Coating process suitable for production of lithium battery

A coating process and lithium-ion battery technology, applied in the direction of battery electrodes, electrode collector coatings, circuits, etc., can solve the problems of high cost, long time, waste of foil materials, etc., to improve production efficiency, reduce costs, Effect of saving foil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

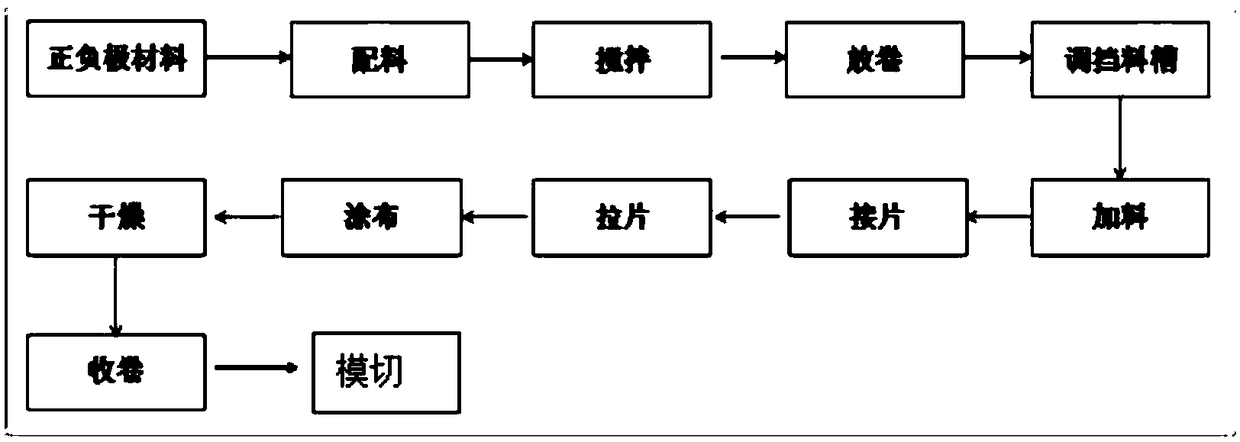

[0025] A coating process suitable for the production of lithium batteries, comprising the following steps: preparing positive and negative electrode materials, preparing the ingredients of the coating slurry, stirring the ingredients of the coating slurry, mixing them for standby, and discharging the positive and negative electrode materials Roll operation; clip the baffle plates on both sides and the middle of the empty foil, then add the coating slurry, and then connect and pull the sheet to carry out large-scale coating; dry the coated slurry, and then mold it after drying. Cutting, and then winding; that is, the coating operation is completed.

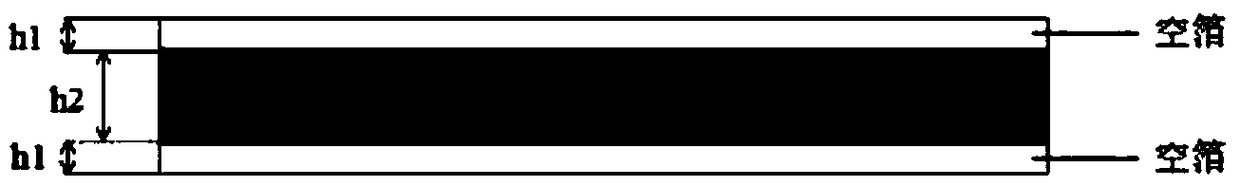

[0026] figure 1 It is a coating process flow chart. The patent of the present invention is very different from the current method in the way of adjusting the chute. The current process is to fix the two sides of the chute with baffles and feed in the middle. The patent of the present invention is the two sides and the middle Clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com