Graphene fabric coating and coating method thereof

A coating method and graphene technology, applied in textiles and papermaking, etc., can solve the problems of large pollution, insufficient coating finishing agent performance, poor stability, etc., and achieve the effect of simple coating method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

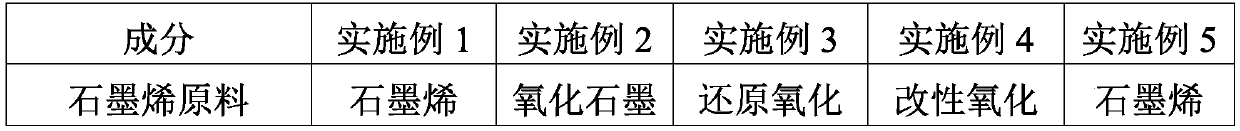

[0024] A kind of graphene fabric coating, the proportioning of the preparation material of this coating is shown in table 1 below.

[0025] Table 1 Ingredients list.

[0026]

[0027]

[0028] The present invention also provides the coating method of this graphene fabric coating, and this method comprises:

[0029] Step 1, unwinding: select the cloth roll that needs to be coated, and put it on the unwinding machine on the cloth roll rack for automatic unwinding; the cloth roll includes polyester cloth roll, nylon cloth roll, cotton linen cloth roll, synthetic fiber cloth roll and blended fabric Any one of the cloth rolls.

[0030] Step 2, tension control: the unrolled fabric is pulled by two tractors, and the fabric is tensioned by adjusting the speed to maintain a certain tension;

[0031] Step 3, sanding: first use a sanding machine to finely sand the surface of the tensioned fabric, so that pits or tiny protrusions appear on the surface of the fabric fiber, and incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com