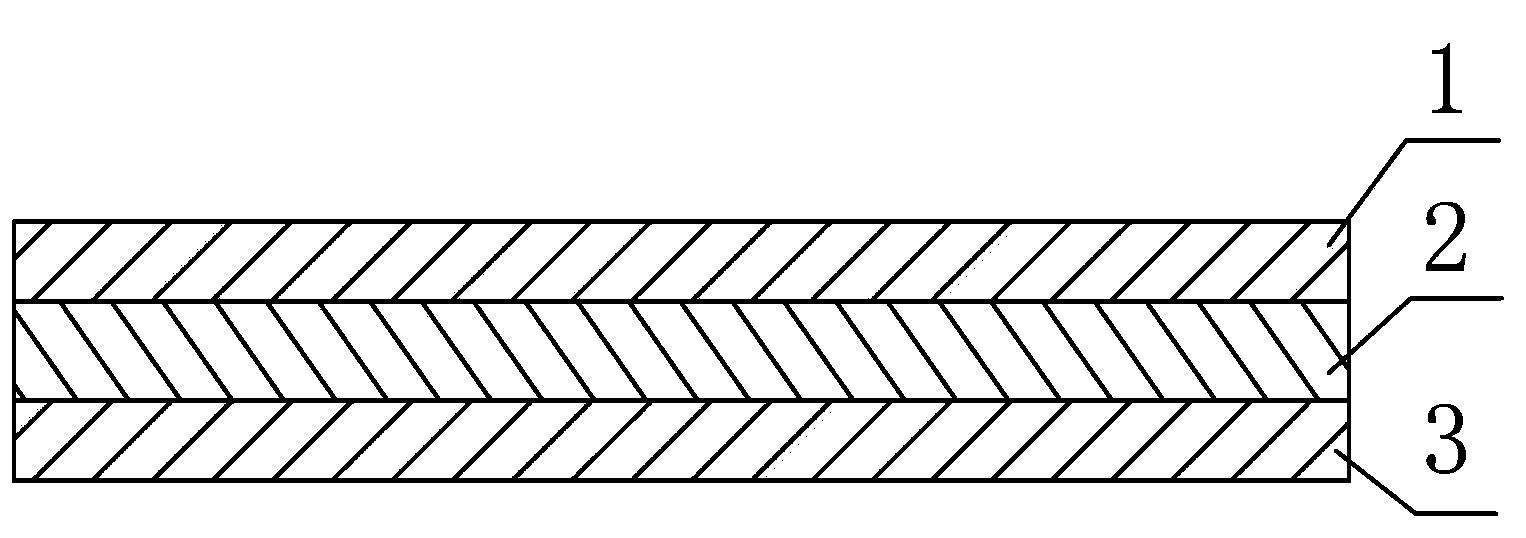

[0027] Such as figure 1 As shown, the BOPP extrusion coating film includes a functional layer 1, a core layer 2, and a secondary functional layer 3. The core layer 2 is located between the functional layer 1 and the secondary functional layer 3. The functional layer 1, the core layer 2, and the secondary functional layer Layer 3 is integrated by biaxial stretching after co-extrusion; the mass percentages of the material of the functional layer, the material of the core layer, and the material of the sub-functional layer are: 5% of the functional layer, 90% of the core layer, and 5% of the sub-functional layer %;

[0028] The material of the functional layer is composed of acrylic resin (Mitsubishi acrylic resin BR-116 product description: brand: Mitsubishi, model: BR-116, origin: Japan), block copolymerized polypropylene, C9 hydrogenated petroleum resin (or C9 plus hydrogenated petroleum resin, hydrogenated C9 petroleum resin), antioxidant, and dispersant, and the mass percen...

Embodiment 2

[0058] Such as figure 1 As shown, the BOPP extrusion coating film includes a functional layer 1, a core layer 2, and a secondary functional layer 3. The core layer 2 is located between the functional layer 1 and the secondary functional layer 3. The functional layer 1, the core layer 2, and the secondary functional layer Layer 3 is integrated by biaxial stretching after co-extrusion; the mass percentages of the material of the functional layer, the material of the core layer, and the material of the sub-functional layer are: 10% of the functional layer, 80% of the core layer, and 10% of the sub-functional layer %;

[0059] The material of the functional layer is composed of acrylic resin (Mitsubishi acrylic resin BR-116 product description: brand: Mitsubishi, model: BR-116, origin: Japan), block copolymerized polypropylene, C9 hydrogenated petroleum resin (or C9 plus hydrogenated petroleum resin, hydrogenated C9 petroleum resin), antioxidant and dispersant, the mass percentag...

Embodiment 3

[0073] Such as figure 1 As shown, the BOPP extrusion coating film includes a functional layer 1, a core layer 2, and a secondary functional layer 3. The core layer 2 is located between the functional layer 1 and the secondary functional layer 3. The functional layer 1, the core layer 2, and the secondary functional layer Layer 3 is integrated by biaxial stretching after co-extrusion; the mass percentages of the material of the functional layer, the material of the core layer, and the material of the sub-functional layer are: 20% of the functional layer, 60% of the core layer, and 20% of the sub-functional layer %;

[0074] The material of the functional layer is composed of acrylic resin (Mitsubishi acrylic resin BR-116 product description: brand: Mitsubishi, model: BR-116, origin: Japan), block copolymerized polypropylene, C9 hydrogenated petroleum resin (or C9 plus hydrogenated petroleum resin, hydrogenated C9 petroleum resin), antioxidant and dispersant, the mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com