Tetrafluoroethylene resin coating

A tetrafluororesin and fluororesin technology, used in anti-corrosion coatings, coatings, etc., can solve problems such as inability to fuse, and achieve the effects of good drying performance, wide application range and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

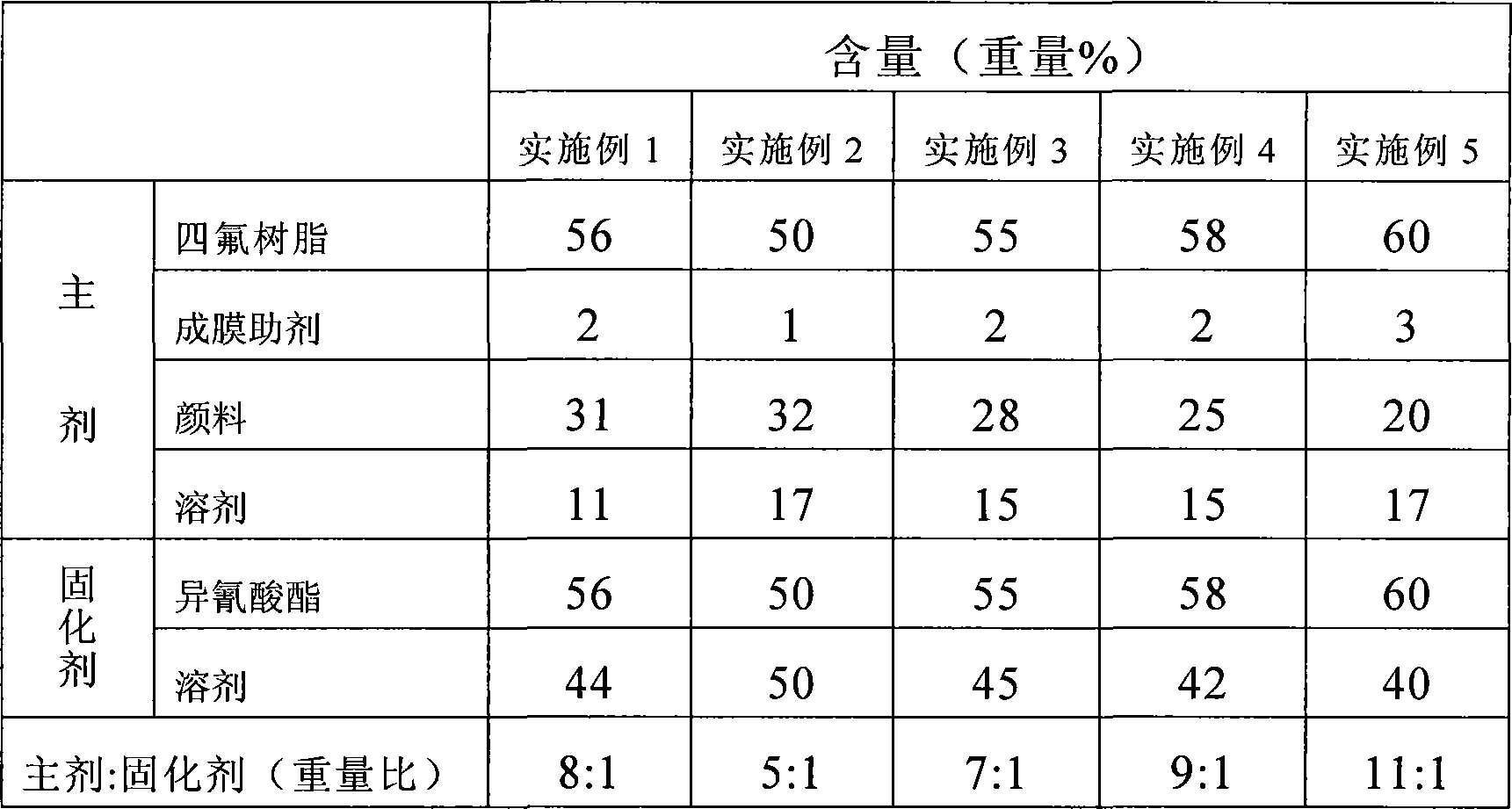

[0028] A tetrafluororesin coating, the coating comprises a main agent and a curing agent, and the specific components and contents are as follows:

[0029]

[0030] In above-mentioned embodiment 1, tetrafluororesin is vinyl tetrafluoride resin, and film-forming aid is polyethylene wax and tetramethylsilane (weight ratio is 1: 1), and pigment is rutile type titanium dioxide and barite powder ( The weight ratio is 1:1), the solvent of the main agent is toluene and isopropanol (the weight ratio is 1:1), the polyisocyanate is polymethylene polyphenyl diisocyanate (PAPI), and the solvent of the curing agent is toluene.

[0031] In above-mentioned embodiment 2, tetrafluororesin is vinyl tetrafluororesin, and film-forming aid is the montmorillonite and tetramethylsilane (weight ratio is 1:1:1) that polyethylene wax, stearic acid are processed , the pigments are carbon black, titanium cyan blue, titanium cyan green, iron oxide red, precipitated barium sulfate and calcium carbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com