Aerosol paint and preparation method thereof

A kind of technology of aerosol paint and paint, applied in the direction of coating, etc., can solve the problems of easy detection of repair marks, poor adhesion of paint, insufficient aesthetics, etc., and achieve the effect of excellent atomization, fine paint film and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

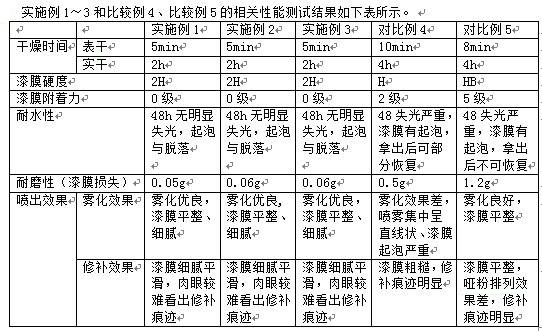

Examples

Embodiment 1

[0039] According to the proportion by weight in Table 1, after mixing the modified resin and reinforcing agent at a ratio of 10:1, disperse at a high speed to ensure that the reinforcing agent is evenly wetted, and adjust by adding an environmentally friendly solvent according to the viscosity; The pulp is ground by a bedroom sand mill, and the fineness of the pulp is controlled to be about 5-10um, that is, the pre-made pulp is obtained.

[0040] According to the formula, add modified resin and dispersant to disperse for 5-10 minutes, add wear-resistant filler, colorant, and pre-slurry for high-speed dispersion, then add leveling agent, post-crosslinking agent, and environmentally friendly solvent to disperse until uniform, adjust paint color, After the viscosity is qualified, filter with filter cloth, that is, the qualified paint is prepared.

[0041] Put stirring beads into the aerosol can, proportion paint: dimethyl ether = 1.3:1 into the aerosol can, put in the aerosol val...

Embodiment 2

[0044] According to the proportion by weight in Table 2, after mixing the modified resin and reinforcing agent at a ratio of 10:1, disperse at a high speed to ensure that the reinforcing agent is evenly wetted, and adjust by adding an environmentally friendly solvent according to the viscosity; The pulp is ground by a bedroom sand mill, and the fineness of the pulp is controlled to be about 5-10um, that is, the pre-made pulp is obtained.

[0045] According to the formula, add modified resin and dispersant to disperse for 5-10 minutes, add wear-resistant filler, colorant, and pre-slurry for high-speed dispersion, then add leveling agent, post-crosslinking agent, and environmentally friendly solvent to disperse until uniform, adjust paint color, After the viscosity is qualified, filter with filter cloth, that is, the qualified paint is prepared.

[0046] Put stirring beads into the aerosol can, proportion by weight paint: propane:butane=1.75:0.4:0.6, pour it into the aerosol can...

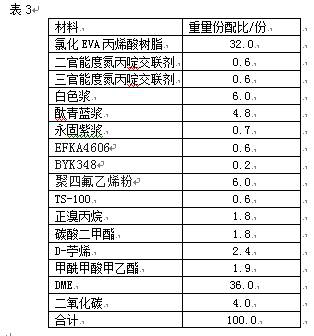

Embodiment 3

[0049] According to the proportion by weight in Table 3, after mixing the modified resin and reinforcing agent at a ratio of 10:1, disperse at a high speed to ensure that the reinforcing agent is evenly wetted, and adjust by adding environmental protection solvent according to the viscosity; The pulp is ground by a bedroom sand mill, and the fineness of the pulp is controlled to be about 5-10um, that is, the pre-made pulp is obtained.

[0050] According to the formula, add modified resin and dispersant to disperse for 5-10 minutes, add wear-resistant filler, colorant, and pre-slurry for high-speed dispersion, then add leveling agent, post-crosslinking agent, and environmentally friendly solvent to disperse until uniform, adjust paint color, After the viscosity is qualified, filter with filter cloth, that is, the qualified paint is prepared.

[0051] Put stirring beads into the aerosol can, proportion by weight paint: dimethyl ether: carbon dioxide = 1.5:0.9:0.1, pour it into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com