Hot melt adhesive tape for speaker mesh bonding and preparation method of hot melt adhesive tape

A technology of hot melt adhesive and horn mesh, which is applied in the direction of heat-activated film/sheet, film/sheet without carrier, pressure-sensitive film/sheet, etc. It can solve the problems of high cost, troublesome process, thick product, etc., and achieve thickness can be achieved. adjustment, simplification of process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

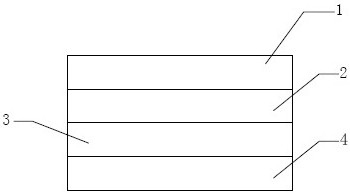

Image

Examples

Embodiment 1

[0026] (1) Add 100 parts of water-based polyurethane heat-activated resin to 5 parts of blocked isocyanate curing agent, 3 parts of water-based black paste, and 2 parts of fumed silica matting powder, put them in a container, and after high-speed dispersion, filter to prepare Obtain thermosetting polyurethane glue;

[0027] (2) Coat the thermosetting polyurethane glue prepared above on the matte OPP film by knife-edge or CED coating methods. The thickness of the matte OPP film is 50µm, the coating thickness is 25µm, and the oven temperature is set at 60°C , 80°C, 100°C, 110°C, 110°C, 85°C, 60°C, the coating speed is 20m / min, after the drying is complete, it is rewound from the back to obtain a black matte thermosetting polyurethane layer (semi-finished product);

[0028] (3) Take 100 parts of high-viscosity acrylate pressure-sensitive adhesive glue, 2.5 parts of isocyanate curing agent, 3 parts of black paste, and 10-40 parts of solvent, put them in a container, disperse at hi...

Embodiment 2

[0031] (1) Add 100 parts of water-based polyurethane heat-activated resin to 5 parts of blocked isocyanate curing agent, 3 parts of water-based black paste, and 2 parts of fumed silica matting powder, put them in a container, and after high-speed dispersion, filter to prepare Obtain thermosetting polyurethane glue;

[0032] (2) Coat the thermosetting polyurethane glue prepared above on the matte CPP film by knife-edge or CED coating methods. The thickness of the matte CPP film is 50µm, the coating thickness is 45µm, and the oven temperature is set at 60°C , 80°C, 100°C, 110°C, 110°C, 85°C, 60°C, the coating speed is 10m / min, after the drying is complete, it is rewound from the back to obtain a black matte thermosetting polyurethane layer (semi-finished product);

[0033] (3) Take 100 parts of high-viscosity acrylate pressure-sensitive adhesive glue, 2.5 parts of isocyanate curing agent, 3 parts of black paste, and 10-40 parts of solvent, put them in a container, disperse at hi...

Embodiment 3

[0036] (1) Add 8 parts of blocked isocyanate curing agent, 3 parts of water-based black paste, and 2 parts of fumed silica matting powder to 100 parts of water-based polyurethane heat-activated resin, put them in a container, disperse at high speed, and filter to prepare Obtain thermosetting polyurethane glue;

[0037] (2) Coat the thermosetting polyurethane glue prepared above on the matte PP synthetic paper by knife edge or CED coating method. The thickness of the matte PP synthetic paper is 100µm, the coating thickness is 30µm, and the oven temperature is set 60°C, 80°C, 100°C, 110°C, 110°C, 85°C, 60°C, the coating speed is 14m / min, after drying completely, it is rewound from the back to obtain a black matte thermosetting polyurethane layer (semi-finished product) ;

[0038] (3) Take 100 parts of high-viscosity acrylate pressure-sensitive adhesive glue, 3.5 parts of isocyanate curing agent, 3 parts of black paste, and 10-40 parts of solvent, put them in a container, disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com