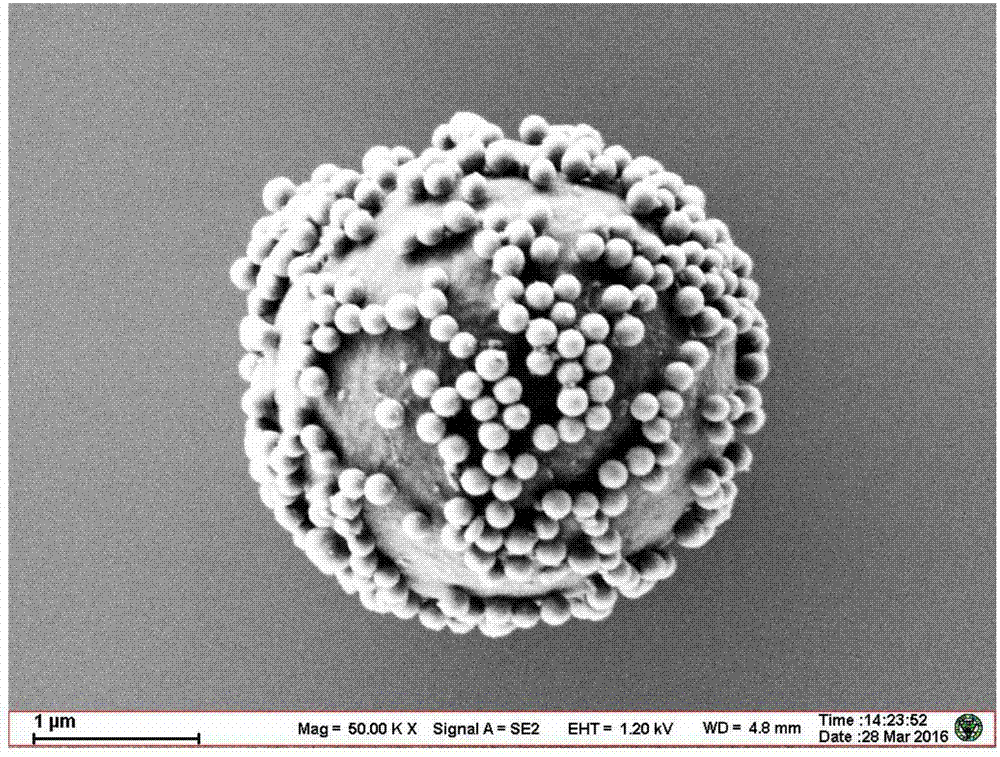

Super-hydrophobic coating with raspberry-like structured composite particles and preparation method thereof

A composite particle, super-hydrophobic technology, applied in microsphere preparation, coating, microcapsule preparation and other directions, can solve the problems of raspberry-like particle stability affected by system environment, complicated preparation steps, low practical application, etc. Coating method is simple and easy, strong super-hydrophobicity, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

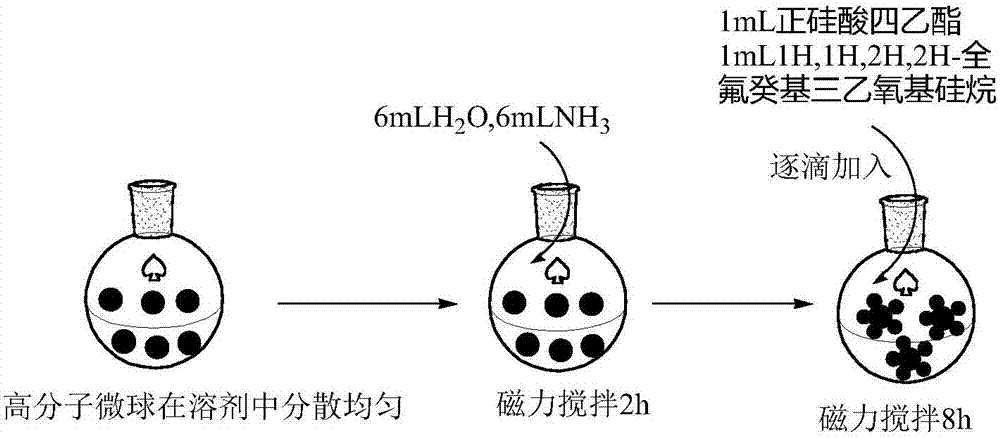

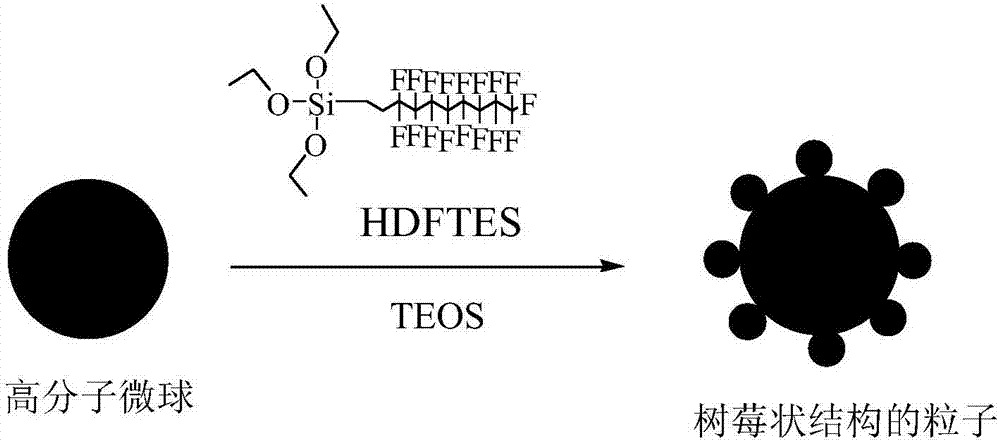

[0031] The preparation method of the superhydrophobic coating of the organic-inorganic composite raspberry particle of above-described embodiment comprises the following process:

[0032] The first step: prepare or select the polymer spherical core as the primary structure; take polyacrylic acid microspheres as an example, use the precipitation distillation polymerization method, take a certain amount of ethylene glycol dimethacrylate and acrylic acid and disperse them in acetonitrile, add The initiator, azobisisobutyronitrile, is heated from room temperature to boiling of the solution within 15 minutes, and after maintaining for 5 minutes, the solvent is evaporated until half of the solvent is evaporated, and the reaction is completed, centrifuged, and the obtained solid is washed three times and then dried. Obtain polymer microspheres.

[0033] Step 2: Weigh the ball (core) and disperse it in an organic solvent, sonicate for 10 minutes, add organic solvent, distilled water a...

Embodiment 1

[0037] Weigh 0.1g of polyacrylic acid microspheres (using precipitation distillation polymerization method, take a certain amount of ethylene glycol dimethacrylate and acrylic acid and disperse them in acetonitrile, add initiator azobisisobutyronitrile, and heat up from room temperature within 15min After the solution boils and is maintained for 5 minutes, the solvent is evaporated until half of the solvent is evaporated, the reaction is completed, centrifuged, the obtained solid is washed three times and then dried to obtain polymer microspheres.) Place in a 250mL clean and dry three-necked flask , add 80mL of ethanol, and ultrasonically disperse to make it evenly mixed. Add 6mL water, 6mL ammonia water and stir at room temperature for 2h, then add 1mL tetraethyl orthosilicate, 1mL 1H,1H,2H,2H-perfluorodecyltriethoxysilane at the same time, stir vigorously for 8h to obtain a superhydrophobic coating , spread it on a glass slide, dry it at room temperature, and measure its con...

Embodiment 2

[0039]Take by weighing 0.1g polymethacrylic acid microspheres (using the precipitation distillation polymerization method, get a certain amount of ethylene glycol dimethacrylate and acrylic acid and disperse them in acetonitrile, add initiator azobisisobutyronitrile, within 15min by Room temperature is heated to the boiling point of the solution, and after maintaining for 5 minutes, the solvent is evaporated until half of the solvent is evaporated, and the reaction is completed, centrifuged, and the obtained solid is washed three times and then dried to obtain polymer microspheres.) Placed in a 250mL clean and dry In a three-neck flask, add 80 mL of ethanol, and ultrasonically disperse to make it evenly mixed. Add 6mL water, 6mL ammonia water and stir at room temperature for 2h, then add 1mL tetraethylorthosilicate, 1mL1H,1H,2H,2H-perfluorodecyltriethoxysilane at the same time, and stir vigorously for 8h to obtain a superhydrophobic coating. Spread it on a glass slide, dry it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com