Anticorrosive wetting coating material and method and condensing unit heat exchanger

A technology for coating materials and tubular heat exchangers, applied in anti-corrosion coatings, evaporators/condensers, coatings, etc., can solve problems such as corrosion effects of metal heat exchangers, improve wetting effect, and improve The service life and the effect of improving the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

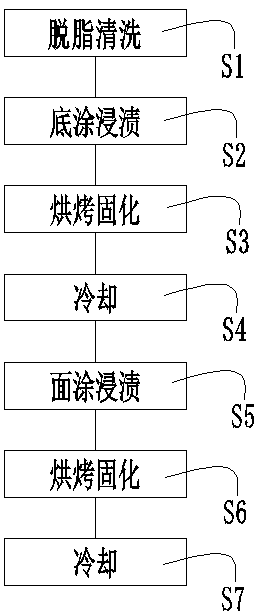

[0040] A kind of anticorrosion wetting coating material of the present embodiment, comprises primer paint and finish paint;

[0041] The primer coating is made of the following raw materials in weight percentage: modified resin 60%, water 22.5%, alcohol ether solvent 10%, curing agent 7%, defoamer 0.5%; since the primer coating is added with modified resin , the three-dimensional polymer network film formed by the cross-linking reaction of the modified resin can not only make the primer coating have excellent anti-corrosion performance, eliminate the influence of water quality, but also improve the interlayer composite force between the coating and the coating , and the interlayer composite force between the coating and the surface of the heat exchanger carrier, it is not easy to fall off.

[0042] The topcoat is made of the following raw materials in weight percentage: 15% modified acrylic resin, 22% modified polyacrylamide resin, 8% alcohol ether solvent, 0.5% defoamer, and ...

Embodiment 2

[0057] A kind of anticorrosion wetting coating material of the present embodiment, comprises primer paint and finish paint;

[0058] The primer coating is made of the following raw materials in weight percentage: 52.95% modified resin, 40% water, 6% alcohol ether solvent, 1% curing agent, and 0.05% defoamer; since the modified resin is added to the primer coating , the three-dimensional polymer network film formed by the cross-linking reaction of the modified resin can not only make the primer coating have excellent anti-corrosion performance, eliminate the influence of water quality, but also improve the interlayer composite force between the coating and the coating , and the interlayer composite force between the coating and the surface of the heat exchanger carrier, it is not easy to fall off.

[0059] The topcoat is made of the following raw materials in weight percentage: 9% modified acrylic resin, 12% modified polyacrylamide resin, 4% alcohol ether solvent, 0.05% defoame...

Embodiment 3

[0074] A kind of anticorrosion wetting coating material of the present embodiment, comprises primer paint and finish paint;

[0075] The primer coating is made of the following raw materials in weight percentage: 47.7% modified resin, 40% water, 8% alcohol ether solvent, 4% curing agent, and 0.3% defoamer; since the modified resin is added to the primer coating , the three-dimensional polymer network film formed by the cross-linking reaction of the modified resin can not only make the primer coating have excellent anti-corrosion performance, eliminate the influence of water quality, but also improve the interlayer composite force between the coating and the coating , and the interlayer composite force between the coating and the surface of the heat exchanger carrier, it is not easy to fall off.

[0076] The topcoat is made of the following raw materials in weight percentage: 12% modified acrylic resin, 17% modified polyacrylamide resin, 6% alcohol ether solvent, 0.3% defoamer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com