Coating material composition and coating material system containing coating material composition

A composition and coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of not meeting the polishability requirements of automotive coatings and low hardness of the covering layer, and achieve good initial peelability and coating The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

[0218] Examples 1-15 (the coating system does not contain the third composition)

[0219] Add each component of the first composition shown in table 1 into a container while stirring, keep stirring at a speed of 1500 rpm for 20 minutes, stop stirring, filter, and leave it for 24 hours, then use a spray gun ( SATA HVLP4000 (purchased from Sata, Germany) was applied to the surface of the test substrate to form the first coating, baked at 60°C for 20 minutes or dried under the conditions of temperature 23±2°C and humidity 50%±5%. One coat, the thickness of the first coat after drying is 20µm-30µm.

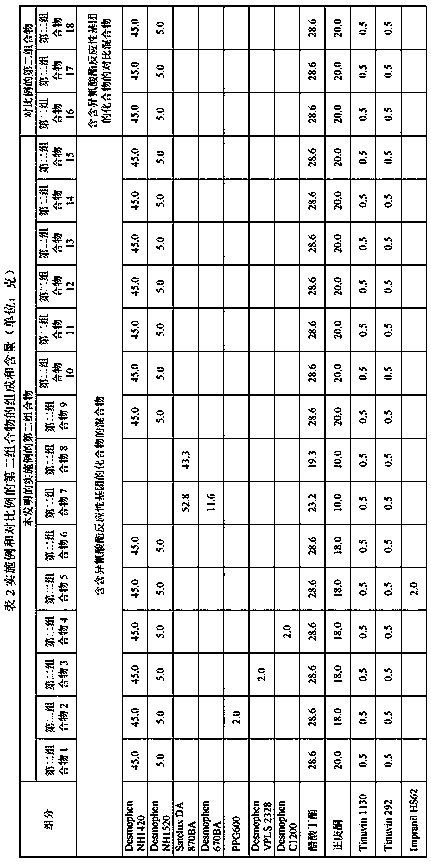

[0220] According to the amount shown in Table 2, the components are uniformly mixed to obtain the mixture containing the compound containing isocyanate reactive groups and the mixture containing isocyanate compounds respectively, and the mixture containing the compound containing isocyanate reactive groups and the compound containing isocyanate Mix the mixture evenly to obtain the ...

Embodiment 16-17

[0221] Examples 16-17 (The coating system further comprises a third composition)

[0222] Add each component of the first composition shown in table 1 into a container while stirring, keep stirring at a speed of 1500 rpm for 20 minutes, stop stirring, filter, and leave it for 24 hours, then use a spray gun ( SATA HVLP4000, purchased from Sata, Germany) was applied to the surface of the test substrate to form the first coating, baked at 60°C for 20 minutes or dried at a temperature of 23±2°C and a humidity of 50%±5%. One coat, the thickness of the first coat after drying is 20µm-30µm.

[0223] Use a spray gun (SATA HVLP4000, purchased from Sata, Germany) to apply the third composition shown in Table 3 to the surface of the first coating to form the third coating, bake at 60 ° C for 20 minutes or at a temperature of 23 Dry the third coating at ±2°C and a humidity of 50%±5%, and the thickness of the third coating after drying is 20µm-30µm.

[0224] According to the amount sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com