Tin-free and copper-free environment-friendly marine antifouling coating as well as preparation method and application thereof

A marine anti-fouling and environment-friendly technology, applied in anti-fouling/underwater coatings, epoxy resin coatings, rosin coatings, etc., can solve problems such as biological variation, marine and marine biological pollution, and poor anti-fouling effects, and achieve The effect of high fullness, large inhibition range of biological species, and stable release rate of antifouling agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

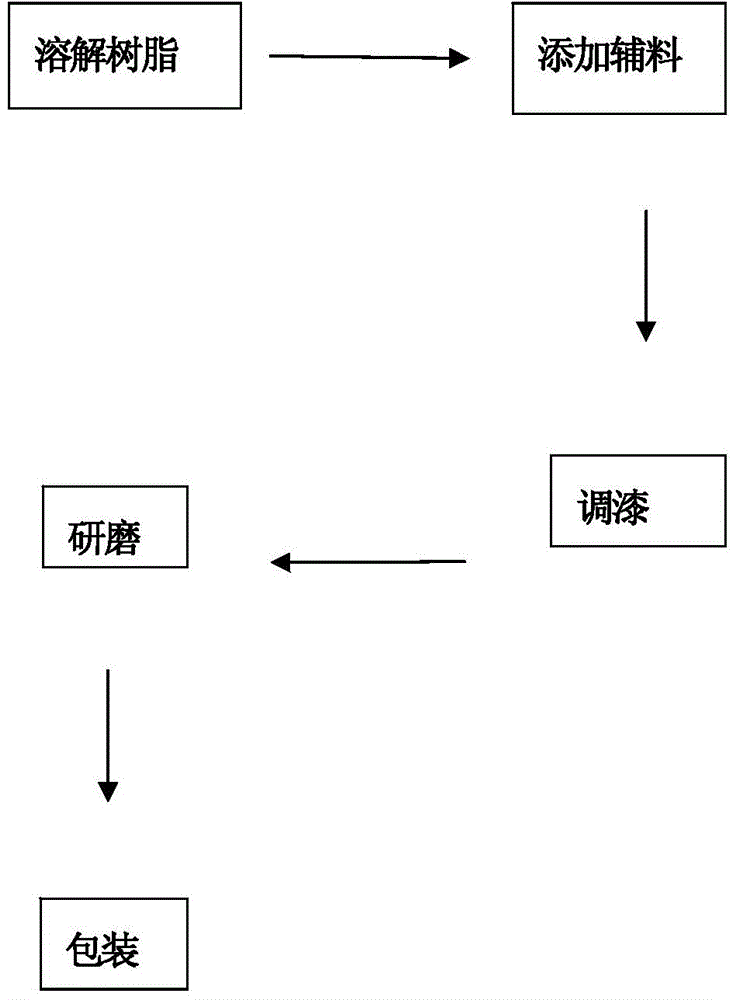

[0082] Embodiment 1: the preparation method of the tin-free, copper-free environment-friendly marine antifouling paint of the present invention:

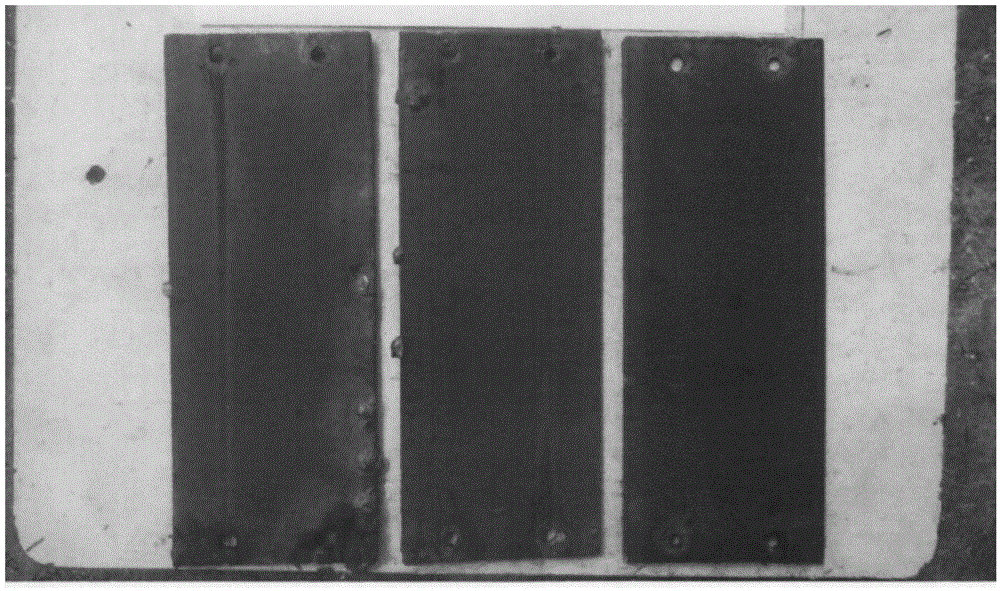

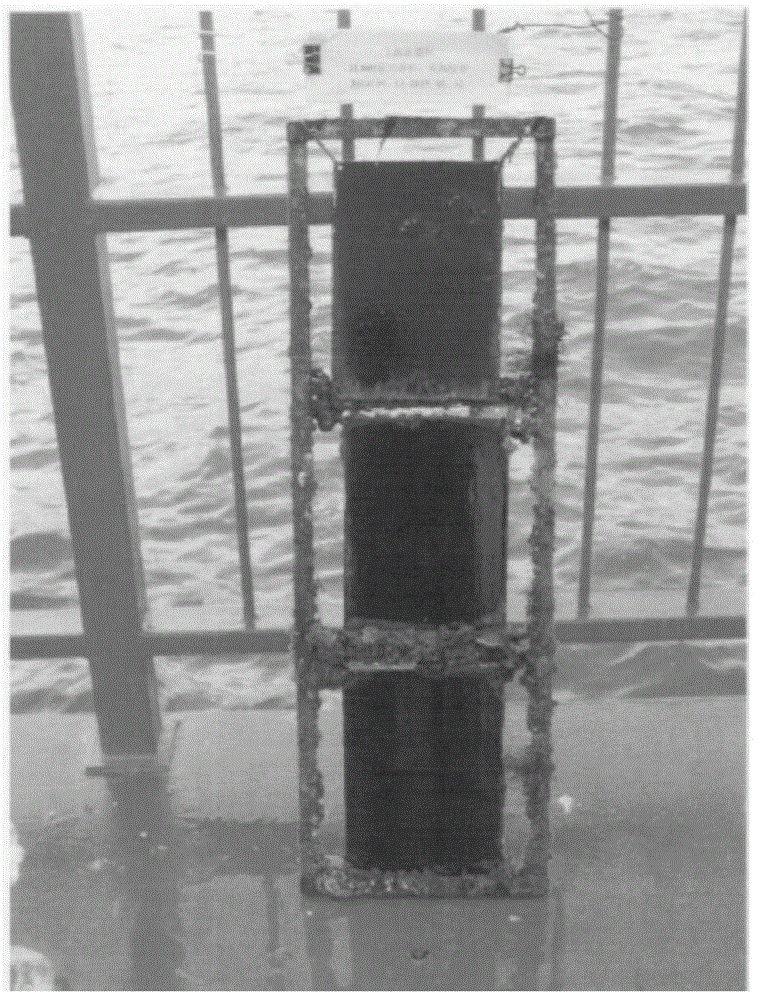

[0083] Slowly stir 13.3kg of xylene, 5kg of PMA (propylene glycol methyl ether acetate) and 11.3kg of rosin resin until completely dissolved, dissolve at 28°C for 50 minutes, add 6kg of chloroether resin, stir for 15 minutes, and the speed of the stirrer is 2023 rpm Then the rotating speed is adjusted to 1840 rev / min, and the powder material (soy lecithin 0.4kg, talcum powder 10kg, zinc oxide 20.6kg, iron oxide red 8kg, medium yellow 1kg, bentonite 0.7kg, antifouling agent N) is started to be added at 34°C -(2,4,6)-Trichlorophenyl (maleimide) and pyrithione copper zinc each 4.5kg), because it is too thick, add 10g of light aromatic hydrocarbon solvent in advance, add glass beads and start frosting at 26°C, speed 3870 rpm; after grinding, adjust the speed to 1800 and add the rest (plasticizer (261A) 2kg, light aromatic solvent (S100)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com