A kind of solid waste base superhydrophobic coating and coating method thereof

A super-hydrophobic coating and coating technology, applied in coatings and other directions, can solve the problems of difficult application, high price and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

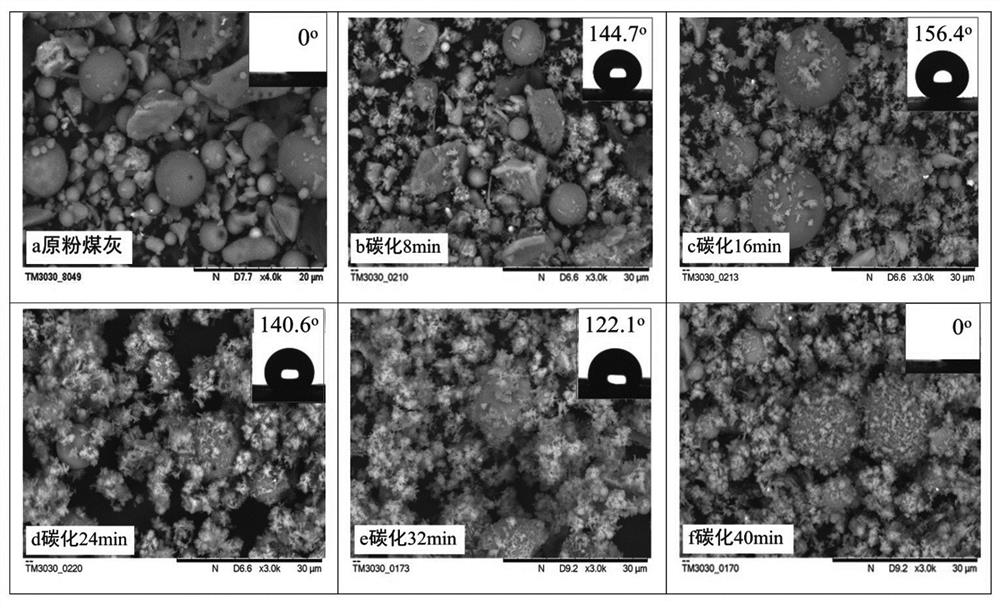

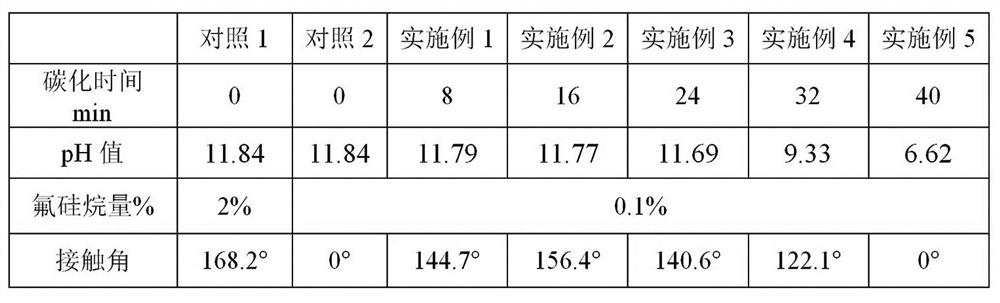

[0024] Put 10g of superfine pulverized coal furnace fly ash with an average particle size of 2.8μm, 10g of calcium hydroxide, and 150g of water into a three-neck flask with a temperature of 60 degrees in a water bath, with a stirring speed of 1000r / min, and adjust the gas flow to Inject CO at 1.2L / min 2 The gas undergoes carbonization reaction, and the change of pH during the reaction process is recorded online. After 8 minutes, the aeration is stopped to end the reaction, and the modified ultrafine solid waste particles are obtained by filtering and drying.

[0025] In 50ml of heptadecafluorodecyltriethoxysilane ethanol solution with a concentration of 0.1%, add 1g of carbonized modified ultrafine pulverized coal furnace fly ash, and ultrasonicate for 20min to obtain a superhydrophobic coating.

Embodiment 2

[0027] Put 10g of superfine pulverized coal furnace fly ash with an average particle size of 2.8μm, 10g of calcium hydroxide, and 150g of water into a three-neck flask with a temperature of 60 degrees in a water bath, with a stirring speed of 1000r / min, and adjust the gas flow to Inject CO at 1.2L / min 2 The gas was carbonized, and the pH change during the reaction was recorded online. After 16 minutes, the aeration was stopped to end the reaction, and the carbonic acid modified particles were obtained by filtration and drying.

[0028] In 50ml of heptadecafluorodecyltriethoxysilane ethanol solution with a concentration of 0.1%, add 1g of carbonized modified ultrafine pulverized coal furnace fly ash, and ultrasonicate for 20min to obtain a superhydrophobic coating.

Embodiment 3

[0030] Put 10g of superfine pulverized coal furnace fly ash with an average particle size of 2.8μm, 10g of calcium hydroxide, and 150g of water into a three-neck flask with a temperature of 60 degrees in a water bath, with a stirring speed of 1000r / min, and adjust the gas flow to Inject CO at 1.2L / min 2 The gas was carbonized, and the pH change during the reaction was recorded online. After 24 minutes, the aeration was stopped to end the reaction, and the carbonic acid modified particles were obtained by filtering and drying.

[0031] In 50ml of heptadecafluorodecyltriethoxysilane ethanol solution with a concentration of 0.1%, add 1g of carbonized modified ultrafine pulverized coal furnace fly ash, and ultrasonicate for 20min to obtain a superhydrophobic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com