Patents

Literature

38results about How to "Easy to die cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

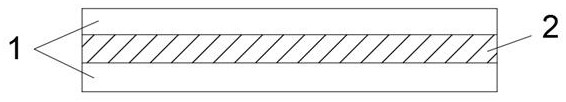

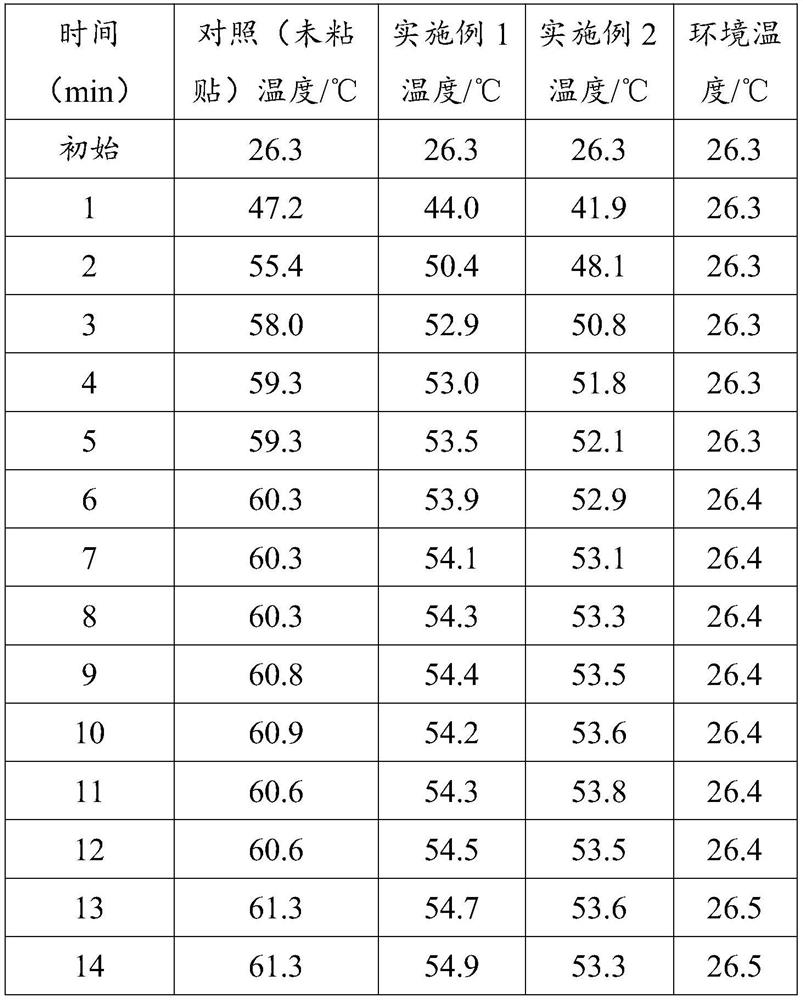

A kind of insulating and heat-conducting double-sided adhesive tape and preparation method thereof

InactiveCN102260466AImprove thermal conductivityGood thermal conductivity and electrical insulationFilm/foil adhesivesPolyureas/polyurethane adhesivesThermal insulationRoom temperature

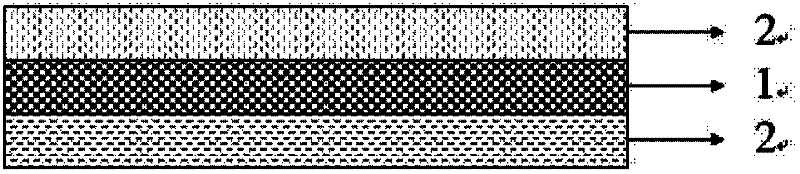

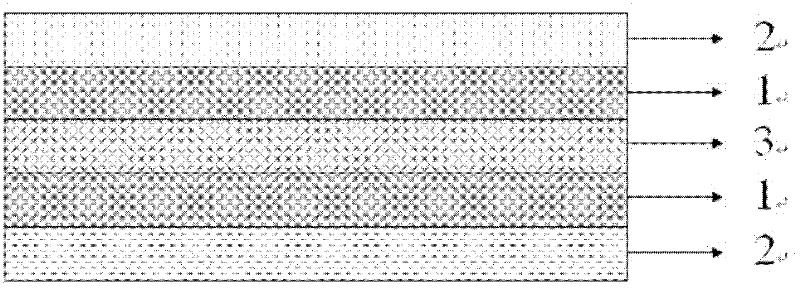

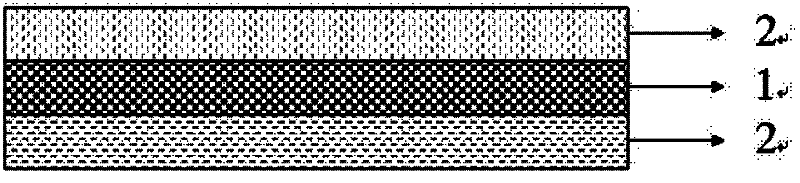

The invention provides an insulating and heat-conducting double-sided adhesive tape and a preparation method thereof. In the insulating and heat-conducting double-sided adhesive tape, the outer layers on both sides are release paper, and a single layer of insulating and heat-conducting adhesive is arranged between the two layers of release paper. Or the outer layers on both sides are release paper, a single-layer substrate is arranged between the two layers of release paper, and an insulating and heat-conducting adhesive is arranged between the substrate and the release paper. The preparation method is as follows: mixing heat-conducting medium and solvent, adding insulating heat-conducting glue, stirring, coating and drying, and the preparation is completed. The adhesive tape of the invention has the advantages of good thermal conductivity, electrical insulation, stability at room temperature, easy die-cutting, reworkable characteristics, and easy operation.

Owner:ZHONGSHAN KINGLABEL ADHESIVE PRODS

Shielding and grounding foam tape with metal foil as base material and preparing method thereof

ActiveCN105111952AImprove electrical conductivityExcellent three-dimensional electromagnetic shielding functionNon-macromolecular adhesive additivesFilm/foil adhesivesPressure sensitiveMetal foil

The invention discloses a shielding and grounding conductive foam tape with a metal foil sheet as the base material. The tape comprises shielding and grounding conductive foam, a hot melting adhesive layer, the metal foil sheet base material, a conductive adhesive layer and a release material layer which are sequentially stacked from top to bottom. The invention further discloses a method for preparing the shielding and grounding conductive foam tape. Compared with products in the current market with conducive cloth or gauze as the base material, the shielding and grounding conductive foam tape with the metal foil sheet as the base material has the advantages that conductivity is high, electromagnetic shielding function is better, die cutting can be achieved more easily, and the phenomenon which can happen on the conductive cloth that broken filaments appear is avoided. Compared with the method according to which ordinary conductive pressure-sensitive adhesive is adopted for gluing foam to a base material, the shielding and grounding conductive foam tape with the metal foil sheet as the base material has the advantage that the rebound resilience of foam is higher, and the problem that the rebound resilience of the foam is poor due to the fact that the foam is stuck with glue during die cutting or using is solved.

Owner:SHENZHEN MEIXIN ELECTRONICS

Ultrathin aerogel composite material and method for preparing same

InactiveCN107129262ASimple processImprove mechanical propertiesFibre typesCeramicwareFiberSilicon dioxide

The invention discloses an ultrathin aerogel composite material and a method for preparing the same. Organic cloth or inorganic fiber surface felt is used as reinforcement, composition is carried out on the reinforcement and silicon dioxide aerogel to obtain the ultrathin aerogel coiled material or sheet, the organic heat conduction coefficient is lower than or equal to 0.018 w / mk, hydrophobic angles are larger than 150 degrees, the thickness of the ultrathin aerogel composite material with the organic cloth is 0.05-2 mm, and the thickness of the ultrathin aerogel composite material with the inorganic fiber surface felt is 0.1-1.5 mm. The ultrathin aerogel composite material and the method have the advantages that the ultrathin aerogel composite material prepared by the aid of the method is thin, the optimal thickness of the ultrathin aerogel composite material can reach 0.05 mm, the problems in the aspect of methods for preparing aerogel materials with the thicknesses lower than 0.3 mm and the qualification rates of products can be solved, the conventional thickness ranges of aerogel can be expanded, and the ultrathin aerogel composite material and the method can be applied to the field of electronic products with high requirements on thicknesses.

Owner:航天海鹰(镇江)特种材料有限公司

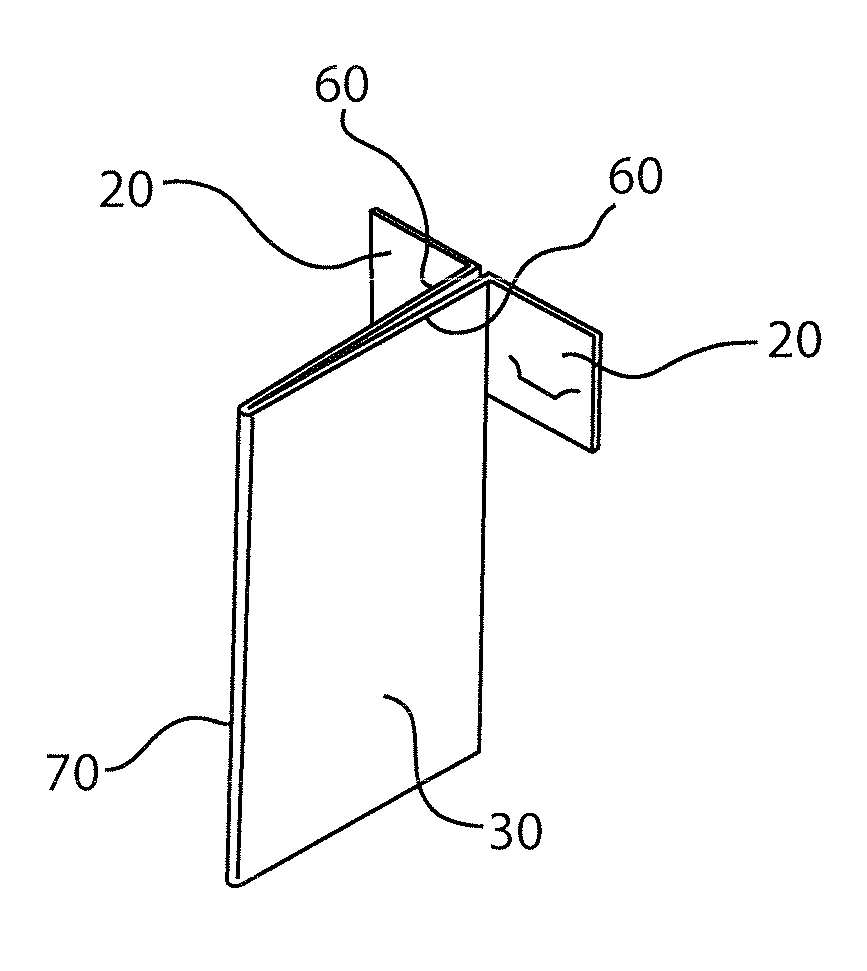

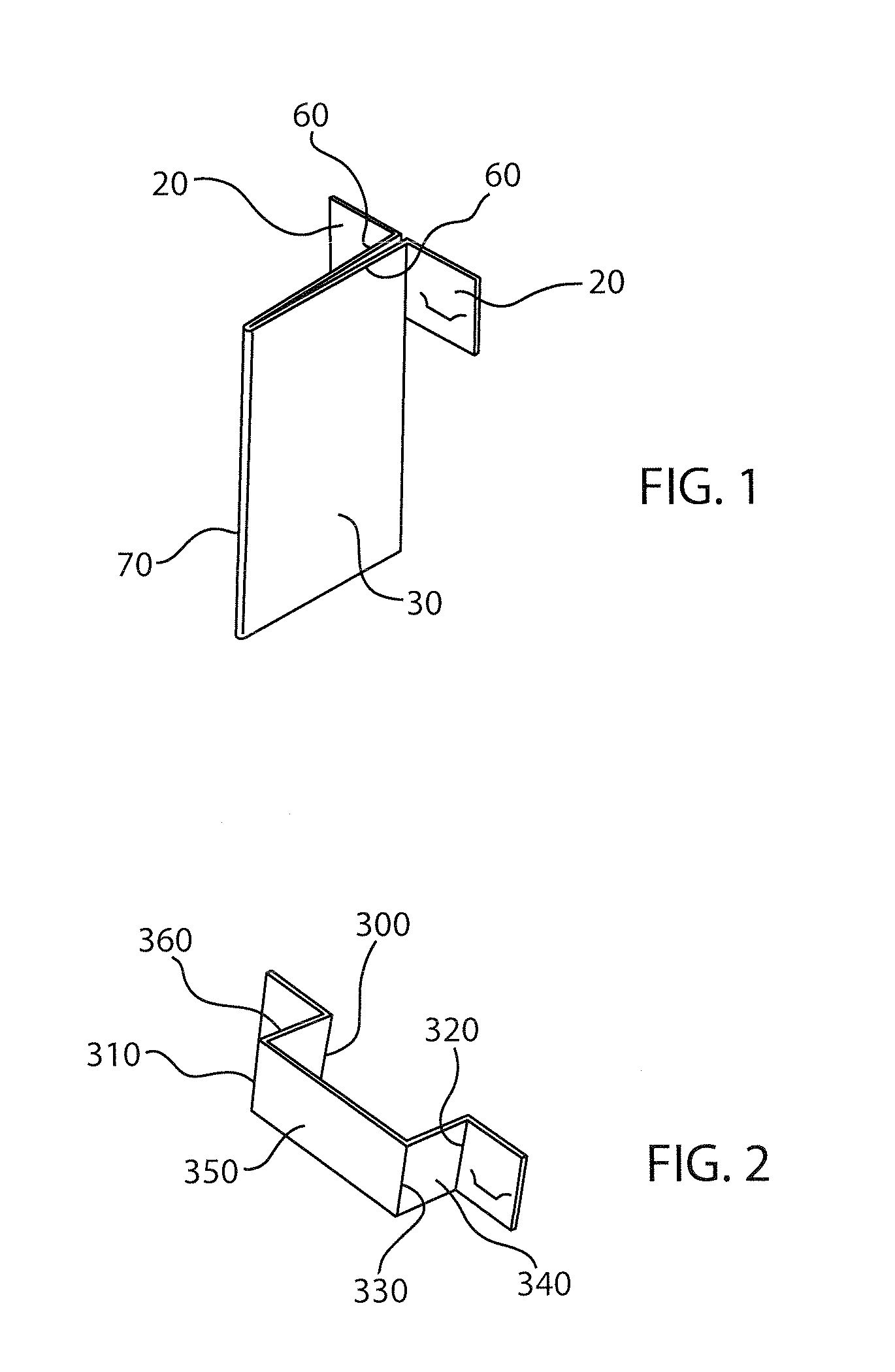

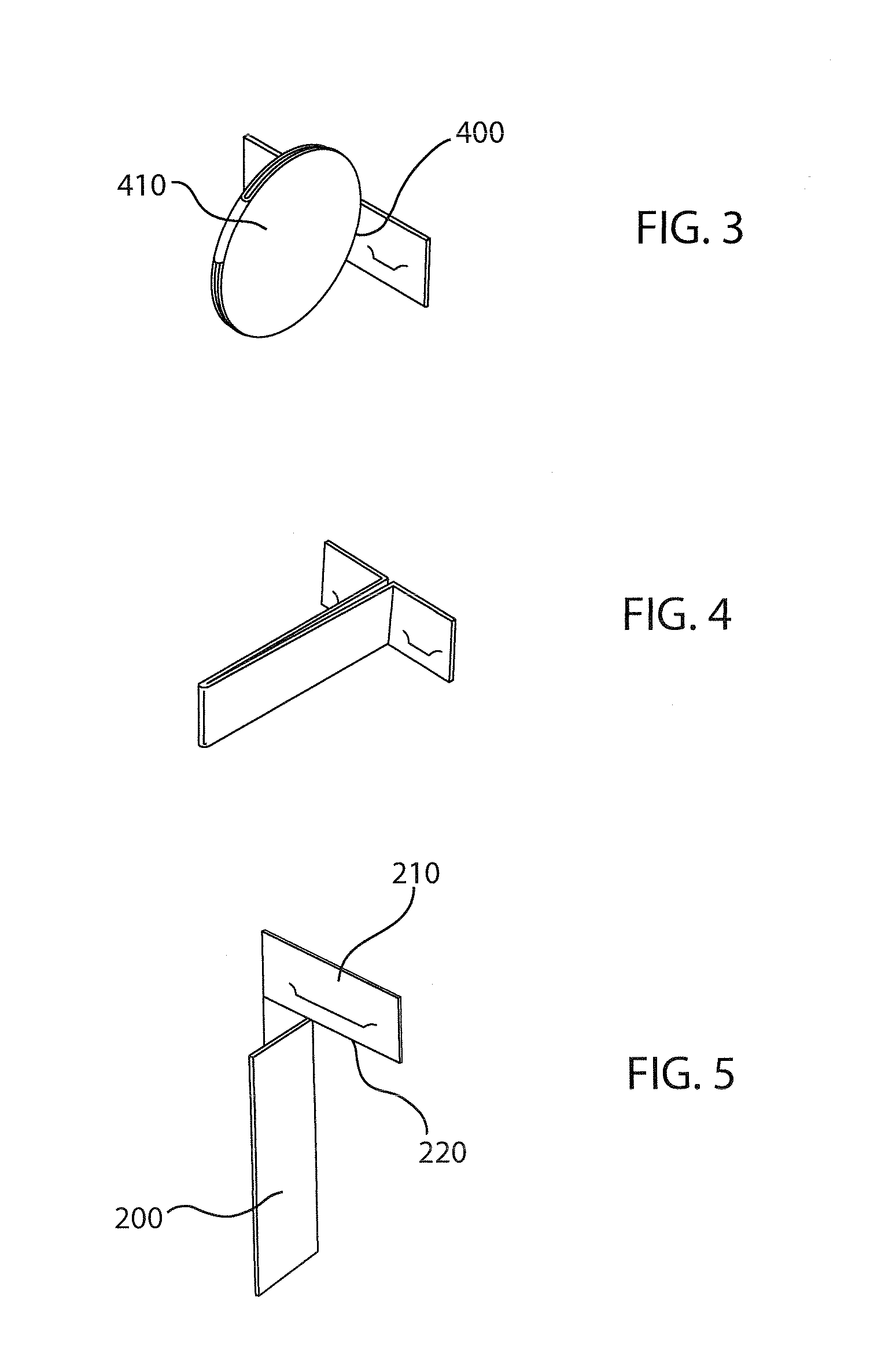

Multi-dimensional shelf label

InactiveUS20110214325A1Easy to die cutEfficient use ofStampsIdentification meansDisplay deviceEngineering

An advertising display mounting device is provided for attaching promotional displays to a price channel mounted on the edge of a grocery or other retail store shelf. This mounting device is made from a flat piece of paper stock having score lines for folding. Die cuts that form clips when pushed out from mounting flaps of the device are adapted to mate with the price channel of the shelf. The device, when folded and mounted to the price channel has a center portion that extends outwards from the price channel. A die cut where the center portion meets the center portion causes a gap thereat, which enables the center portion to descend vertically from the price channel.

Owner:DARRESS RONALD

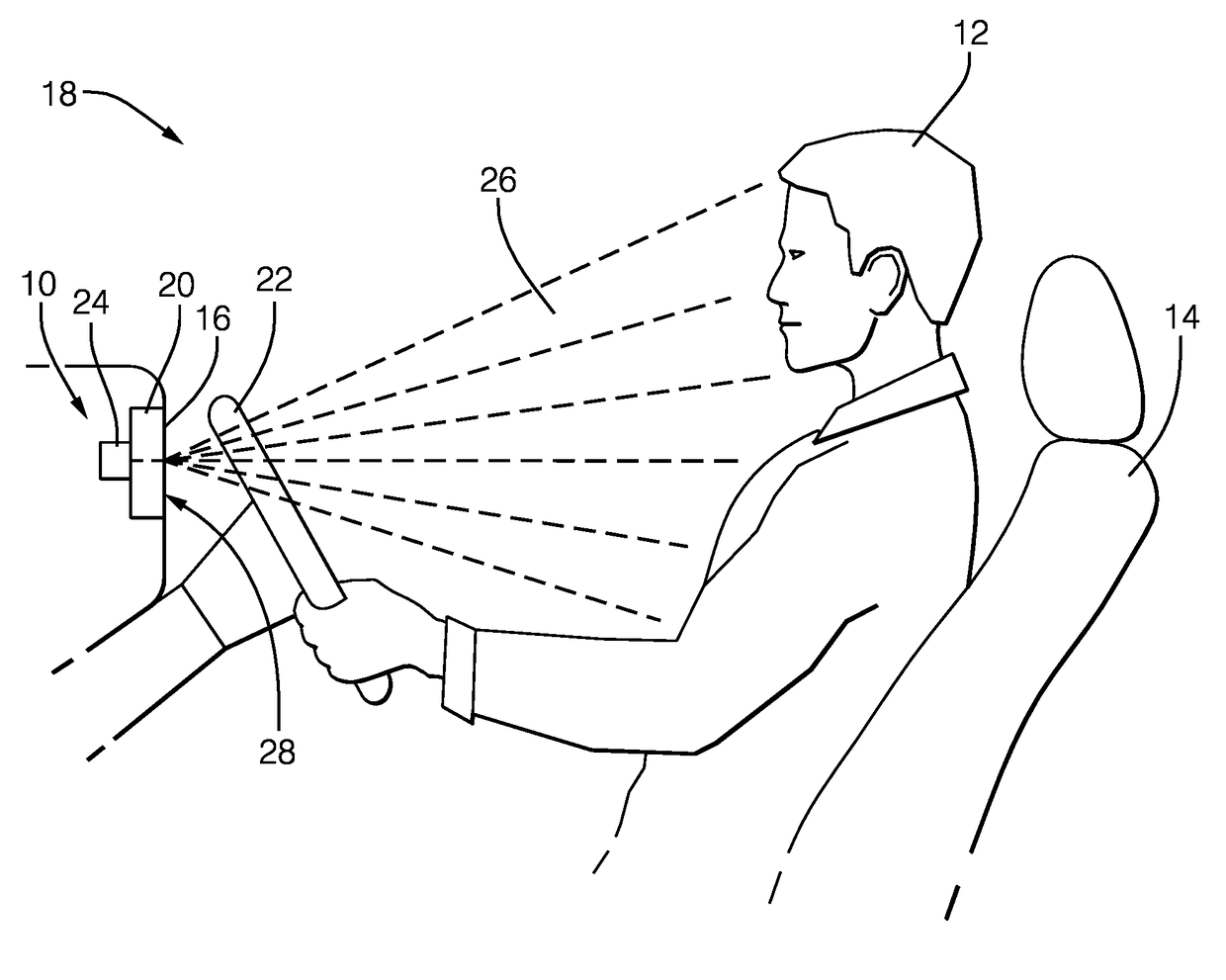

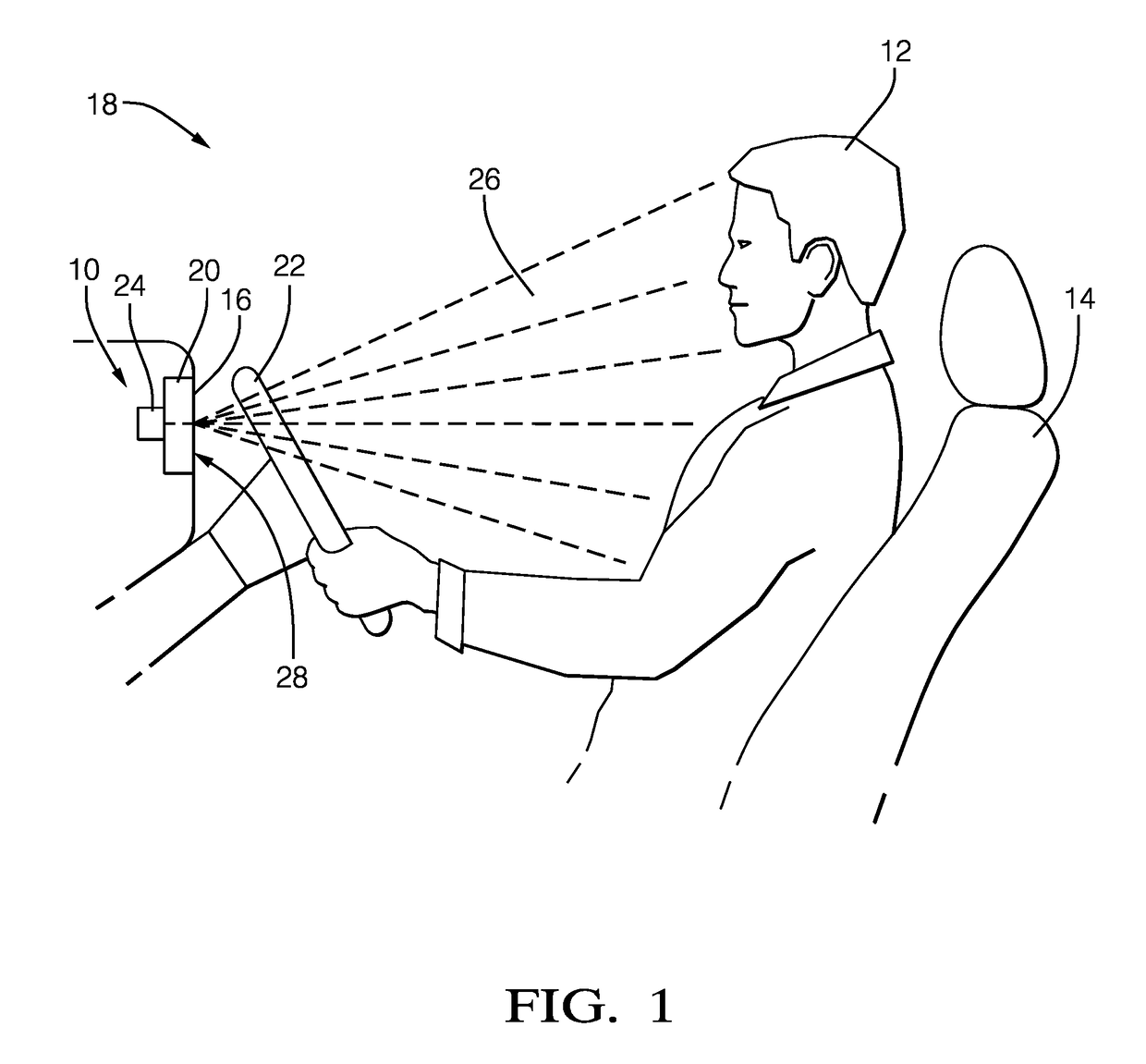

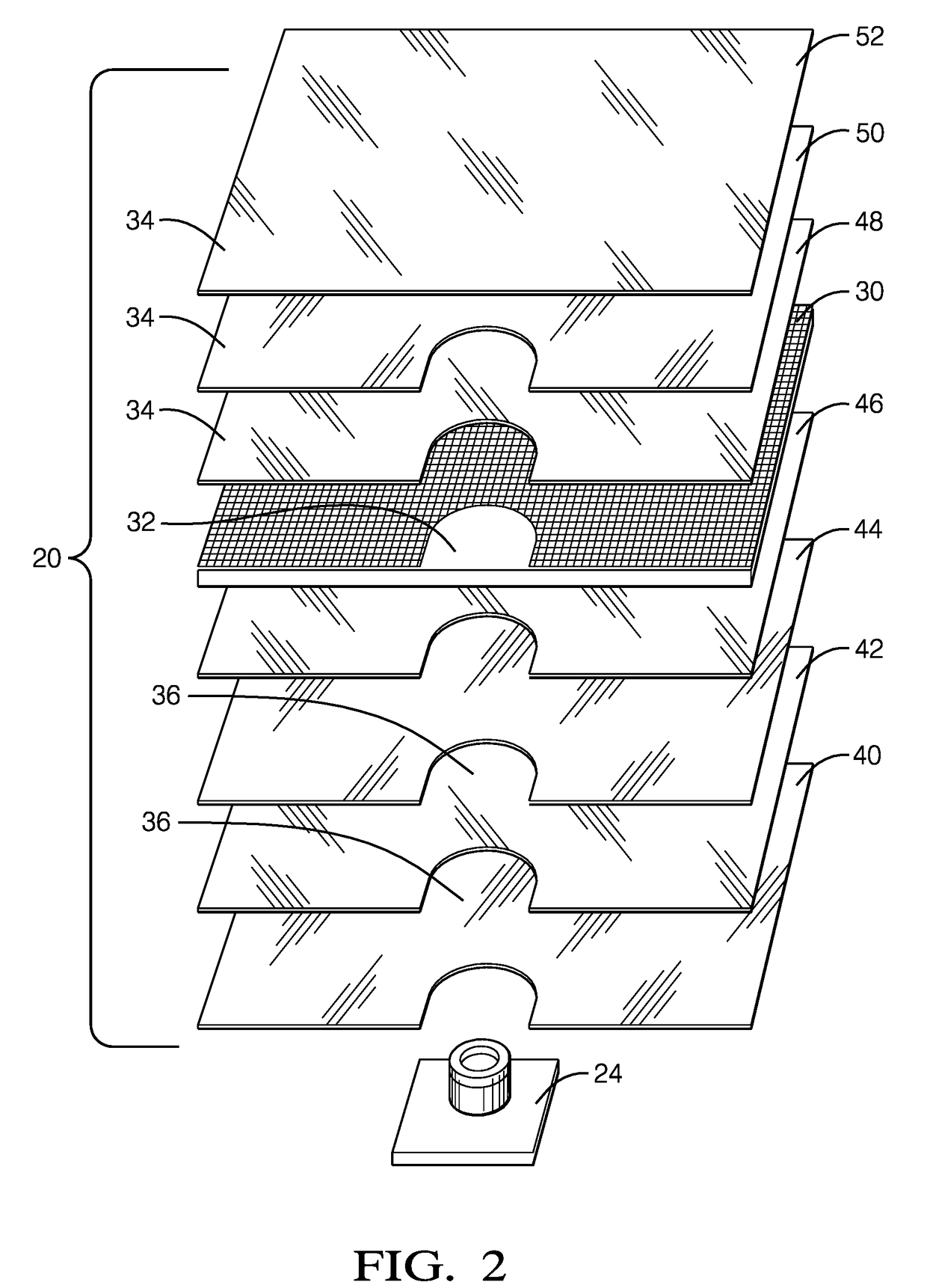

Reconfigurable display with camera aperture therethrough

InactiveUS20180079370A1Easy to die cutLow costVehicle sub-unit featuresSignalling/lighting devicesDisplay deviceField of view

A reconfigurable display system includes a camera, a thin-film-transistor layer, and a film layer. The camera is located behind a display and oriented to have a field-of-view of a viewable-side of the display. The thin-film-transistor layer of the display defines a window whereby the camera views the field-of-view through the thin-film-transistor layer. The film layer of the display defines an aperture though the film layer, wherein the film layer is positioned so that the aperture is aligned with the window. As a result, the camera views the field-of-view through the aperture and the thin-film-transistor layer.

Owner:APTIV TECH LTD

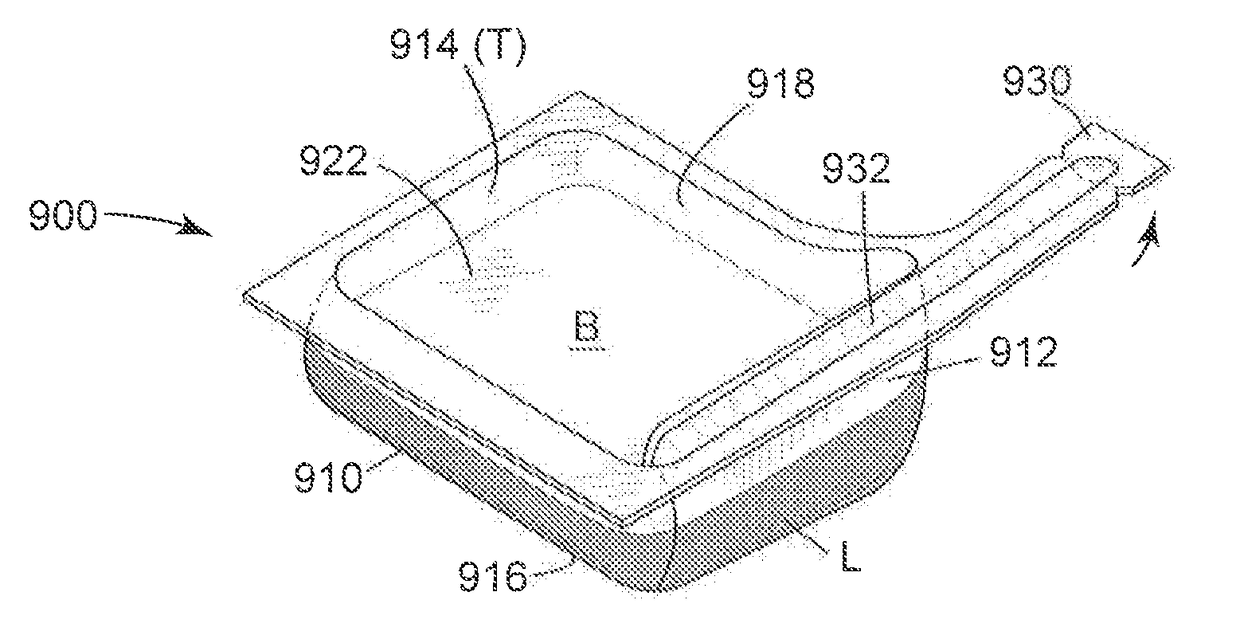

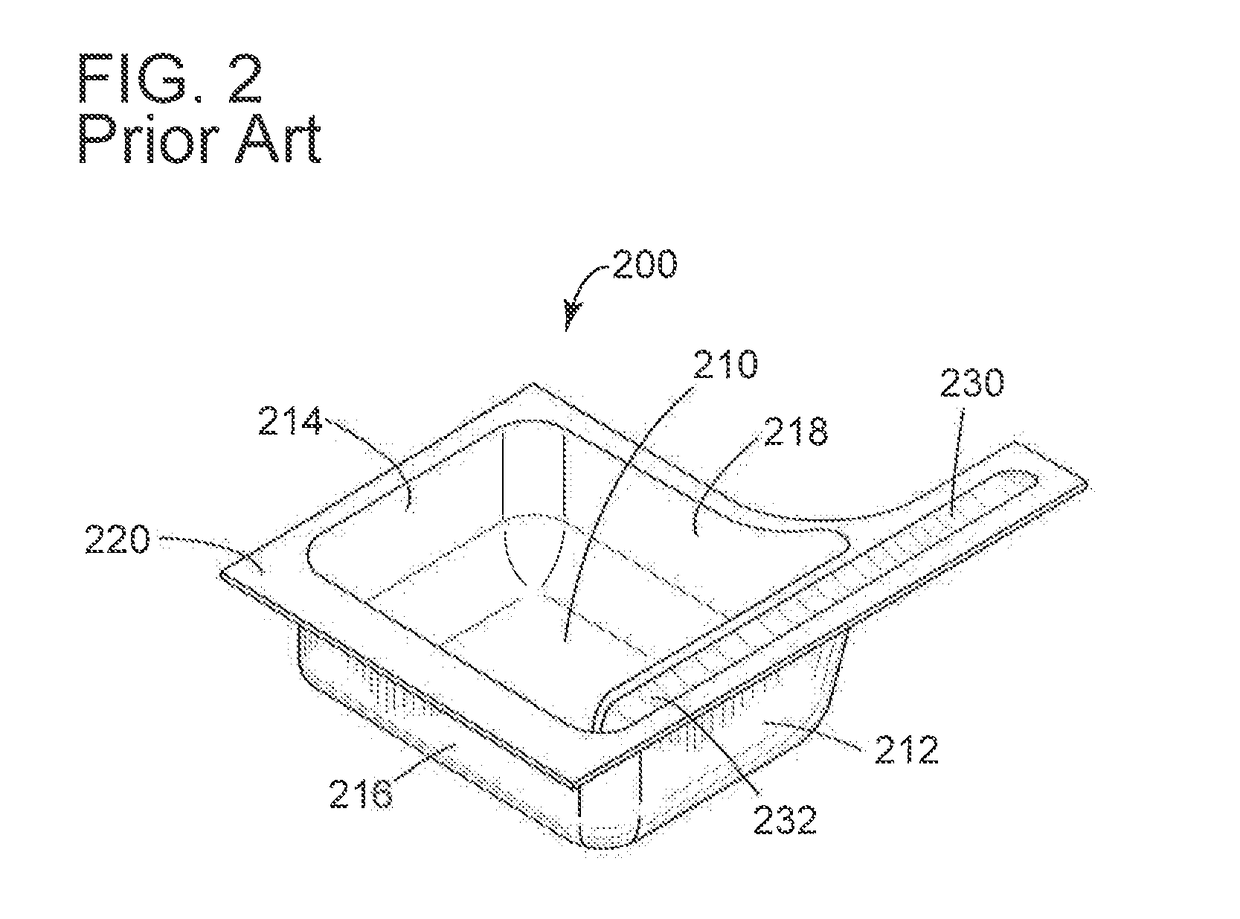

Thermoformed flexible dispensing container with integrally formed flat bottom for a stand-up configuration

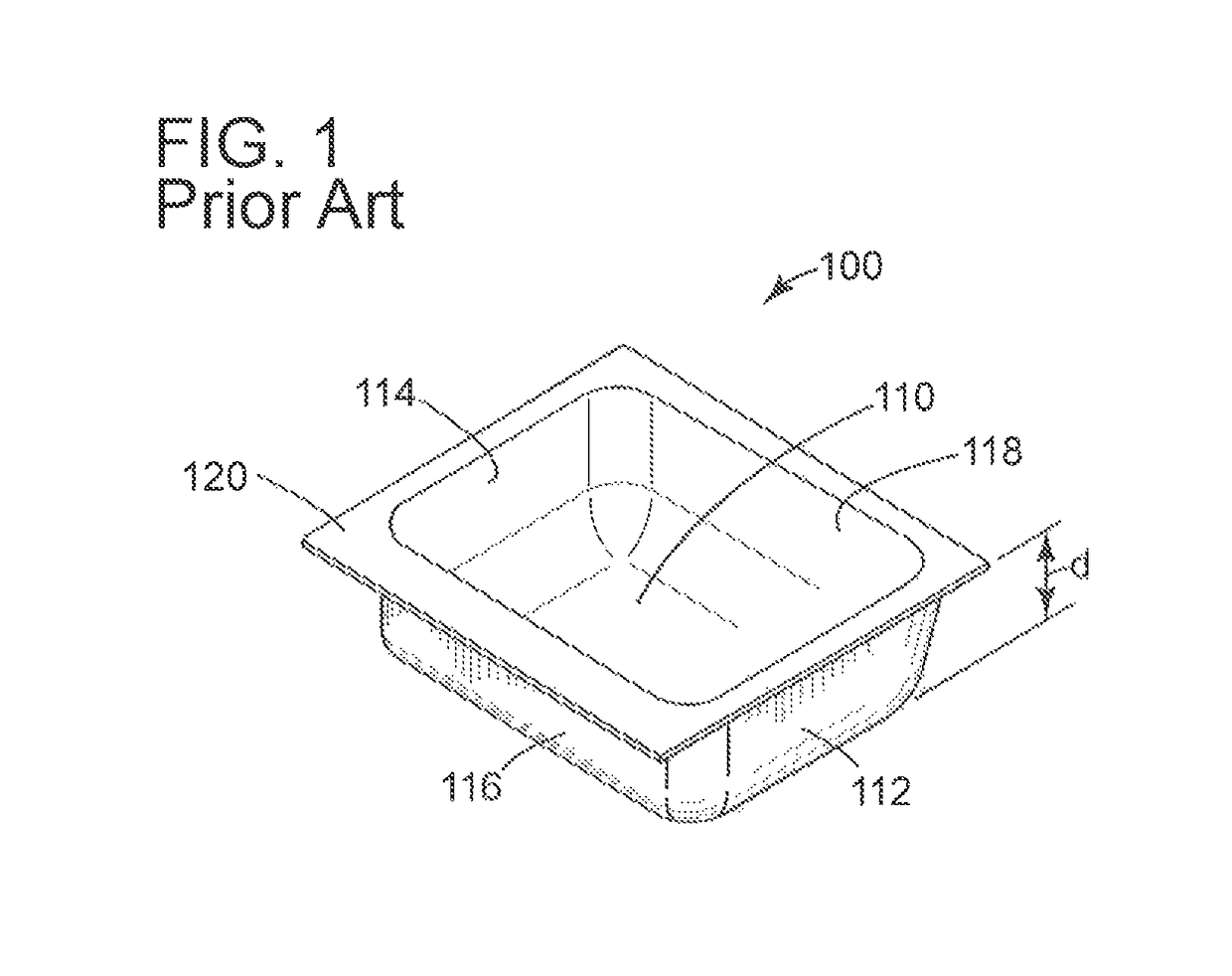

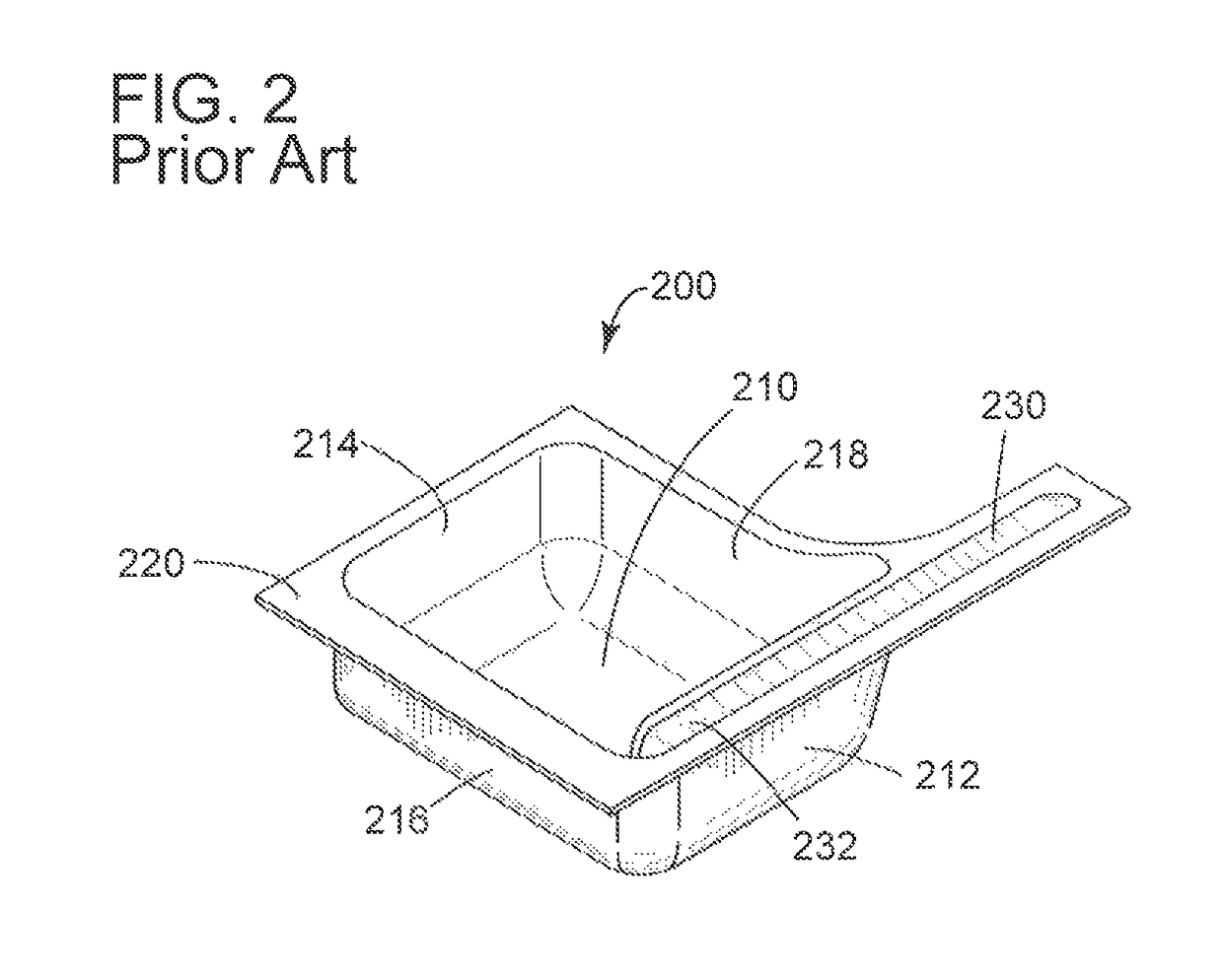

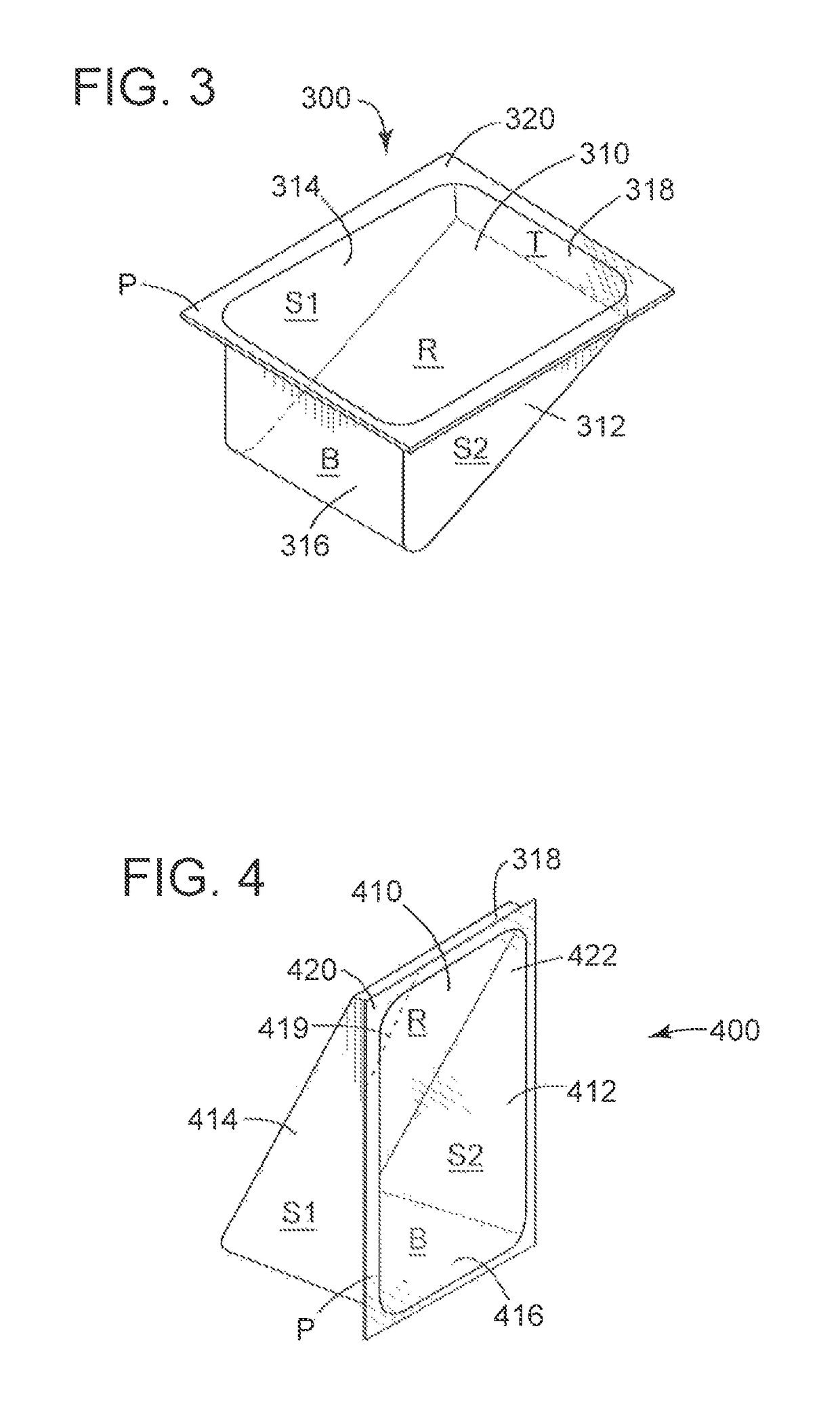

ActiveUS20170096271A1Lower center of gravityStable stand-up package orientationSuccessive articlesHermetic packagingEngineering

A flexible thermoformed dispensing package for a flowable material that can be massed produced on a horizontal thermoform-fill-seal (HTFFS) machine includes a container portion that is dimensioned and configured with a flat self-supporting base, integral opposing side walls and a rear wall extending from the base, and a top wall or seam integrally formed from a single sheet or web, the side walls tapering from the base toward the integral rear wall and terminating at the top wall or seam; and a front wall that is heat-sealed as a separate sheet to the periphery of the periphery of the base, side walls and top wall to form a fluid-tight package that maintains a stand-up orientation when in use, and optionally includes an integral dispensing tube with an optional internal extension terminating proximate the supporting base for withdrawing liquid contents from the package.

Owner:BARTON GRP LLC

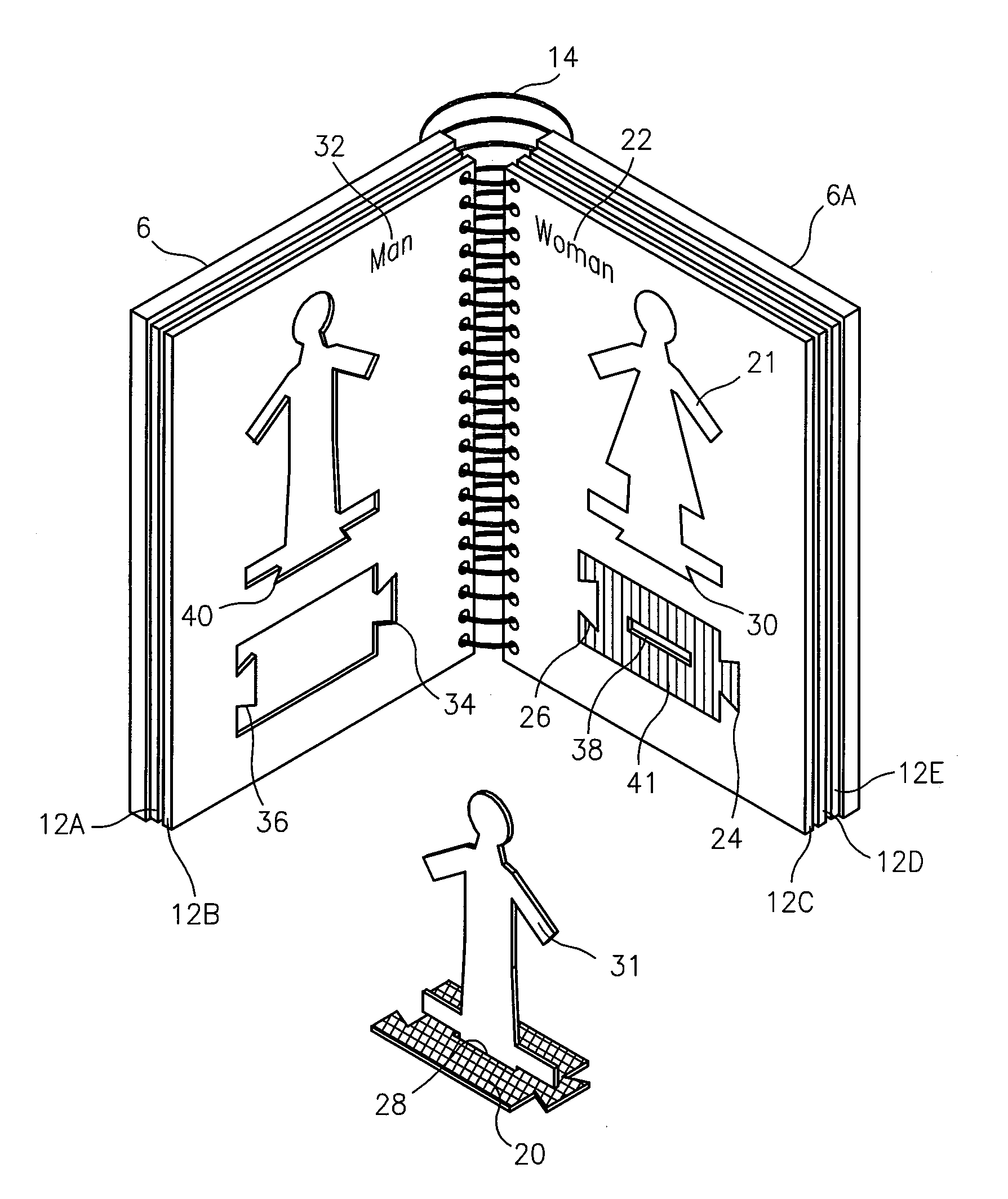

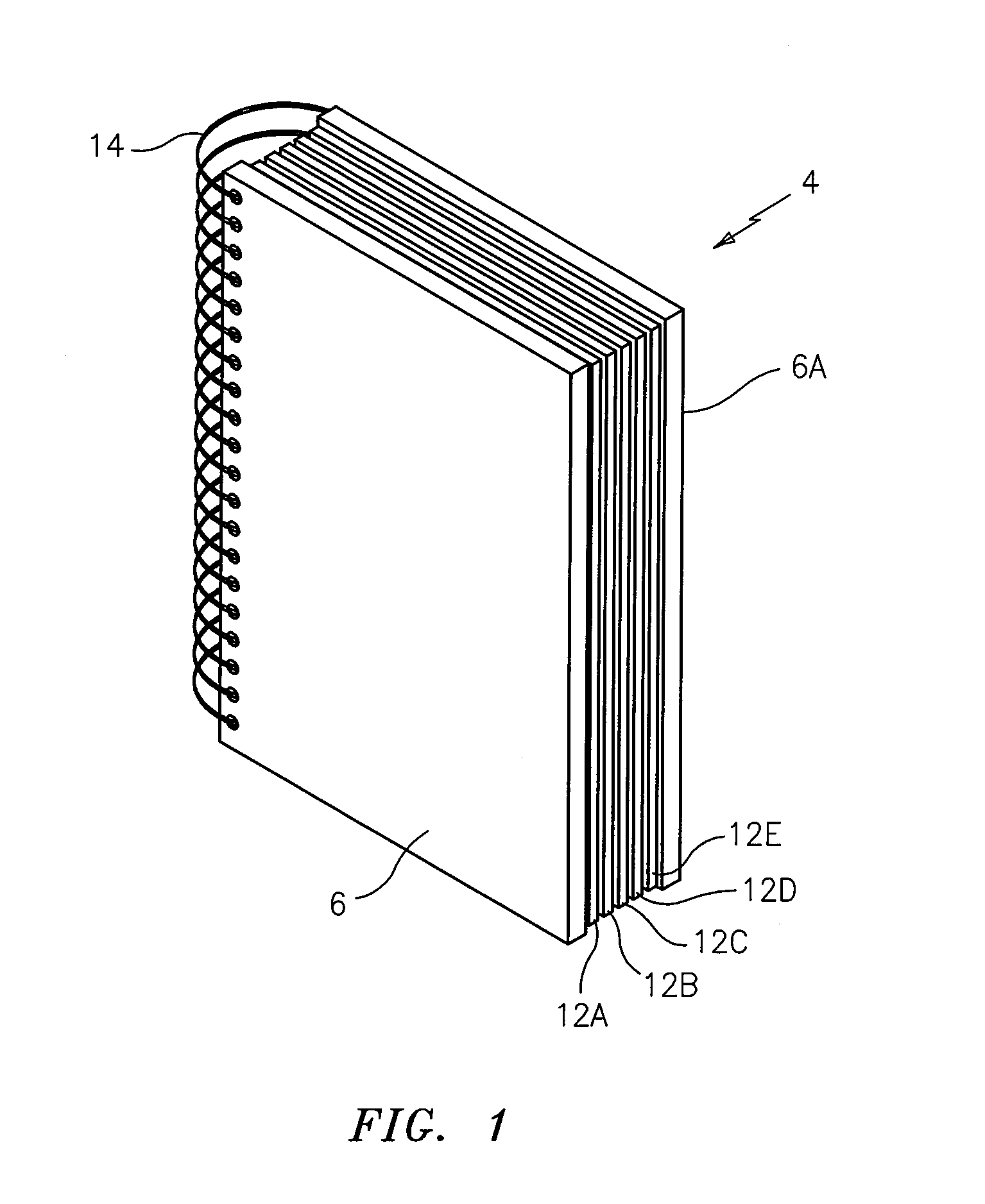

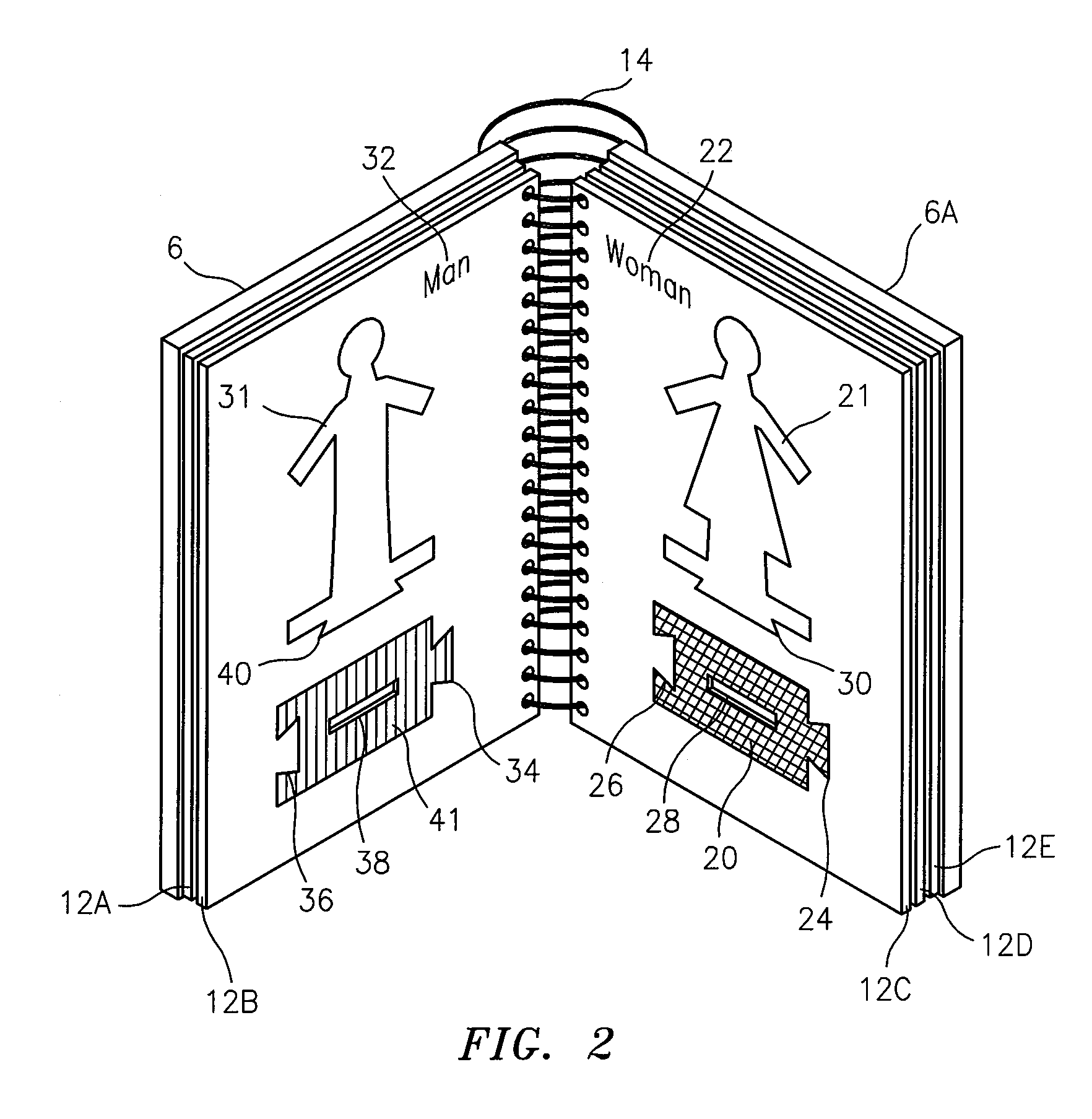

Book with interactive element

InactiveUS20110133441A1Easy to die cutLoss of structural integrityBookletsToysBiomedical engineeringStructural integrity

A book having at least one bound-in removable interactive element is described. The book is constructed from material having sufficient rigidity and structural integrity to maintain the shape of the cover and each page while still facilitating efficient removal and insertion of individual removable interactive elements. The removable interactive elements are preferably formed by die-cutting a cover or page of the book such that the desired shape and its corresponding outline are formed. No backing material is provided on either side of the cover or page such that each removable interactive element may be inserted or removed from either side. This facilitates greater interactivity and flexibility in its use. The removable interactive element may be used as an object of play, as a puzzle piece, in a game, as part of a story, or in any other activity either within or outside the book.

Owner:INNOVATIVE USA

Thermoformed flexible dispensing container with integrally formed flat bottom for a stand-up configuration

ActiveUS10059498B2Stable stand-up package orientationLower center of gravitySuccessive articlesMechanical engineeringLiquid content

A flexible thermoformed dispensing package for a flowable material that can be massed produced on a horizontal thermoform-fill-seal (HTFFS) machine includes a container portion that is dimensioned and configured with a flat self-supporting base, integral opposing side walls and a rear wall extending from the base, and a top wall or seam integrally formed from a single sheet or web, the side walls tapering from the base toward the integral rear wall and terminating at the top wall or seam; and a front wall that is heat-sealed as a separate sheet to the periphery of the periphery of the base, side walls and top wall to form a fluid-tight package that maintains a stand-up orientation when in use, and optionally includes an integral dispensing tube with an optional internal extension terminating proximate the supporting base for withdrawing liquid contents from the package.

Owner:BARTON GRP LLC

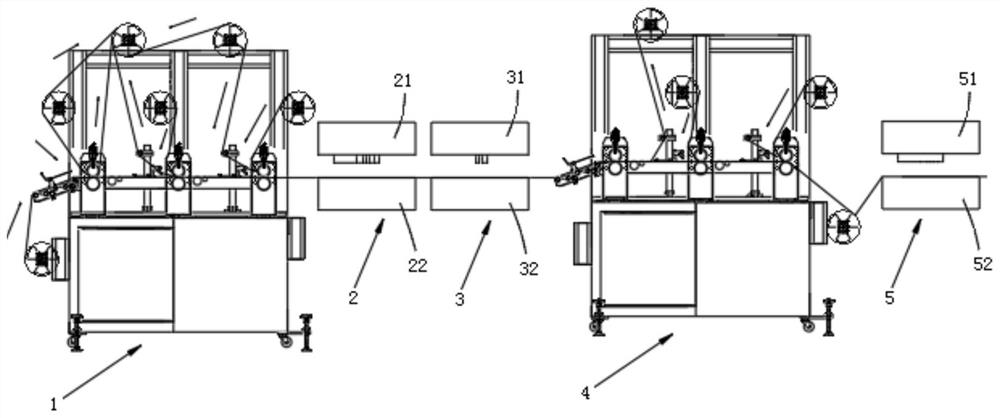

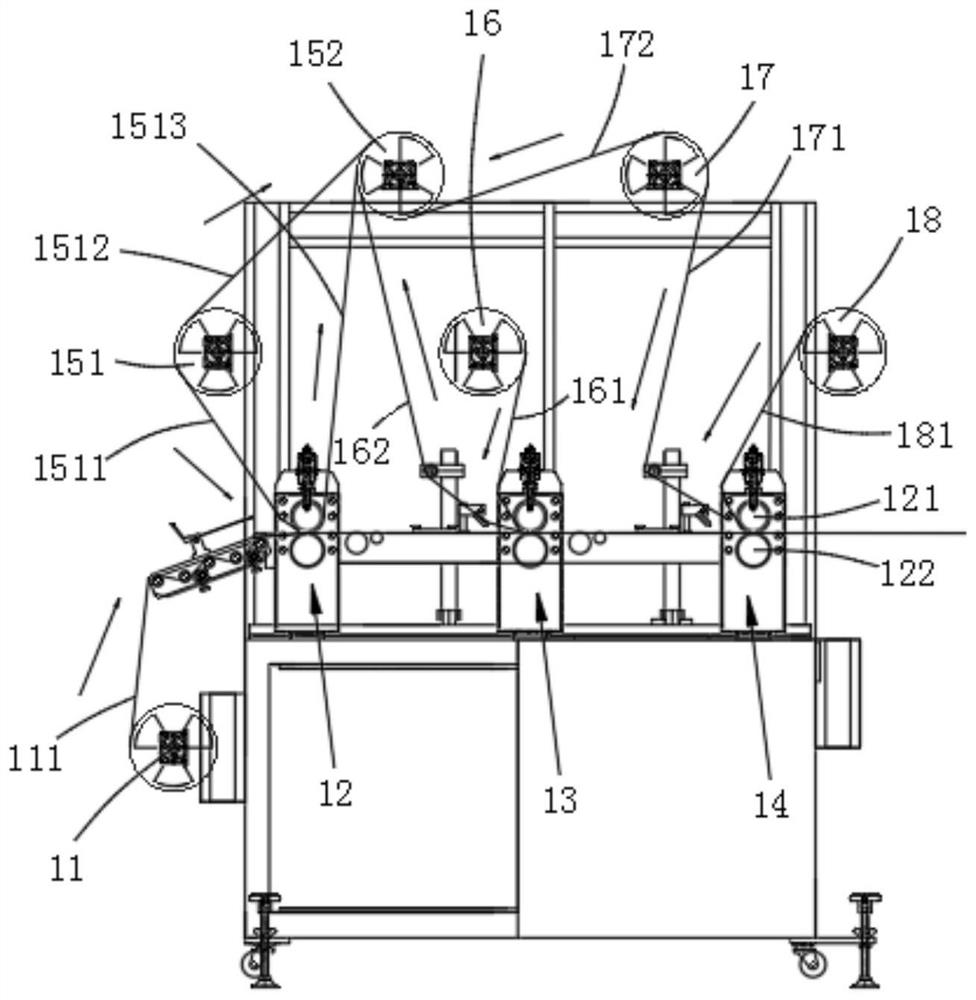

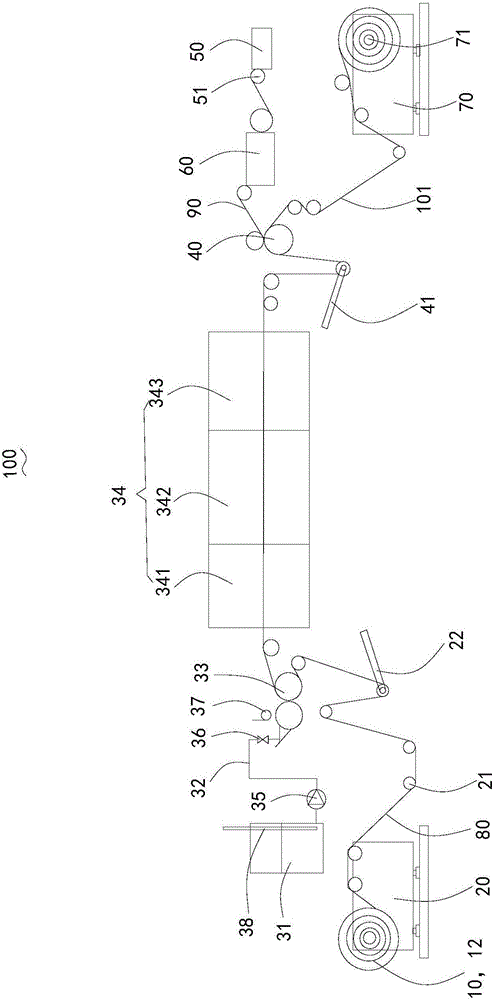

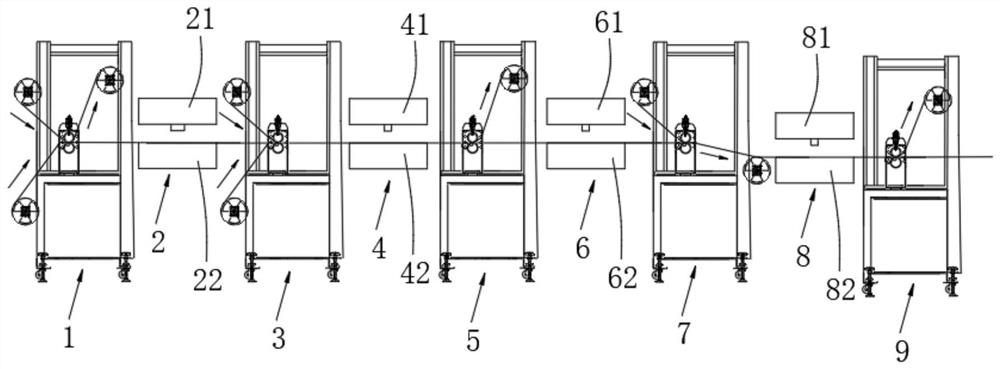

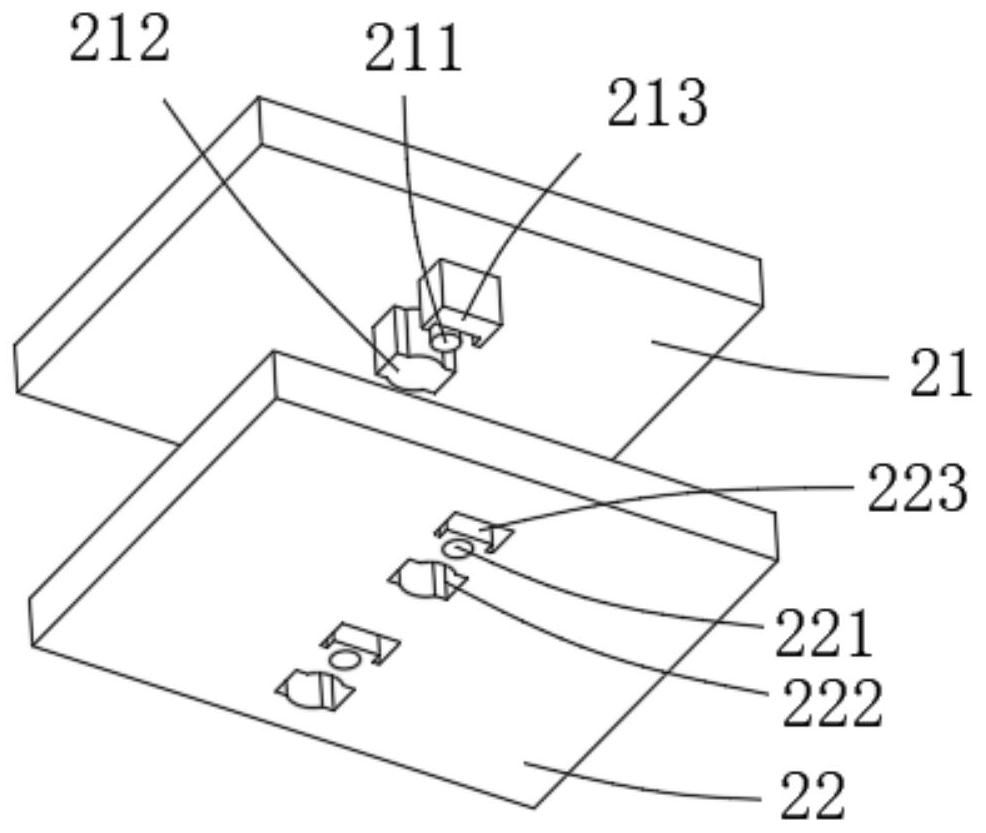

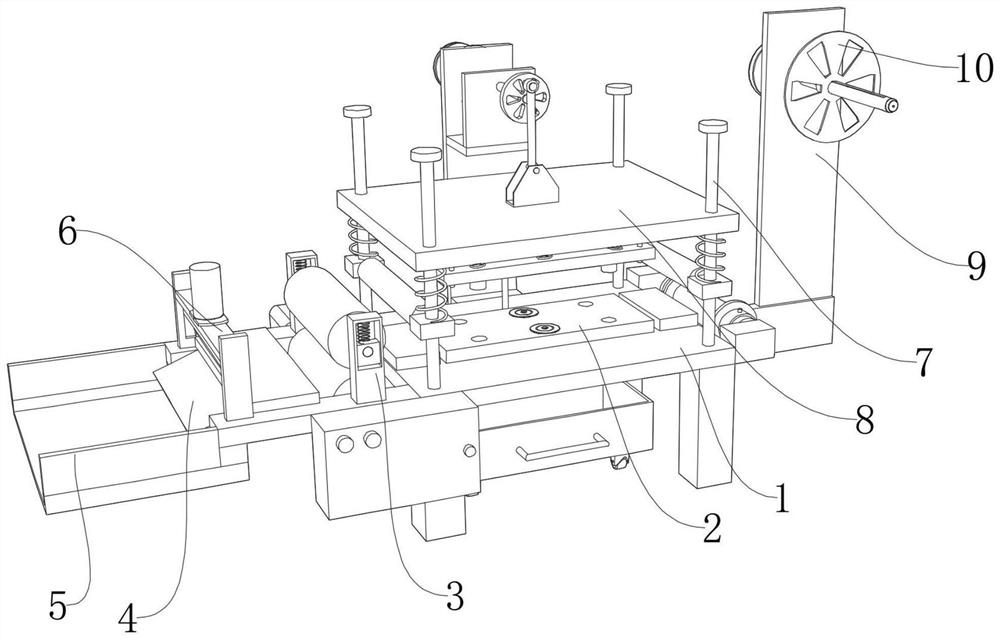

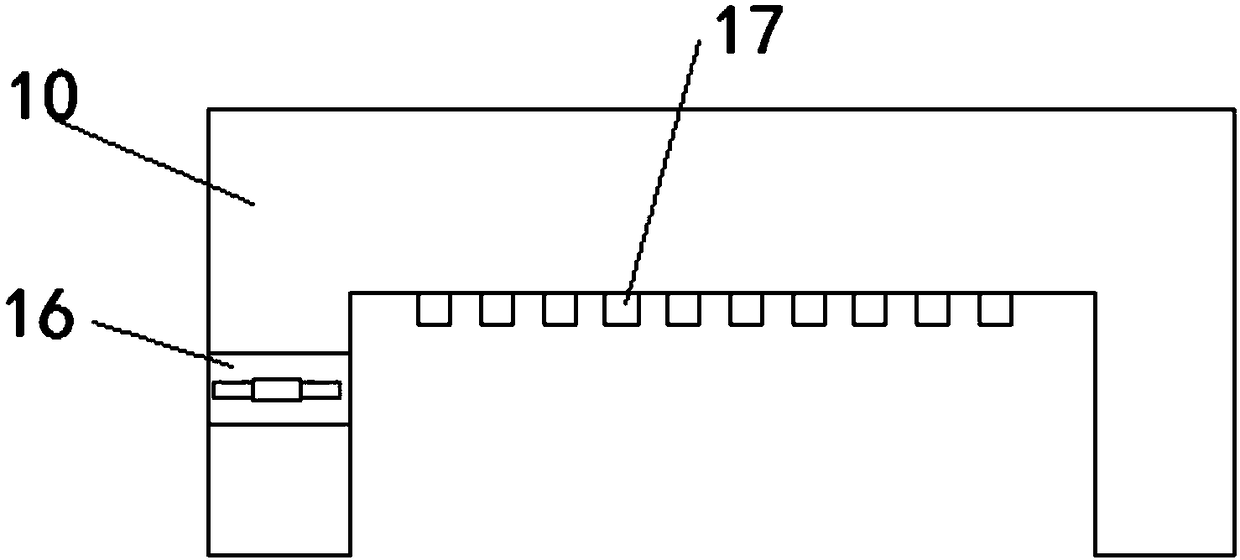

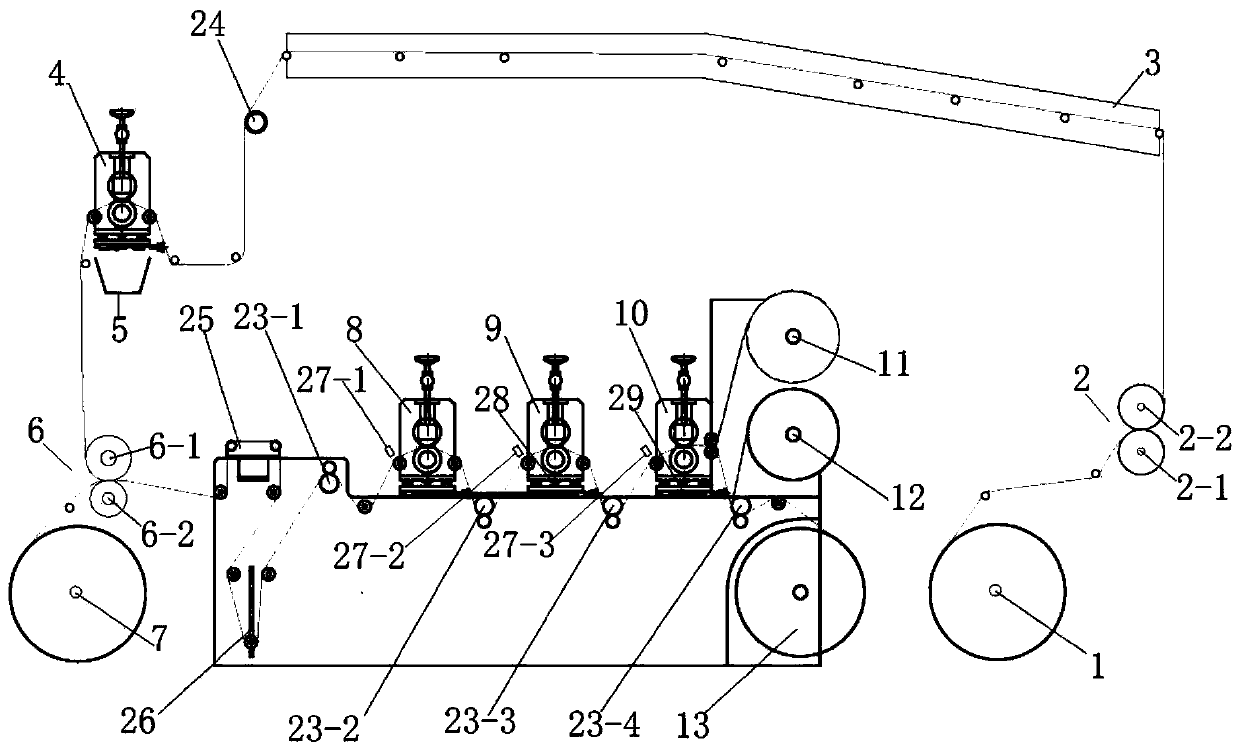

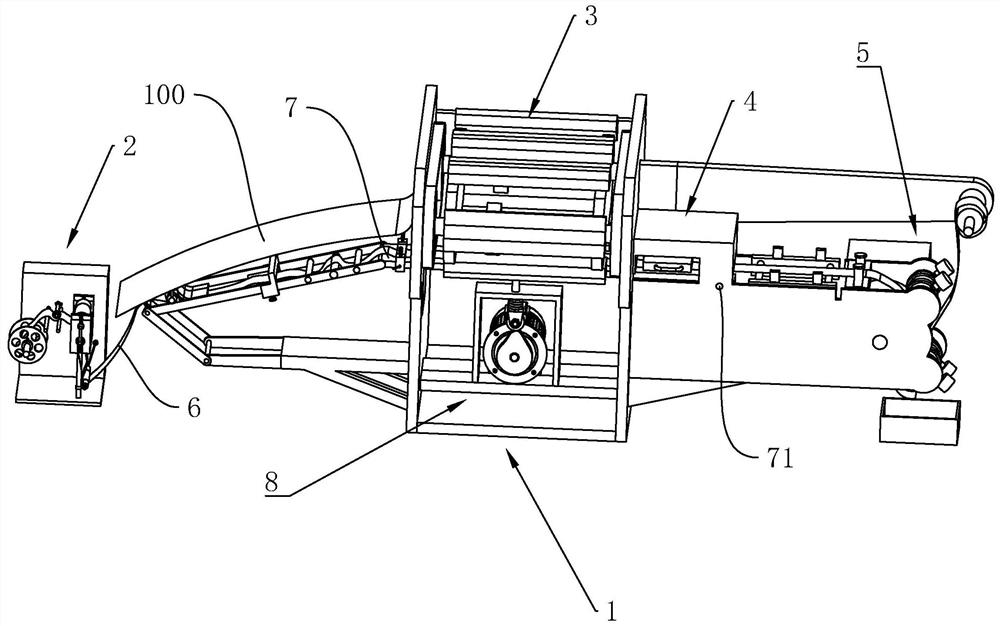

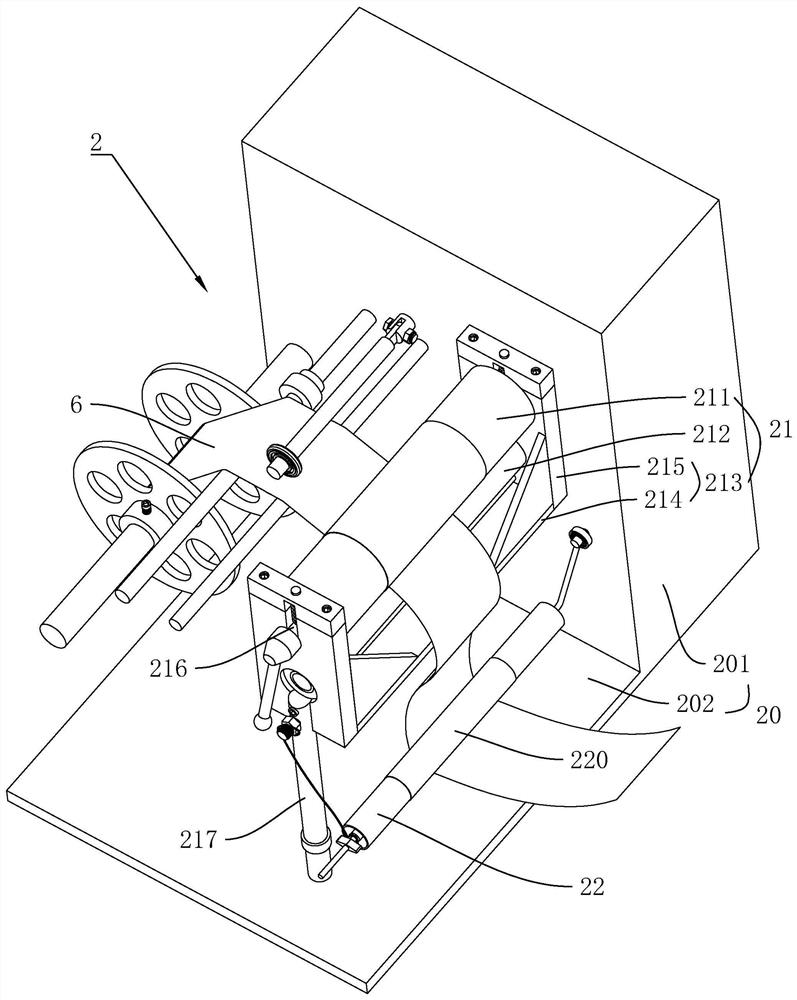

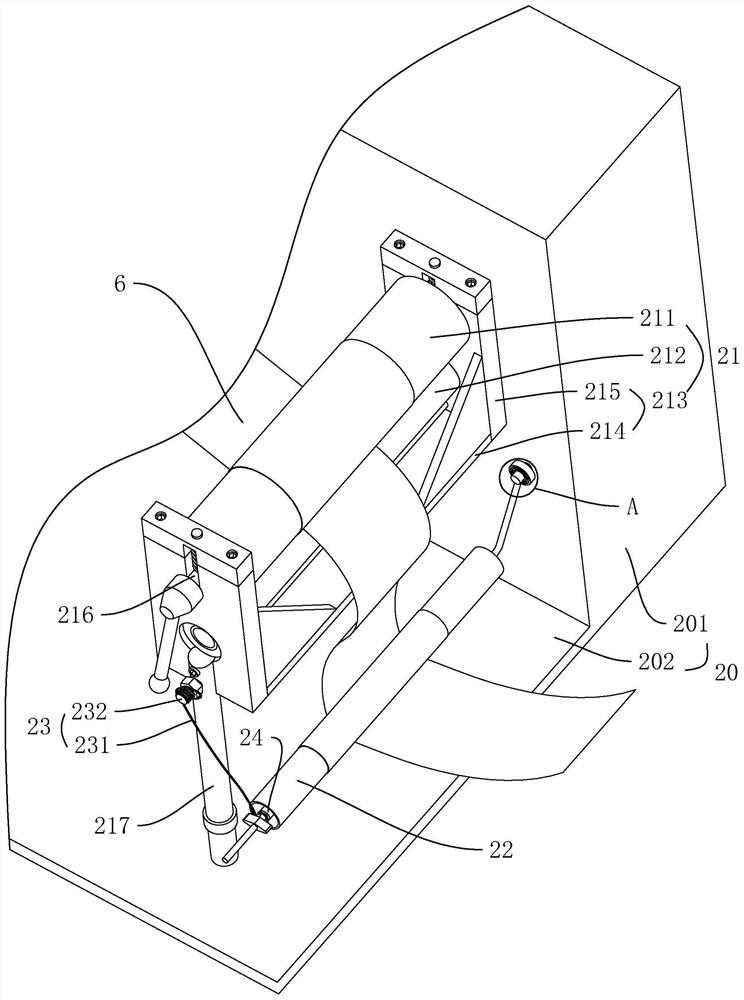

Automatic foam adhesive film waste discharge production line

InactiveCN112643774AReduce labor intensityImprove waste discharge efficiencyMetal working apparatusProduction lineAdhesive belt

The invention discloses an automatic foam adhesive film waste discharge production line which comprises a feeding device, a first die cutting mechanism, a waste discharge mechanism, a laminating device and a second die cutting mechanism. The feeding device is located on the upstream of the first die cutting mechanism, the first die cutting mechanism is located on the upstream of the waste discharge mechanism, the waste discharge mechanism is located on the upstream of the laminating device, and the laminating device is located on the upstream of the second die cutting mechanism. The feeding device sequentially comprises a protective film discharge roller, a first tape pressing mechanism, a second tape pressing mechanism and a third tape pressing mechanism according to the production process, the protective film discharge roller is sleeved with a protective film, a first adhesive tape unwinding mechanism is arranged above the first tape pressing mechanism, and a foam discharge roller is arranged above the second tape pressing mechanism. According to the automatic foam adhesive film waste discharge production line, all the layers are attached, then die cutting and waste discharge are conducted, the automation degree is high, whether waste is discharged or not is observed through a red recognition film, and the product yield is guaranteed.

Owner:昆山域之光电子有限公司

Graphene-based thermal conductive film preparing method

The invention provides a graphene-based thermal conductive film preparing method which includes the steps that biological materials are stirred and squeezed broken, and a solvent is added to the biological materials to dilute the materials; ultrasonic suction filtration is conducted on the obtained biological material pulp, and filter liquor of the biological material pulp is obtained and sealed for use; ultrasound is conducted on a graphite oxide solution, and oxidized graphene sol is obtained; the biological material filter liquid is mixed with the oxidized graphene sol, the mixed solution is made to react, and a reduced graphene film is obtained; the thermal annealing is conducted on the obtained film under the conditions of the inert atmosphere and low temperature, and the high-thermal-conductive graphene film is obtained. The graphene film prepared through the method has the advantages of being thermal conductive, electric conductive, good in mechanical property, controllable in thickness, wide in raw material source and capable of achieving batch production easily.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

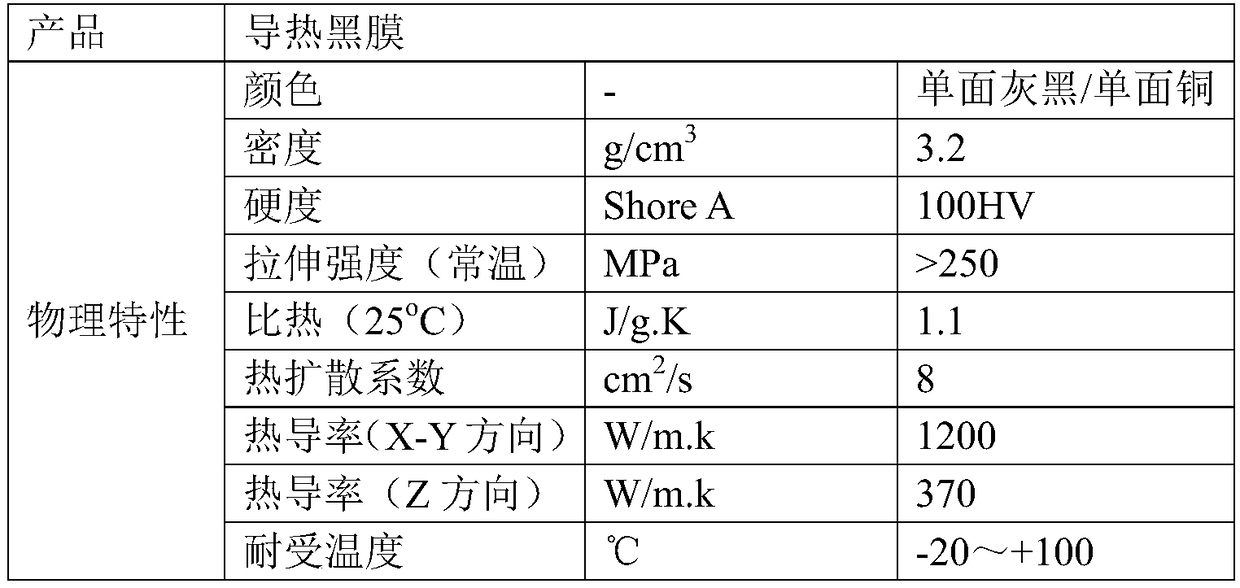

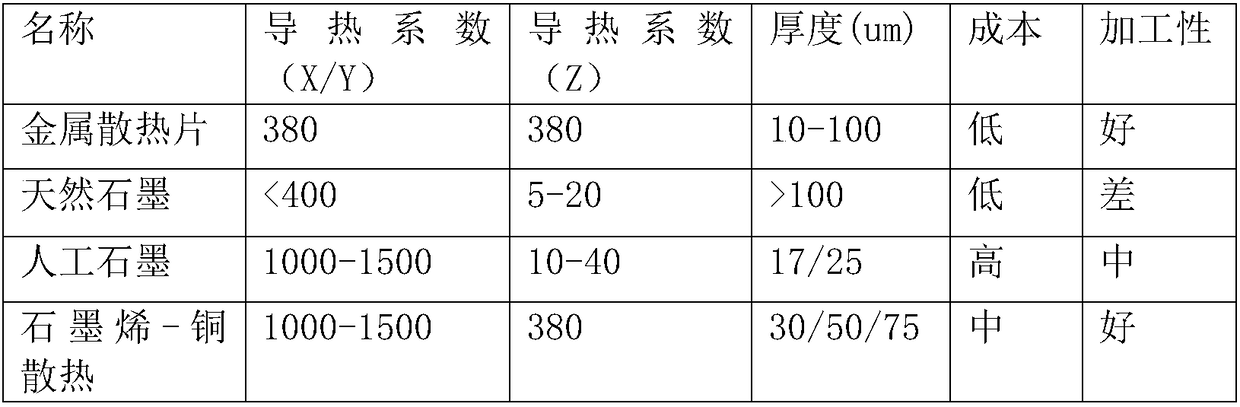

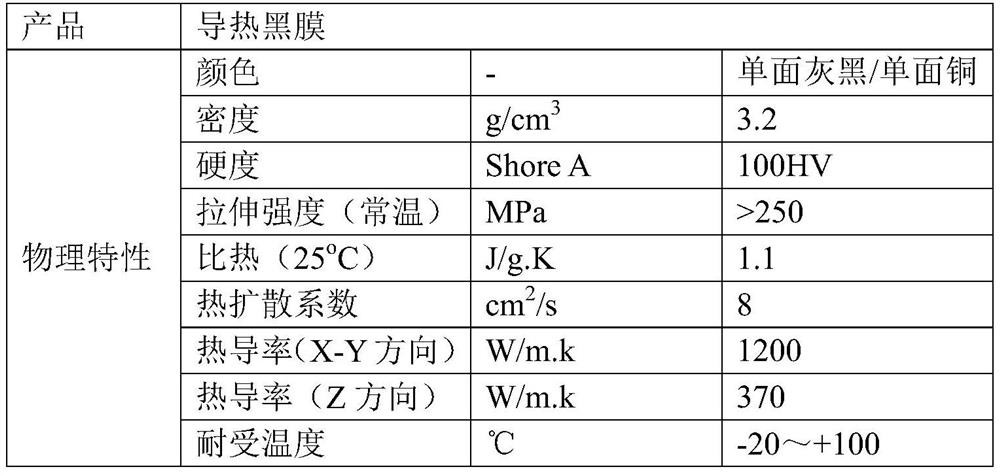

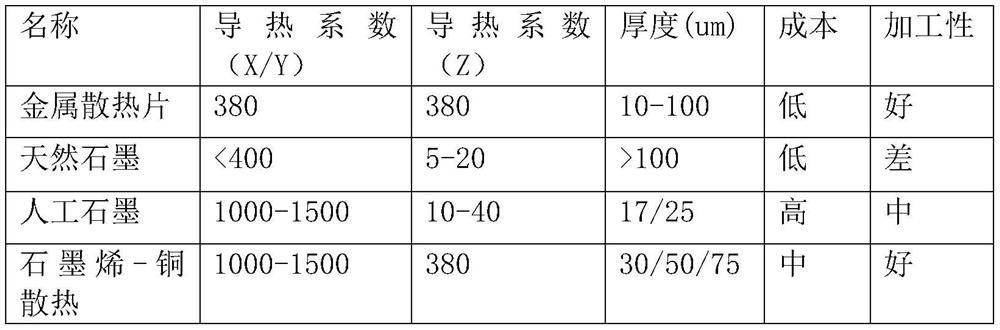

Graphene-copper composite heat-dissipating film as well as preparation method and application thereof

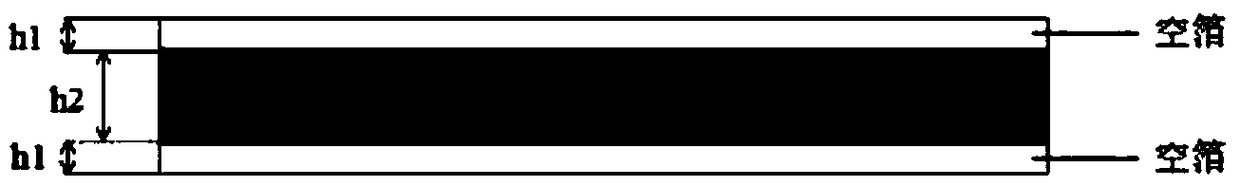

ActiveCN109334155ASpeed up distributionAchieve protective effectGrapheneOptical articlesCopper foilNatural graphite

The invention relates to a graphene-copper composite heat-dissipating film as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, pretreating natural graphite, and then sequentially performing high-speed shearing, ultrasonic stripping and emulsification to obtain graphene; mixing the graphene, then preparing the graphene into a film,drying to obtain a graphene film, then heating the graphene film at a preset temperature to prepare a micro-balloon, and mechanically rolling the micro-balloon at a preset pressure to prepare micro-pleats; compacting the graphene film with copper foil, and then sticking a heat-conductive black film onto the other side of the copper foil to obtain the graphene-copper composite heat-dissipating film. According to the preparation method of the graphene-copper composite heat-dissipating film provided by the invention, the heat dissipation is accelerated by equalizing a point-like heat source to asurface and then emitting the heat in a longitudinal direction, so that a protection effect on a product component is achieved, and the heat dissipation effect is superior to that of graphite sheetsin the traditional process and artificial graphite sheets.

Owner:宁波顶峰机器人有限公司

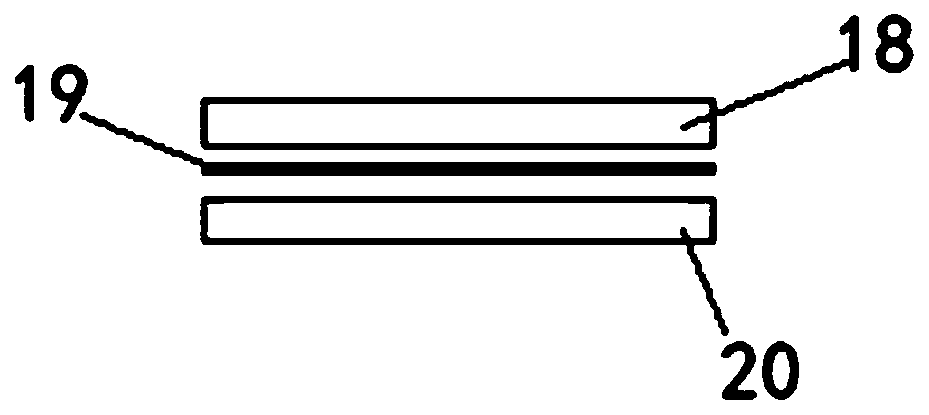

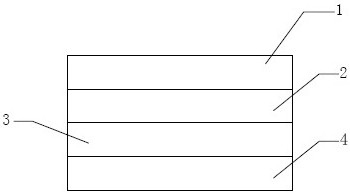

Protection membrane with multiple application layers and preparation method of protection membrane

InactiveCN104669734ASimple processEasy to die cutSynthetic resin layered productsLaminationColloidal silicaBond line

The invention relates to the technical field of a protection membrane, and particularly relates to a protection membrane with multiple application layers and a preparation method of the protection membrane. The protection membrane is provided with a plurality of application layers, and each application layer can be stripped from top to bottom; a base material of each application layer is a transparent polyester film, one side of the transparent polyester film is a hardening surface which is treated in a hardening manner, the other side of the transparent polyester film is a corona surface which is treated in a corona manner, a bonding layer is arranged between the corona surface of the upper application layer and the hardening layer of the lower application layer, each bonding layer comprises an area A and an area B, and the stripping force of the area A is 20g / 25mm to 45g / 25mm greater than that of the area B; the corona surface of the transparent polyester film on the bottommost layer is coated with a silica gel coating, and the surface of the silica gel coating is provided with a protection film layer. After the surface layer of the protection membrane is damaged, the application layer on the surface layer can be directly removed, the protection membrane can be further used, and the application cost is reduced. The preparation method is simple and convenient to popularize and use.

Owner:深圳市博泰高分子材料有限公司

Easily-uncover aluminum plastic compound single film for glass bottle sealing opening

InactiveCN105197399AModerate fastnessEasy to die cutSealingMetal layered productsLow-density polyethyleneLinear low-density polyethylene

The invention relates to an easily-uncover aluminum plastic compound single film for a glass bottle sealing opening. The film comprises a body, wherein a compound layer, a base layer, and a heat sealing layer are arranged on the body in sequence; a blocking layer is arranged on the compound layer; the body comprises the components in percentage by weight: 29.47%-30.59% of low-density polyethylene, 39.05%-40.81% of linear low-density polyethylene and 29.72-30.36% of an ethylene-(methyl) acrylate copolymer. The film has the advantages that the low-density polyethylene, the linear low-density polyethylene and the ethylene-(methyl) acrylate copolymer are mixed for preparing the body, so that the glass bottle sealing opening is proper in fastness, and is proper in stripping force when being uncovered; a stripping interface is clean, an obvious attenuation phenomenon after refrigeration does not exist, and the film is wide in application range of packaged products; due to arrangement of the blocking layer, the body has the very good blocking performance, stiffness and forming performance, the blocking layer can enable the packaged products to obtain very good protection, the stiffness enables the compound film to be conveniently cut into single pieces, the forming performance enables pressing lines to be processed and arranged conveniently, and the use effect is good.

Owner:GLODSTONE PACKAGING JIAXING

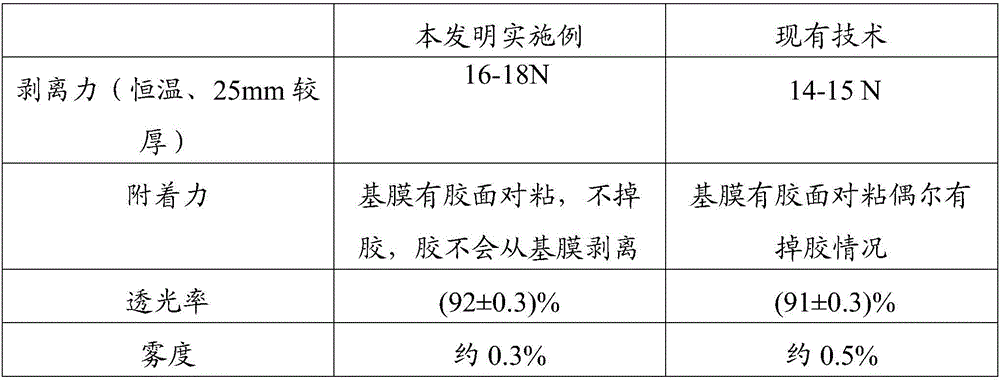

Explosion-proof membrane production method

InactiveCN106183327AExtend your lifeImproved adhesion and peelLamination ancillary operationsLayered product treatmentAdhesiveCoating

The invention discloses an explosion-proof membrane production method. The method comprises the following steps: providing a release film, putting a first uncoiler on the release film, passing the release film through a coating roller and a baking oven of a coating machine in order, then passing the release film through a composite wheel; providing an optical adhesive, adding a hardener in the optical adhesive, uniformly stirring the materials; separating the set temperature of the baking oven of the coating machine from an inlet to an outlet to a first temperature zone, a second temperature zone and a third temperature zone; providing a hardening membrane, putting a second uncoiler on the hardening membrane, passing one end of the hardening membrane through a corona machine and the composite wheel by the second uncoiler, applying a first surface of the hardening membrane and the first surface of the release film at the position of the composite wheel; turning on an explosion-proof membrane production device, coating the optical adhesive to the first surface of the release film by the coating machine, performing corona on the first surface of the hardening membrane by the corona machine, and compositing the first surface and the first surface of the release film on the composite wheel to form the explosion-proof membrane. According to the explosion-proof membrane production method, the produced explosion-proof membrane has the advantages of low cost, high quality and long service life.

Owner:DONGGUAN XUANLANG IND

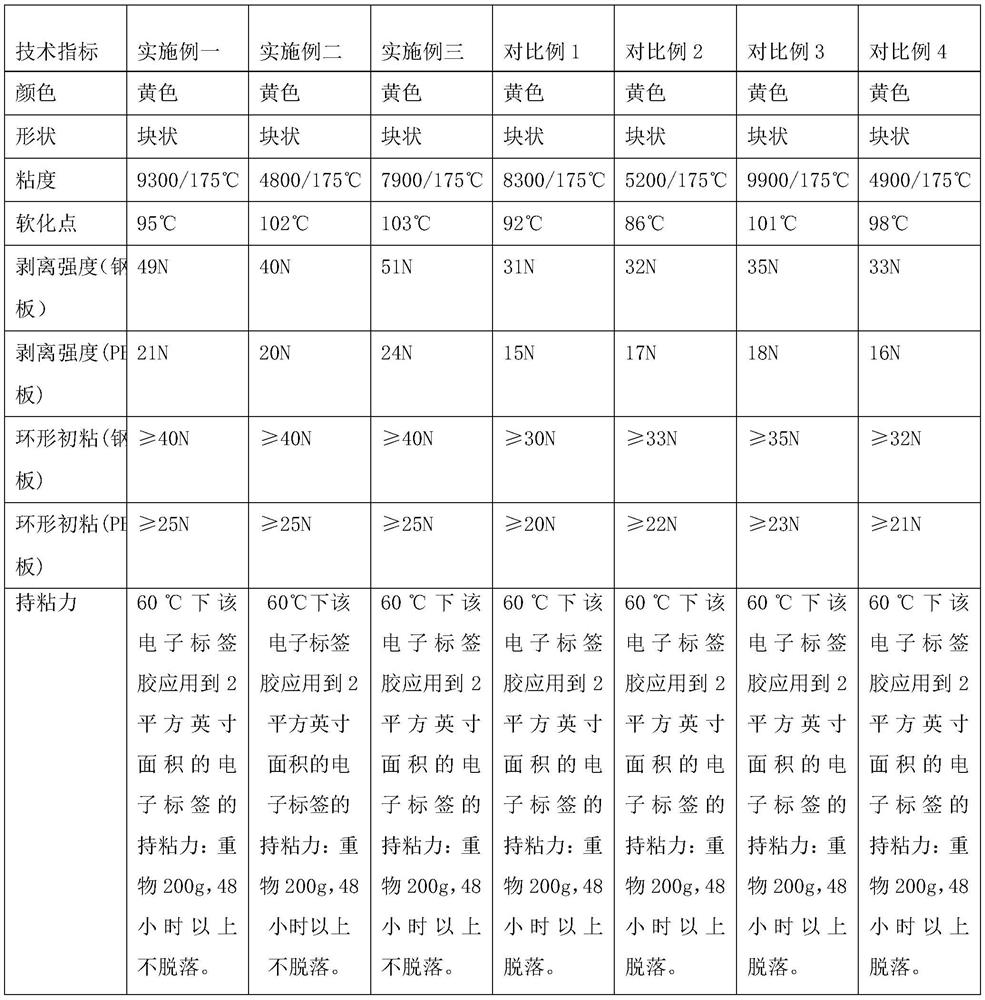

Hot-melt pressure-sensitive adhesive for RFID electronic tag and preparation method of hot-melt pressure-sensitive adhesive

PendingCN114163954AGood first stickGood adhesionMineral oil hydrocarbon copolymer adhesivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a hot-melt pressure-sensitive adhesive for an RFID (Radio Frequency Identification Device) electronic tag, which is prepared from the following raw materials in parts by weight: 30 to 45 parts of styrene-isoprene-styrene block copolymer, 35 to 70 parts of tackifying resin, 20 to 35 parts of softening agent and 0.5 to 2 parts of antioxidant. The styrene-isoprene-styrene block copolymers comprise at least two of a specification A, a specification B, a specification C and a specification D, and the weight ratio of any two specifications in the styrene-isoprene-styrene block copolymers is (5-7): (1-3). The hot-melt pressure-sensitive adhesive for the RFID electronic tag has the advantages of good initial adhesion, strong bonding force, good adhesion to a base material, good die cutting and excellent high and low temperature resistance, and is suitable for a high-speed coating machine of 100m / min.

Owner:佛山市南海骏驰新材料有限公司

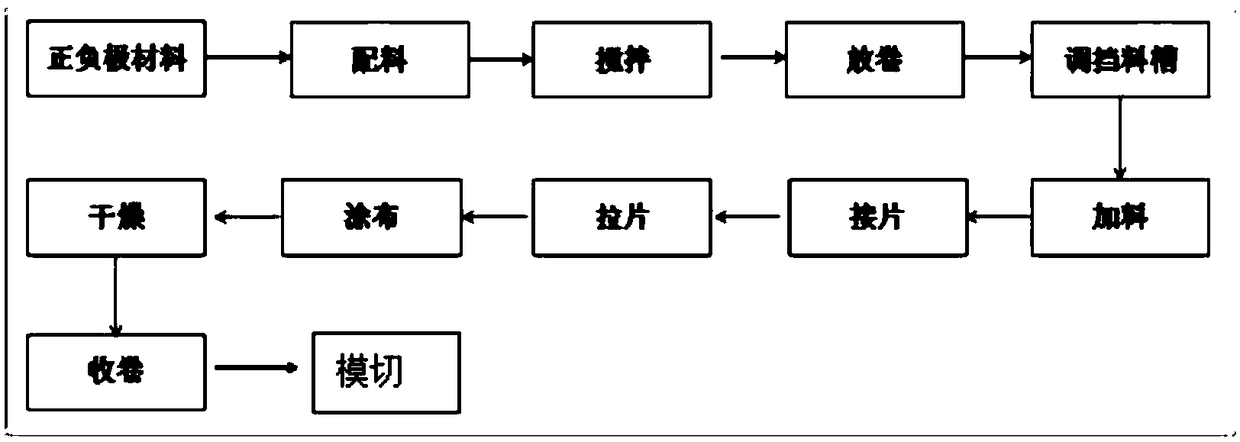

Coating process suitable for production of lithium battery

InactiveCN108520940AIncrease productivityPromote innovationElectrode collector coatingMaterials preparationMetallurgy

The invention discloses a coating process suitable for production of a lithium battery, which includes the steps of: material preparation, stirring, unreeling, adjustment of baffles of a material trough, material addition, joint of sheets, pulling of sheets, coating, drying, reeling and mold-cutting. In the coating step, a void foil remains between foil materials of electrode sheets, so that aftercoating and drying, the product can be directly mold-cut, thus omitting a cutting step. The coating process is subjected to creative modification; the modified coating method is simple and has convenience in mold-cutting, so that the coating process has better effect on lithium batteries, can save use amount of a foil material, reduces cost and increases production efficiency.

Owner:桑顿新能源科技(长沙)有限公司

Graphene-copper composite heat dissipation film and its preparation method and application

ActiveCN109334155BSpeed up distributionAchieve protective effectLaminationGrapheneCopper foilNatural graphite

The invention relates to a graphene-copper composite heat dissipation film and its preparation method and application. The preparation method comprises the following steps: firstly pretreating natural graphite, and then successively undergoing high-speed shearing, ultrasonic stripping and emulsification to obtain graphene; The graphene is mixed, then prepared into a film and dried to obtain a graphene film, and then the graphene film is heated at a preset temperature to prepare a micro-airbag, and then the micro-airbag is mechanically rolled at a preset pressure to Prepare micro-folds; compact the graphene film and copper foil, and then paste the thermally conductive black film on the other side of the copper foil to obtain a graphene-copper composite heat dissipation film. The preparation method of the graphene-copper composite heat dissipation film of the present invention accelerates the dissipation of heat by balancing the point-like heat source to the surface, and then radiates it longitudinally, so as to achieve the protection effect of product components, and its heat dissipation effect is better than that of traditional Craft graphite flakes and artificial graphite flakes.

Owner:宁波顶峰机器人有限公司

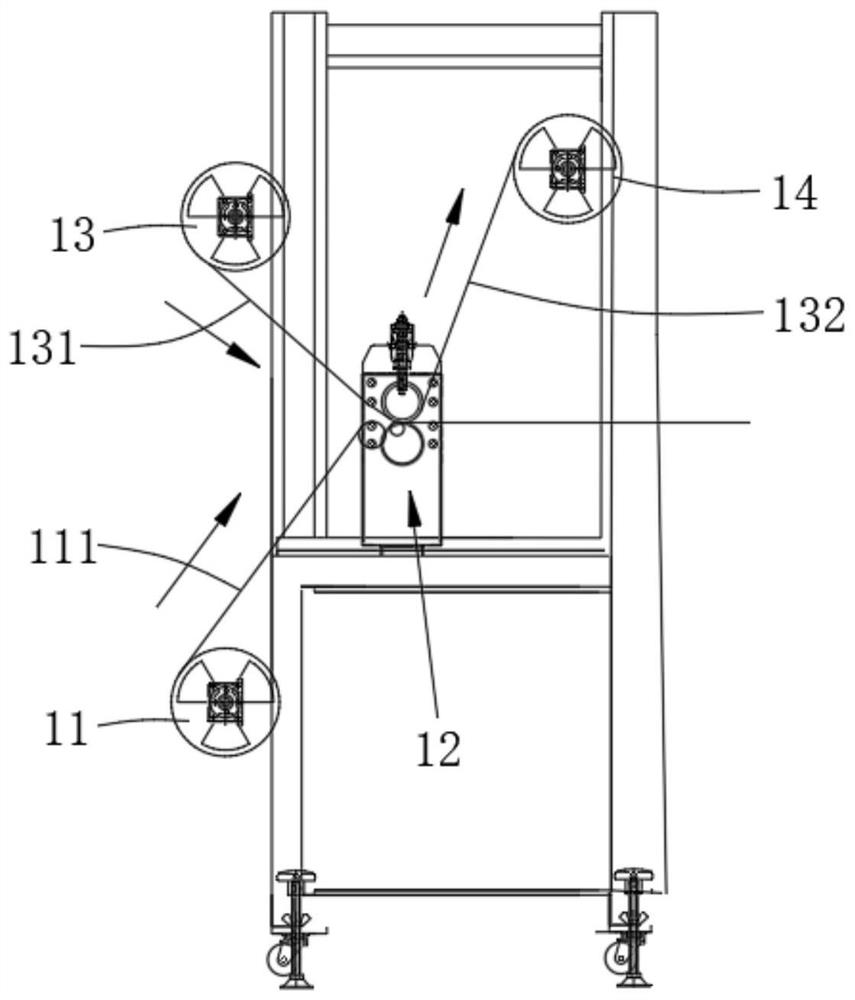

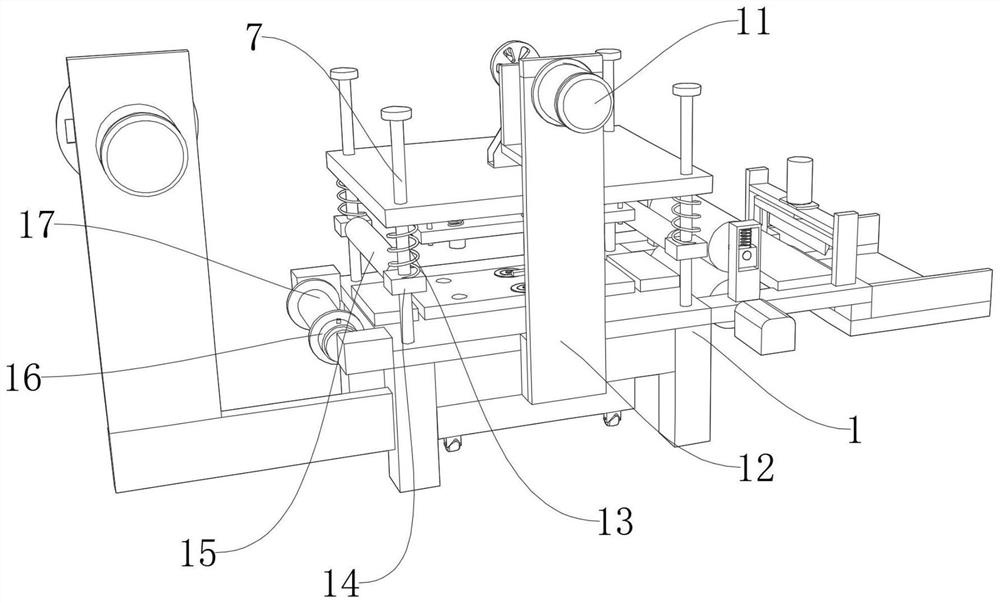

Buffering foam adhesive film production line

PendingCN112659240AEasy to observeHigh degree of automationMetal working apparatusProduction lineEngineering

The invention discloses a buffering foam adhesive film production line which sequentially comprises a first laminating device, a first die cutting mechanism, a second laminating device, a second die cutting mechanism, a first waste discharging mechanism, a third die cutting mechanism, a third laminating device, a fourth die cutting mechanism and a second waste discharging mechanism according to the production process. The first laminating device sequentially comprises a foam paying-off roller and a first tape pressing mechanism according to the production process, a first adhesive tape paying-off roller is arranged above the first tape pressing mechanism, the foam paying-off roller is sleeved with a foam layer, the foam layer is pressed on the first tape pressing mechanism, the first adhesive tape paying-off roller is sleeved with first adhesive tape, the first adhesive tape penetrates through the first tape pressing mechanism to be attached to the foam layer, and a first release film of the first adhesive tape is connected with a first release film taking-up roller. The buffering foam adhesive film production line performs die cutting and waste discharging after laminating all layers, the automation degree is high, and whether waste is removed or not can be conveniently observed.

Owner:昆山域之光电子有限公司

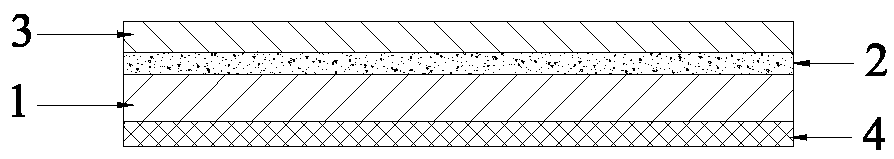

BOPP functional film and preparation method thereof

InactiveCN109291590AImprove temperature resistanceExtended service lifeSynthetic resin layered productsFlat articlesMasterbatchAntistatic agent

The invention discloses a BOPP functional film and a preparation method thereof. The BOPP functional film comprises a BOPP film layer, an adsorption layer, an antistatic layer and a release layer, andthe antistatic layer, the adsorption layer, the BOPP film layer and the release layer are sequentially stacked, or the release layer, the antistatic layer, the adsorption layer and the BOPP film layer are sequentially stacked; the components of the BOPP film layer are scientifically configuring, anti-aging masterbatch can be added, the temperature resistance of the material is improved, the ultraviolet aging degree of the material is alleviated, and the service life of the material is prolonged. Compared with a PET substrate, the cost is lower, the stiffness is lower, the flexibility is stronger, the functional film is more suitable for the high-performance display film material, and the BOPP film layer can be degraded and recycled; the anti-static layer can improve the anti-static performance of the product, eliminate negative impact to the industrial production brought by the electrostatic accumulation, avoids the defects of deformation, folding and improper fitting during the use of the product, is benefit for operation and die cutting, and improves product utilization rate.

Owner:DONGGUAN DINGLI FILM TECH

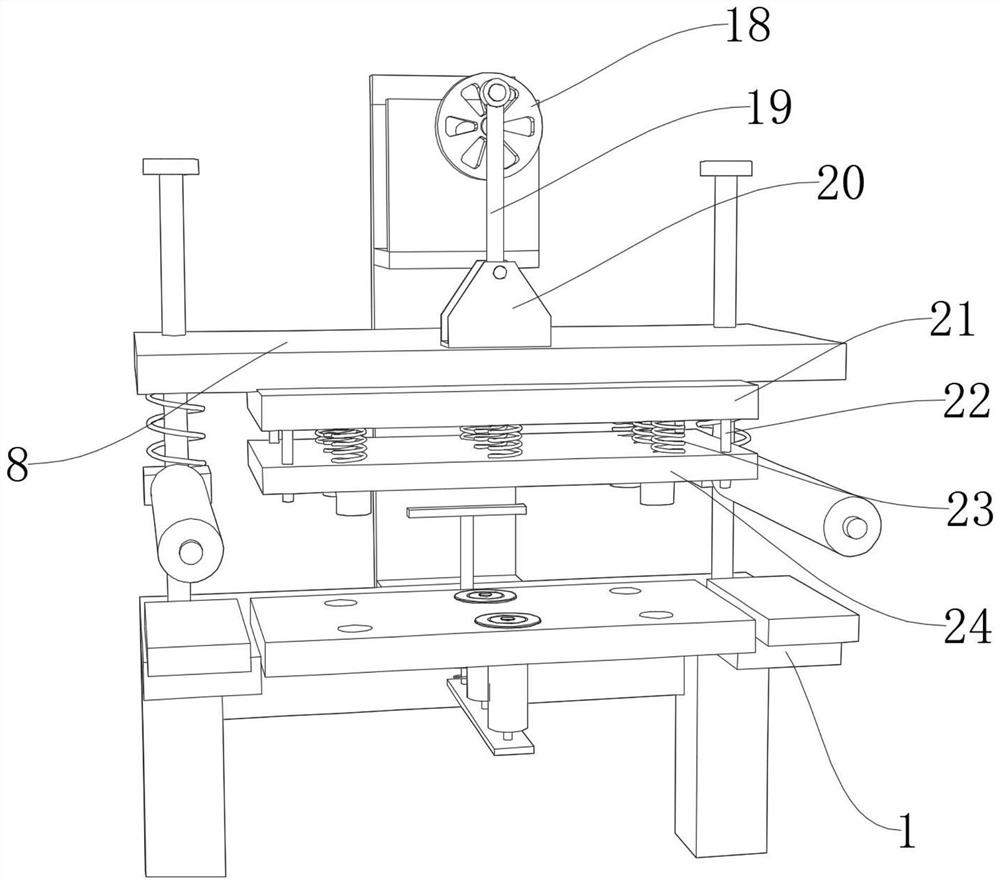

Die cutting equipment for aluminum foil circuit board processing

InactiveCN114800688AReduce mistakesHigh precisionInsulating layers/substrates workingMetal working apparatusElectric machineEngineering

The invention relates to die cutting equipment for aluminum foil circuit board processing, and belongs to the technical field of aluminum foil circuit board processing. Comprising a rack, four guide columns are fixedly connected to the upper surface of the rack, a sliding plate is movably connected among the four guide columns, a connecting base is fixedly connected to the top of the sliding plate, a mounting frame is fixedly connected to one side of the rack, a first motor is fixedly connected to one side of the mounting frame, and a rotating disc is fixedly connected to one end of an output shaft of the first motor; according to the aluminum foil flattening device, the bottom of an aluminum foil can be adsorbed, so that the aluminum foil is flattened, errors generated when the aluminum foil is machined are reduced, meanwhile, the two sides of the aluminum foil can be pressed through a first pressing roller, and the aluminum foil can be flattened through a second pressing roller; and the die cutting precision of the aluminum foil is further improved, the aluminum foil rolls can be fixed, the die cutting device adapts to the aluminum foil rolls with different inner diameters, and the using flexibility of the device is improved.

Owner:益阳众兴材料科技有限公司

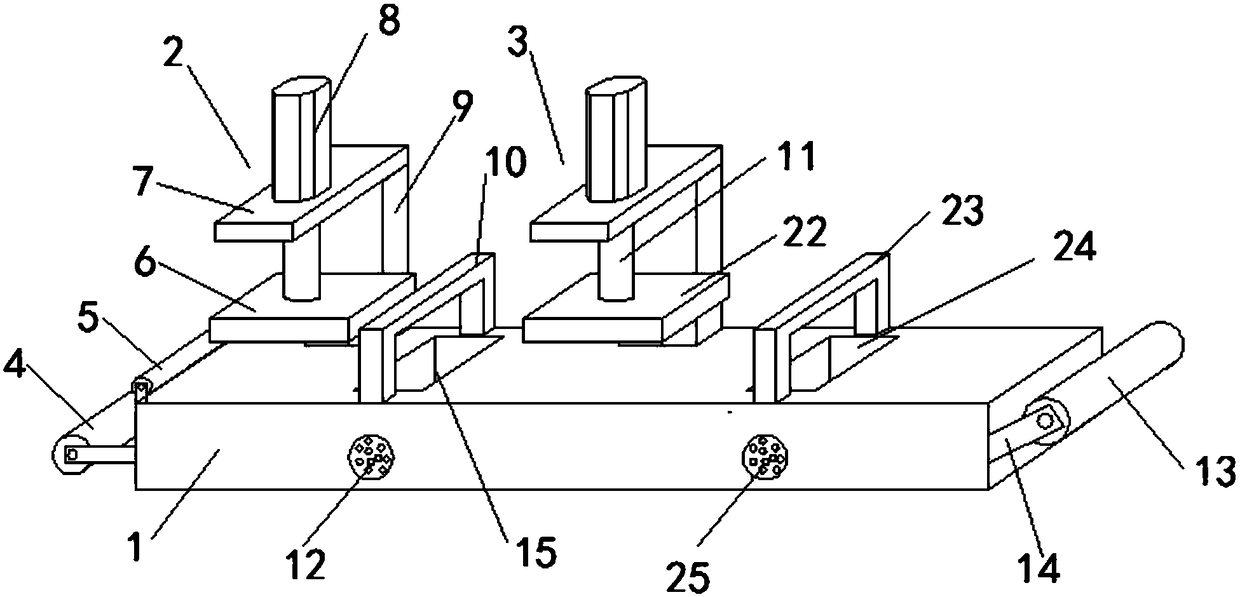

Die cutting machine capable of discharging waste

The invention relates to a die cutting machine capable of discharging waste. The die cutting machine comprises a workbench, a first die cutting device and a second die cutting device; the first die cutting device and the second die cutting device are arranged on the upper surface of the workbench; and the first die cutting device is located in front of the second die cutting device, and comprisesa supporting rod, a supporting plate, an air cylinder and a first die cutting plate, and the supporting rod is fixedly connected to the side of the workbench. According to the die cutting machine capable of discharging the waste, the first die cutting device and the second die cutting device are arranged, in addition, the first die cutting device is arranged in front of the second die cutting device and used for cutting inner waste of a die cutting material, the second die cutting device is used for cutting outer waste of the die cutting material, through the design, the inner waste and the outer waste of the die cutting material are discharged separately, and thus, the waste is removed more conveniently and thoroughly.

Owner:孙柳英

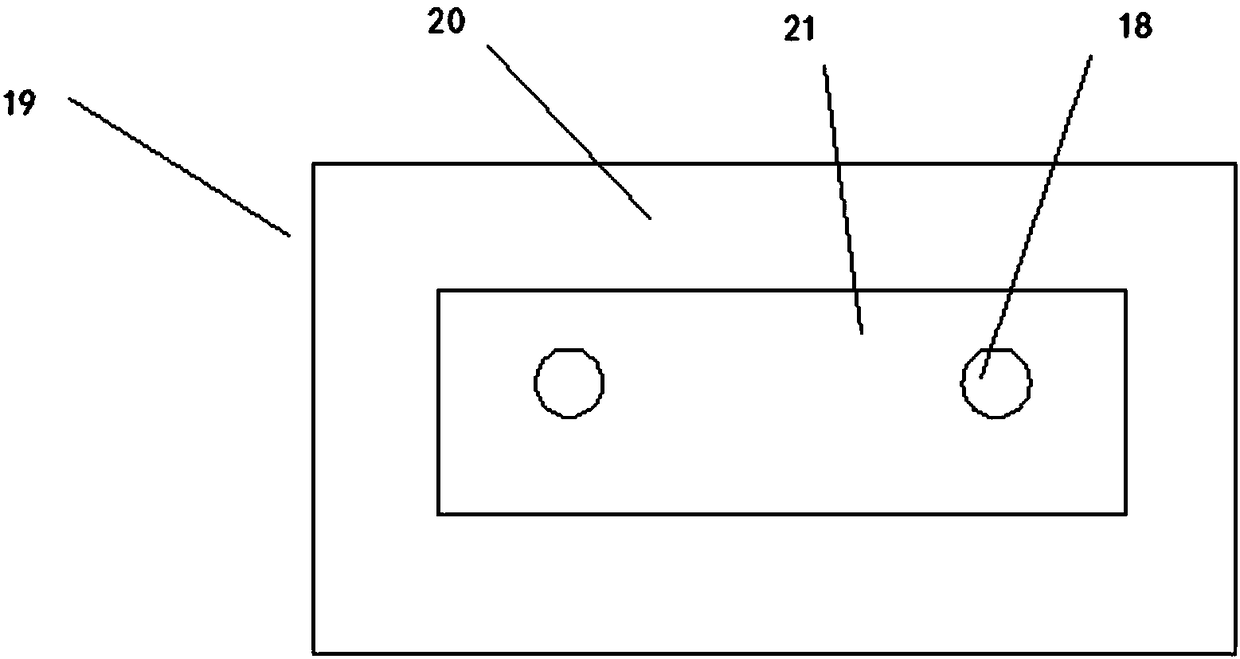

Environment-friendly dust-free foam and preparation method thereof

The invention discloses environment-friendly dust-free foam and a preparation method thereof. The method comprises the steps that waste foam is smashed into particles, wherein the particles are added into raw materials for manufacturing the foam, and granular polyurethane is added into the raw materials for manufacturing the foam; and then the foam manufacturing raw materials are uniformly stirred and mixed with the waste foam particles and the polyurethane so that the waste foam particles are uniformly fused with the raw materials. The preparation method comprises the following specific preparation steps: S1, preparing foam particles: crushing recycled waste foam into particles; s2, preparing a foam stock solution, namely mixing and stirring raw materials for preparing foam to form the stock solution; s3, preparing a foam foaming agent: uniformly mixing and stirring a foam stock solution and foam particles; s4, foam forming: pouring a foaming agent into the mold, and taking out a finished product after the foaming agent is formed. The foam product disclosed by the invention is halogen-free and accords with an ROHS2.0 environment-friendly material; high rebound resilience, high adhesive force and retention force are achieved, and the waterproof and anti-permeation functions are achieved; and good market application values are realized.

Owner:SHENZHEN HENGXINGJIA TECH CO LTD

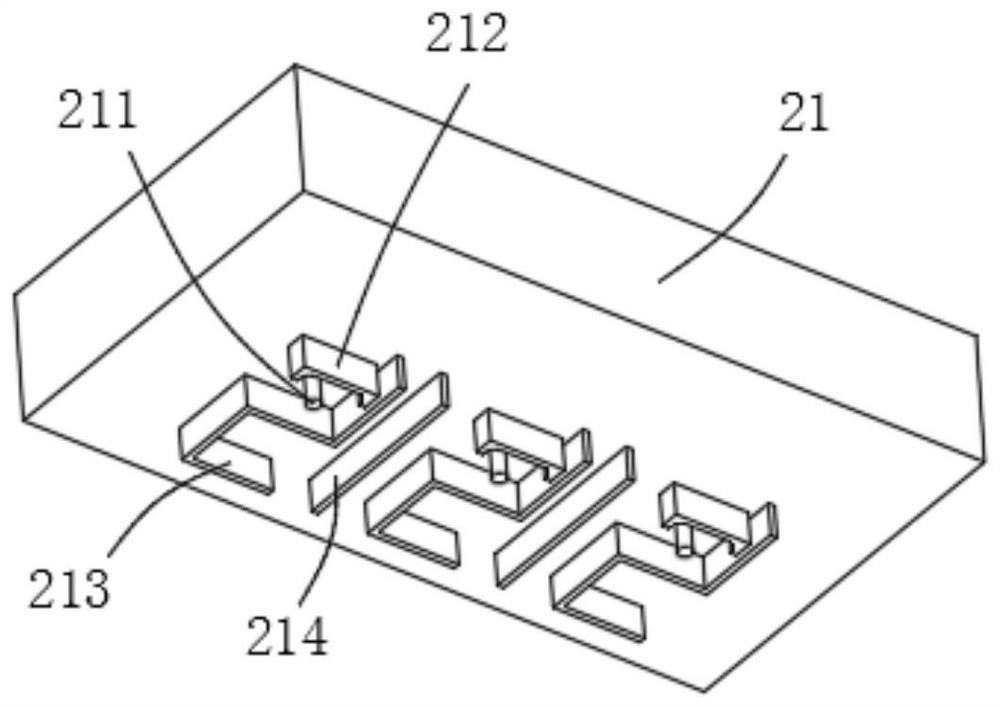

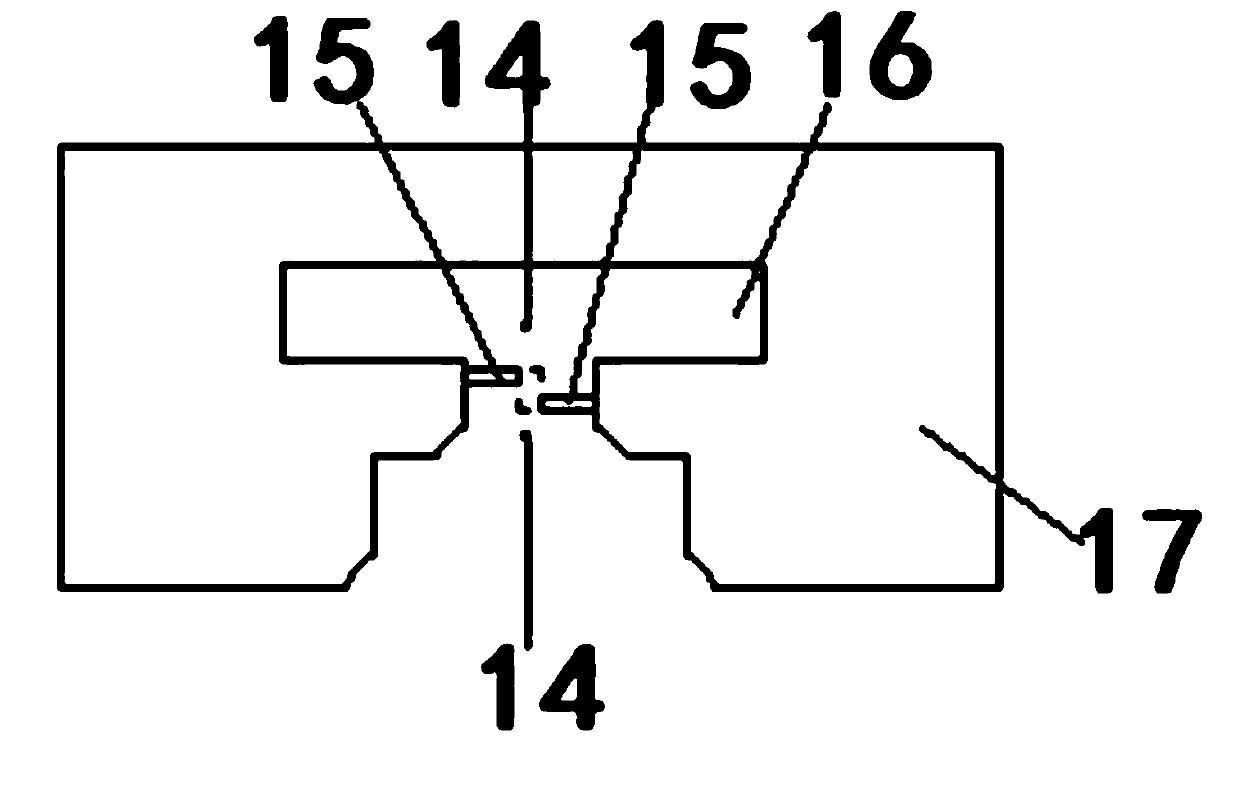

Composite and multi-station full-die-cutting ultrahigh-frequency antenna processing device and method

PendingCN111275155AReduce pollutionDoes not affect the processing effectLiquid surface applicatorsLamination ancillary operationsTag antennaElectronic tagging

The invention provides a composite and multi-station full-die-cutting ultrahigh-frequency antenna processing device and method. An antenna body of an ultrahigh-frequency tag antenna is provided with achip binding positioning point formed in a die cutting mode and a chip binding point formed in a die cutting mode. The processing equipment is characterized by comprising a first die cutting mechanism, a second die cutting mechanism and a floating roller device. The invention solves the following problems in the prior art: 1, problems in the prior art are solved; the problem of how to produce a chip binding point and a chip binding positioning point of an ultrahigh-frequency electronic tag antenna by using an etching process is solved. Problem 2: how to completely avoid the application of anetching process in the production process of the ultrahigh frequency electronic tag antenna. 3, how to prevent the position of the antenna layer from deviating during movement or transmission in the machining process; 4, how to help the antenna layer to better move or transmit while maintaining tension; and 5, how to help the chip binding point and the chip binding positioning point to be accurately machined.

Owner:黄光伟

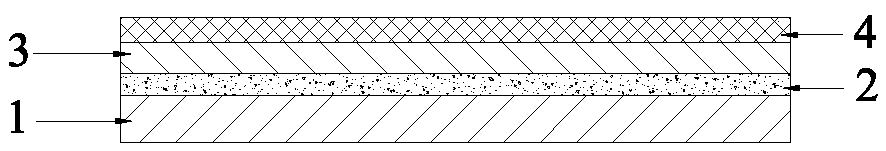

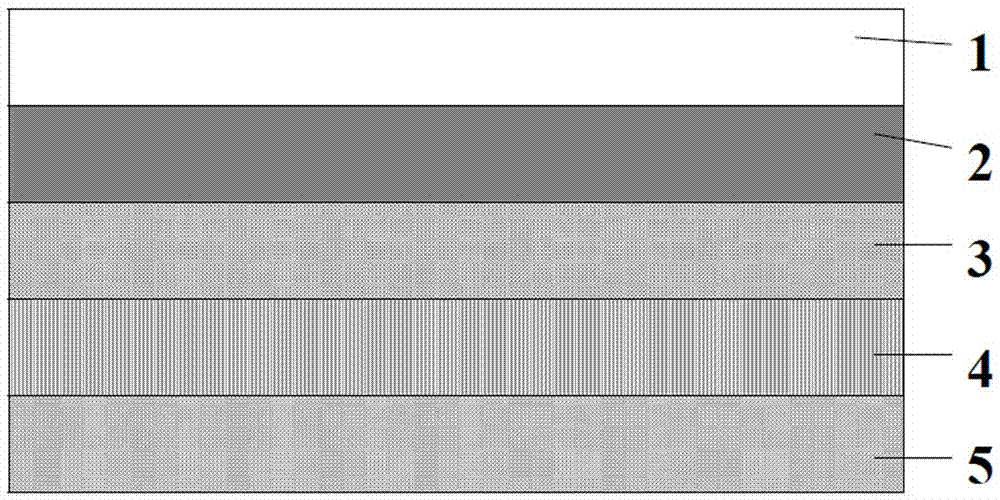

Graphene composite heat dissipation coating and preparation method thereof, and heat dissipation adhesive tape and preparation method thereof

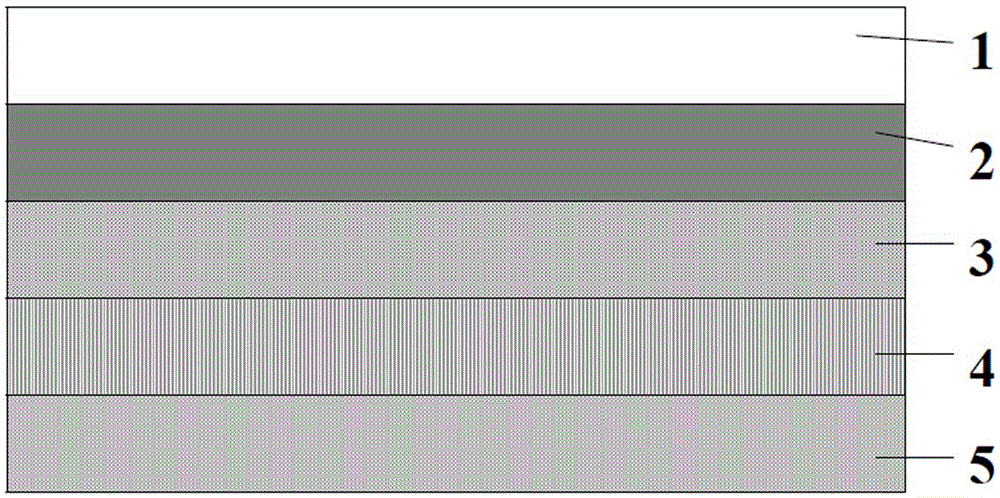

ActiveCN114479580AImprove conduction and heat dissipation performanceEasy to die cutNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesOrganosiliconHydrothermal reaction

The invention belongs to the technical field of heat dissipation adhesive tapes, and discloses a graphene composite heat dissipation coating and a preparation method thereof, and a heat dissipation adhesive tape and a preparation method thereof. Graphene is filled with C60 and heat-conducting powder through a hydrothermal reaction and a normal-temperature drying-freezing-normal-temperature drying mode, a graphene composite heat dissipation micropore structure is formed, and then the graphene composite heat dissipation coating is formed by combining the graphene composite heat dissipation micropore structure with organic silicon modified acrylic resin, a dispersing agent, water and auxiliaries. The heat dissipation adhesive tape is composed of a three-layer structure, the lowest layer is a carrier of the heat dissipation adhesive tape, the middle layer has heat conduction and insulation effects, and the uppermost layer is a coating layer formed by graphene composite heat dissipation paint and mainly has a heat dissipation effect. The heat dissipation adhesive tape is directly pasted into an electronic component, and efficient heat dissipation can be achieved.

Owner:桂林清研皓隆新材料有限公司

A kind of inclined flattening trademark machine

ActiveCN111231502BStable printingEasy to printRotary pressesPrinting press partsPaper tapeStructural engineering

The invention relates to an oblique pressing machine for flattening trademarks, which includes a frame, on which a printing mechanism and a die-cutting mechanism are arranged, and on the said frame, an oblique pressing machine for carrying and conveying self-adhesive label tapes is provided. Flat seesaw, the obliquely pressed flat seesaw is adapted to the printing mechanism and the die-cutting mechanism, one end of the obliquely pressed flat seesaw is hinged to the head end of the frame through a hinged frame, and the other end is hinged to the tail of the frame end, the conveying self-adhesive label tape is conveyed from the head end to the tail end of the frame through the surface of the oblique flat seesaw through the paper pulling mechanism in the frame. The side is inclined to the ground, and the frame is provided with a drive mechanism for driving the end of the oblique pressing flat seesaw to move up and down. The invention has the effects of improving the mold clamping quality and indirectly improving the printing and die-cutting quality.

Owner:深圳市金世冠不干胶制品有限公司

Hot melt adhesive tape for speaker mesh bonding and preparation method of hot melt adhesive tape

InactiveCN113621316ASoft materialHas thermal tackifying effectFilm/foil adhesives without carriersPressure sensitive film/foil adhesivesPolymer scienceHot melt

The invention belongs to the technical field of hot melt adhesive tapes, and particularly relates to a hot melt adhesive tape for speaker mesh bonding and a preparation method thereof, the hot melt adhesive tape comprises a release layer, a hot melt adhesive layer, a pressure-sensitive adhesive layer and a release film layer; the preparation method comprises the following steps: (1) preparing a semi-finished product; (2) preparing a hot melt adhesive tape; and (3) curing to obtain a finished product. The hot melt adhesive tape prepared through the method is soft in material, can be perfectly attached to any curved surface or special-shaped speaker mesh material, has an excellent extinction effect, does not affect the original attractiveness of an electronic product after being attached to the speaker mesh, adopts the hot melt adhesive film and the pressure-sensitive adhesive to be compounded, does not need to be additionally attached to other base materials, is adjustable in product thickness, the cost is reduced, and the process is simplified.

Owner:潍坊同有新材料科技有限公司

Shielding and grounding foam tape with metal foil as base material and preparation method thereof

ActiveCN105111952BIncrease elasticitySolve the problem of sticking and reboundingNon-macromolecular adhesive additivesFilm/foil adhesivesMetal foilElectromagnetic shielding

The invention discloses a shielding and grounding conductive foam adhesive tape with metal foil as the base material, which comprises: shielding and grounding conductive foam, a hot melt adhesive layer, a metal foil base material, Conductive adhesive layer, release material layer. Also disclosed is a preparation method of a shielding and grounding conductive foam tape, which has high conductivity, better electromagnetic shielding function, better die-cutting, and less There will be fuzz problems similar to conductive cloth. Compared with using ordinary conductive pressure-sensitive adhesive to bond the foam to the substrate, the foam has better resilience, which solves the problem of poor rebound when the foam is stuck by the glue during die-cutting or use.

Owner:SHENZHEN MEIXIN ELECTRONICS

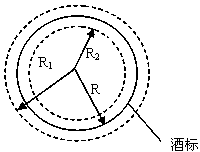

Method for die cutting of wine labels on embossed aluminum-coated paper

InactiveCN102601823BEasy to die cutSimple processMetal working apparatusEngineeringProcess engineering

A method for die-cutting a wine label on embossed aluminized paper, comprising the following steps: first measuring the outer boundary size of the wine label to be die-cut; calculating the measured outer boundary size of the wine label to obtain a wine label shape frame; Cut out one or more corresponding wine label-shaped frames from the old blanket, and install the new rubber printing plate obtained on the cylinder of the equipment with the embossing mechanism; to the feeding chute of the equipment with the embossing mechanism Pour in liquid paraffin; turn on the machine and press, apply liquid paraffin, and get a new wine label after applying liquid paraffin; stack the new wine labels after applying liquid paraffin into paper stacks of tens of millimeters to hundreds of millimeters, put them in Die-cutting is completed on the wine label die-cutting machine, which has the characteristics of easy die-cutting, simple process, high efficiency and cost saving.

Owner:SHAANXI UNIV OF SCI & TECH

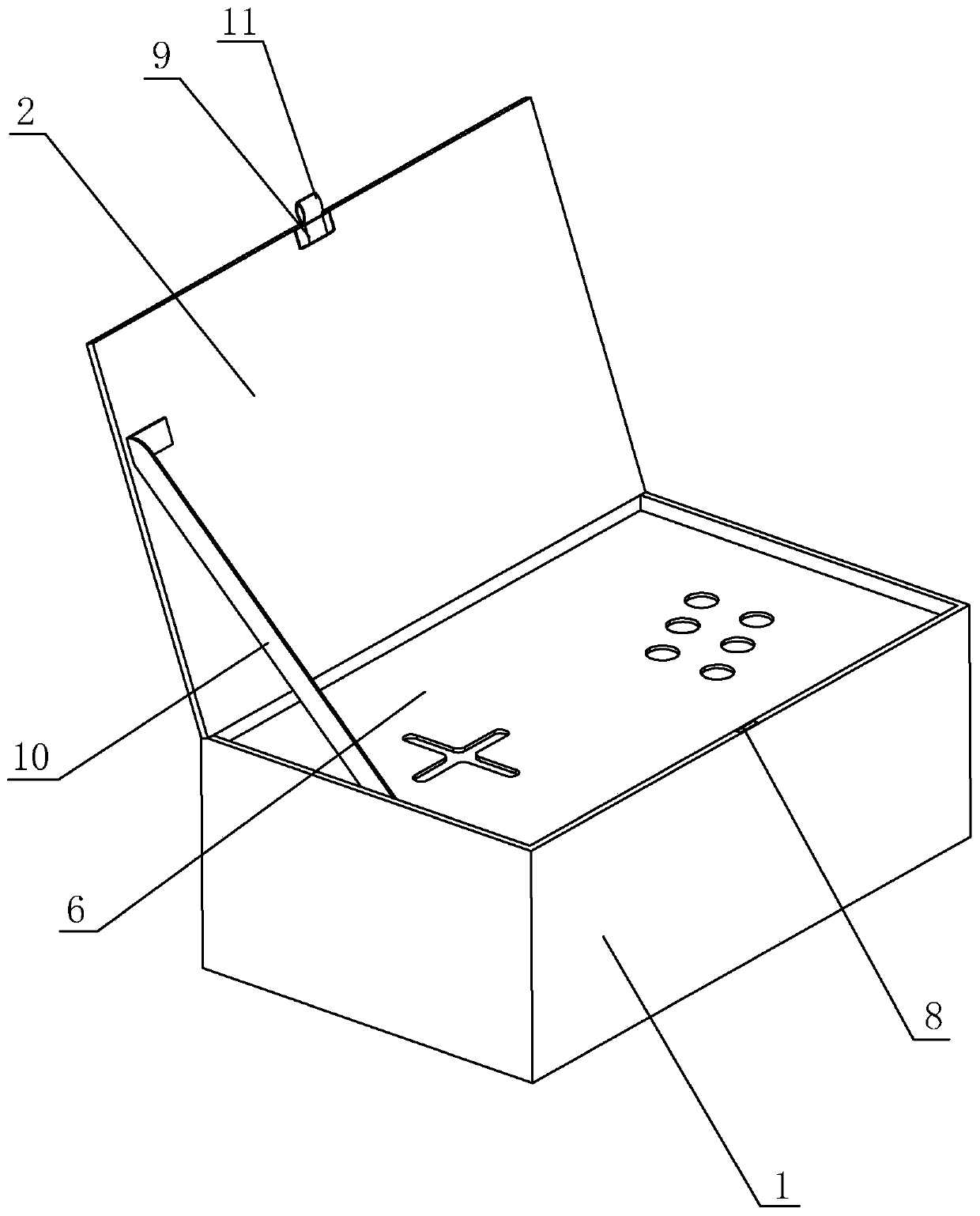

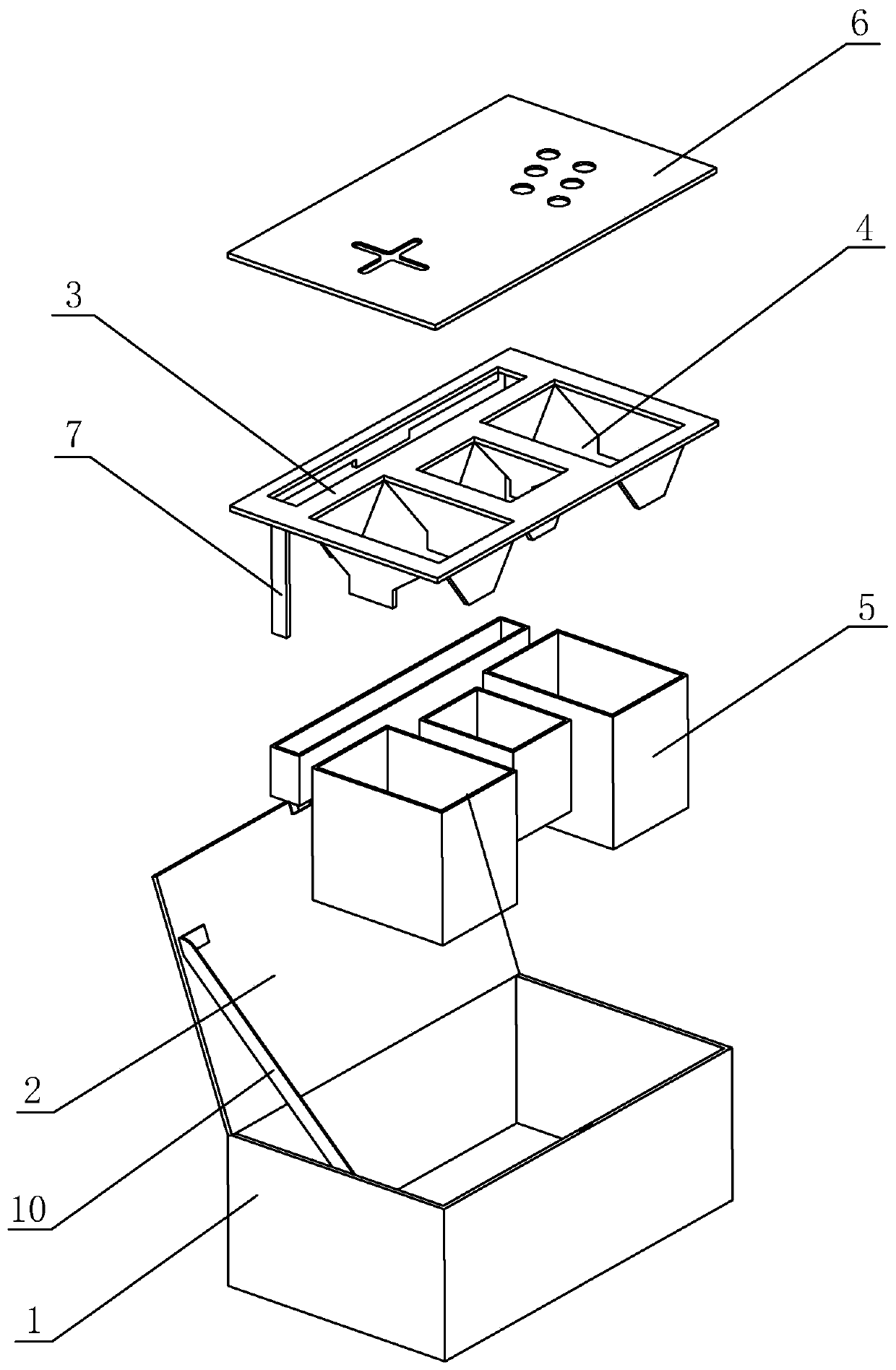

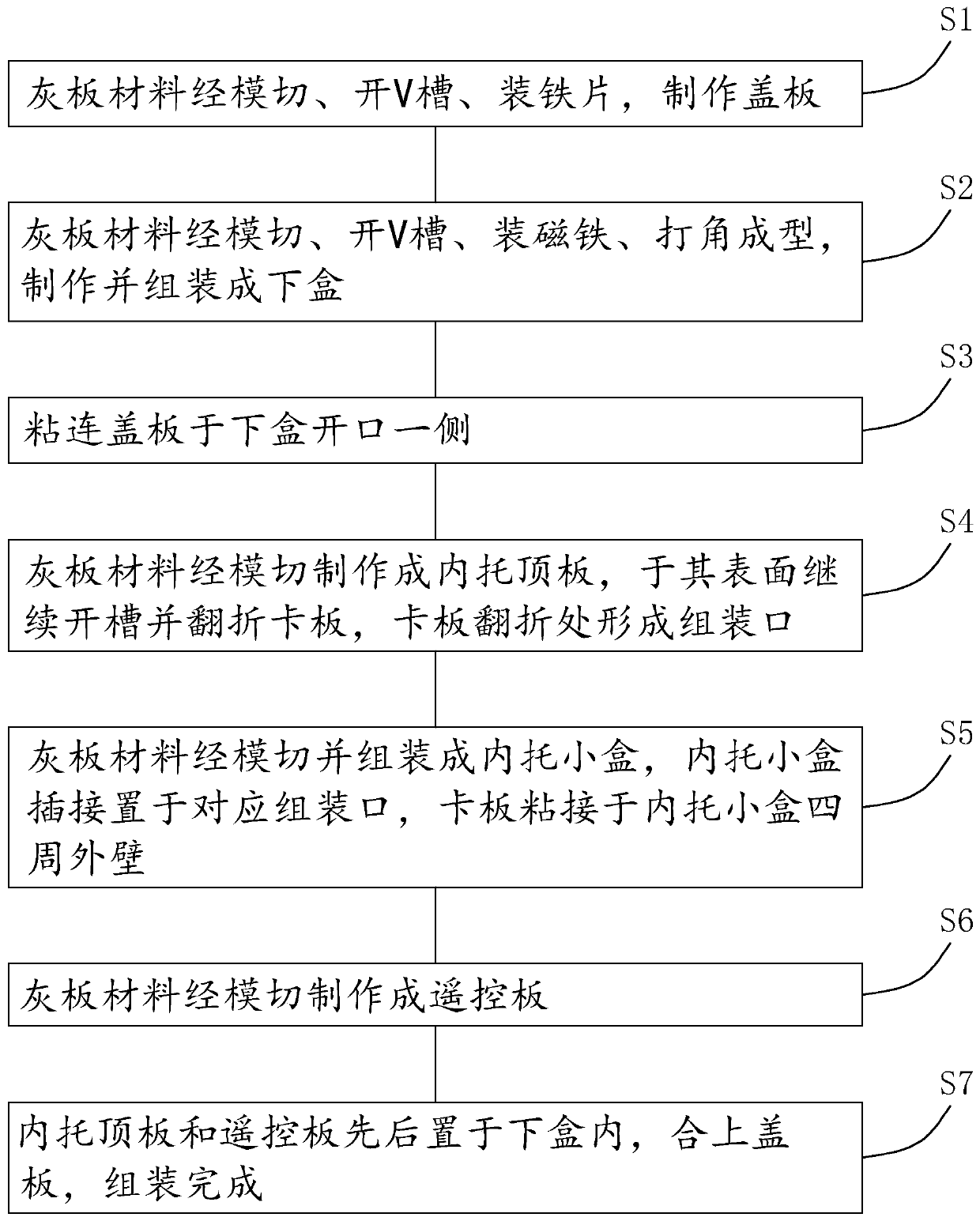

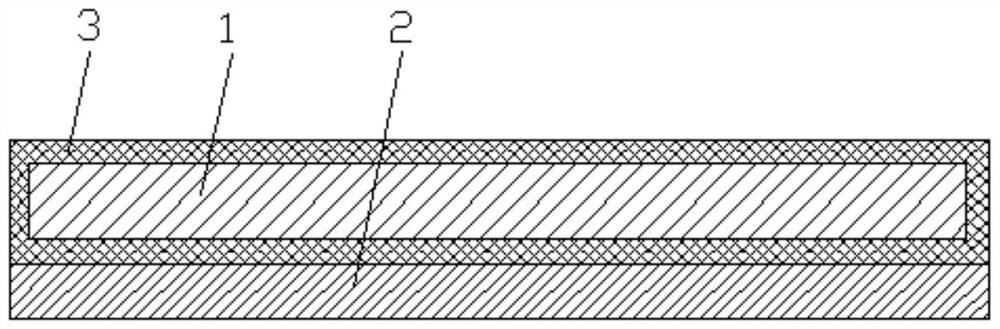

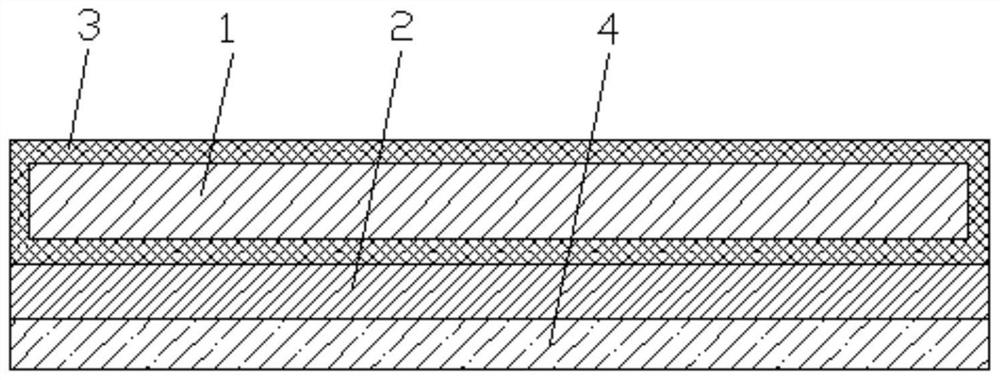

A gift box and its manufacturing process

ActiveCN109720732BEasy to displayGuaranteed stabilityBox making operationsPaper-makingRemote controlStructural engineering

The invention discloses a gift box and a manufacturing process thereof, and relates to the technical field of paper boxes. The box comprises a lower box and a cover plate, an inner supporting ejectingplate is inserted in an opening of the lower box, multiple assembling openings are formed in the inner supporting ejecting plate, inner supporting small boxes are bonded and fixed into the assemblingopenings, a remote control plate is movably arranged on the opening of the lower box, the assembling openings extend downwards to be provided with clamping plates, a magnet is embedded on the side, away from the cover plate, of the opening of the lower box, the side, away from the bending point, of the cover plate is provided with an iron sheet attracted with the magnet magnetically in an embedded manner, through the inner supporting small boxes, products of different sizes can be at the height parallel to the inner supporting ejecting plate, products can be conveniently shown, all positionsof the inner supporting ejecting plate can be supported through the clamping plate and the inner supporting small boxes, it is ensured that the products can be stably shown, in the die cutting processof the clamping plate, the assembling openings can be directly formed, die cutting is rapid and easy to operate, materials are saved, the remote control plate can cover the inner supporting ejectingplate, product scattering is prevented, and the interestingness of the gift box can be improved.

Owner:武汉易锦包装印务有限公司

Anti-static high-temperature-resistant adhesive tape

PendingCN113072896AImprove antistatic performanceWith antistatic functionFilm/foil adhesive primer layersPolymer scienceAdhesive belt

The invention relates to an anti-static high-temperature-resistant adhesive tape. The anti-static high-temperature-resistant adhesive tape comprises a base material with an anti-static function, wherein an adhesive layer with an anti-static function is fixedly adhered to the lower surface of the base material. The anti-static high-temperature-resistant adhesive tape of the invention has the beneficial effects that a preparation method is simple and convenient, and the adhesive tape has the characteristics of static electricity resistance, high temperature resistance, good initial viscosity, high holding power, wide use temperature range, high resistance and the like, and has wide application prospects in the electronic industry.

Owner:赤壁市华腾电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com