Coating method of high-dispersion, strong adhesion, light-transmitting fine particle pre-coating method for laser melting

A technology of fine particle and laser melting, applied in the direction of coating, metal material coating process, etc., to achieve the effect of good adhesion, uniform thickness and strong engineering applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

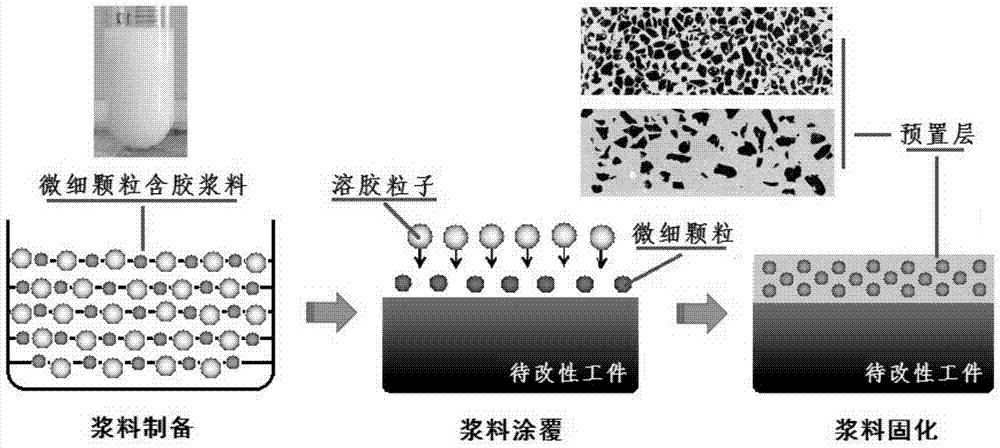

[0029] A method for coating a pre-coated layer of high-dispersion, strong-adhesion and light-transmitting fine particles for laser melting, which is characterized in that it includes the following steps: (1) making the fine powder into a fine particle glue-containing slurry; In the glue-containing slurry, the fine particles account for 5-15% of the slurry mass fraction, the binder accounts for 3-10% of the slurry mass fraction, the dispersant accounts for no more than 1% of the slurry mass fraction, and the balance is ethanol or A mixed solution of ethanol and water. (2) Preheat the workpiece to be modified and apply the fine particle glue-containing slurry; after preheating the workpiece to be modified to 150-180°C, apply the fine particle glue-containing slurry on the preheated workpiece to be modified permanent workpiece surface. (3) Drying and curing the preset layer; place the workpiece to be modified coated with the fine particle-containing glue-containing slurry in a d...

Embodiment 2

[0032] First, fine yttrium oxide powder with an average particle size of 40 nanometers is prepared into a fine yttrium oxide gel-containing slurry; in the fine yttrium oxide gel-containing slurry, the fine yttrium oxide particles account for 10% of the slurry mass fraction, and the The binder (polyvinyl alcohol glue) accounts for 3% of the mass fraction of the slurry, a small amount of sodium hydroxide is used to adjust the pH value to 10, and the balance is alcohol water with a volume ratio of absolute ethanol and deionized water of 2:3 mixture. Then, after the glass slide is preheated to 160° C. in a vacuum drying oven, the fine yttrium oxide-containing paste is brushed on the surface of the preheated glass slide. Finally, the glass slide coated with the fine yttrium oxide glue-containing slurry is placed in a vacuum drying oven for drying and curing. After three times of coating and drying and curing, a pre-layer with fine yttrium oxide particles in a dispersed distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com