Special ink jet printing machine ink for PE optical cables and cables and preparation method of special ink jet printing machine ink for PE optical cables and cables

A technology of inkjet printers and inks, applied in inks, applications, household appliances, etc., can solve problems such as limited technical capabilities, inability to improve the ink adhesion of inkjet printers, and inability to meet the production requirements of PE optical cables and cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

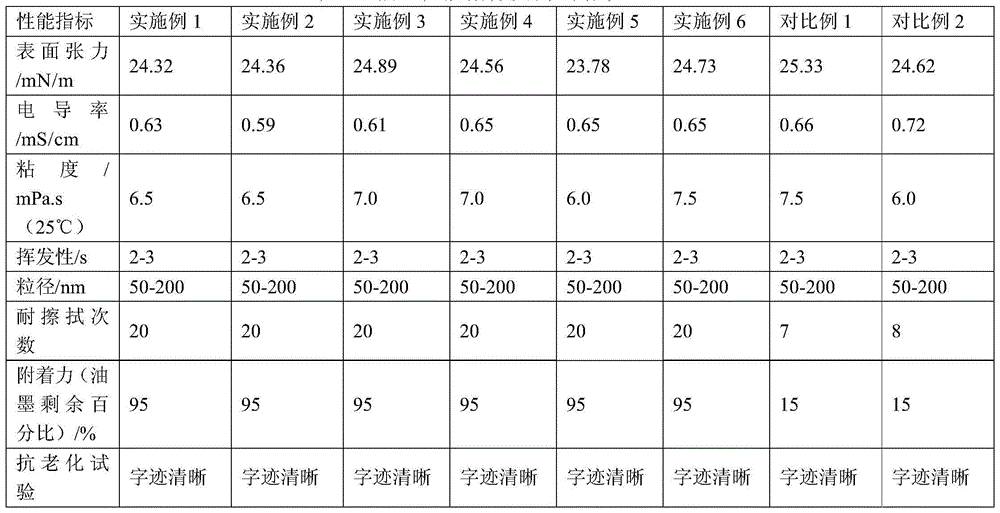

Embodiment 1

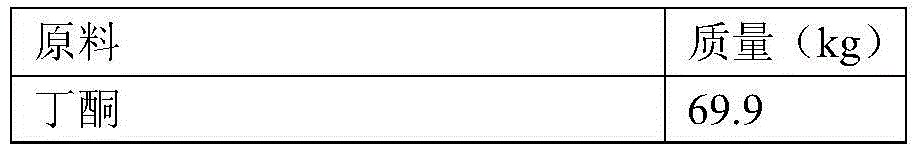

[0043] According to the formulation amount in Table 1, first mix 67.9kg of butanone and 1.0 part of butyl acetate to prepare an organic solvent mixture. Then 10.0kg acrylic resin Paraloid TM Add B-48N and 7.0kg rosin glyceride 138# into the above organic solvent mixture, stir and dissolve at room temperature (25°C) to prepare a mixed resin solution. Next, add 2.5kg of dispersant TEGO Dispers610 and 0.2kg of leveling agent BYK-378 to the mixed resin solution, stir and dissolve at room temperature (25°C), then add 9.0kg of titanium dioxide R-595 and 1.2kg of nano-silica VK -SP30T (slip agent, adhesion promoter, etc. can be added if necessary), stir and disperse at room temperature (25°C) and add to a sand mill (SGM-15M sand mill of Sanyin Industrial Co., Ltd.) to grind, filter, and pour into the filtrate Add 1.2kg of tetrabutylammonium chloride and stir evenly to obtain inkjet printer ink for PE optical cables and cables. The performance parameters are shown in Table 9.

[00...

Embodiment 2

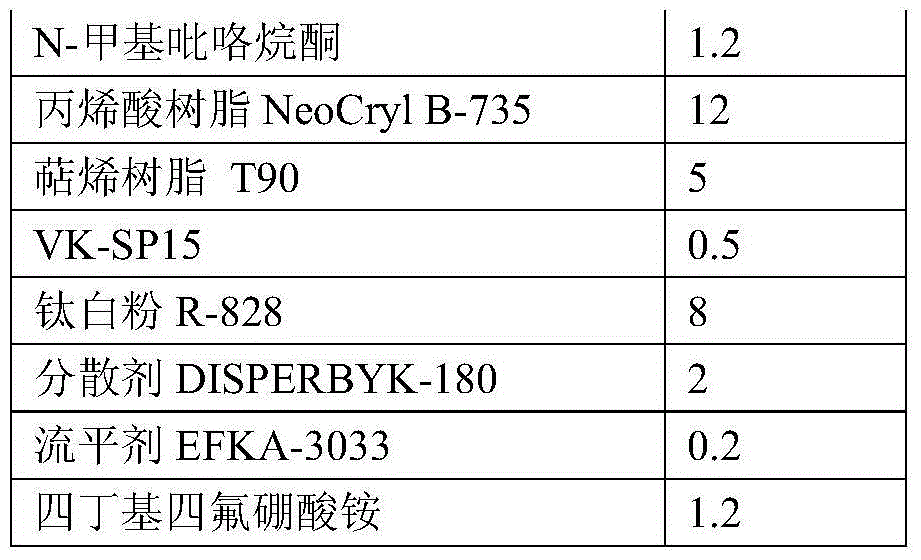

[0047] According to the ink formulation shown in Table 2, the ink for inkjet printers dedicated to PE optical cables and cables was prepared according to the method described in Example 1. The performance parameters are shown in Table 9.

[0048] Table 2 100 parts of ink composition formula

[0049] raw material

Embodiment 3

[0051] According to the ink formulation shown in Table 3, the PE optical cable and cable special inkjet printer ink was prepared according to the method described in Example 1. The performance parameters are shown in Table 9.

[0052] Table 3 100 parts of ink composition formula

[0053] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com