Patents

Literature

102results about "Booklets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

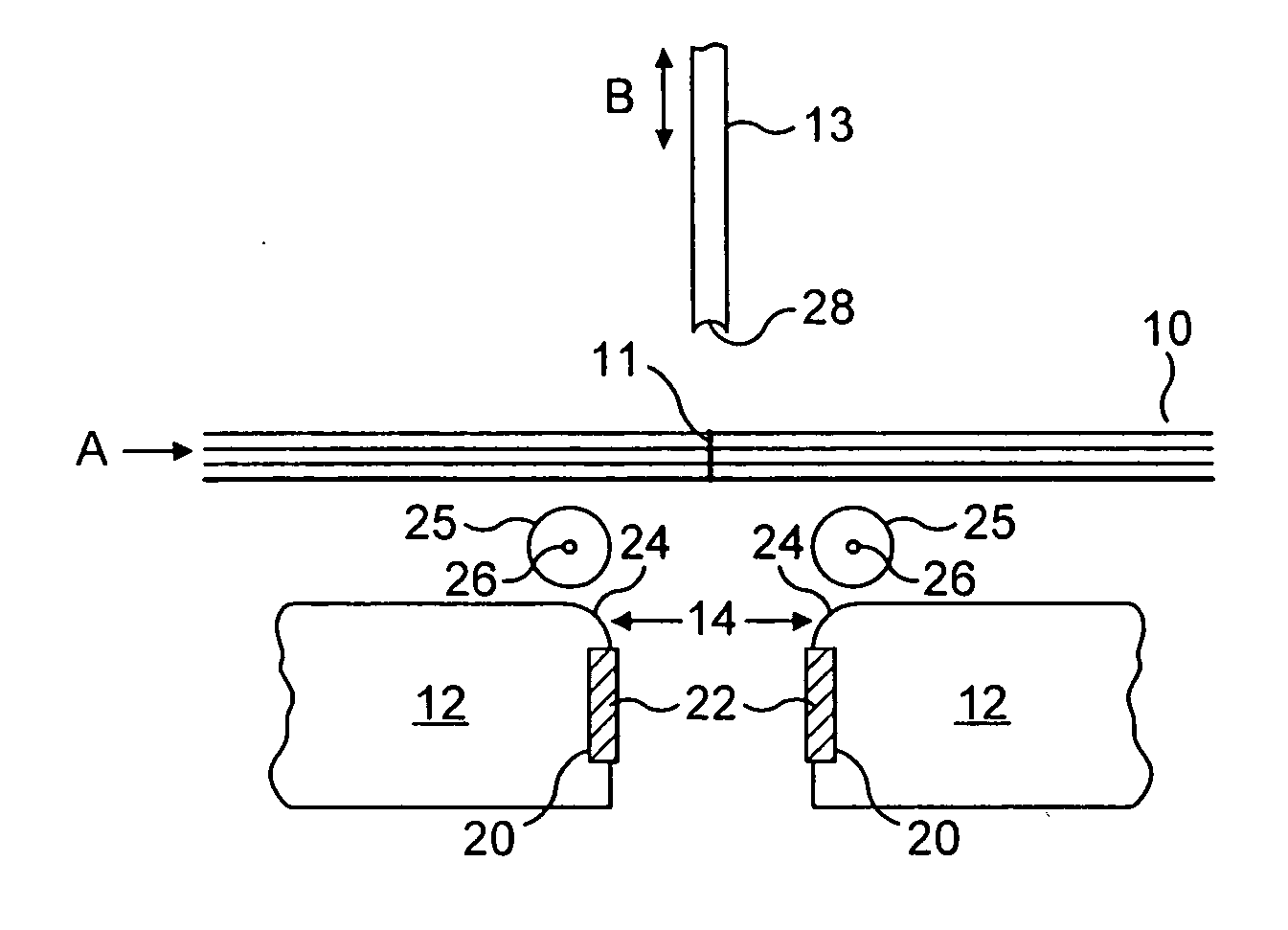

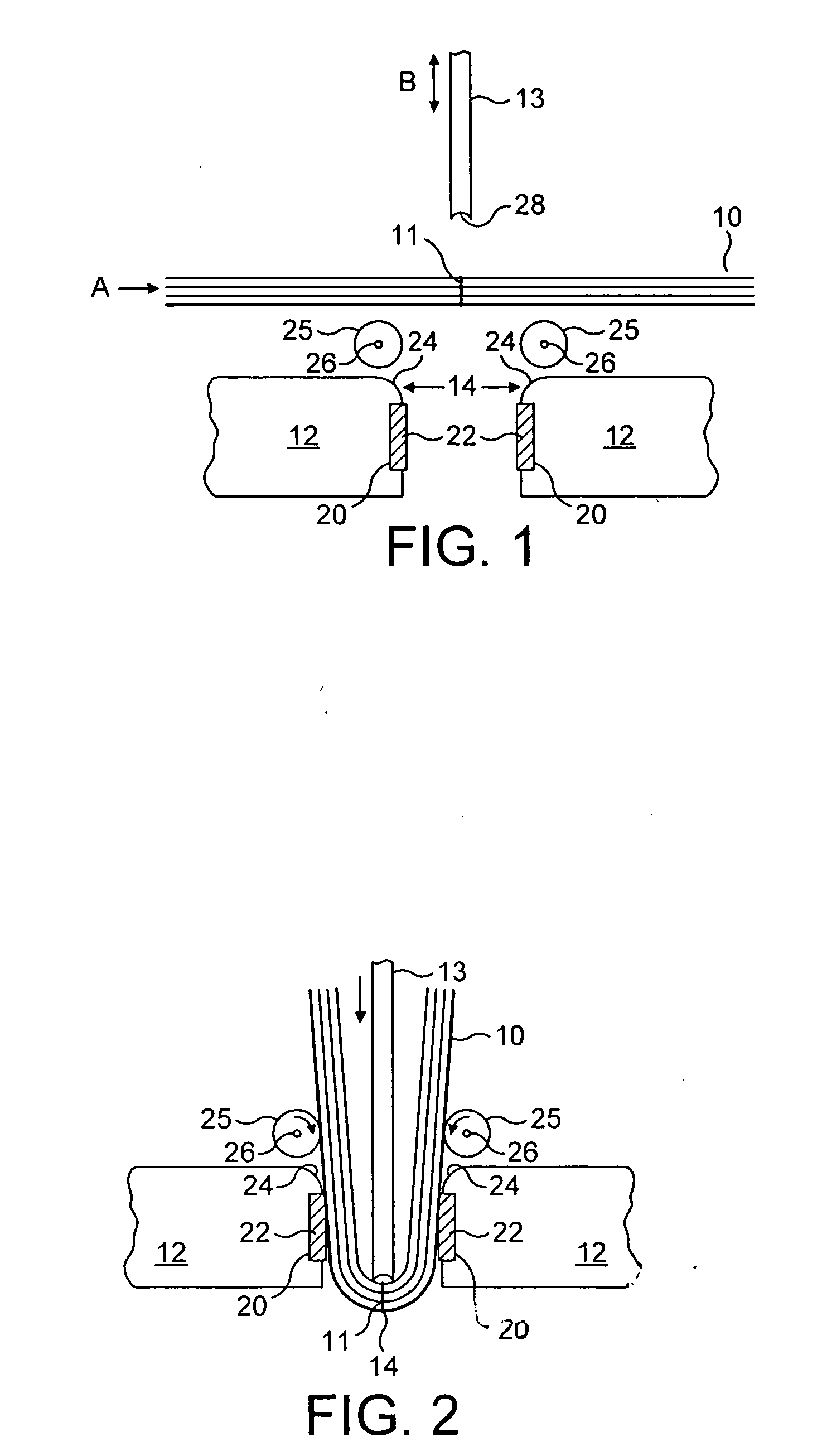

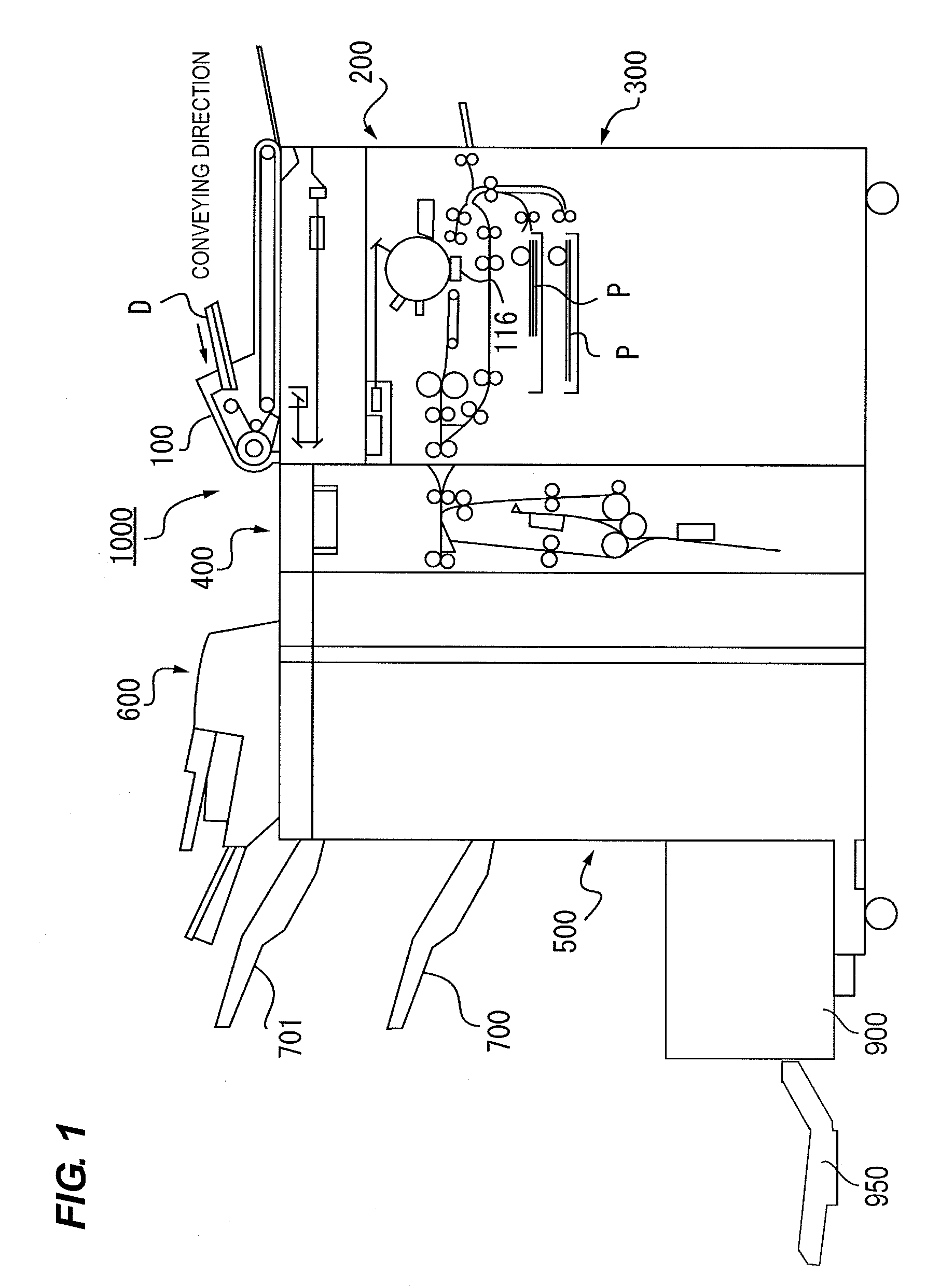

Booklet maker

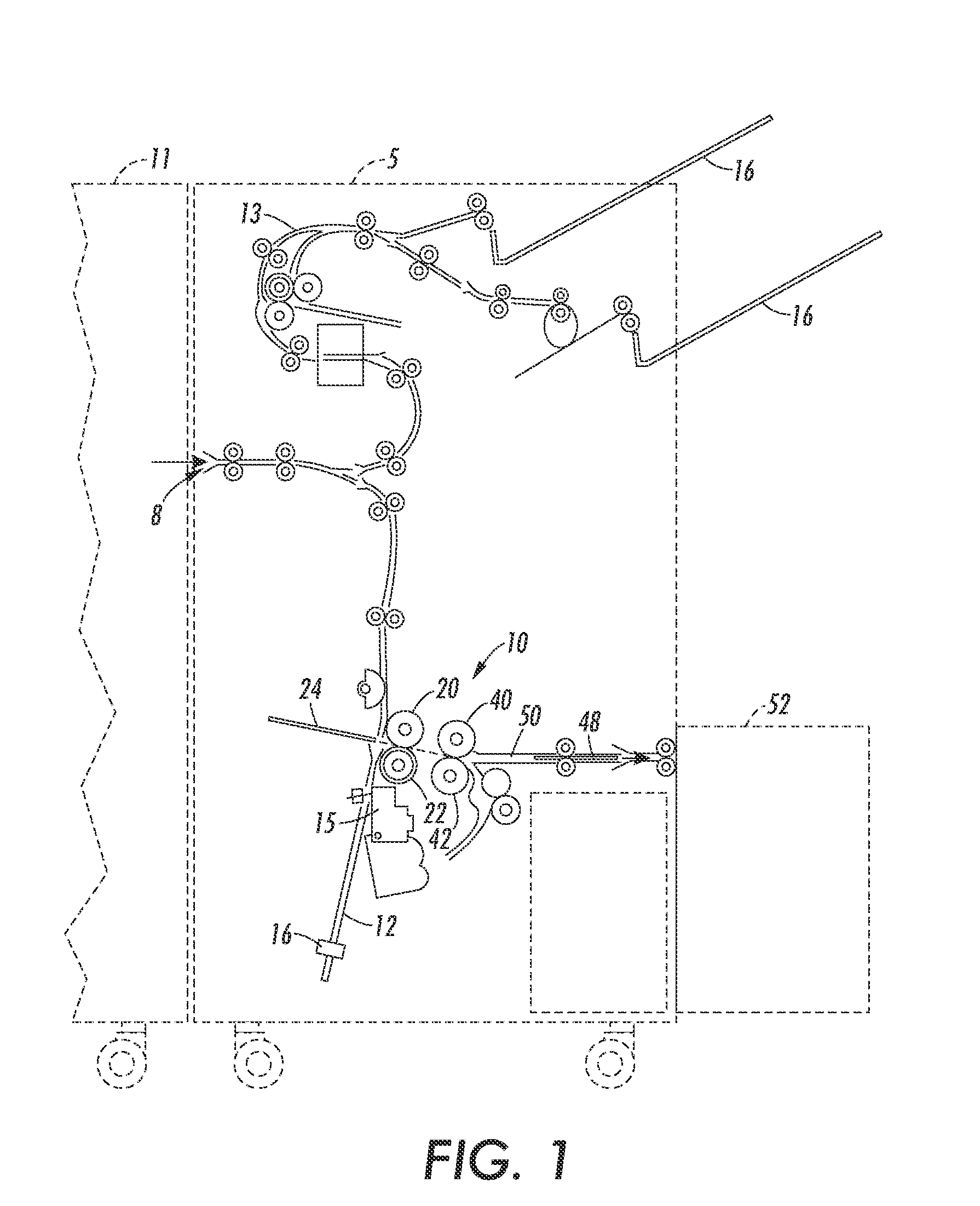

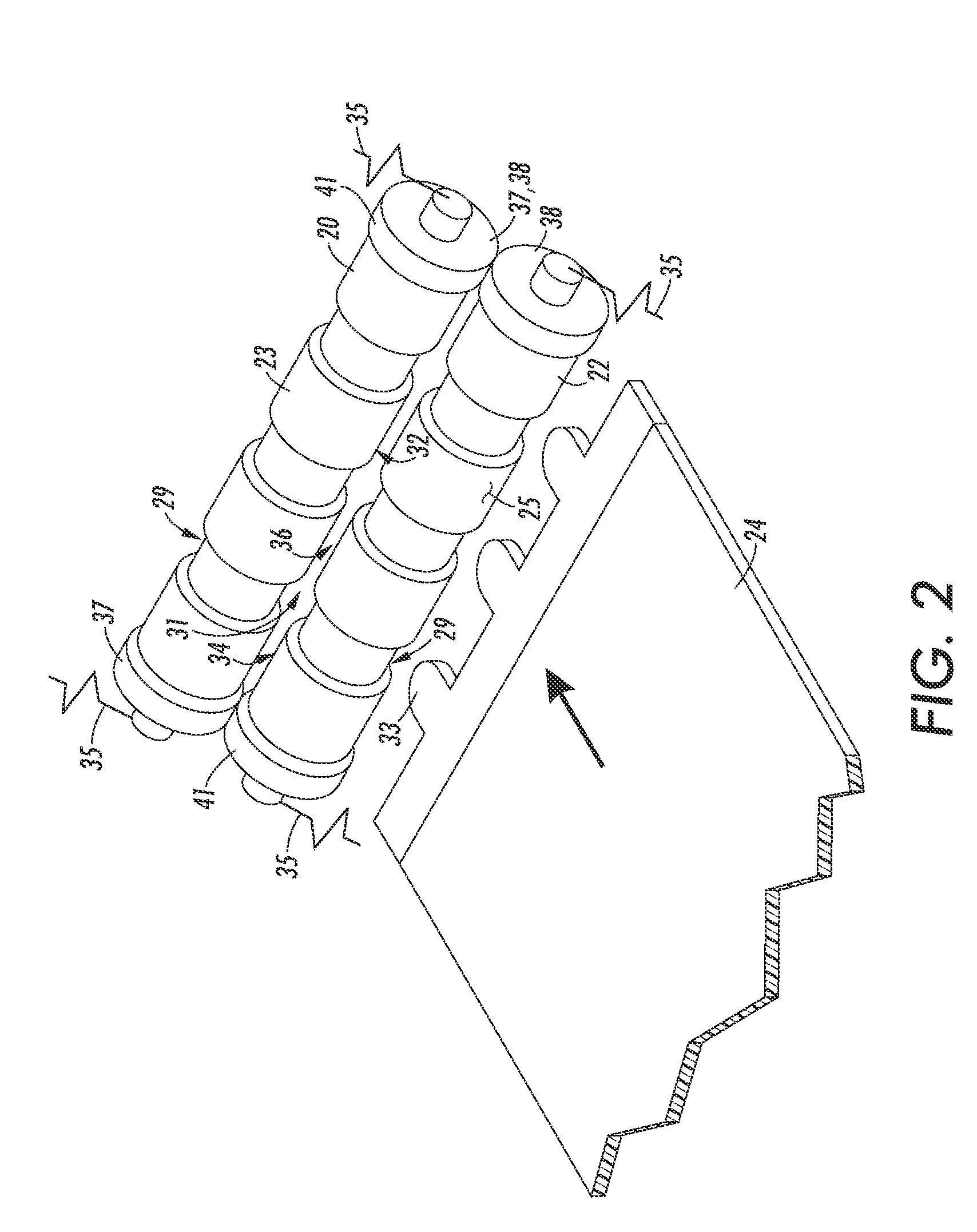

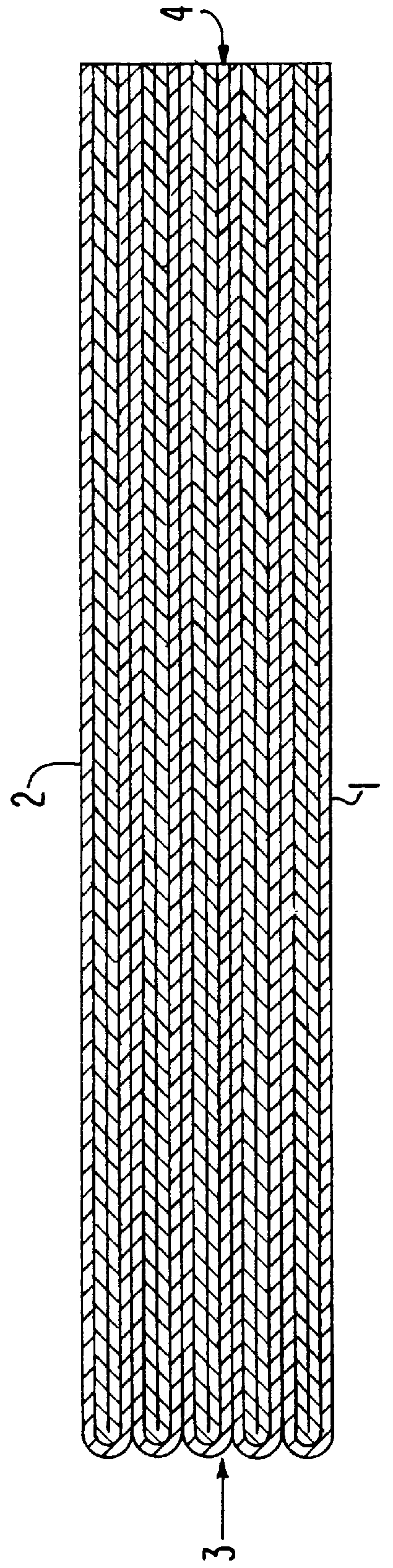

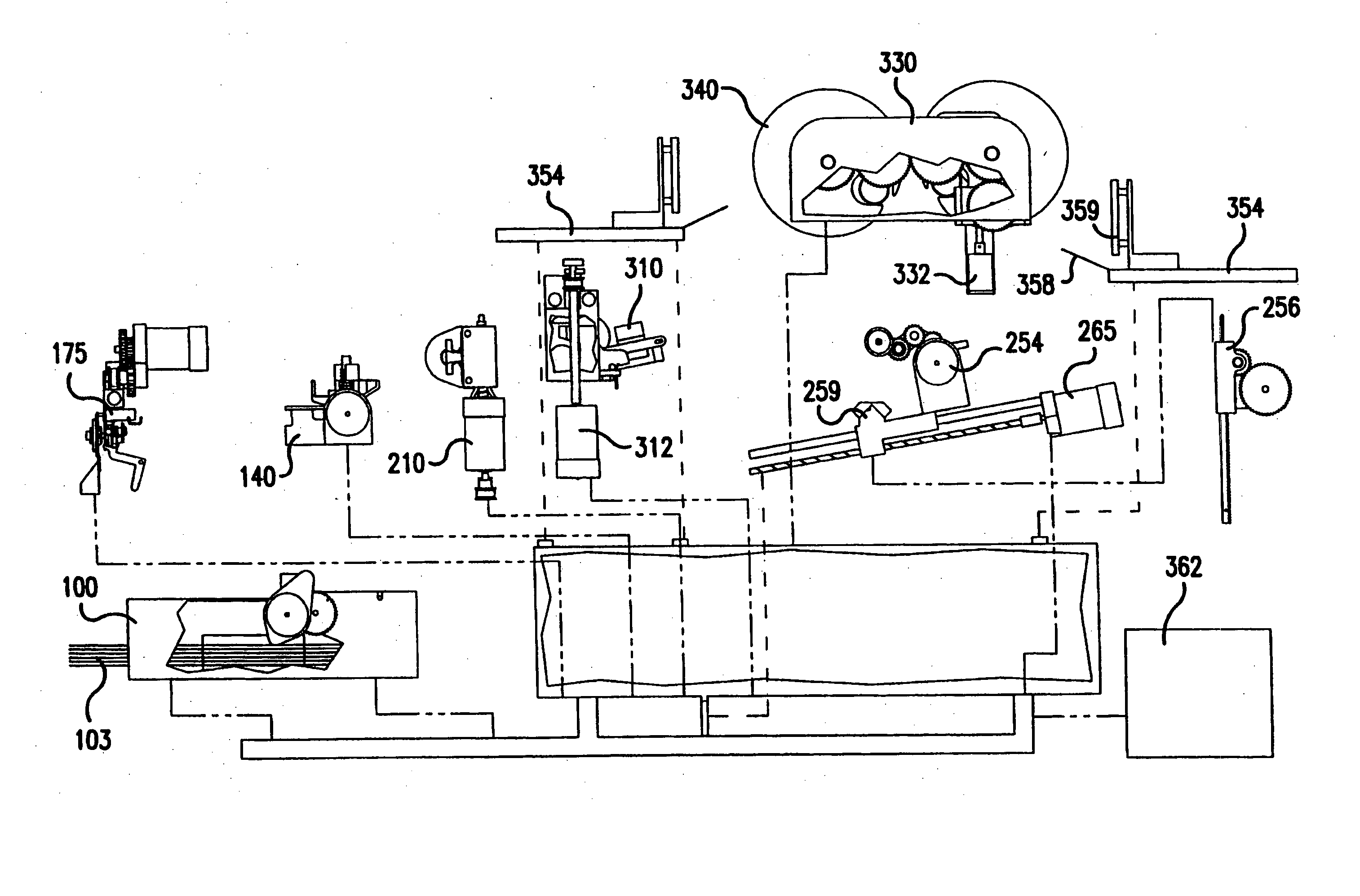

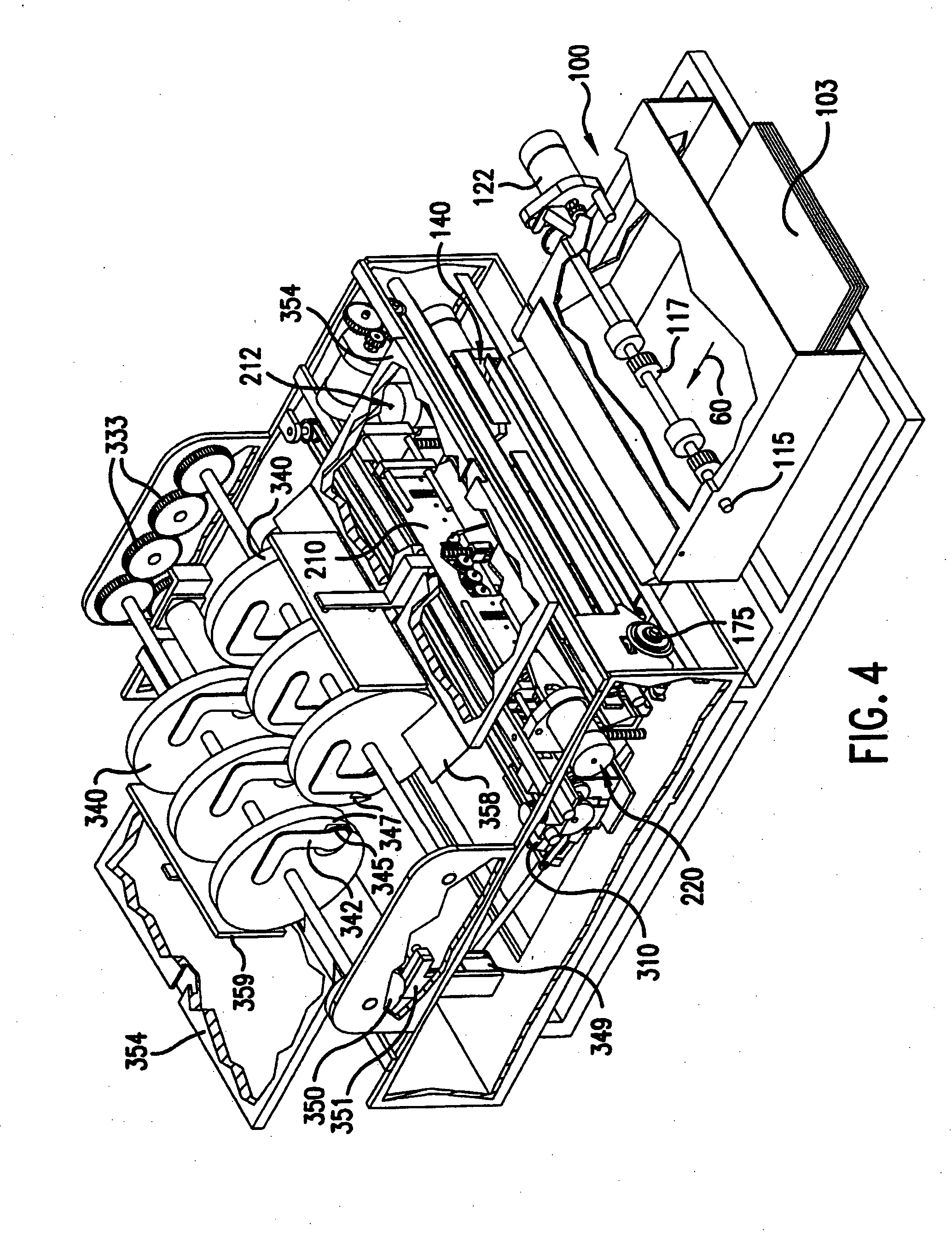

A low cost, high speed, high resolution laser printer method and apparatus for re-writable media is presented. A method for finishing of printed sheets into booklets is described. Novel mechanical operations permit the manufacture of a very low-cost, off-line booklet maker for use with desktop laser and ink jet printers. The technology can scale to medium-speed, in-line booklet manufacture. The method is novel because most of the finishing operations are performed on a sheet-by-sheet basis using precision paper positioning and a transverse tool carrier that cuts, scores, folds, punches, and staples the sheets. To form a finished saddle-stitched booklet, each sheet is cut to length determined by its sequence in the booklet and paper thickness, scored, punched (if required), folded, accumulated in a stack, and stapled. The sheet-wise method allows finishing operations to be done with low-cost tools and low actuation forces.

Owner:HEWLETT PACKARD DEV CO LP

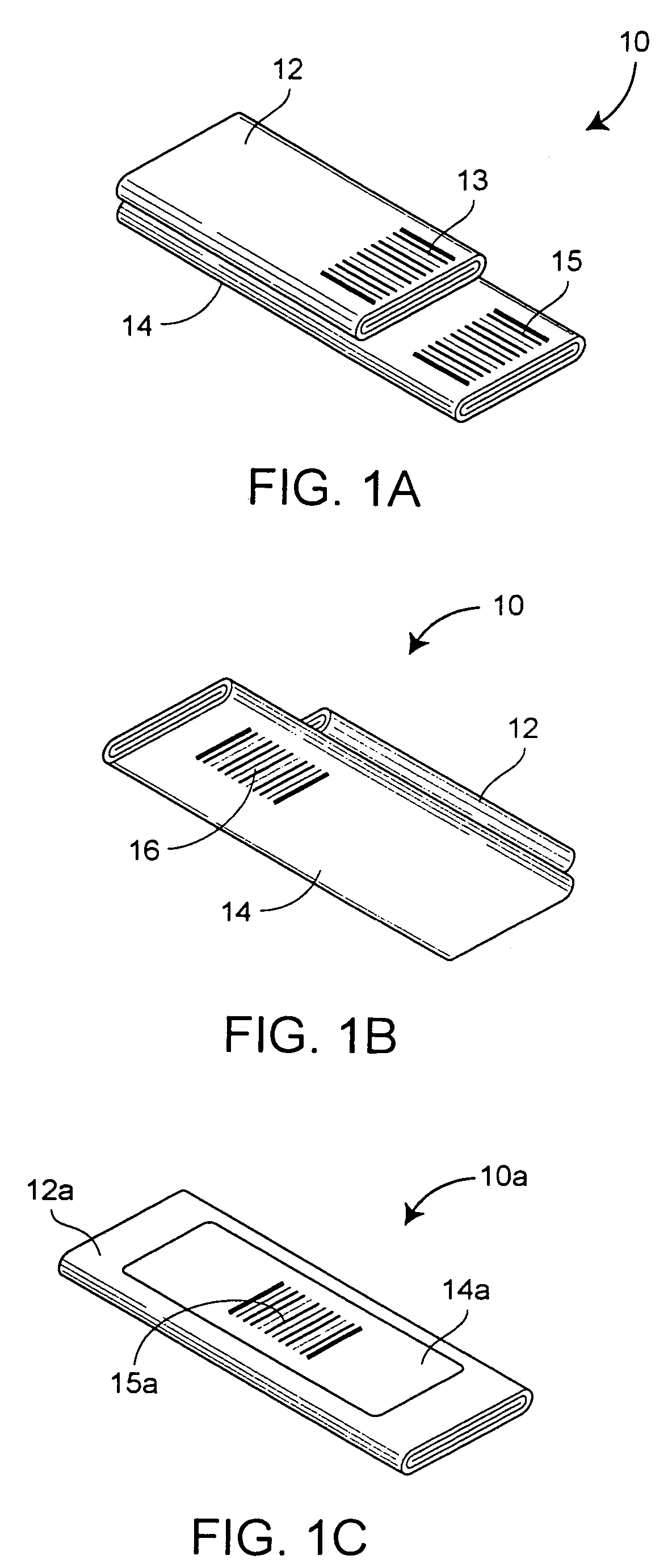

Method of making magazines incorporating pop-ups and strip for use therewith

InactiveUS6953513B1Create efficientlyEliminates of material cost costLamination ancillary operationsBookletsEngineeringMechanical engineering

Methods for making magazines that incorporate pop-up structures formed from two facing pages of the magazine and a strategically placed pop-up piece that is adhesively affixed to both facing pages so as to open into an attention-attracting three-dimensional configuration when the magazine is opened to those two pages. The methods are efficient, economical and well adapted to high speed production using a novel integral continuous strip of pop-up pieces arranged end-to-end, and accordingly, the distribution of magazines incorporating three-dimensional pop-up structures becomes a reality.

Owner:VOLKERT JOHN K

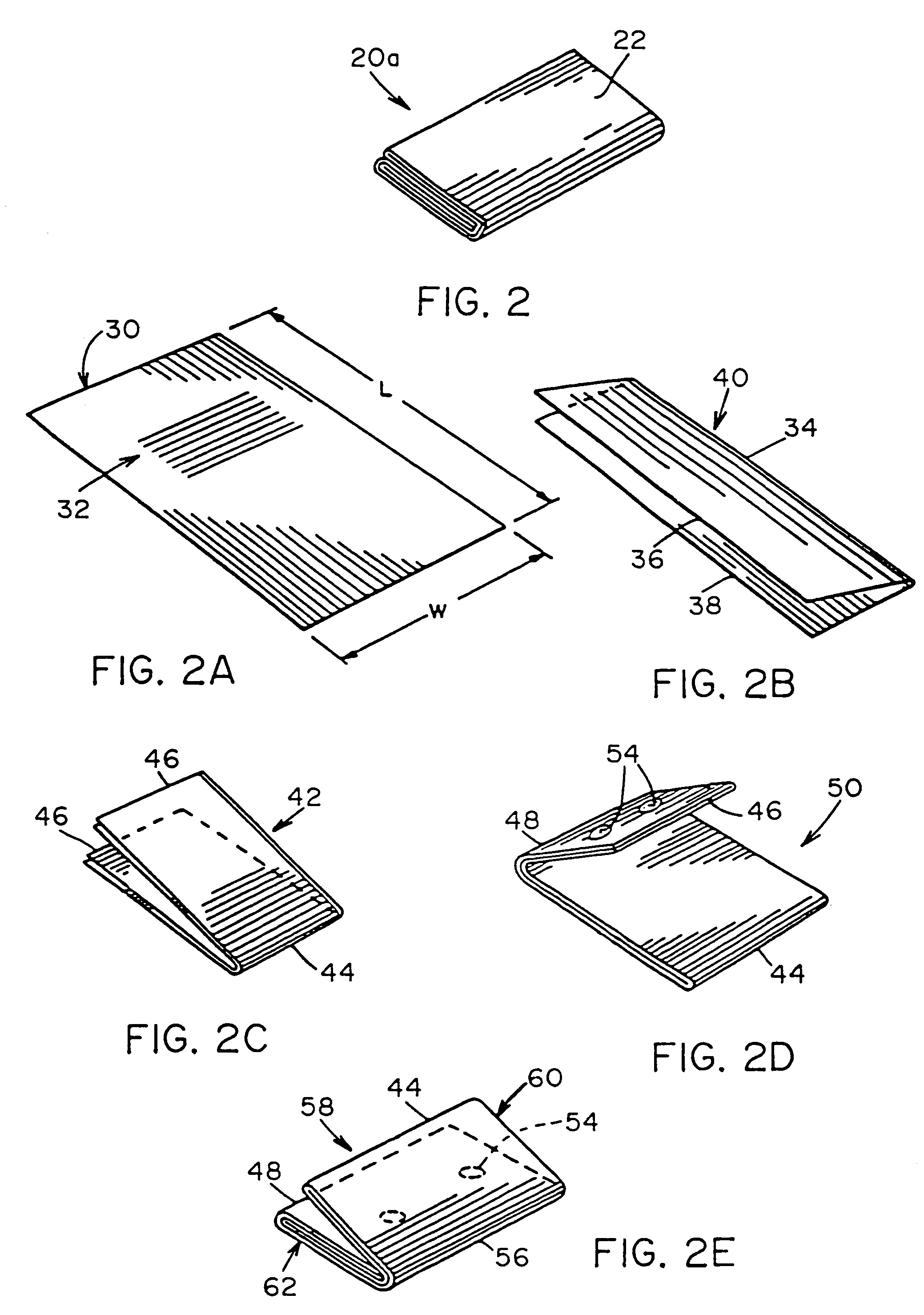

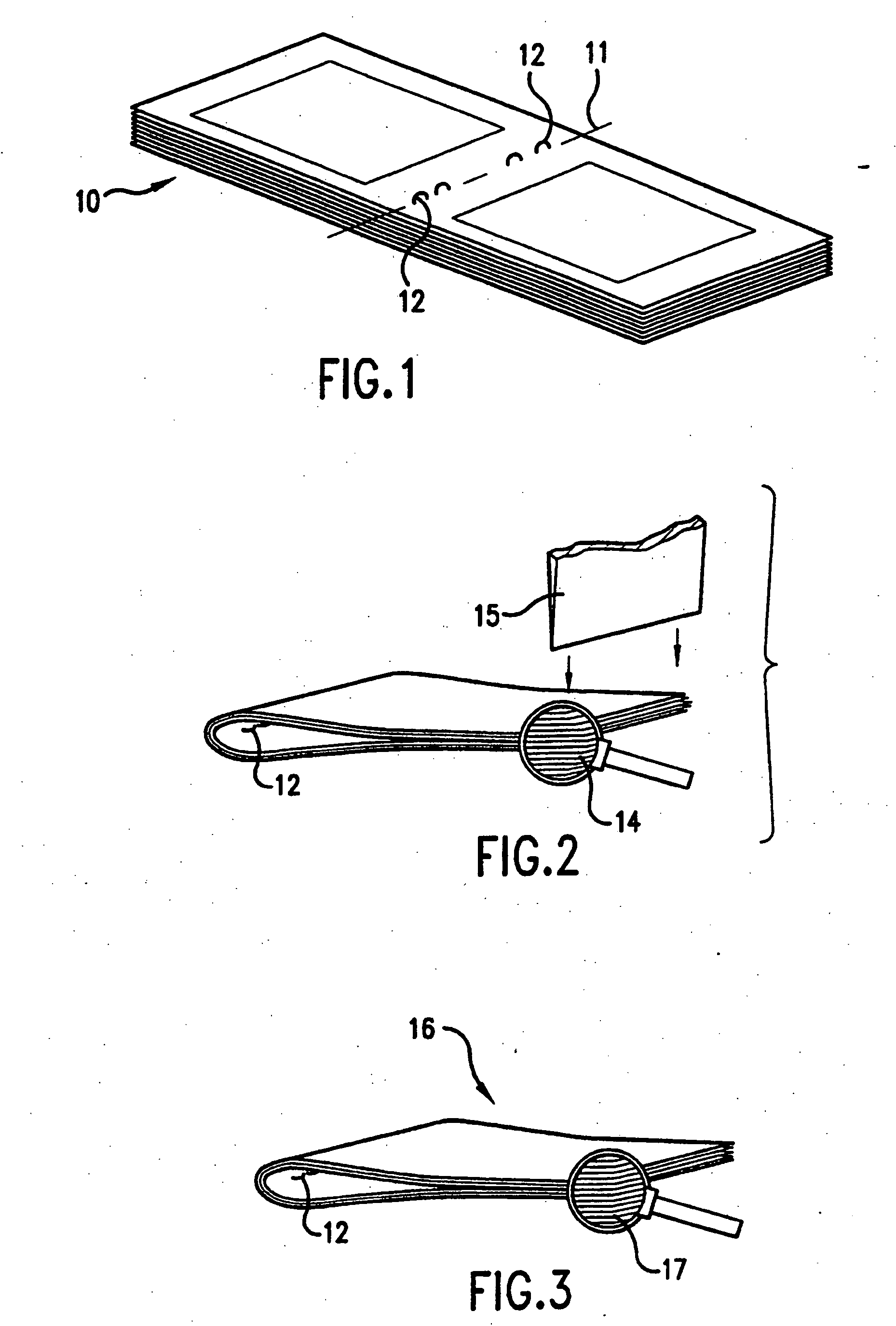

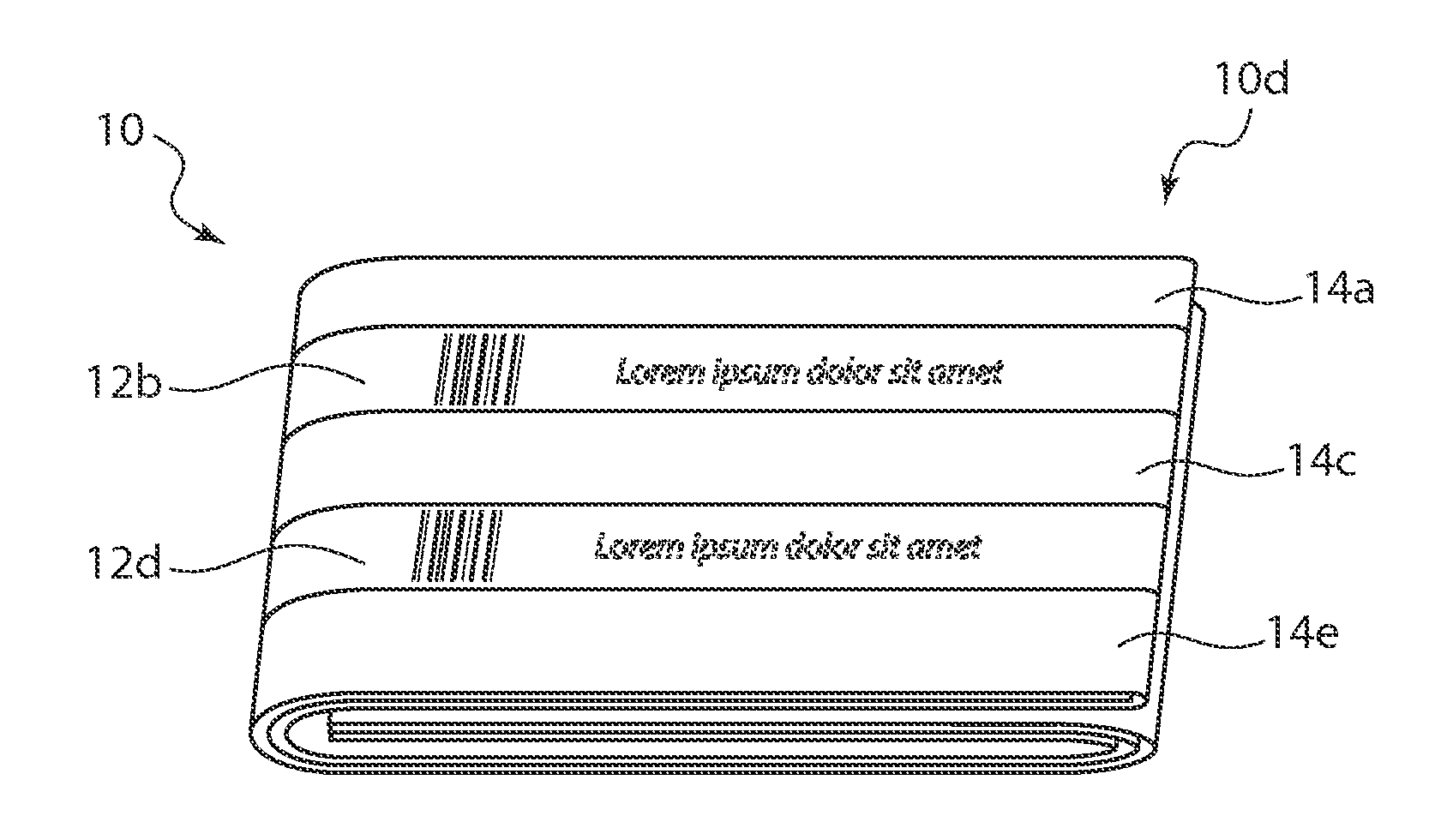

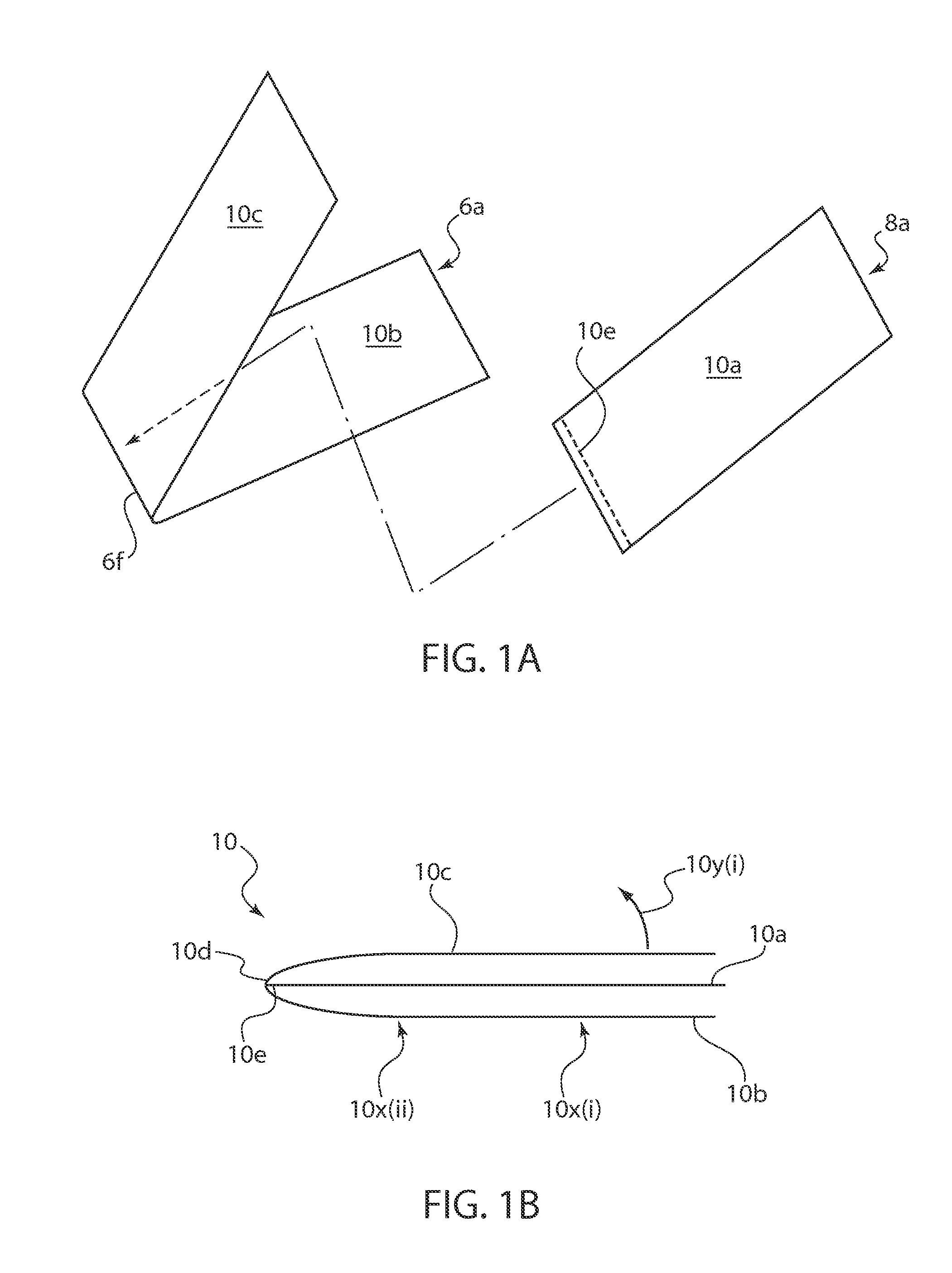

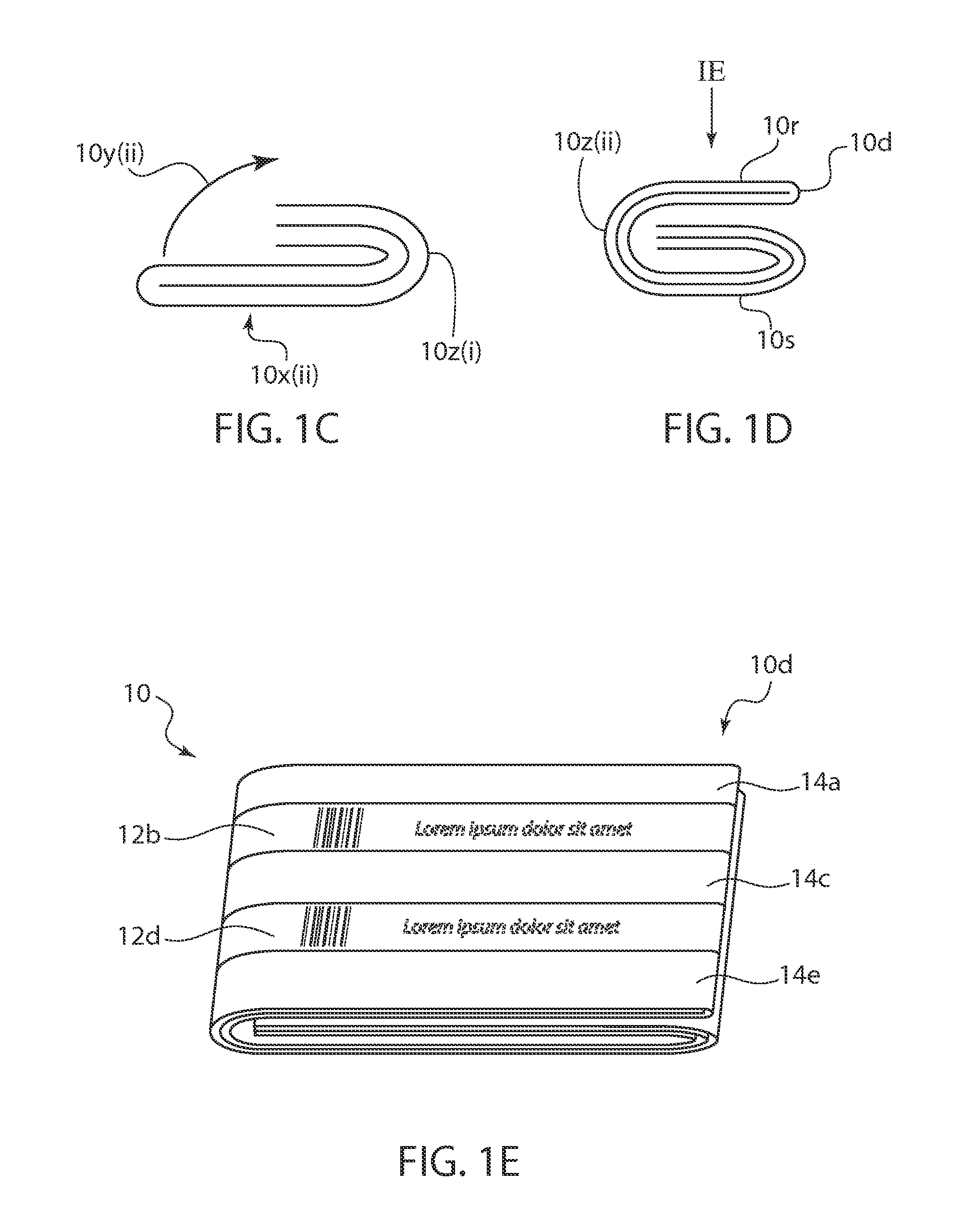

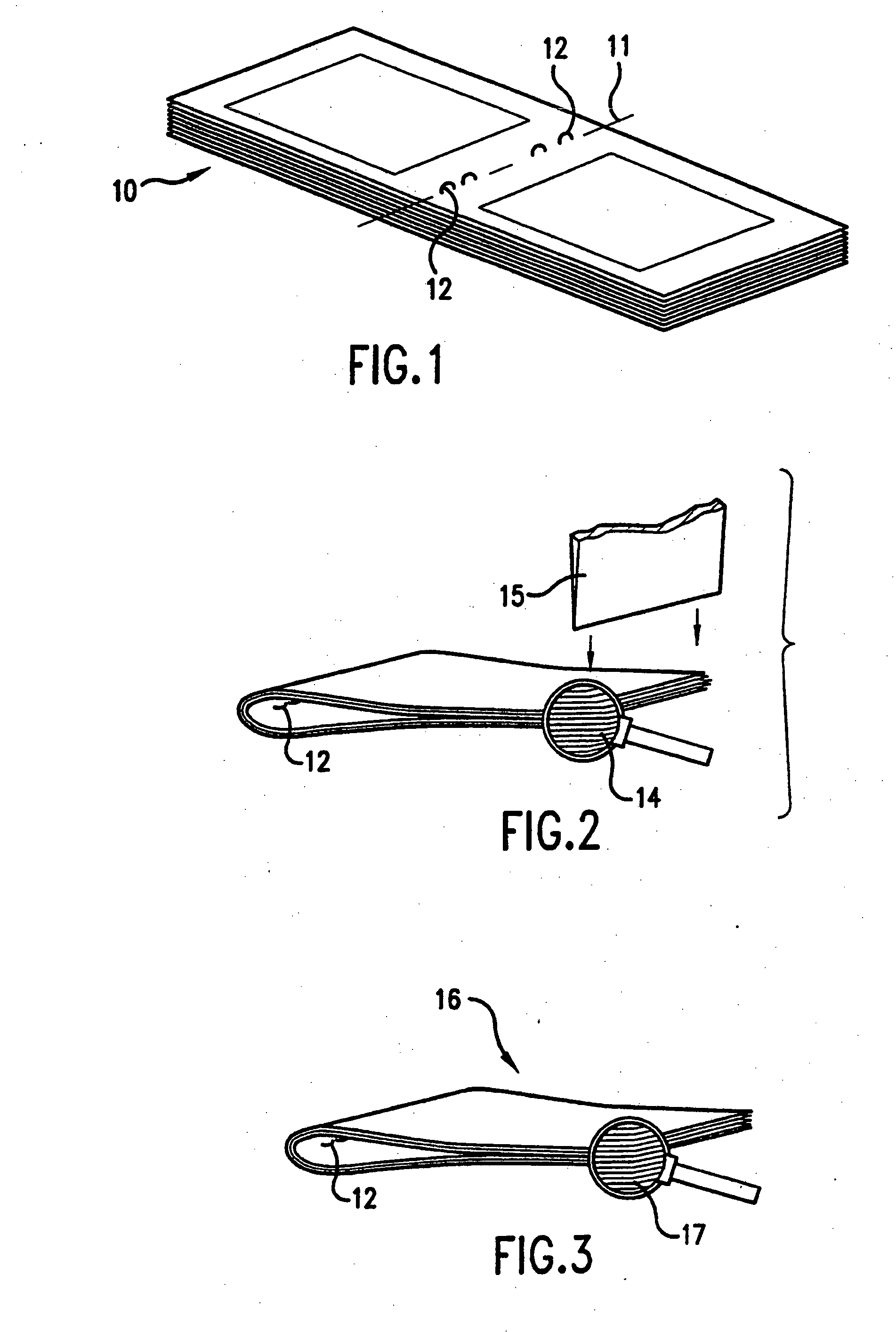

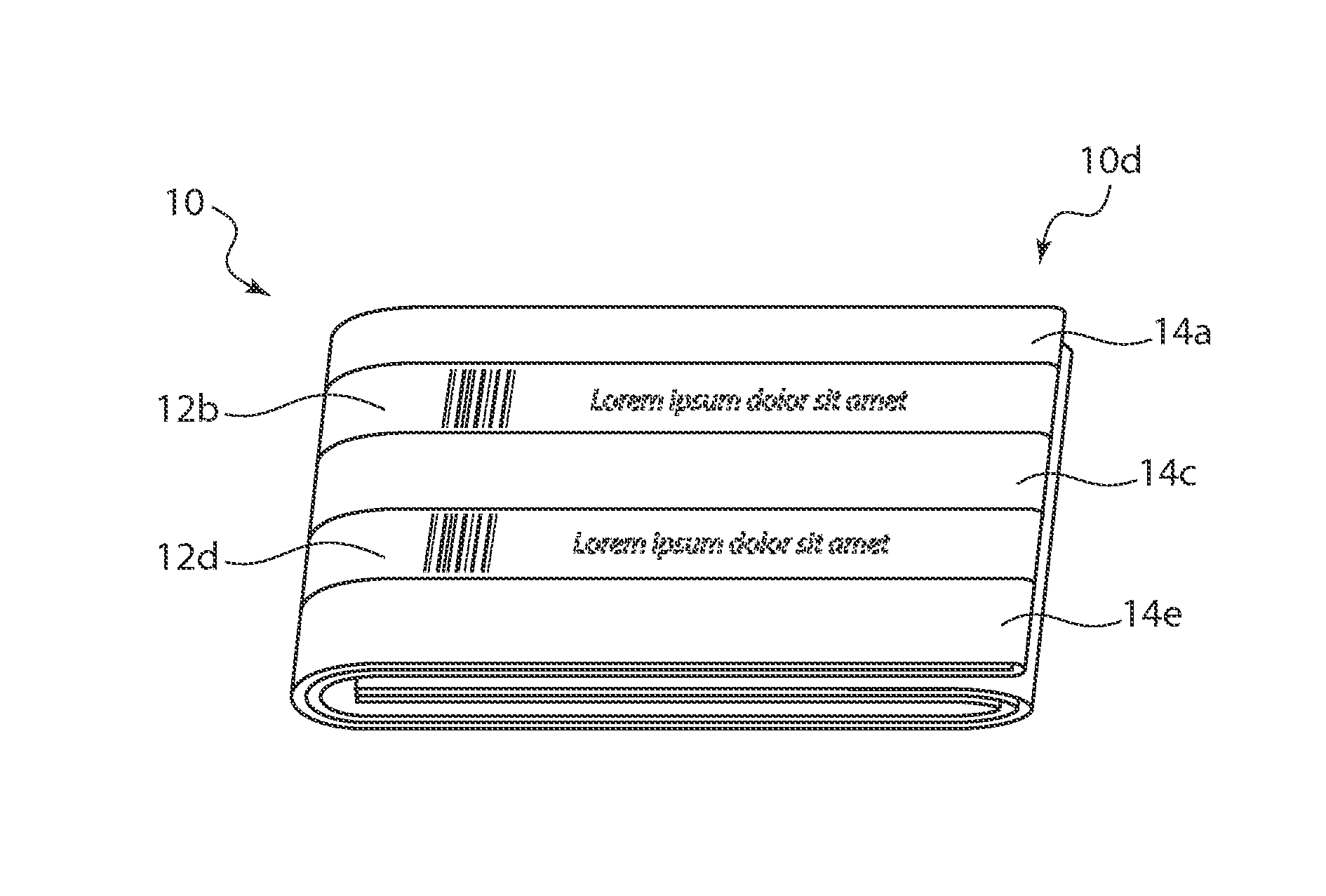

Method of manufacturing a multi-page booklet from a single sheet

A new form of printed material, referred to herein as a booklet, provides printed information concerning commercial products, such as drug products and the like. The booklet is preferably formed from a single sheet of material that is printed, folded, glued and trimmed to form a multi-page booklet. The booklet can also include a removable insert.

Owner:G&K VIJUK INTERN CORP

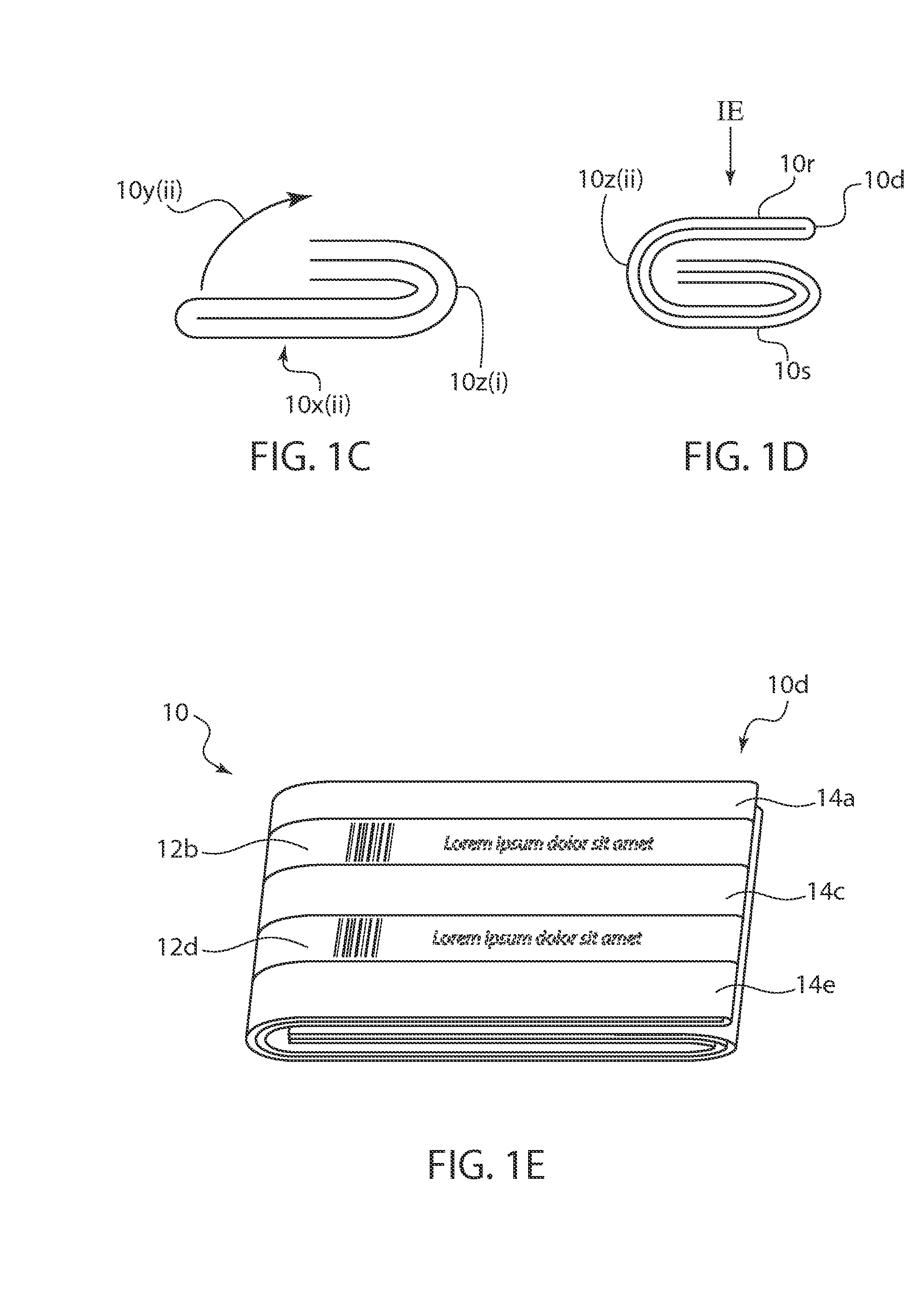

Booklet production

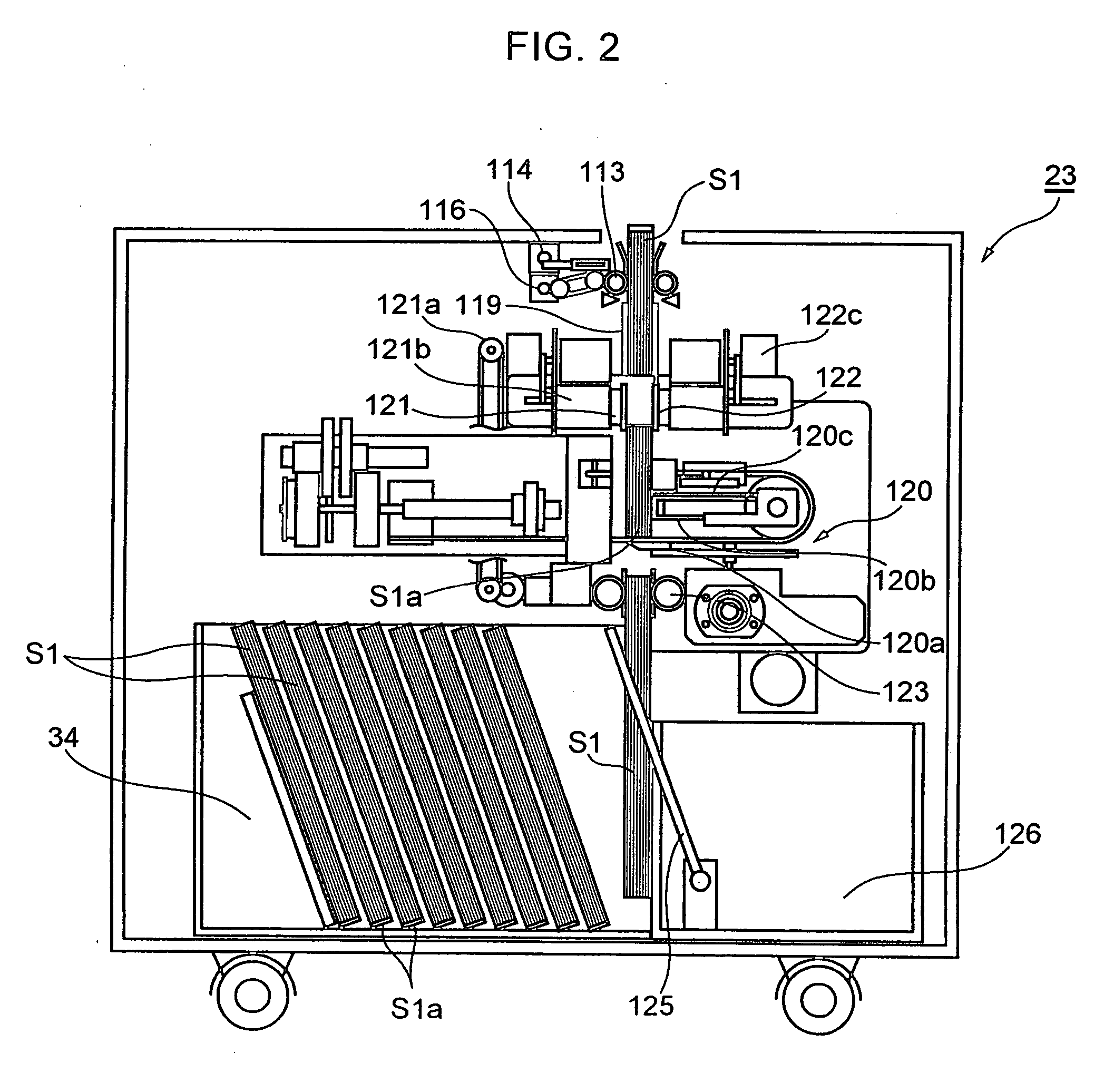

ActiveUS20050008460A1Improve operationIncrease speedMechanical working/deformationBookletsShortest distanceEngineering

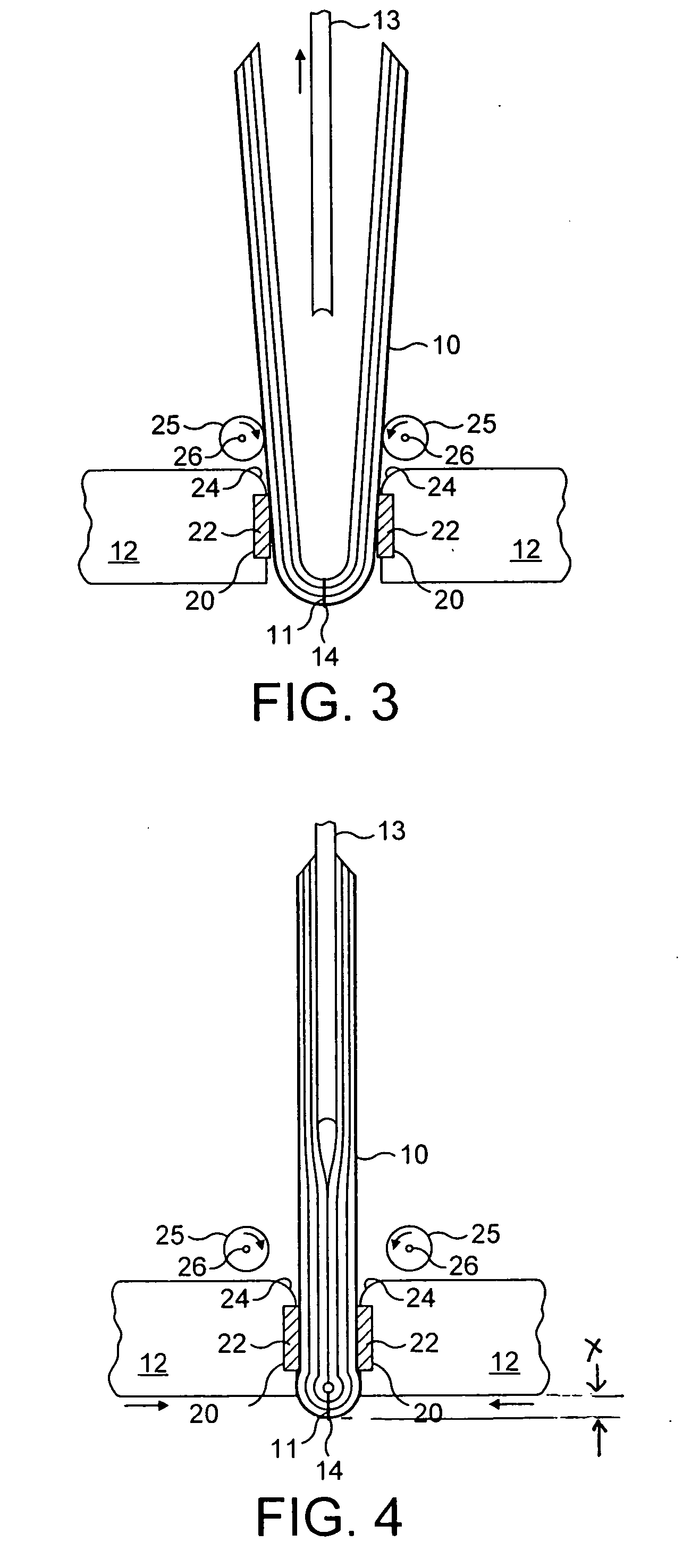

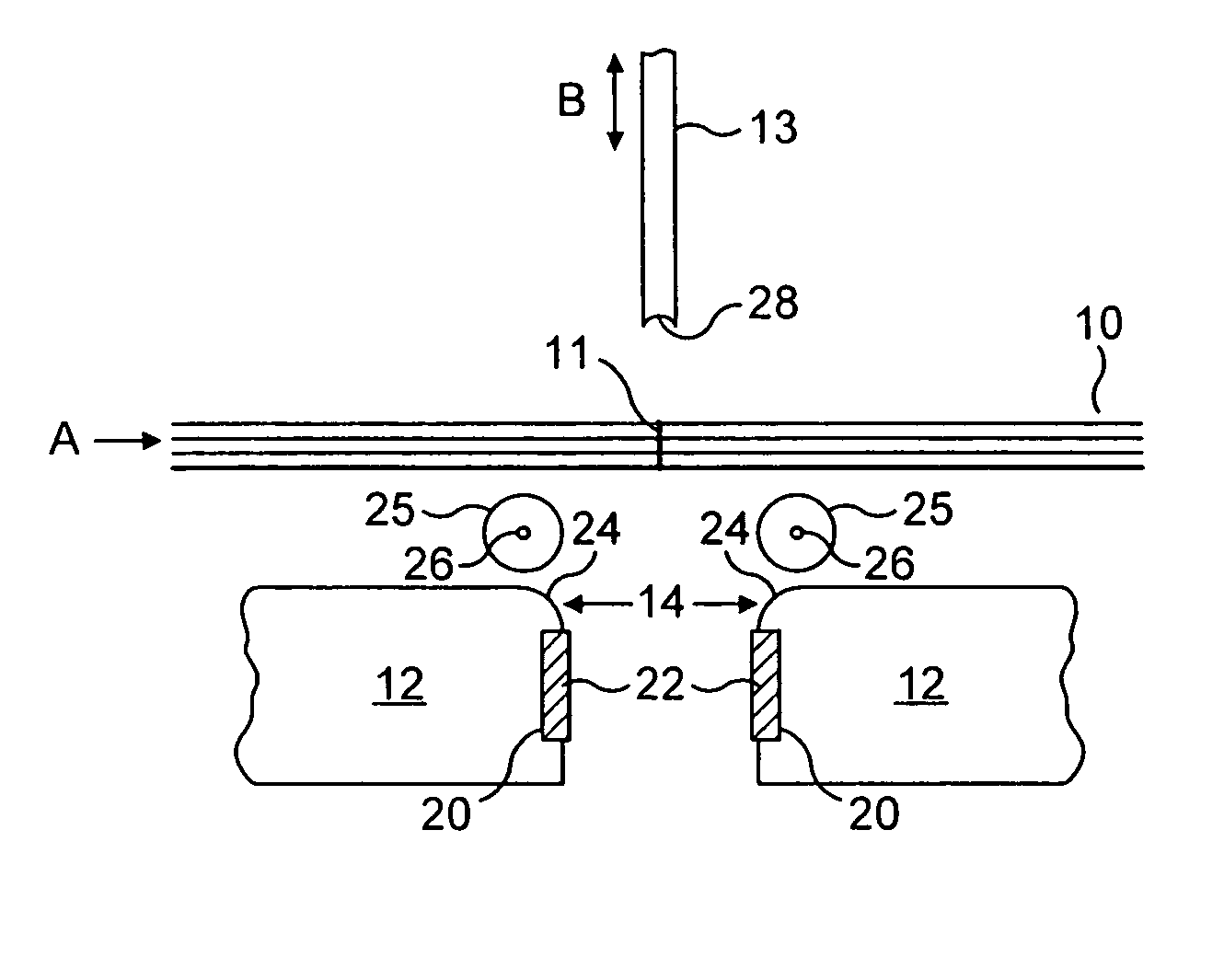

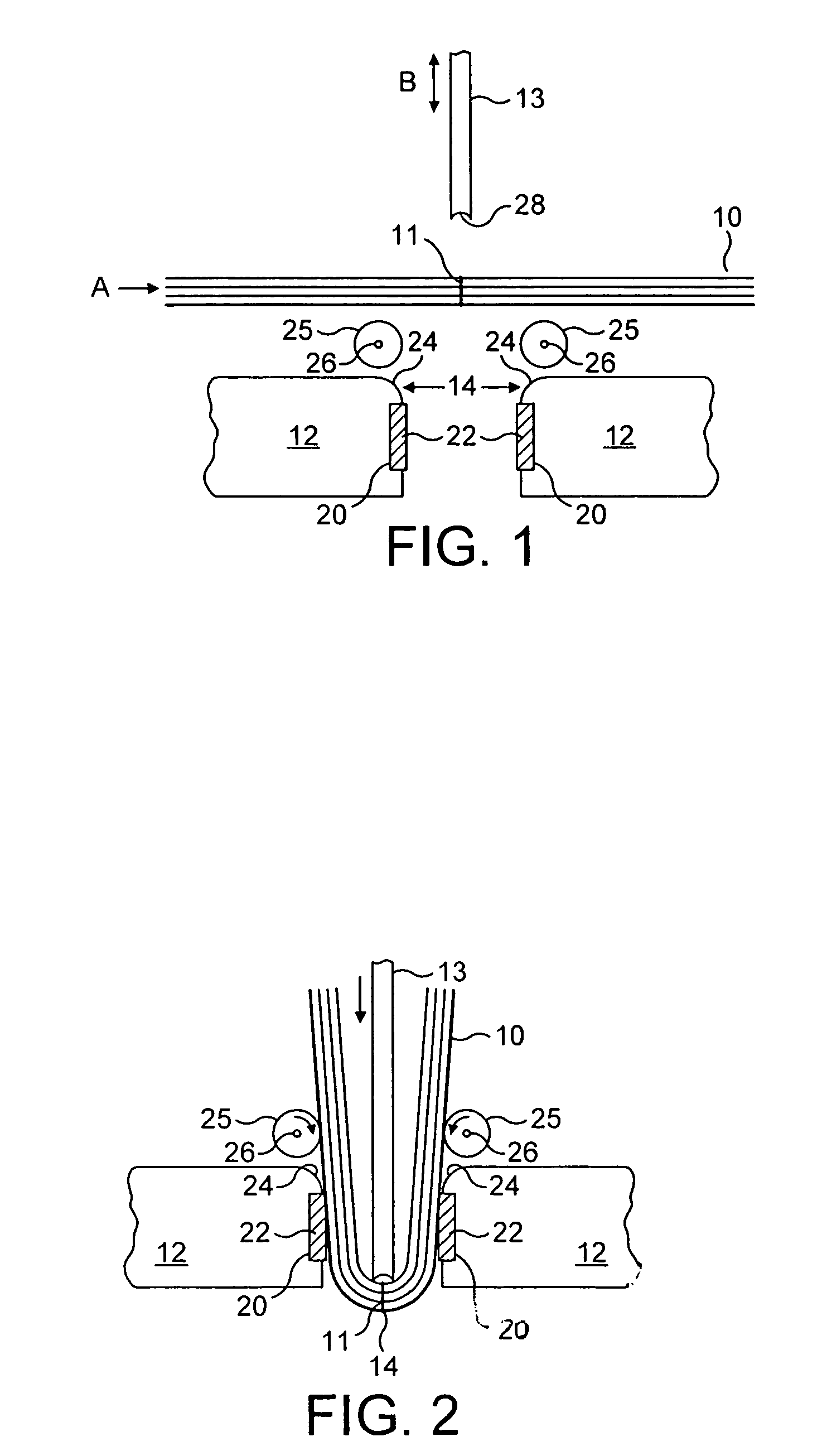

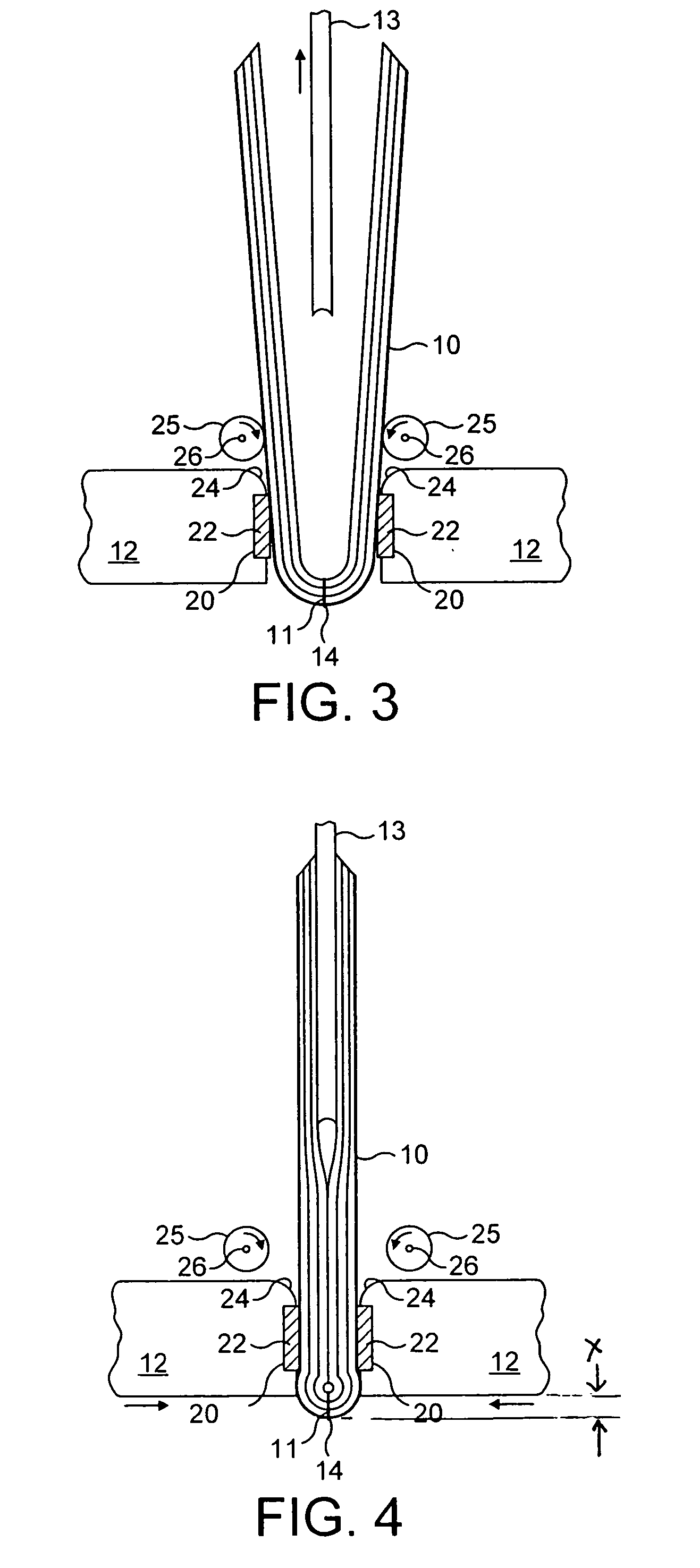

A stack of sheets of sheet material is stapled along an axis and fed to a position from which it is folded along the axis by a blade to form a booklet having a curved spine. The blade also inserts the booklet into a position between clamping jaws and determines its final position therebetween. Rotatable guide rollers guide the sheets into the gap and are fitted with one-way clutches to resist upward movement of the folded sheets upon retraction of the blade from the gap. In a first mode of operation, the curved spine of the booklet protrudes a short distance beyond the jaws. The spine is then flattened by a forming roller which passes along the spine. In a second mode of operation, the spinal portion lies between the jaws and the curved end surface is flattened by the clamping force alone. The first mode is suited to booklets having or more sheets; the second to booklets having fewer than sheets or having loop staples and any number of sheets.

Owner:MORGANA SYST

Method and apparatus for booklet production

ActiveUS7325799B2Improve operationIncrease speedMechanical working/deformationBookletsShortest distanceEngineering

A stack of sheets of sheet material is stapled along an axis and fed to a position from which it is folded along the axis by a blade to form a booklet having a curved spine. The blade also inserts the booklet into a position between clamping jaws and determines its final position therebetween. Rotatable guide rollers guide the sheets into the gap and are fitted with one-way clutches to resist upward movement of the folded sheets upon retraction of the blade from the gap. In a first mode of operation, the curved spine of the booklet protrudes a short distance beyond the jaws. The spine is then flattened by a forming roller which passes along the spine. In a second mode of operation, the spinal portion lies between the jaws and the curved end surface is flattened by the clamping force alone. The first mode is suited to booklets having or more sheets; the second to booklets having fewer than sheets or having loop staples and any number of sheets.

Owner:MORGANA SYST

Sheet processing apparatus

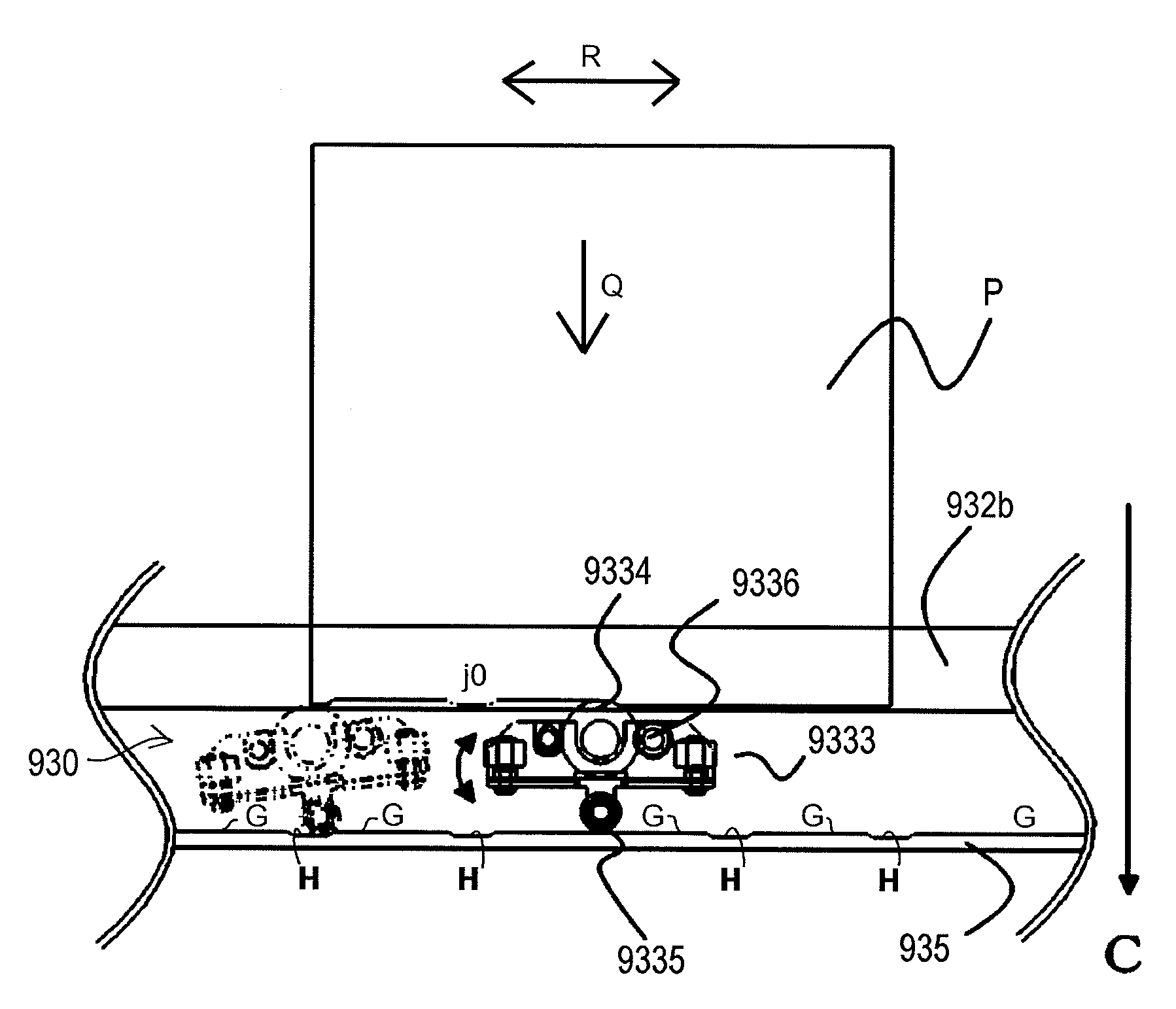

A sheet processing apparatus includes: a holding portion which holds a booklet containing a two-folded sheet; and a pressing portion which presses a spine of a booklet into shapes during movement along the spine of the booklet held by the holding portion. The pressing portion can decrease, or release a pressing force to be applied to the booklet spine within a predetermined area of a moving range in which the pressing roller moves along the booklet spine.

Owner:CANON KK

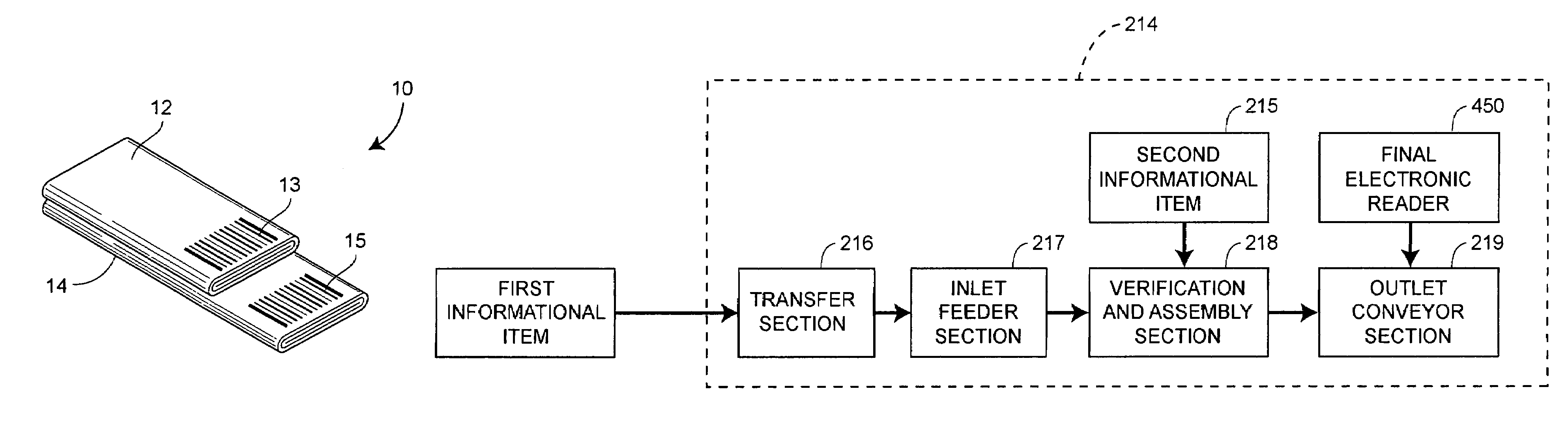

Method of forming composite informational item

InactiveUS7247130B2Mechanical working/deformationPaper/cardboard articlesAdhesiveMechanical engineering

A method of forming a composite informational item having information regarding a pharmaceutical product printed thereon from a first informational item, such as a bidirectionally folded outsert or a booklet, and a second informational item, such as a bidirectionally folded outsert or a booklet, may comprise (a) forming the first informational item; (b) automatically conveying the first informational item from a location in a first feed apparatus to a bonding location; (c) providing a plurality of the second informational items in a second feed apparatus different than the first feed apparatus; (d) automatically depositing a releasable adhesive on a face of one of the informational items; (e) automatically conveying one of the second informational items from a location in the second feed apparatus to the bonding location; and (f) causing a face of the first informational item to make contact with a face of the second informational item so that the first informational item and the one second informational item are releasably bonded together via the releasable adhesive applied to the face of one of the informational items.

Owner:G&K VIJUK INTERN CORP

Method of manufacturing a single booklet

The disclosure is directed to a method of manufacturing a booklet from a rectangular sheet of paper having information regarding a drug product printed thereon. The method comprises applying a first portion of glue to a first face of the sheet of paper along a single linear path, applying a second portion of glue to a second face of the sheet of paper along a single linear path, making a plurality of parallel folds in the sheet of paper in a direction transverse to the single linear paths along which the glue was applied to produce an intermediate item, and trimming the intermediate item in a direction parallel to the plurality of parallel folds to cause the first and second of the plurality of parallel folds to be removed from the intermediate item.

Owner:G&K VIJUK INTERN CORP

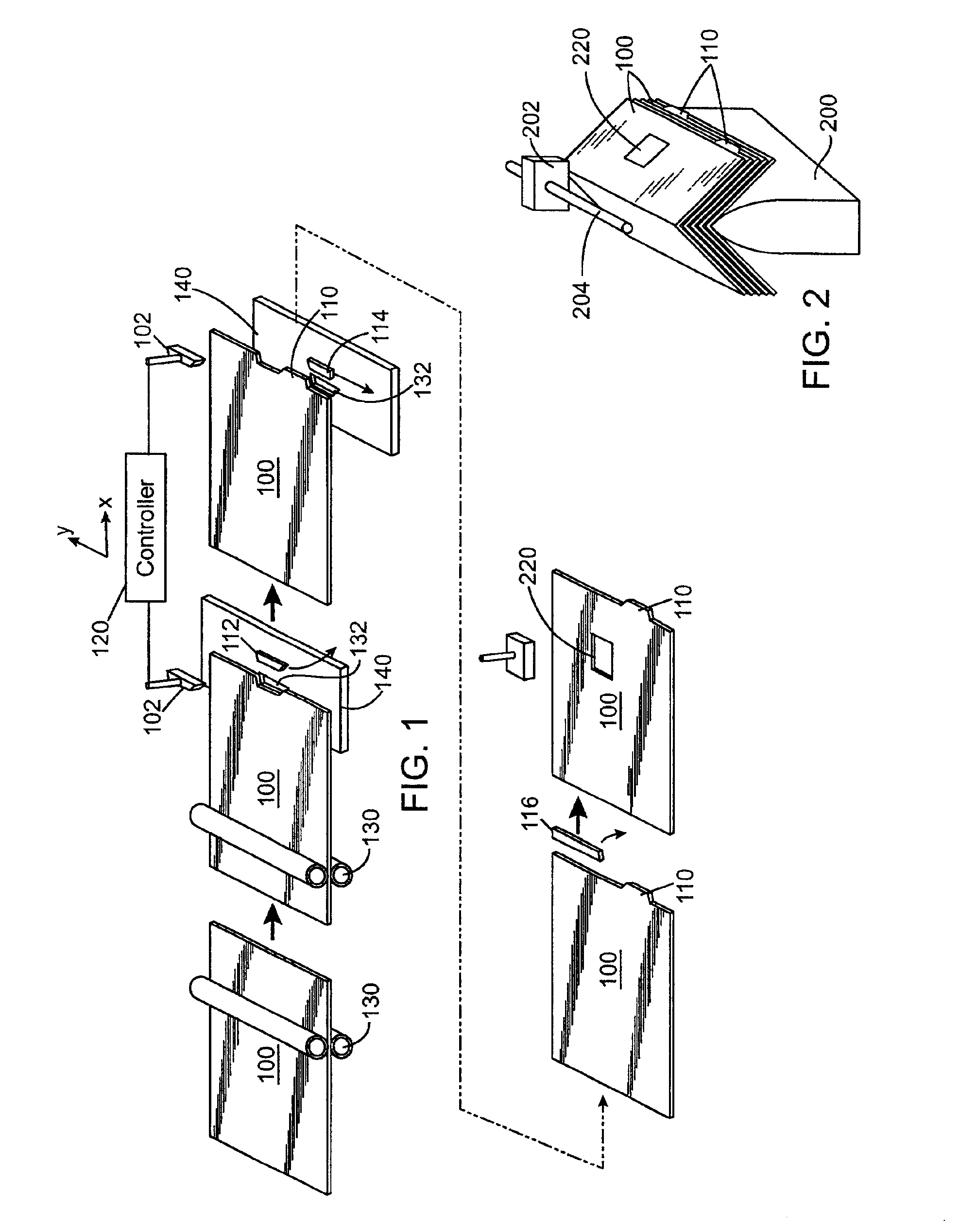

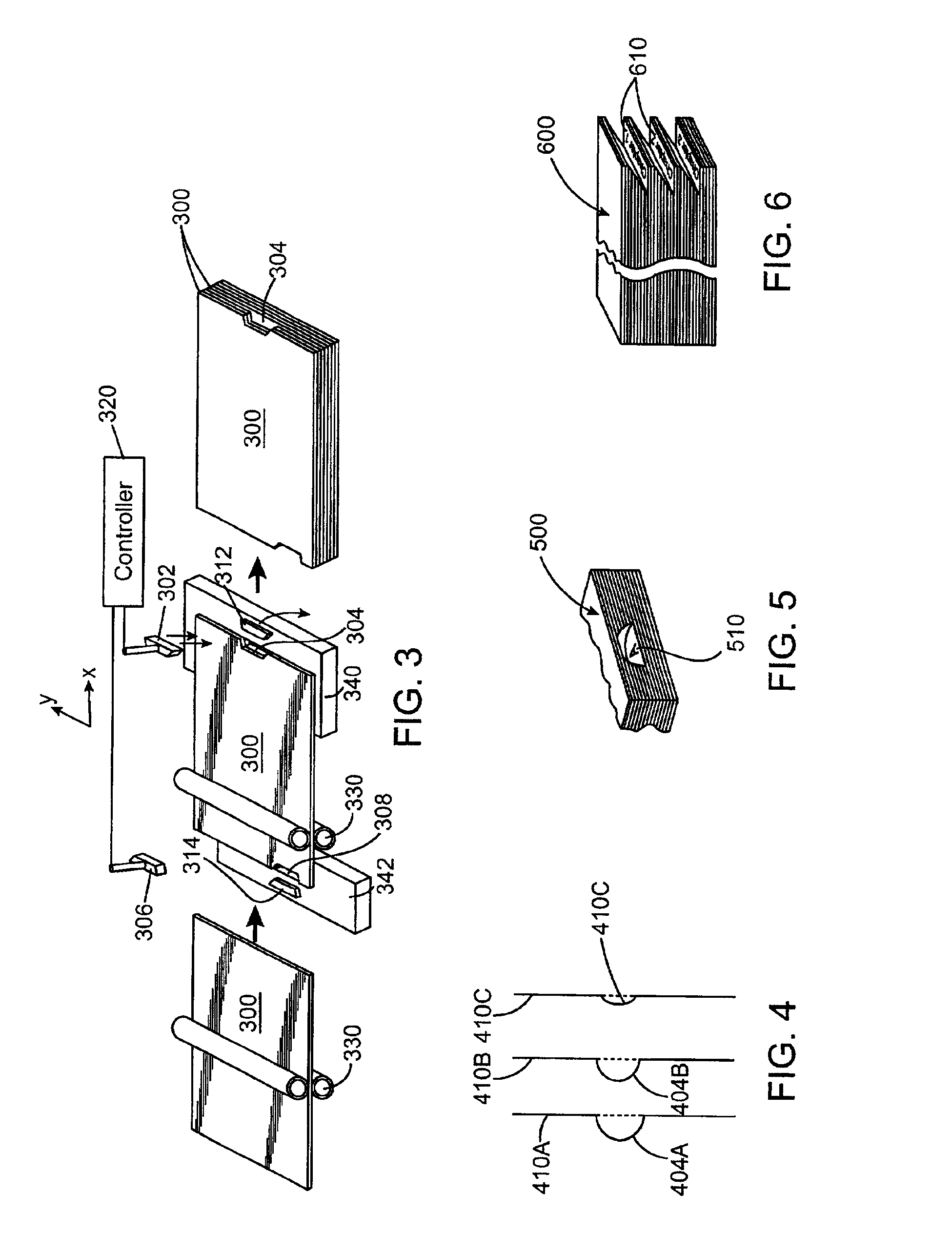

Binding system with sheet-wise formation of features

InactiveUS6966552B2More compactLess expensiveStapling toolsBookbinding casesEngineeringSheet material

The system and method for binding documents as described creates documents having features such as tabs, finger indexes, tear-out cards, and windows. These features are desirable for both their appearance and functionality and are easily added to a document during sheet-by-sheet processing. A sheet-wise binding system includes a sheet transport path for transporting a plurality of printed sheets in a sheet-wise manner and a punch configured to punch a feature into at least one of the sheets traveling through the sheet transport path. A stacking system is provided for stacking the punched and unpunched sheets and a binding system for binding the stacked sheets is used to form a finished document. A controller is programed to control the sheet transport path and the punch to create the features in selected sheets and at selected locations in the sheets according to a punch schedule.

Owner:HEWLETT PACKARD DEV CO LP

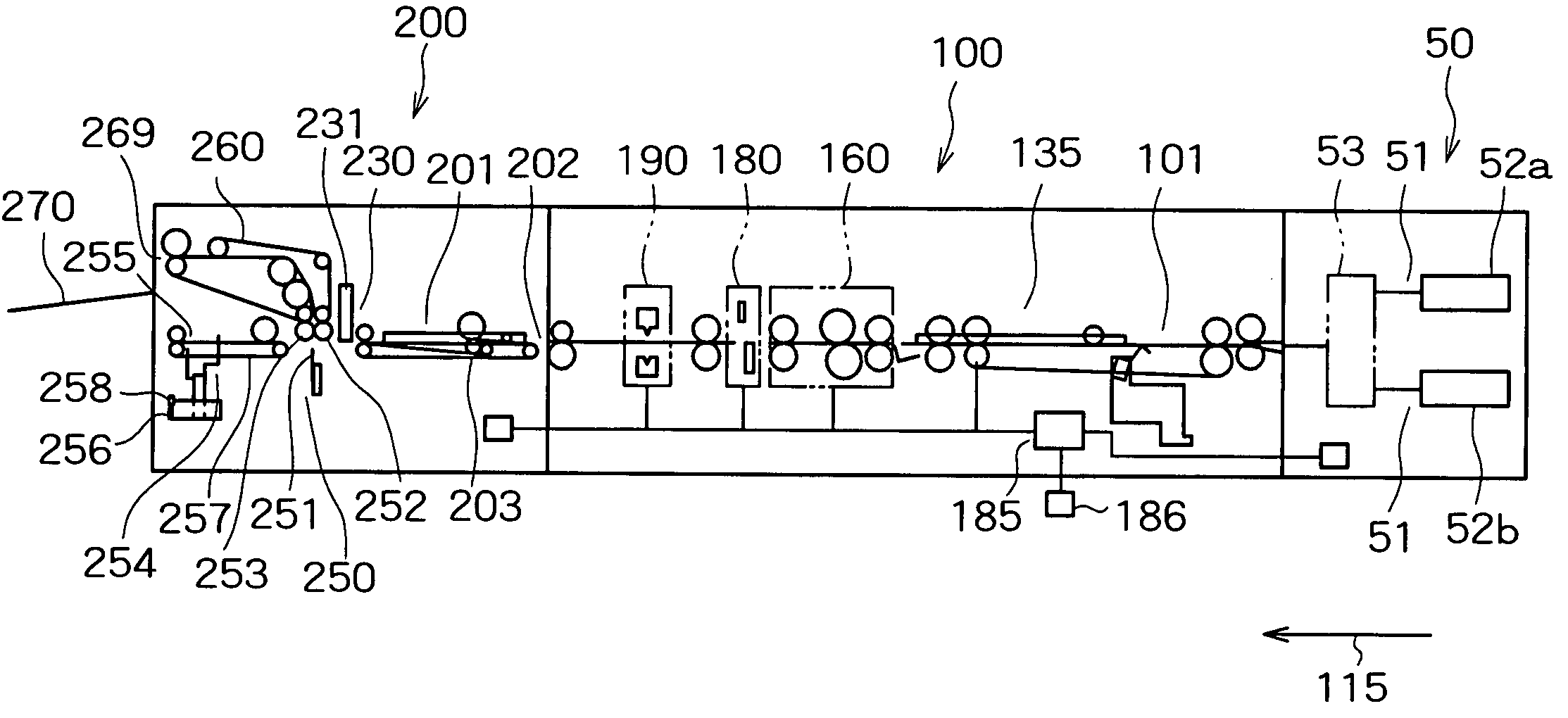

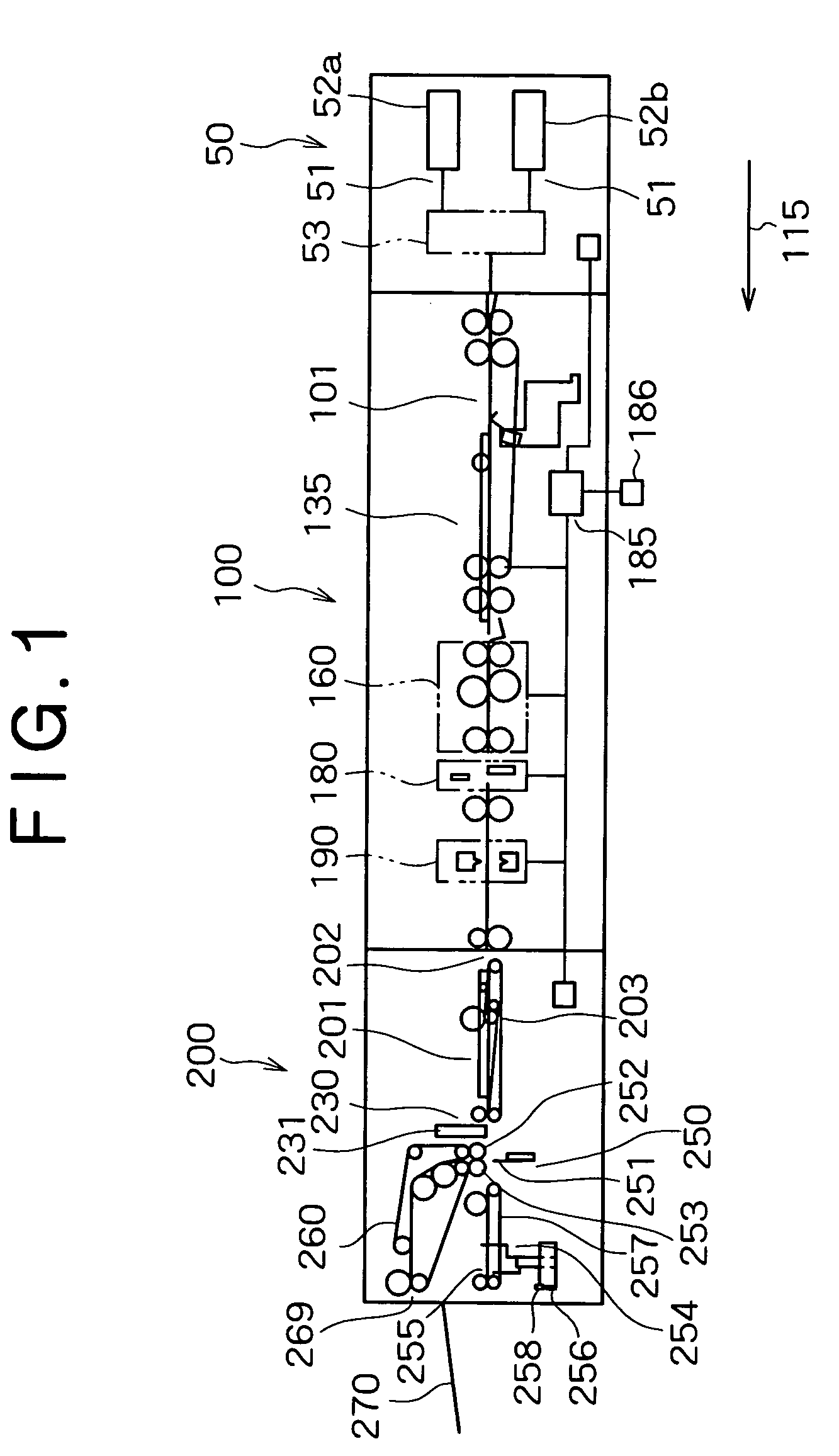

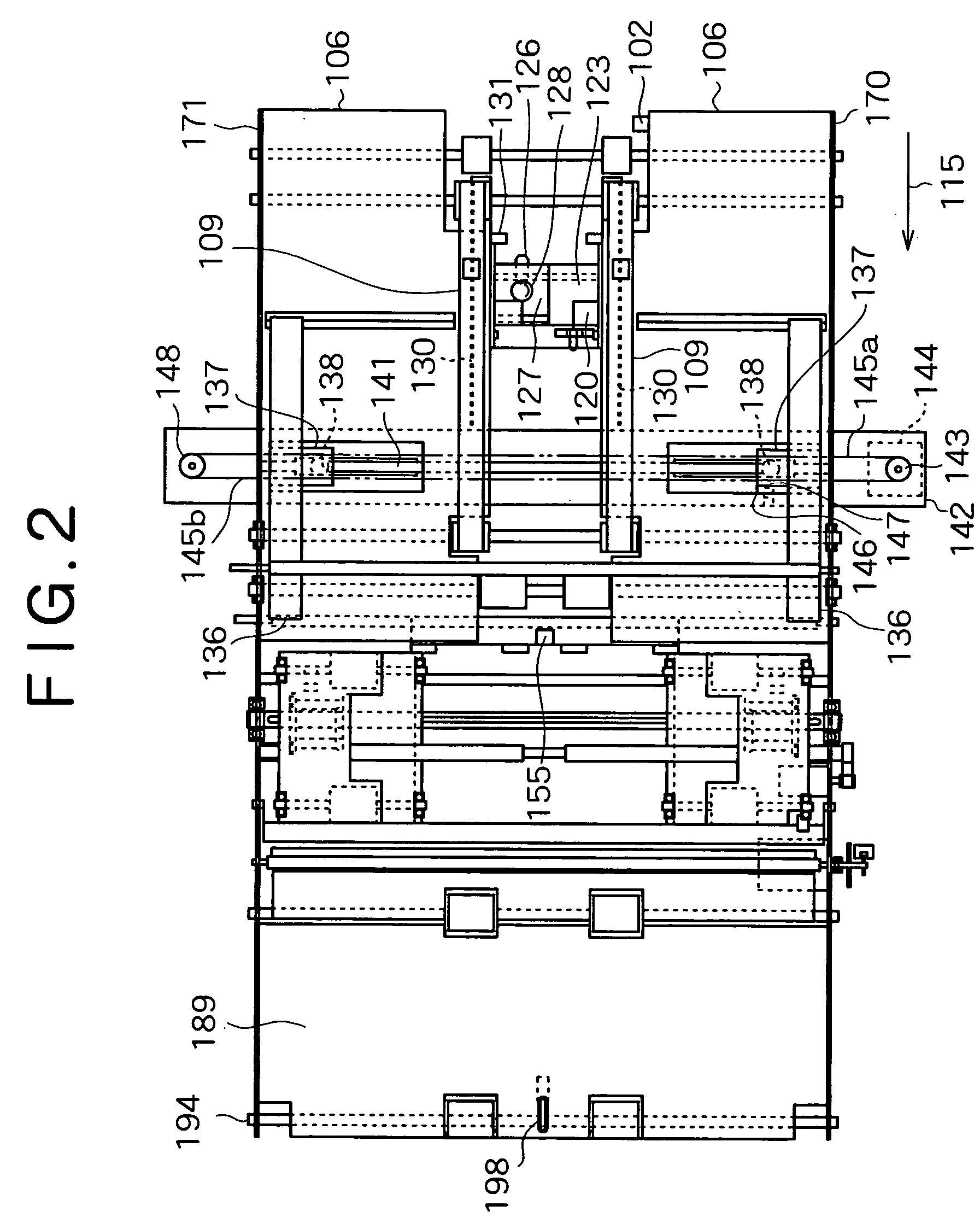

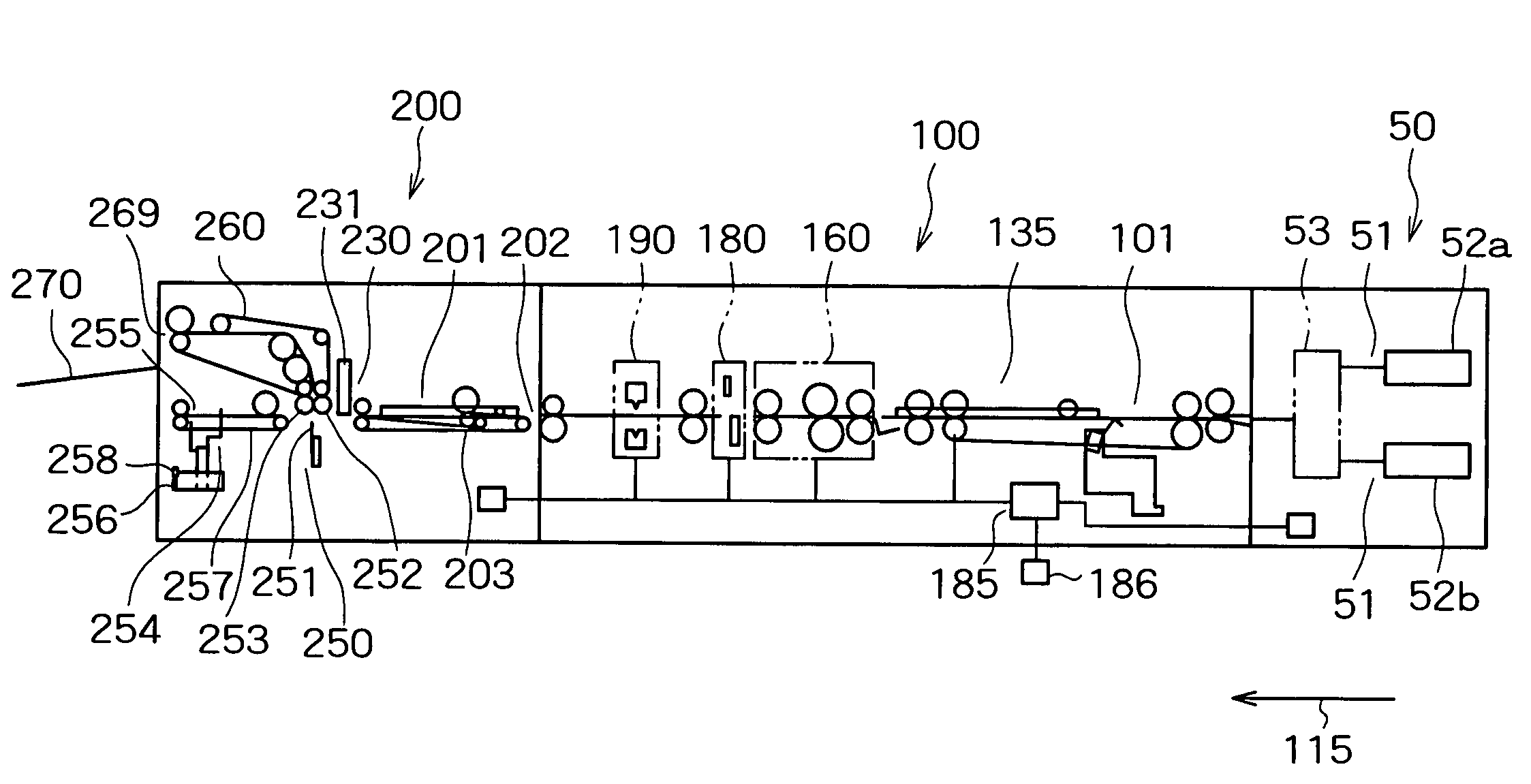

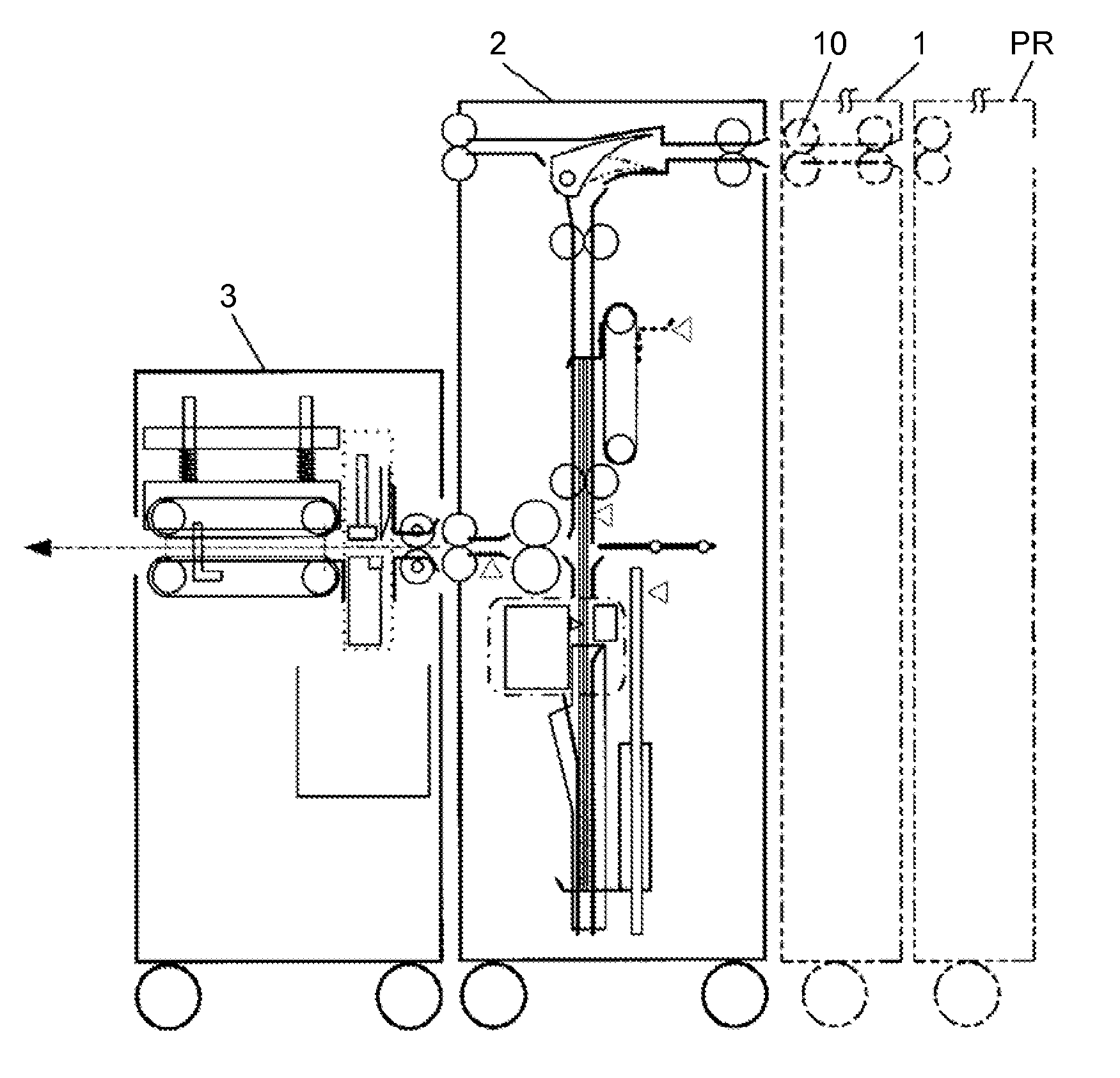

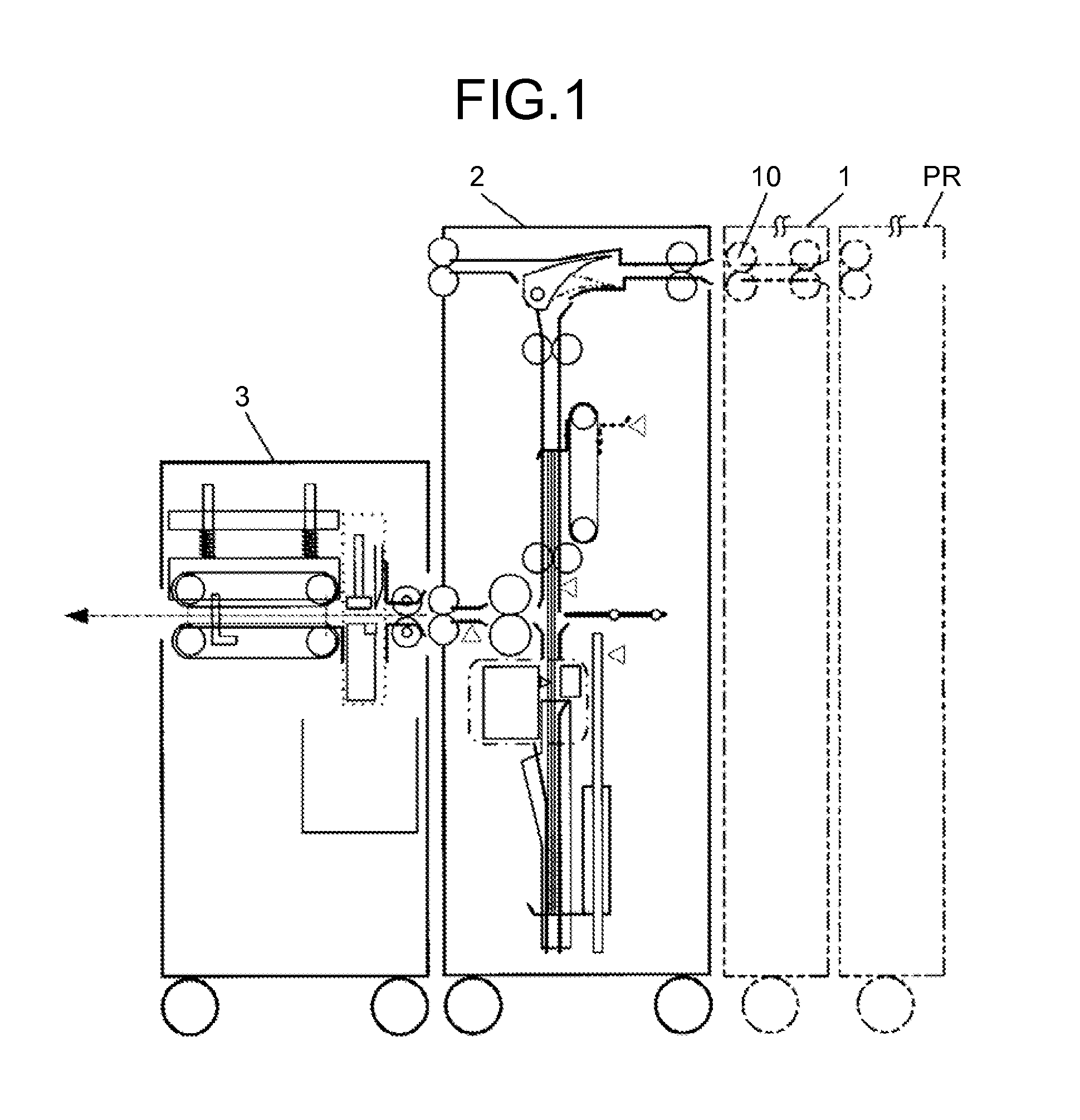

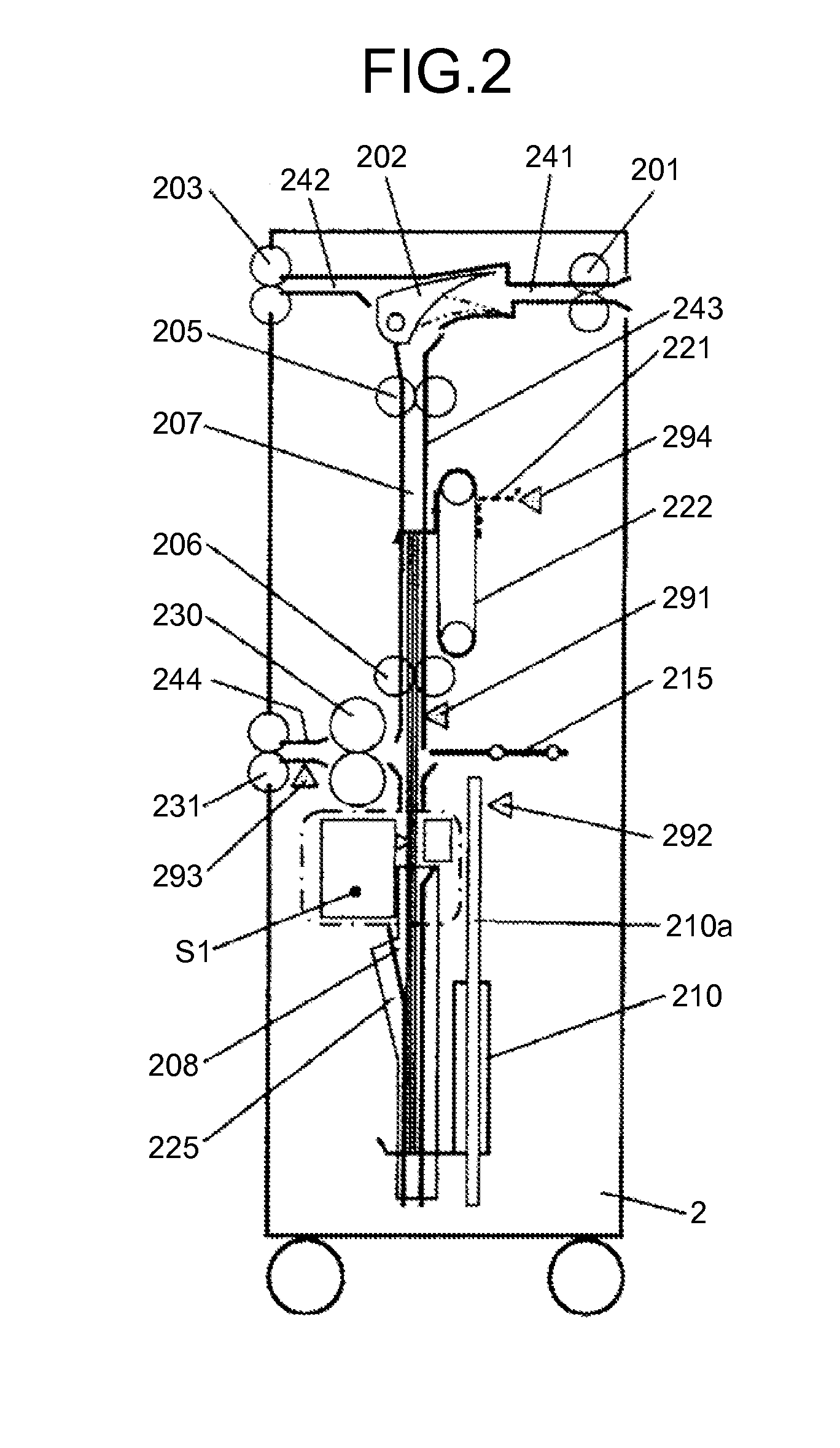

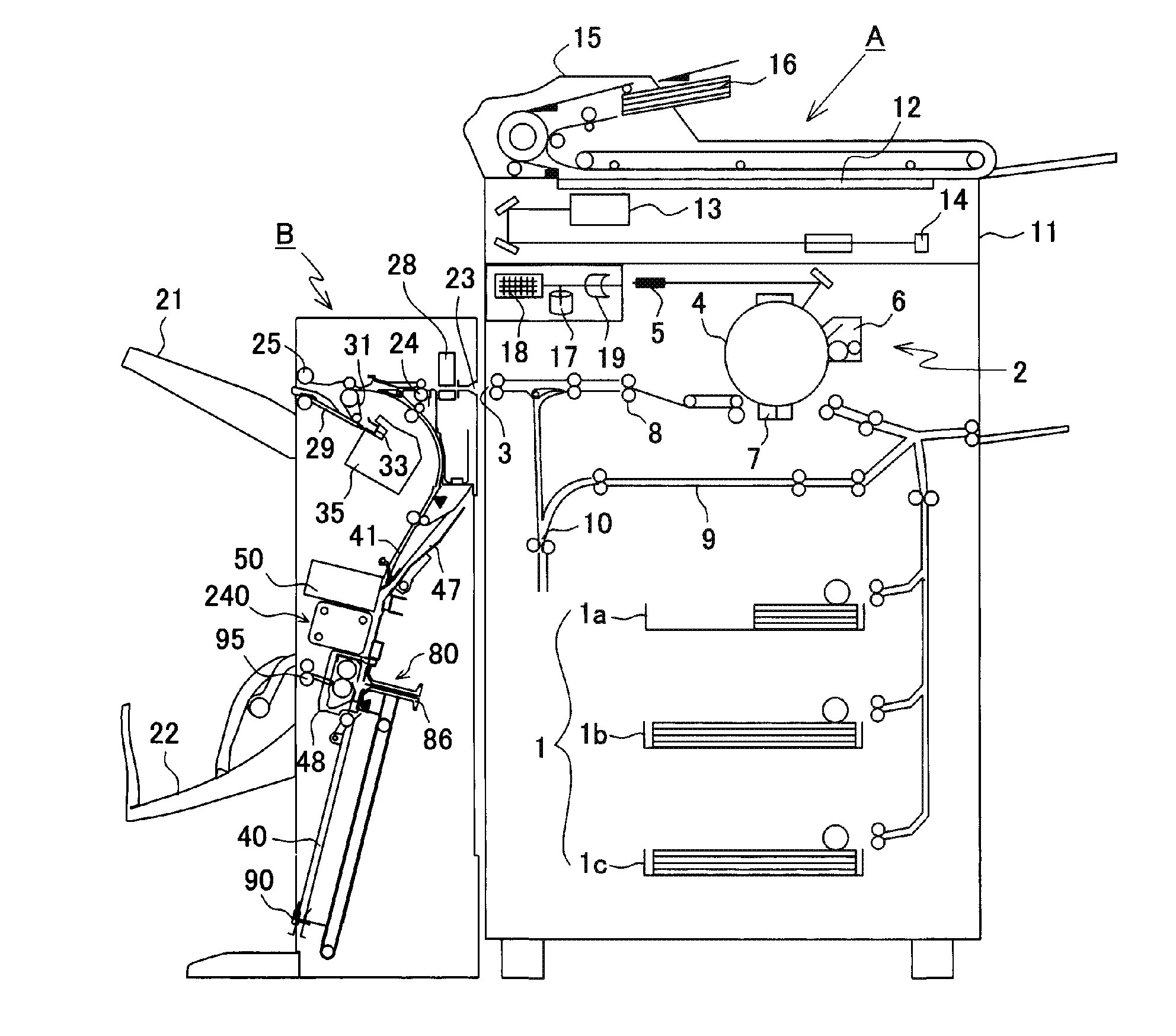

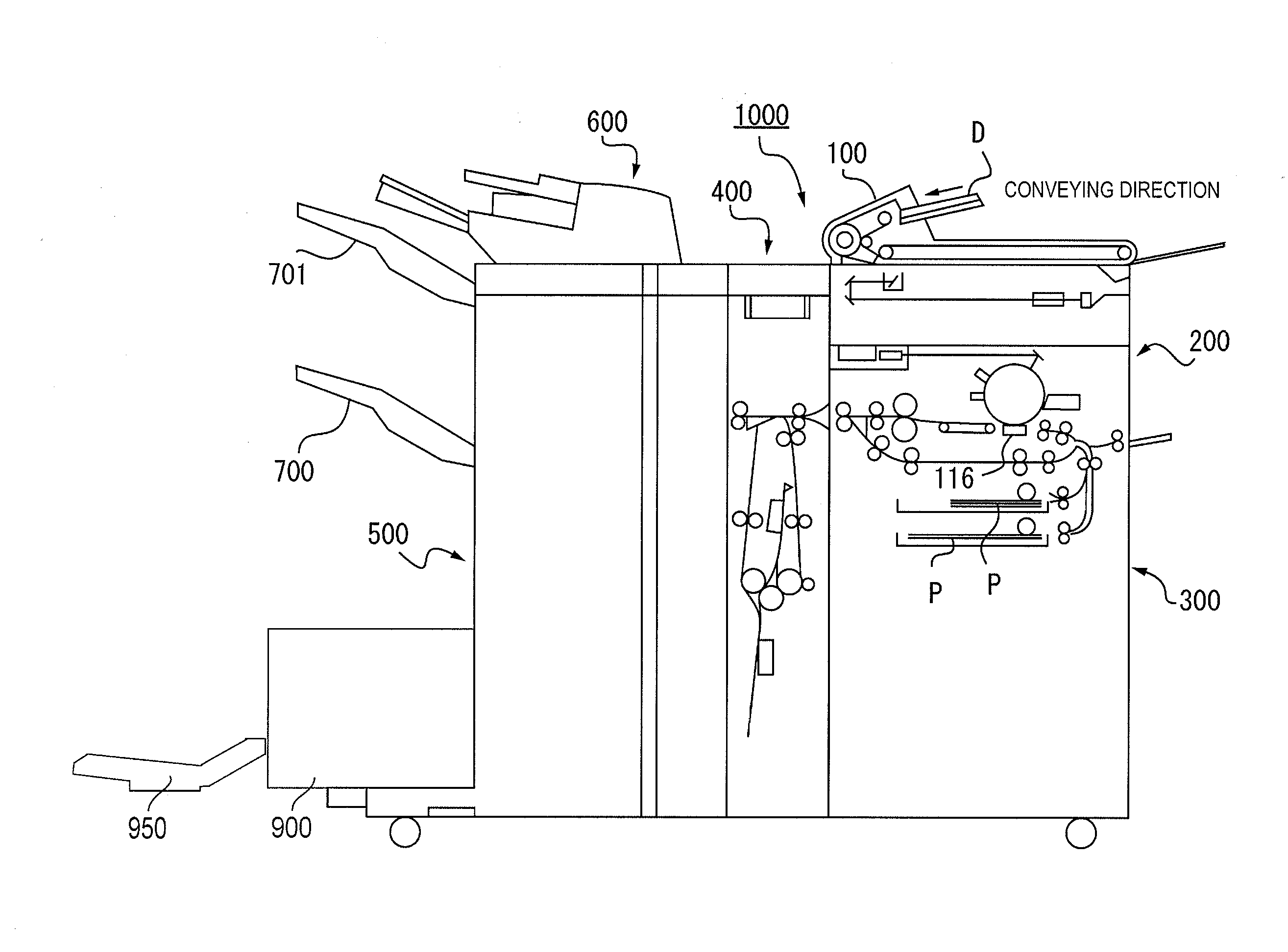

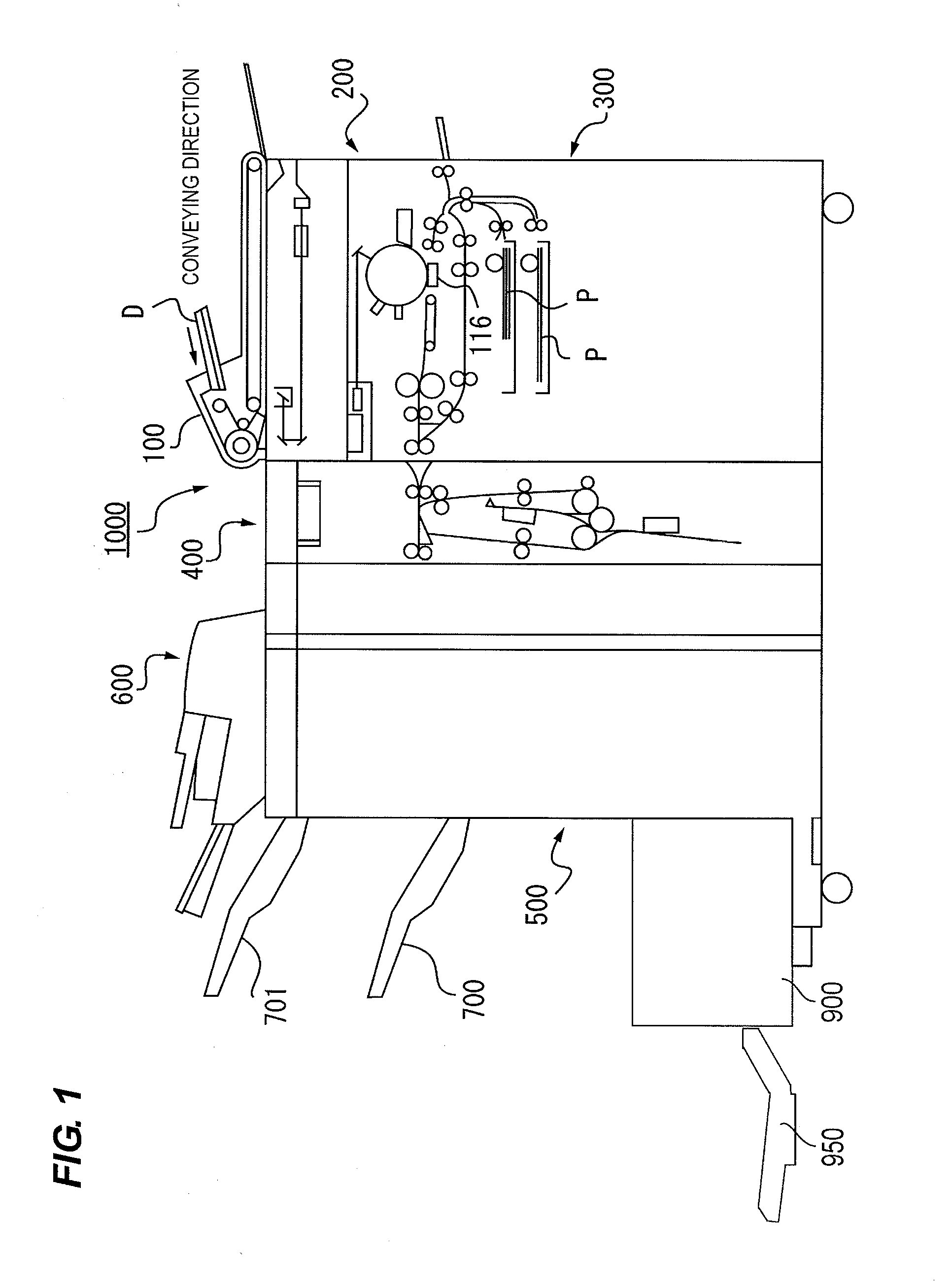

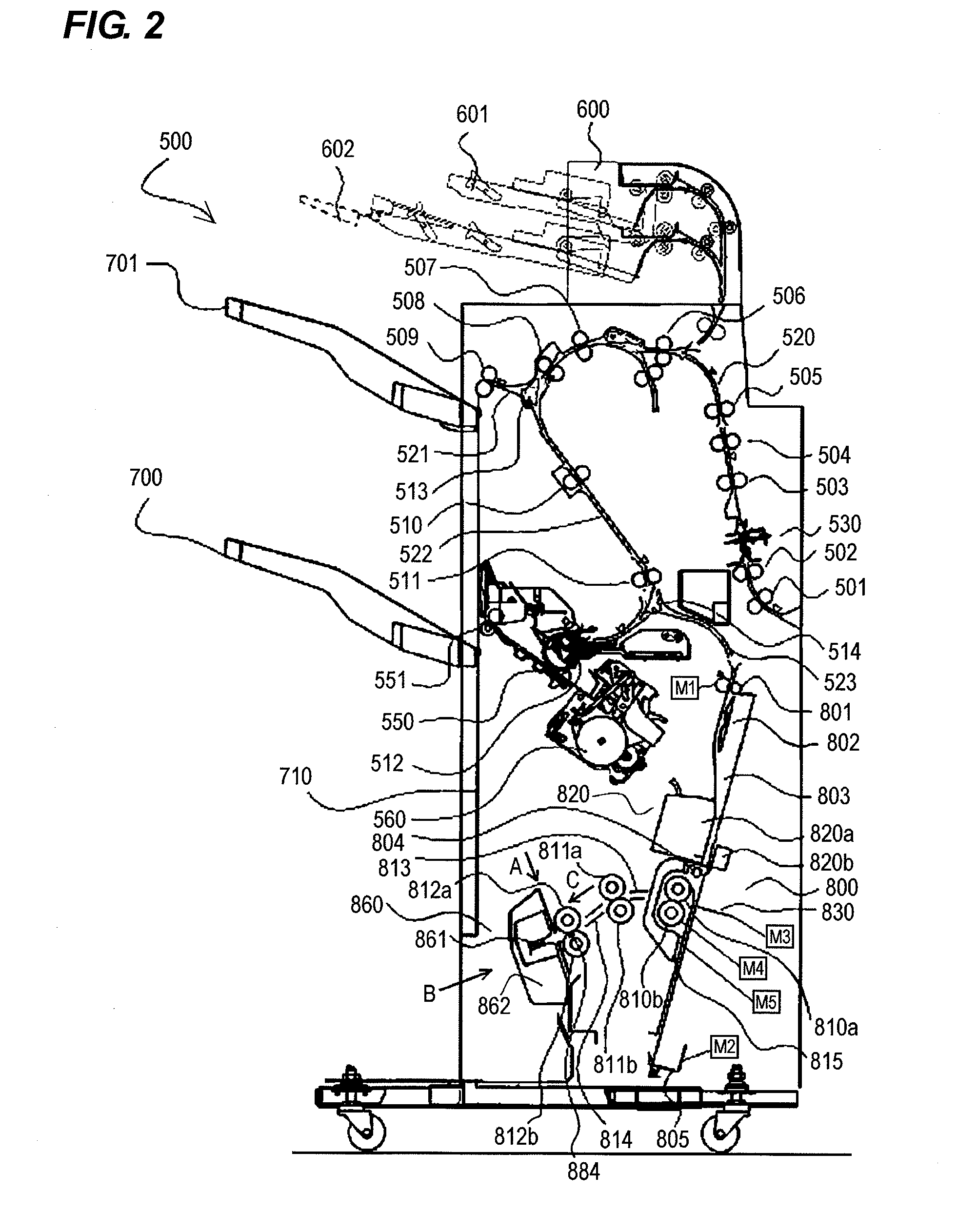

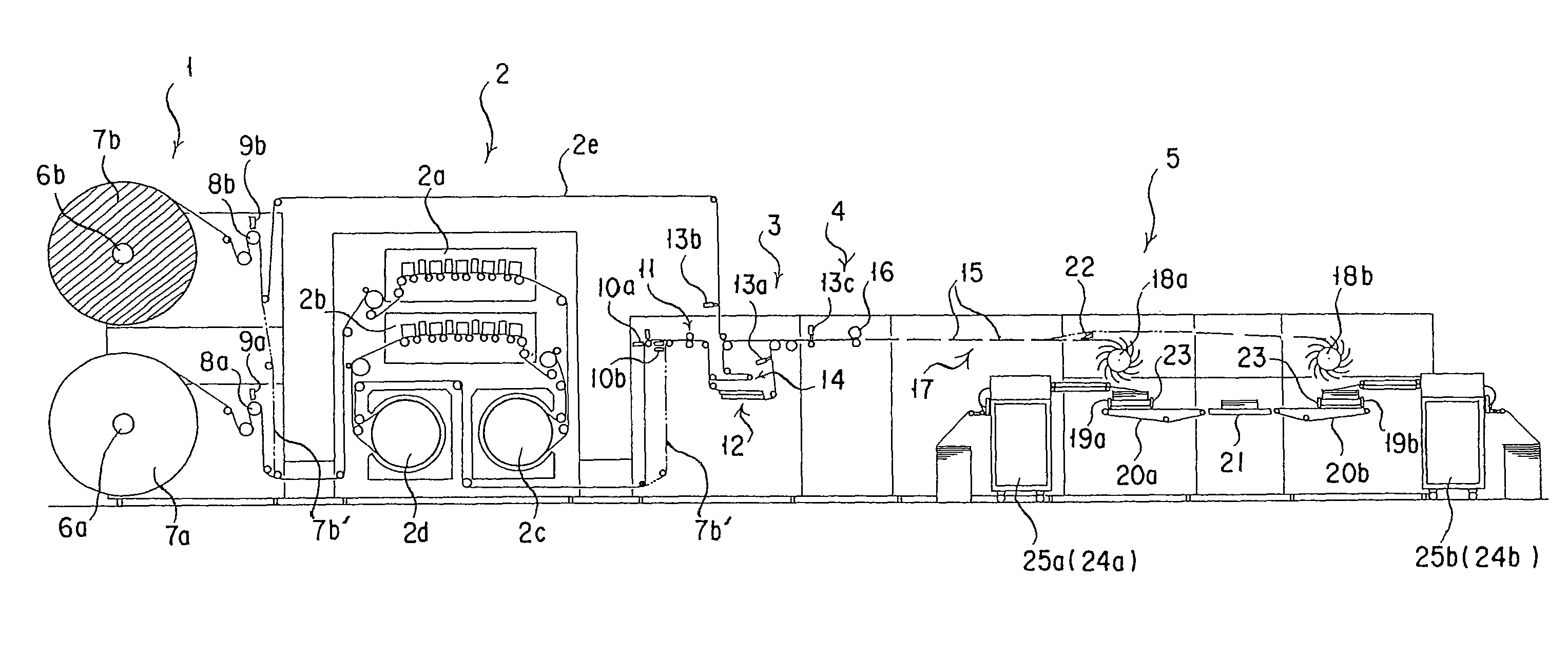

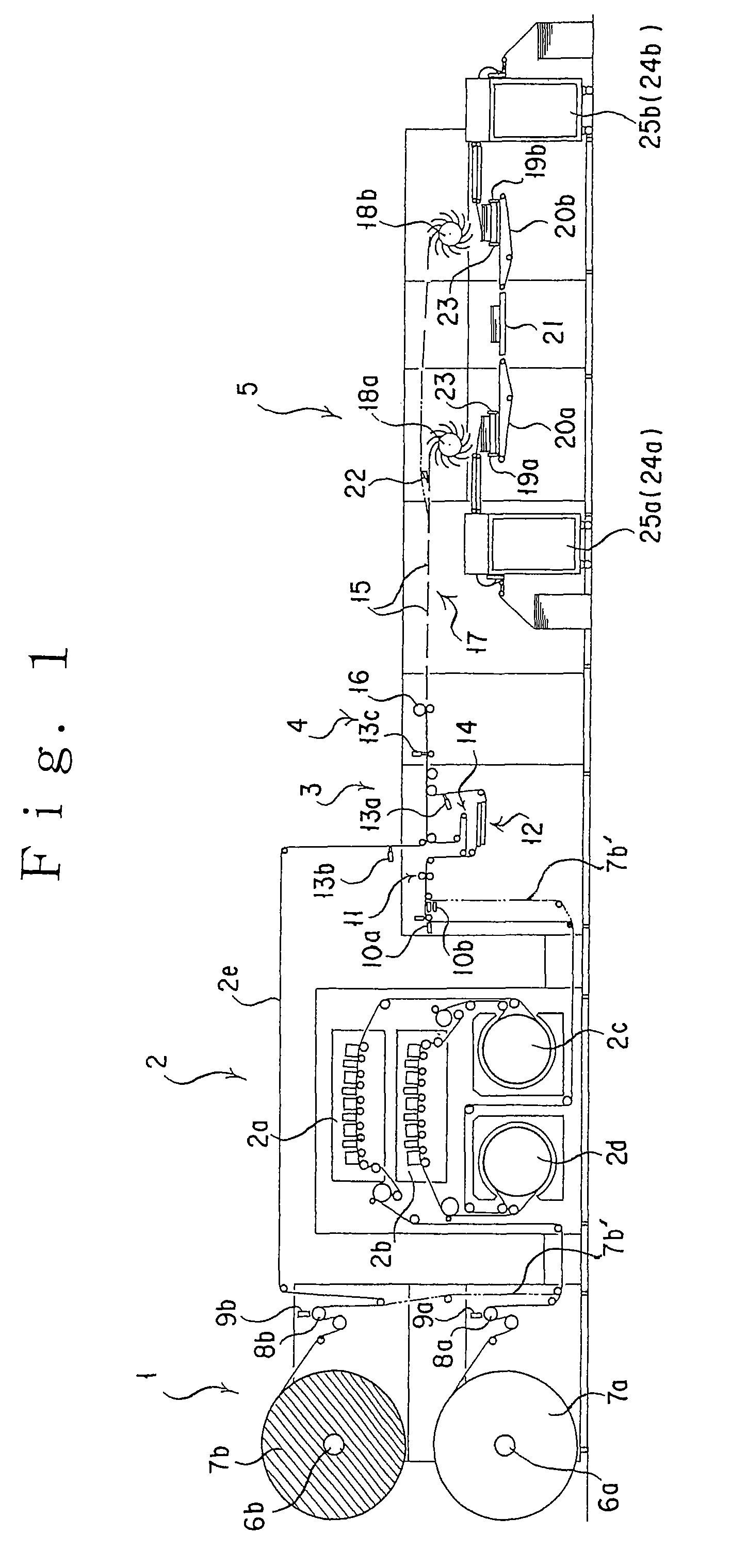

Bookbinding machine and prebinding apparatus

InactiveUS20050100429A1Improve binding efficiencyShort processing timeBookletsBook making processesMechanical engineering

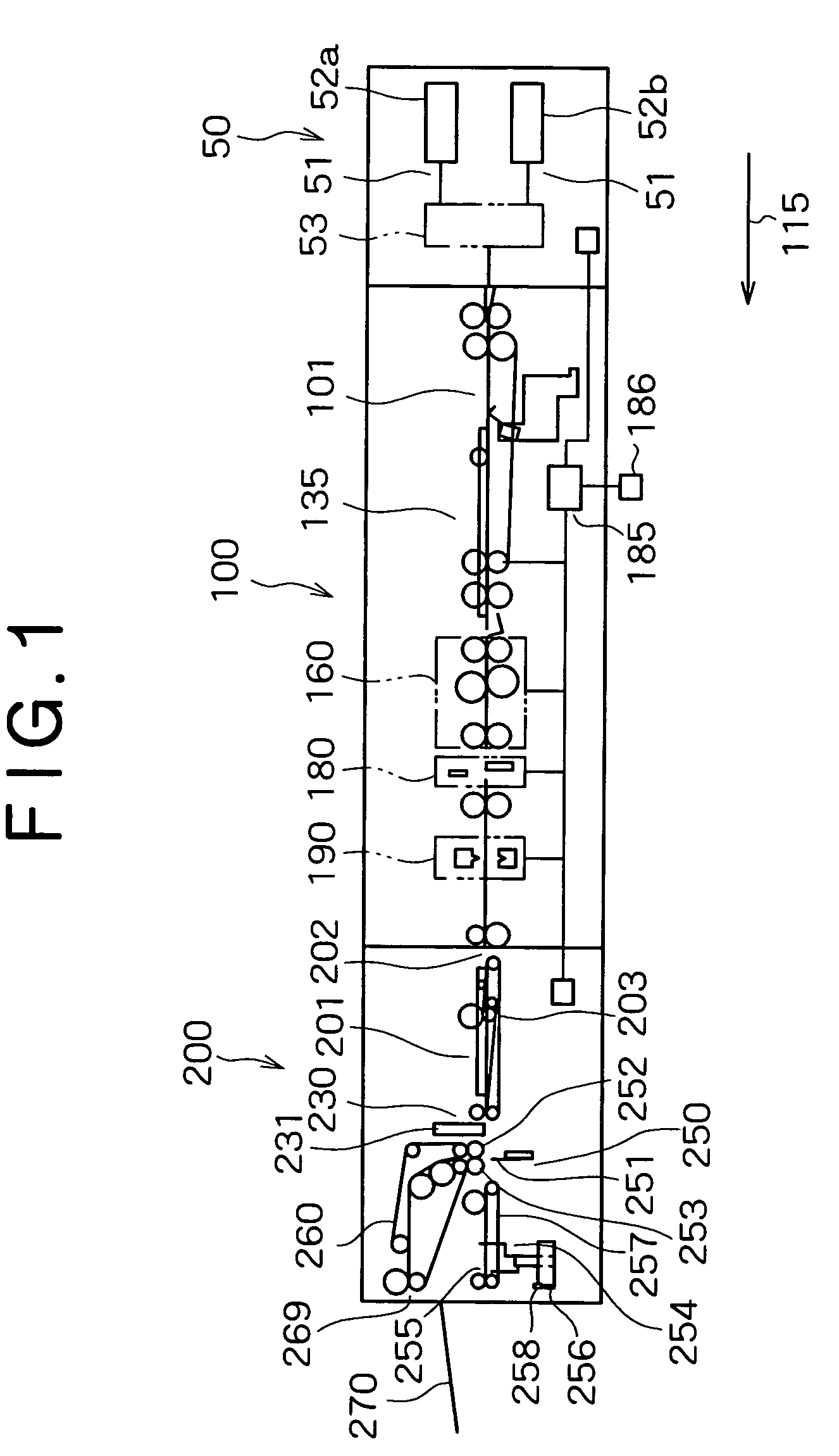

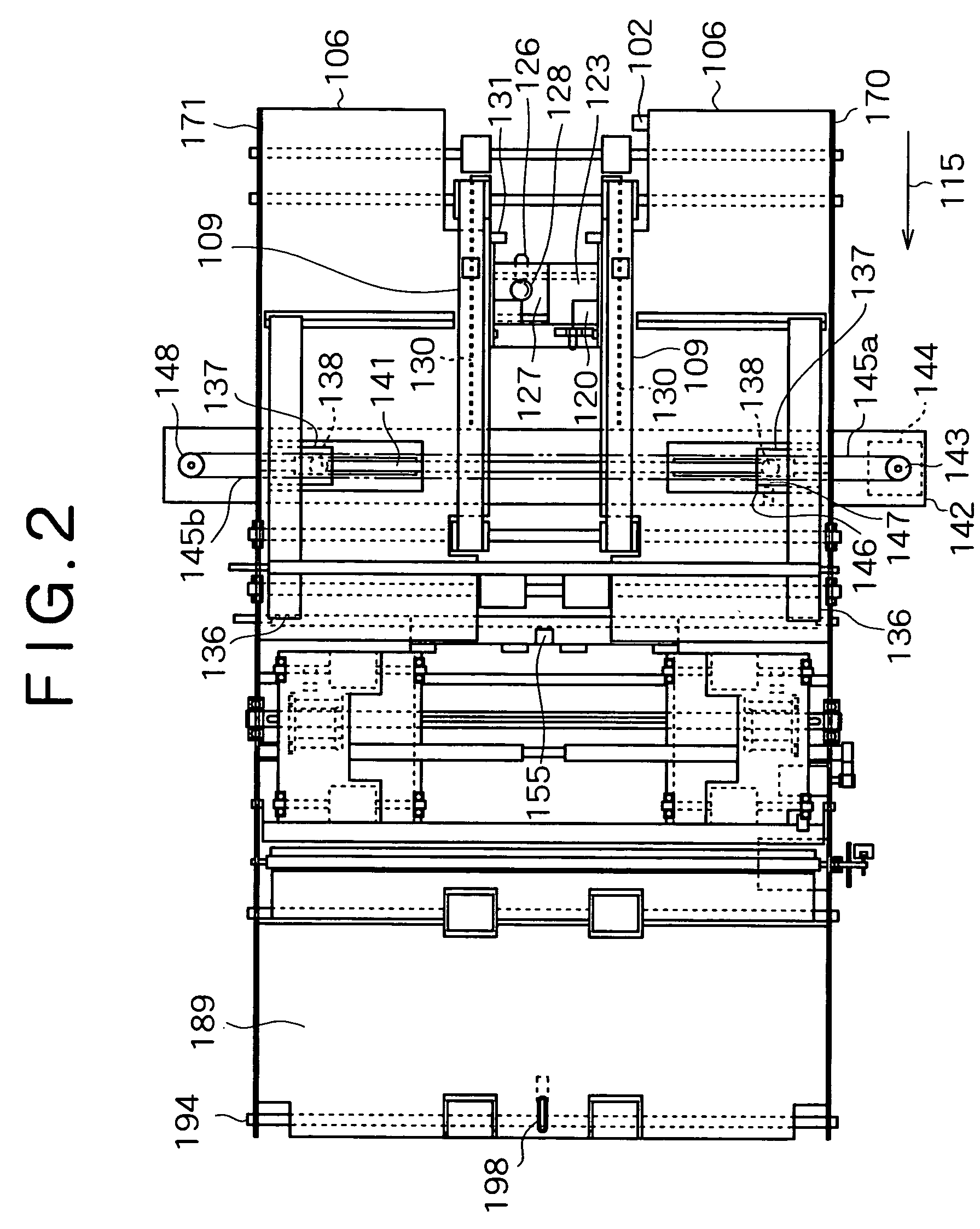

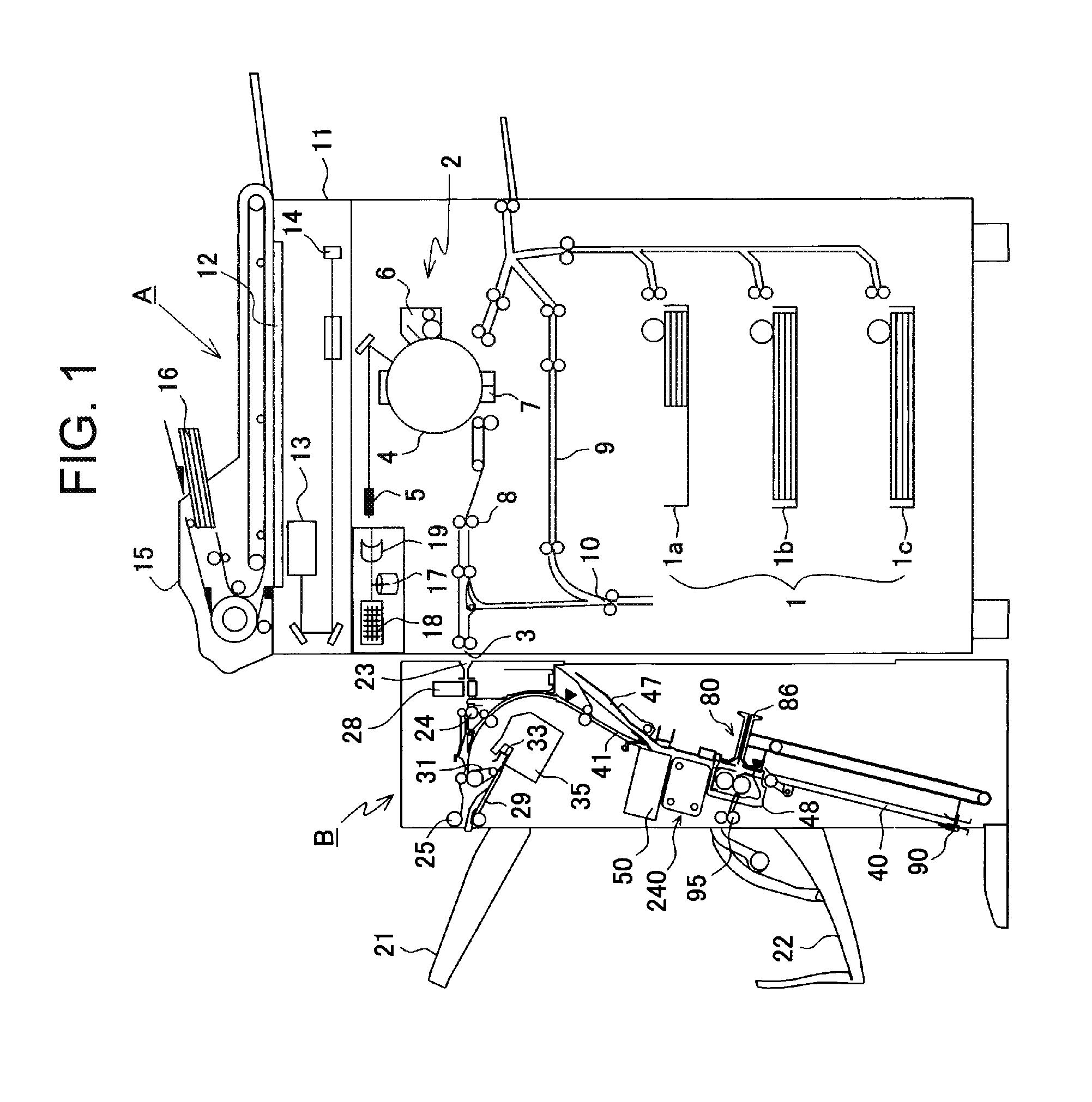

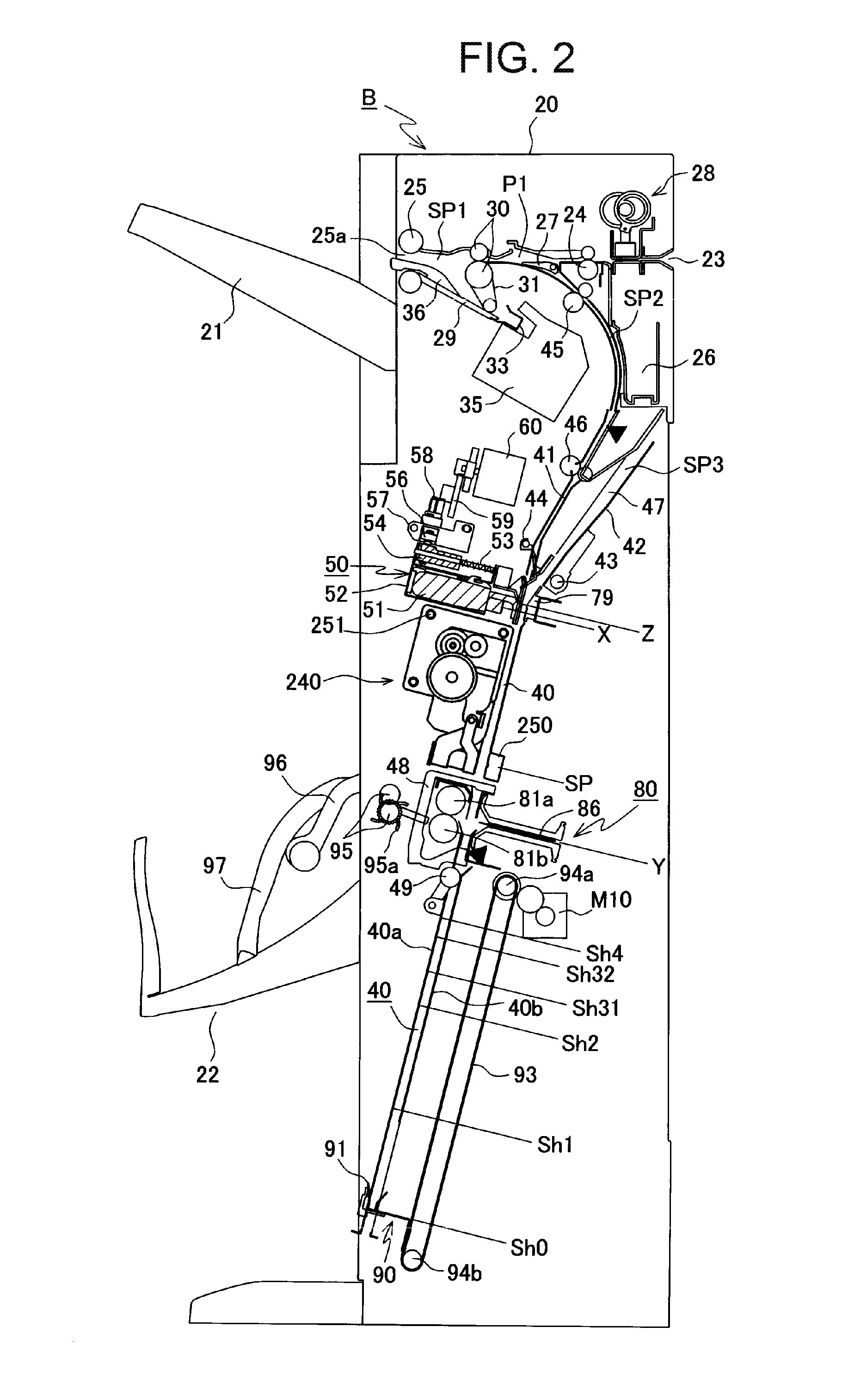

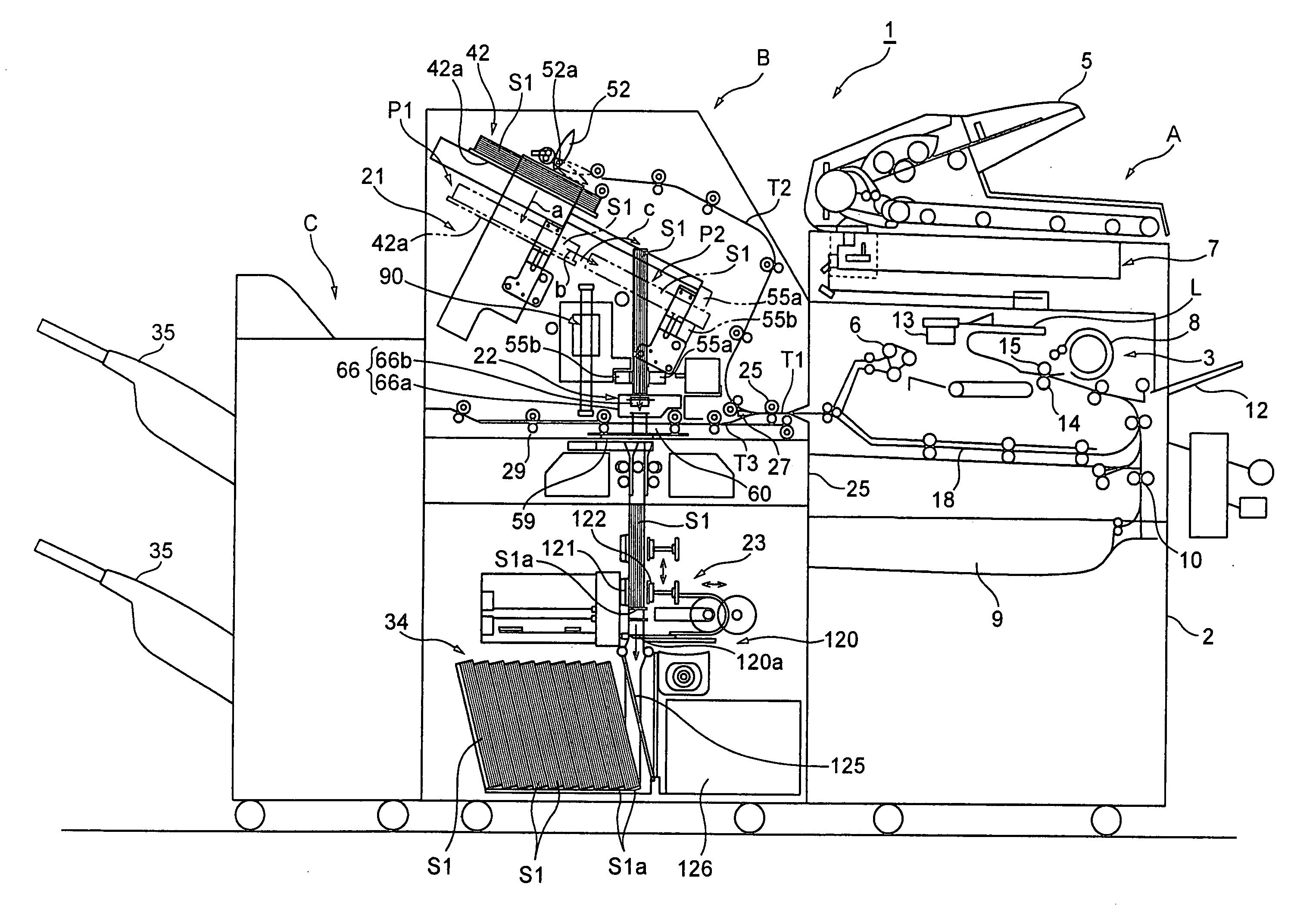

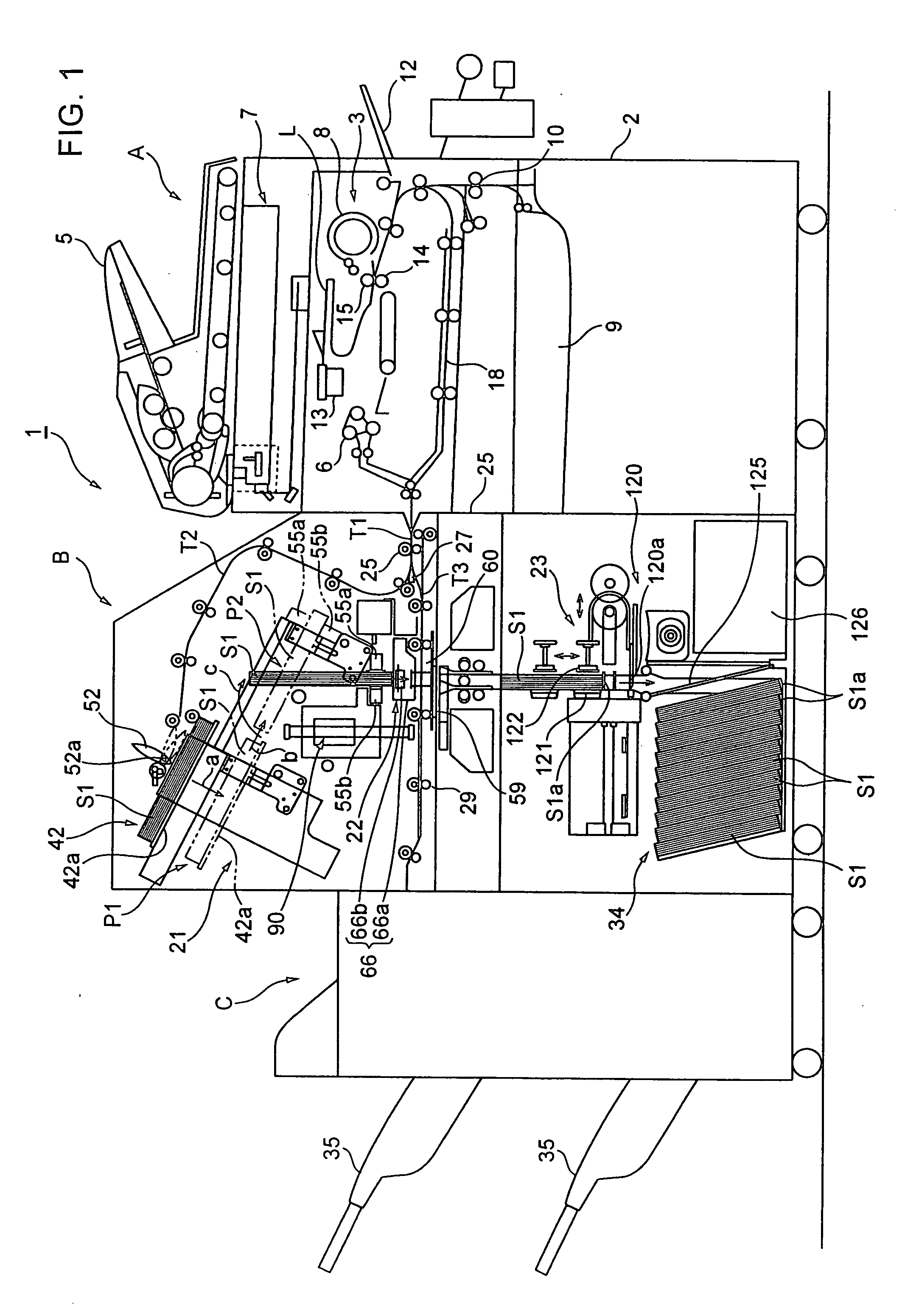

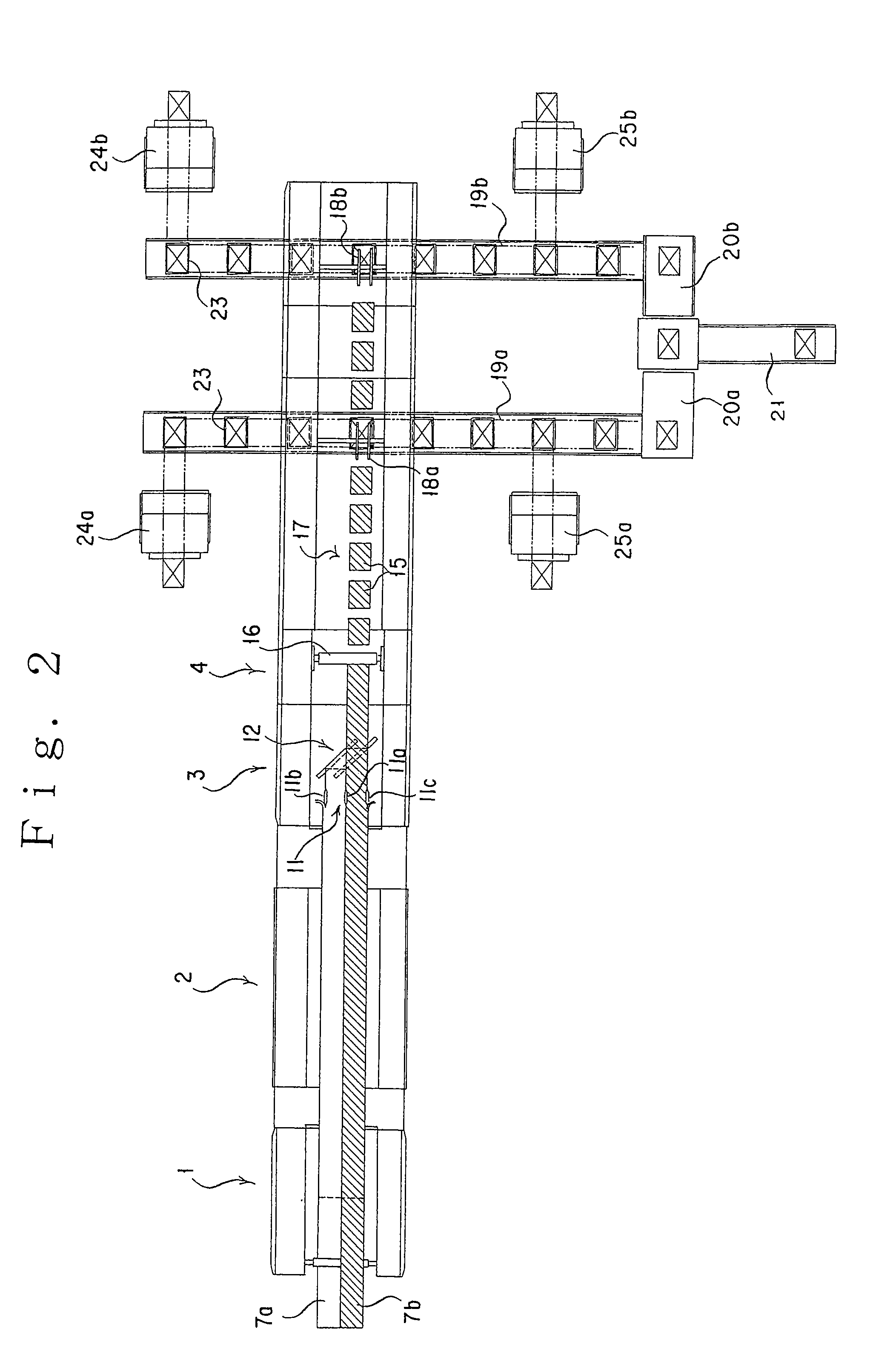

In a bookbinding machine, an image forming apparatus, a prebinding apparatus and a bookbinding apparatus are coupled on line in this order. In the prebinding apparatus, a sheet aligning section, a slitting section which cuts off margins at both side portions of a sheet of paper, a cutting section which cuts off top and bottom margins, and a creasing section are arranged in this order. The prebinding apparatus is provided with a control section which sorts out supplied sheets of paper into those which need an SCC step and those which do not, and performs the SCC step only on the sheets of paper that need the SCC step.

Owner:DUPLO CORP

Bookbinding machine and prebinding apparatus

Owner:DUPLO CORP

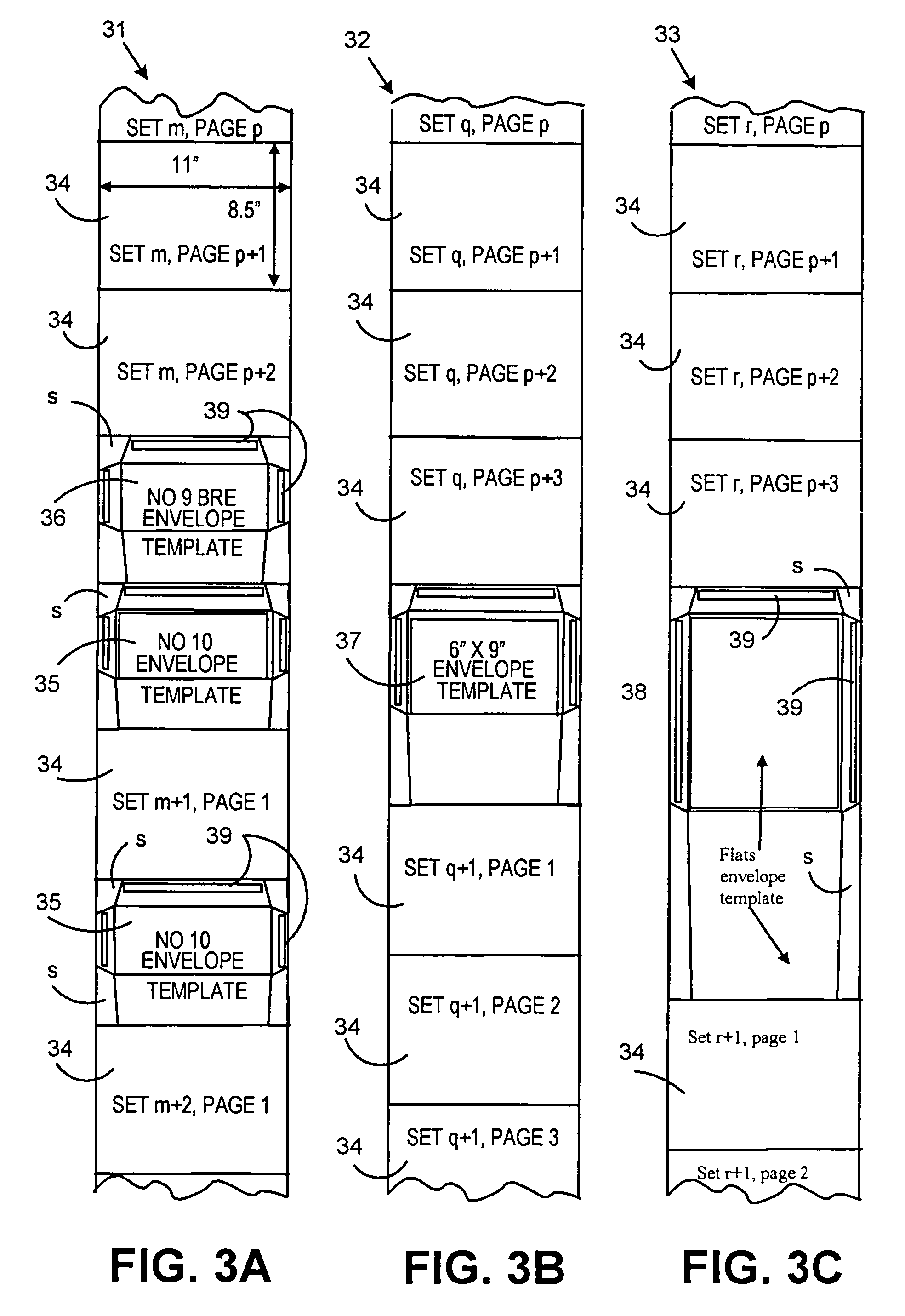

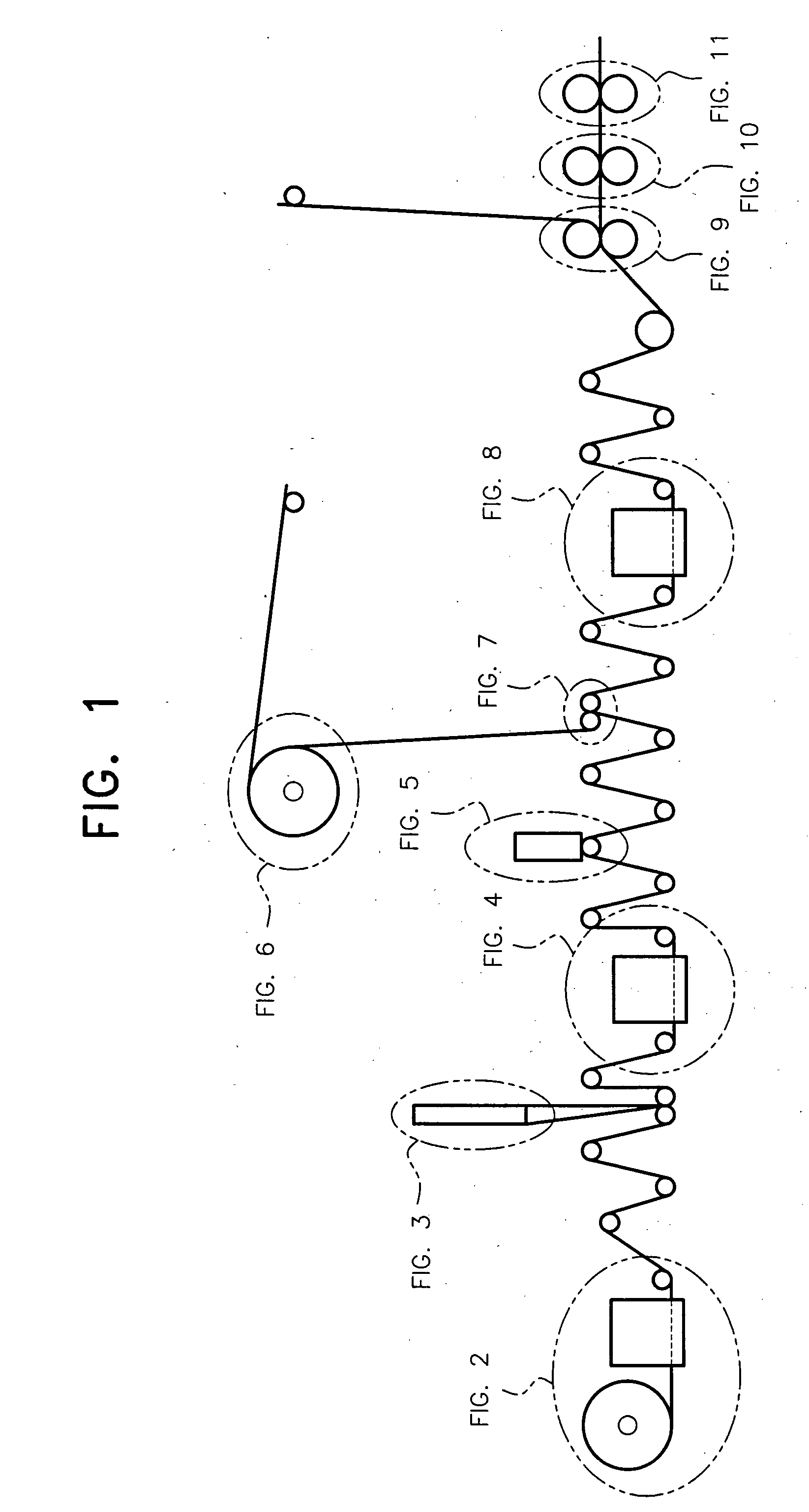

Method and system for creating mailpieces from a single continuous web of printed material

ActiveUS7231750B2Reduce unreliabilitySimple equipmentEnvelopes/bags making machineryBag making operationsEngineeringPaper sheet

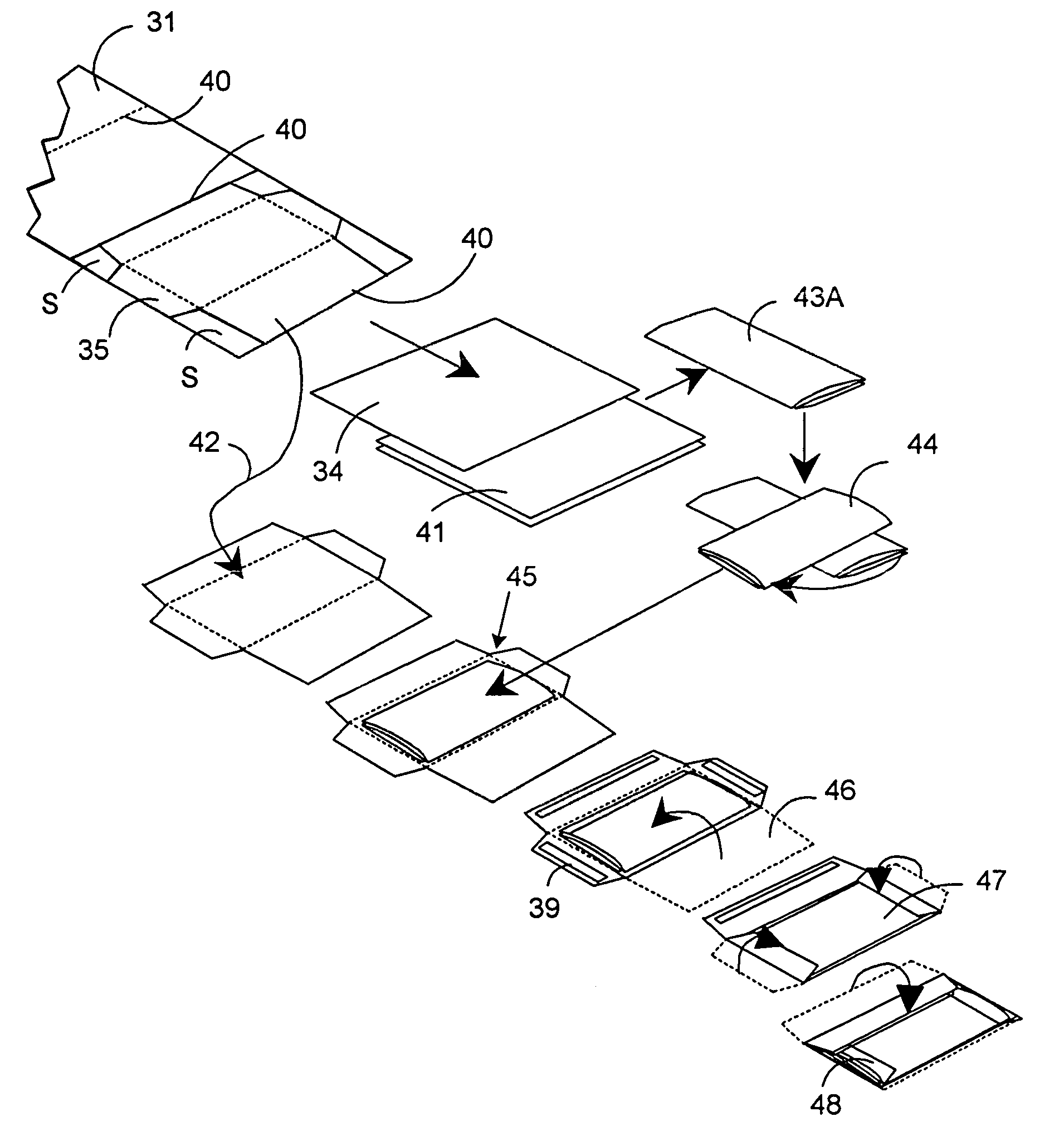

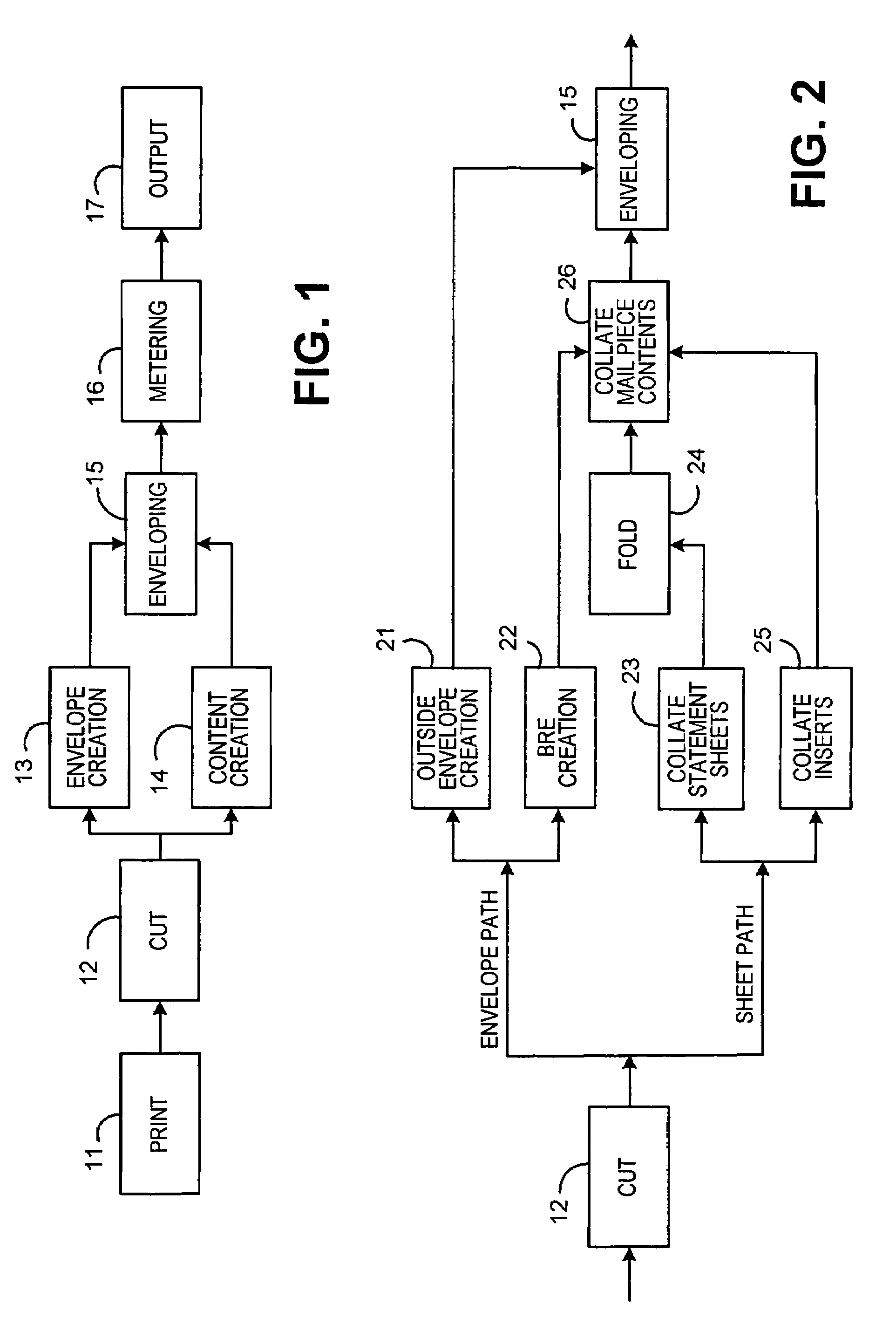

A method for creating mailpieces from a single web of printed material. The web of printed material includes printed matter to be used on envelopes, and other printed matter to be used on mail content to be included in the envelopes. The content pages are rectangular in shape and may be oriented relative to the envelope sheets in a number of different configurations. In some configurations, two sets of content pages and / or envelope sheets can be printed across the width of the web. The method starts with cutting consecutive sections of the web into separated sheets. Some of the separated sheets are envelope sheets including envelope printed matter, and some of the sheets are mail content sheets including mail content printed matter. The method includes cutting variable sized sheets depending on whether a sheet is a mail content sheet, or an envelope sheet. The method further includes cutting variable sized envelope sheets depending on the size of the mailpieces. In a preferred embodiment, the web includes business return envelopes (BREs). The BRE sheets are transported to an envelope creation path and in the envelope creation path where the sheets are formed into envelopes. The envelope creation path is then merged back with a content processing path whereby finished BRE's are stacked with their respective accumulations of folded content sheets to form a complete content stack. BRE's are then enclosed with the content sheets by the enclosing envelope sheets.

Owner:DMT SOLUTIONS GLOBAL CORP

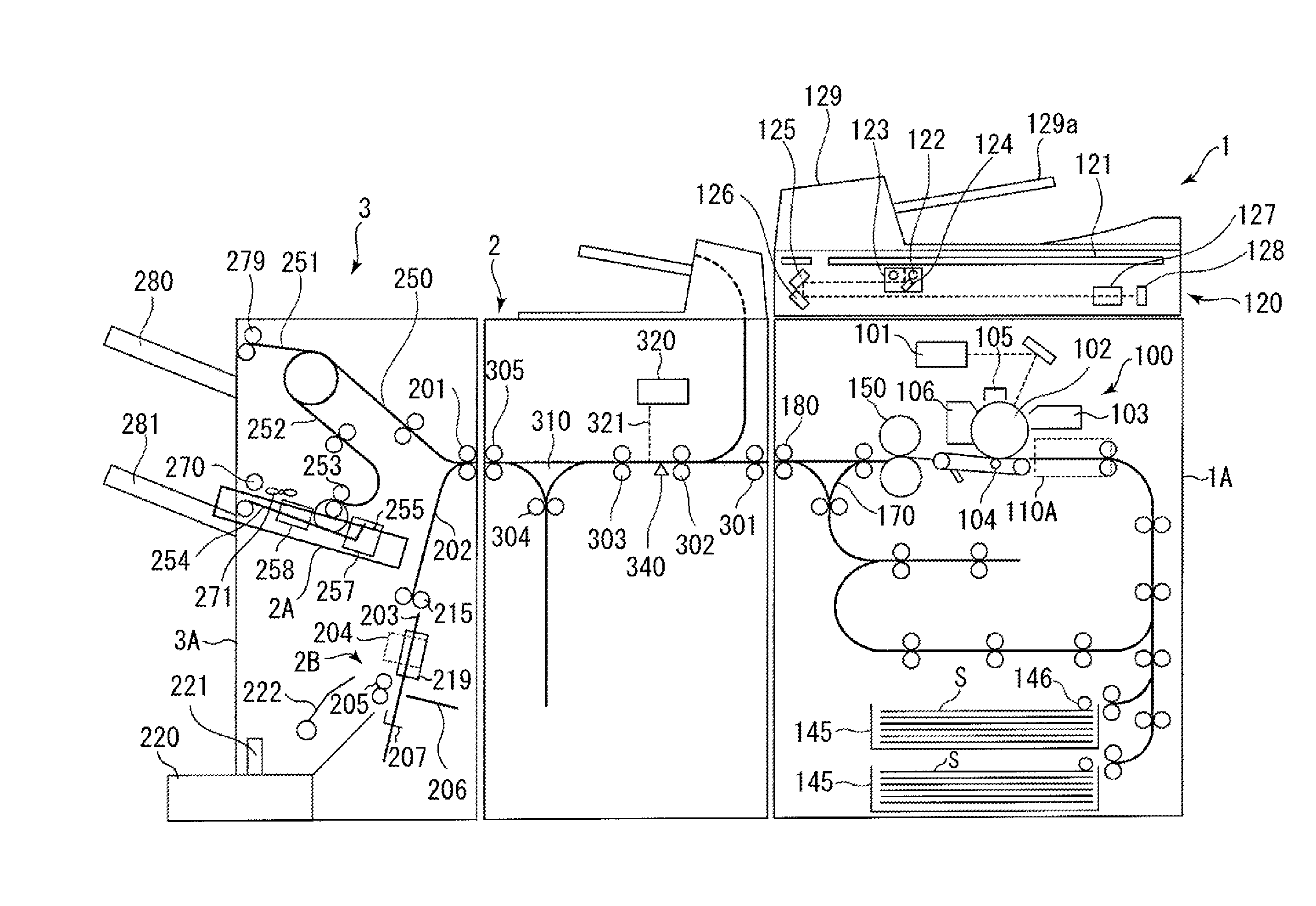

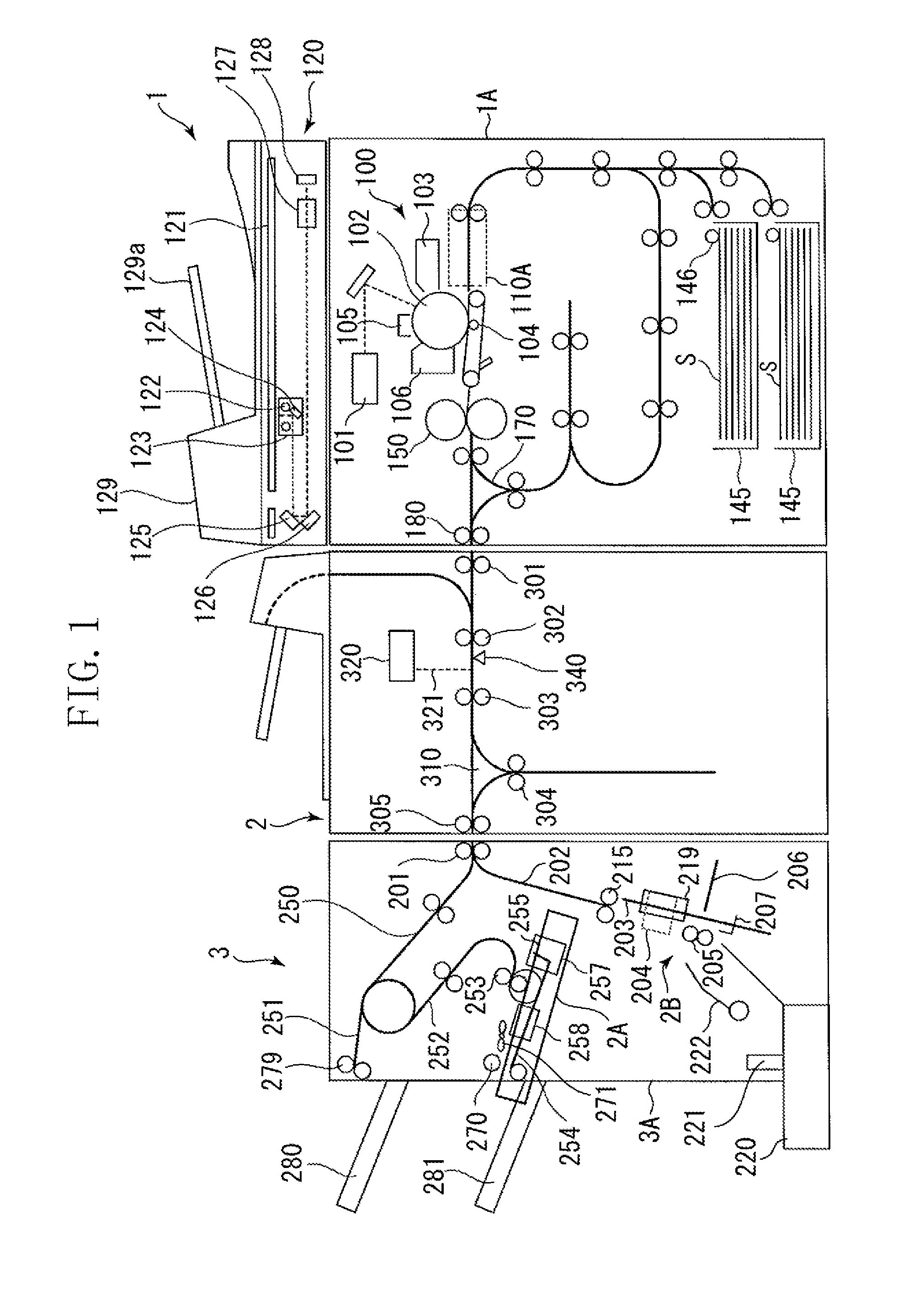

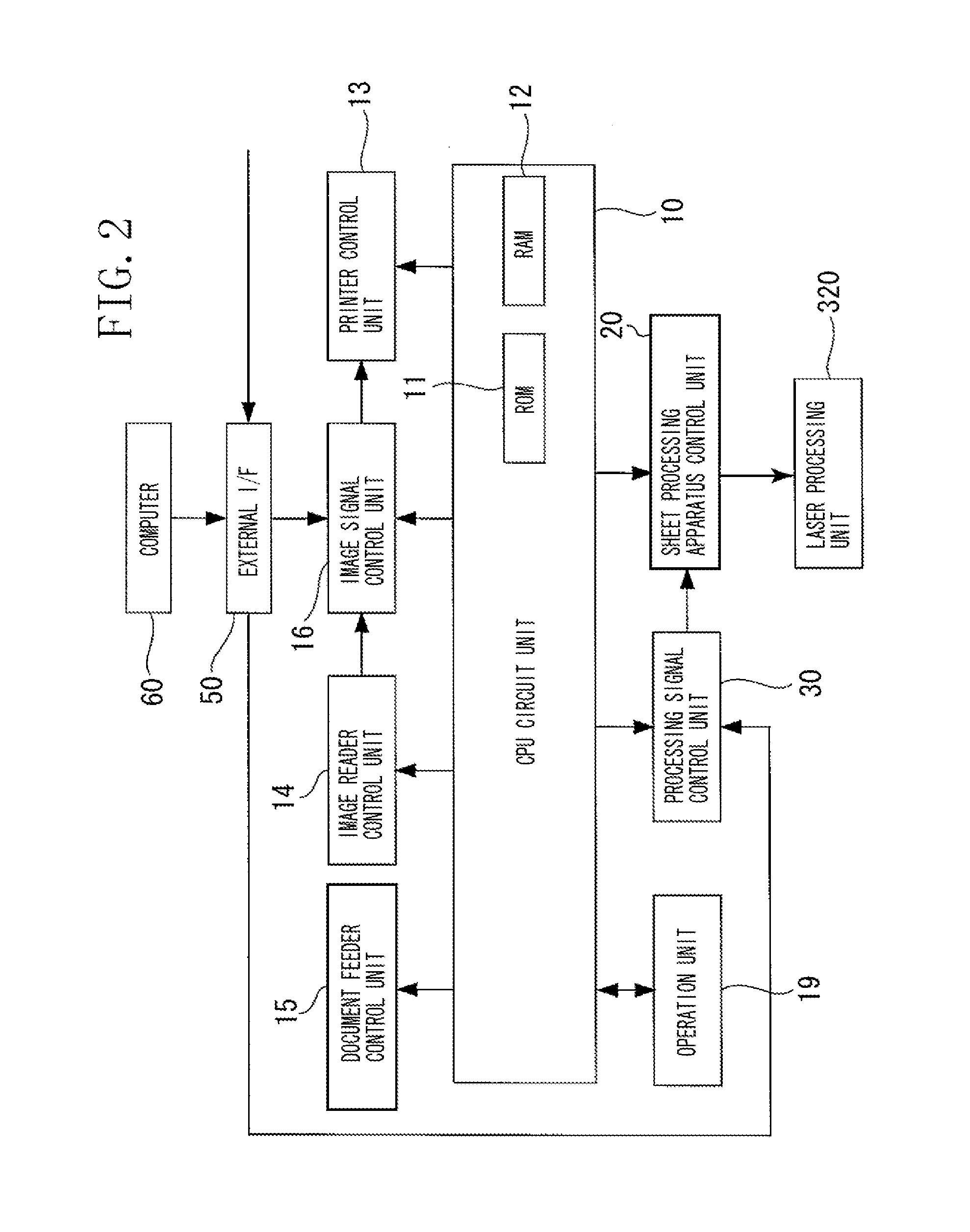

Sheet processing apparatus and image forming system

A sheet processing apparatus includes a conveying unit that conveys a booklet formed by folding a sheet bundle; a processing unit that performs a predetermined process on the booklet; a booklet holding unit that includes first and second holding members to hold the booklet and varies a gap distance between the first and second holding members depending on a state of processing the booklet while the sheet processing unit is performing the process on the booklet; and a pressing unit that presses and fixes the booklet while the processing unit is processing the booklet

Owner:RICOH KK

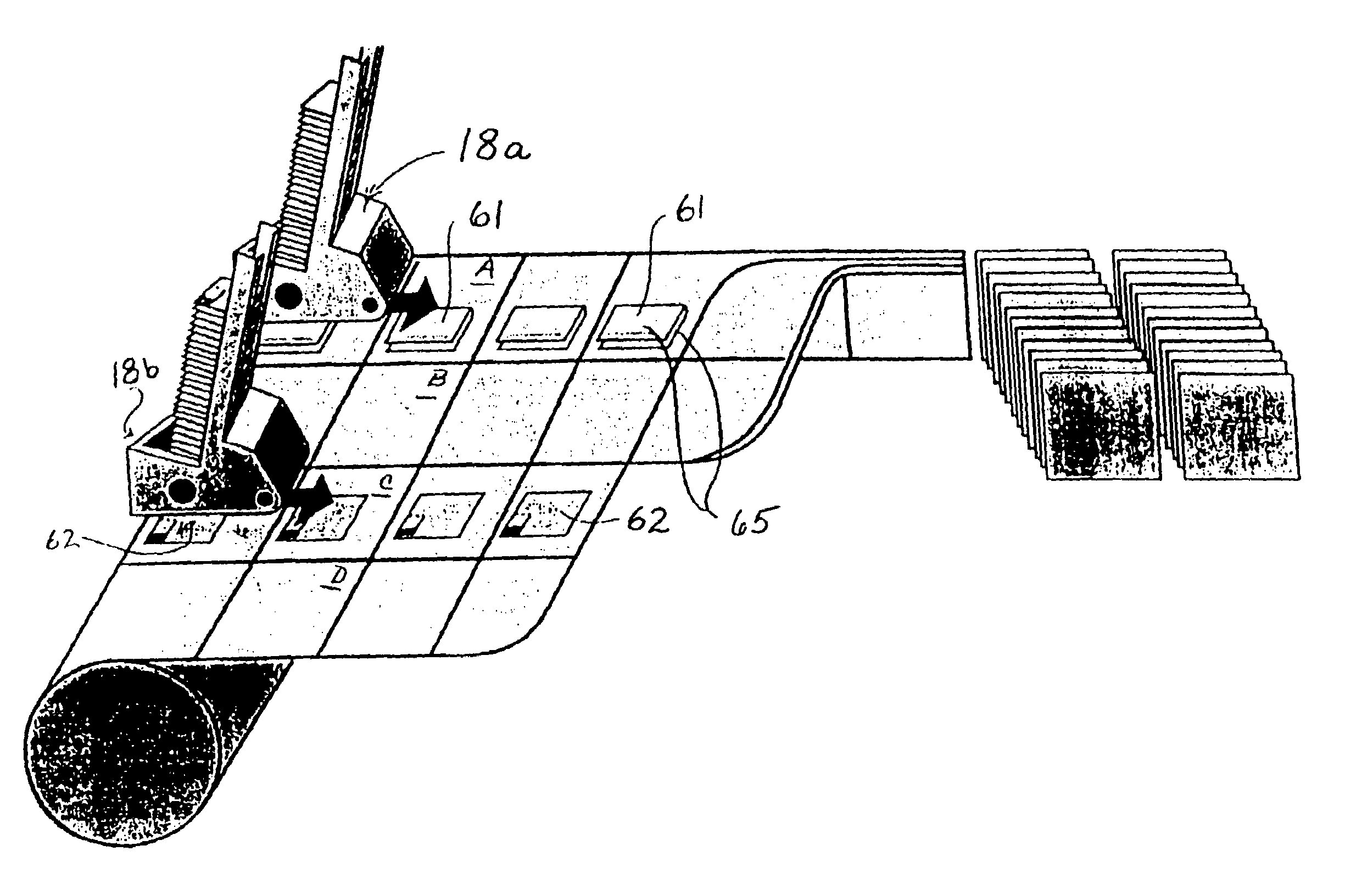

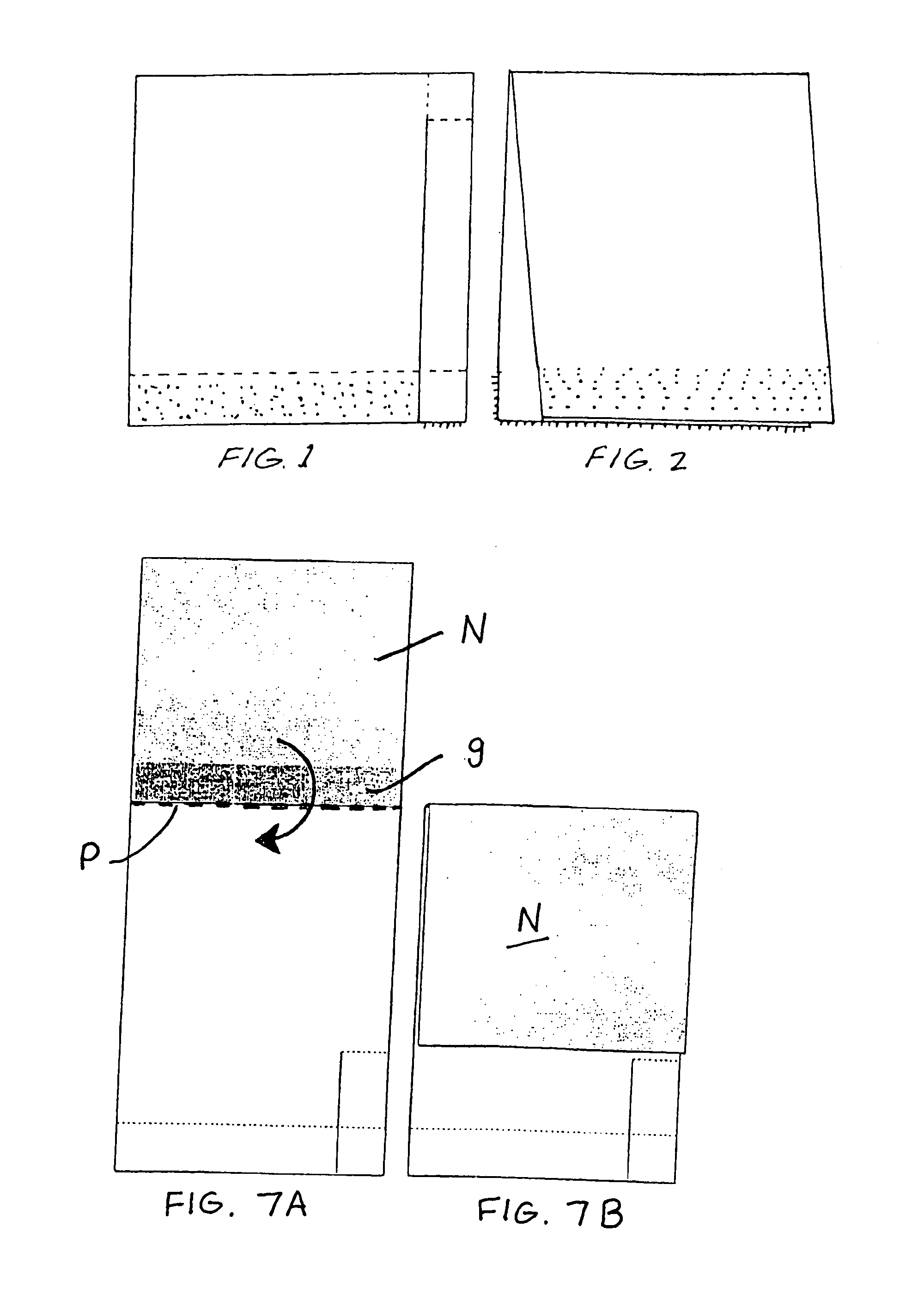

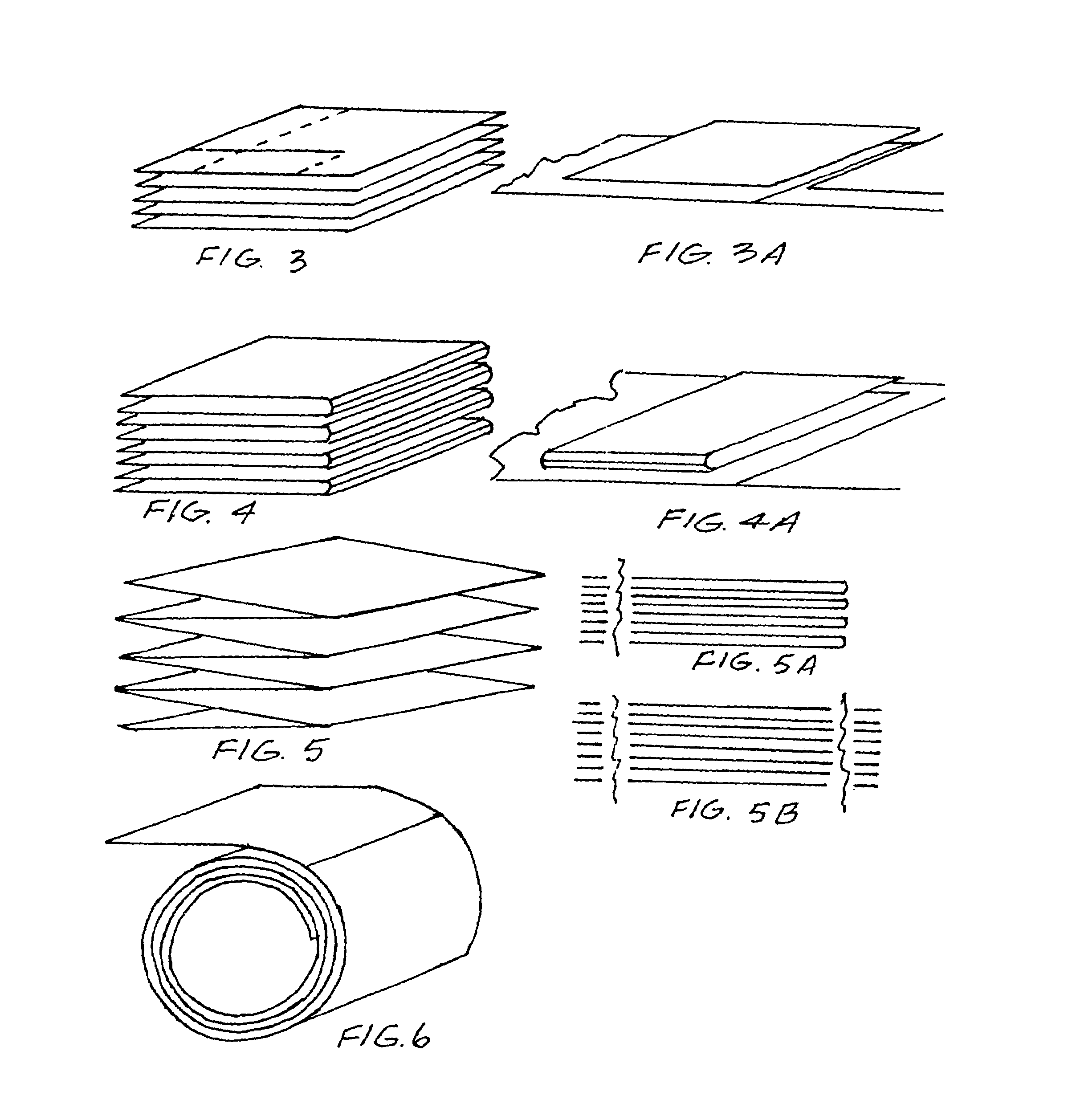

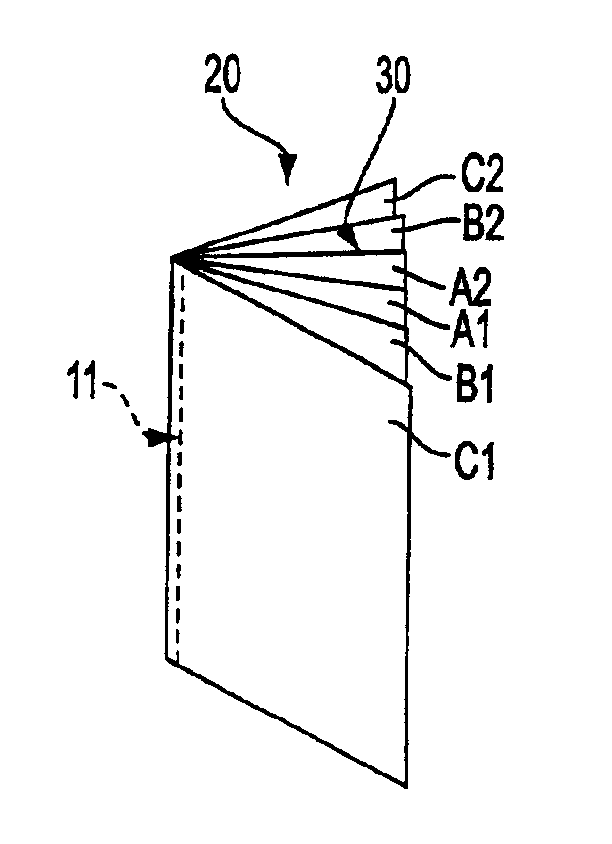

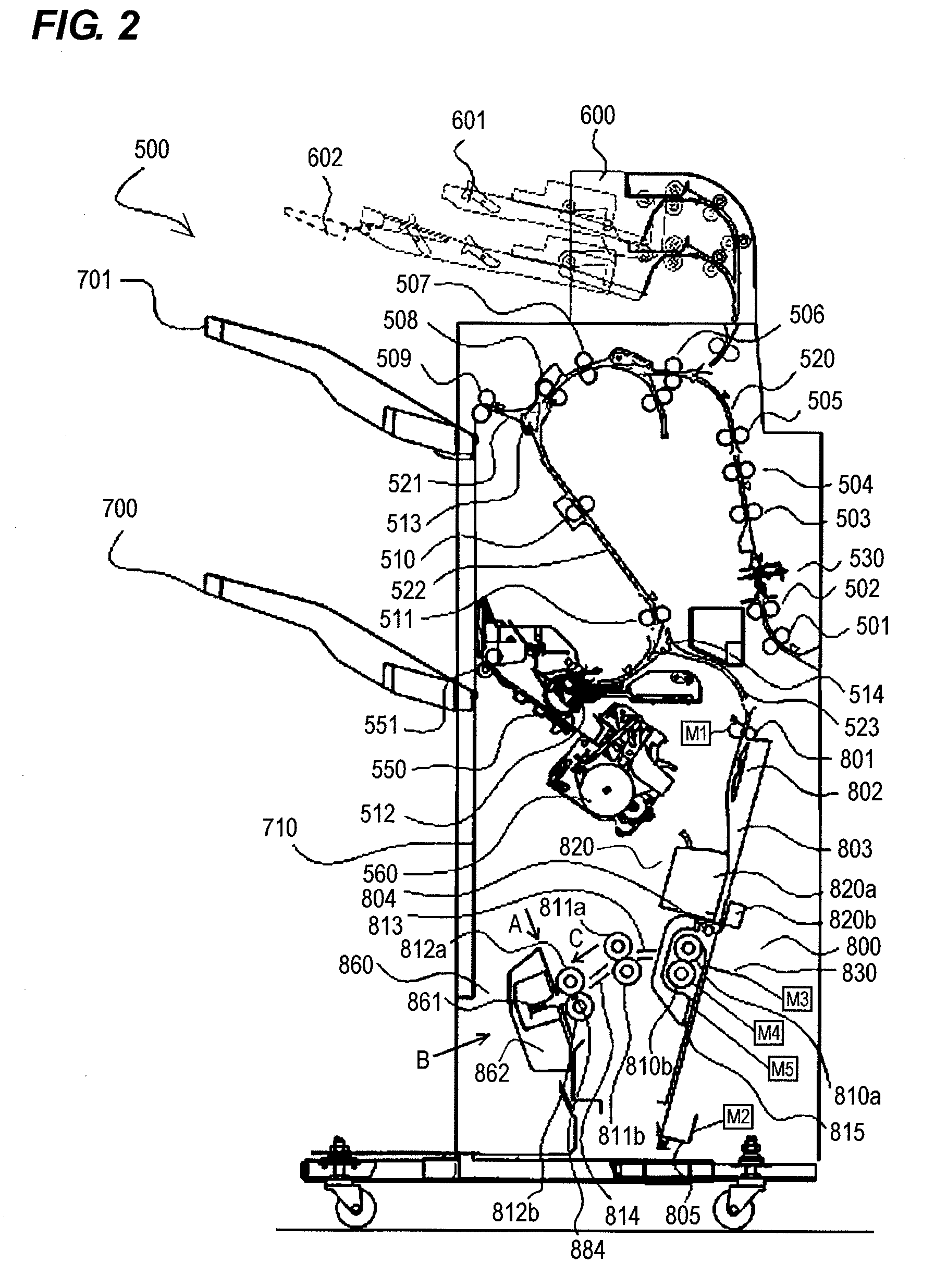

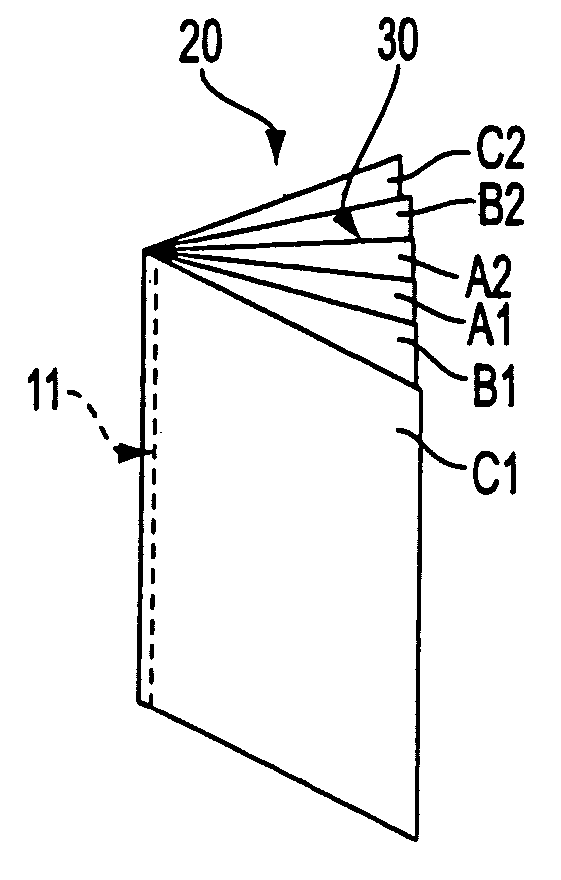

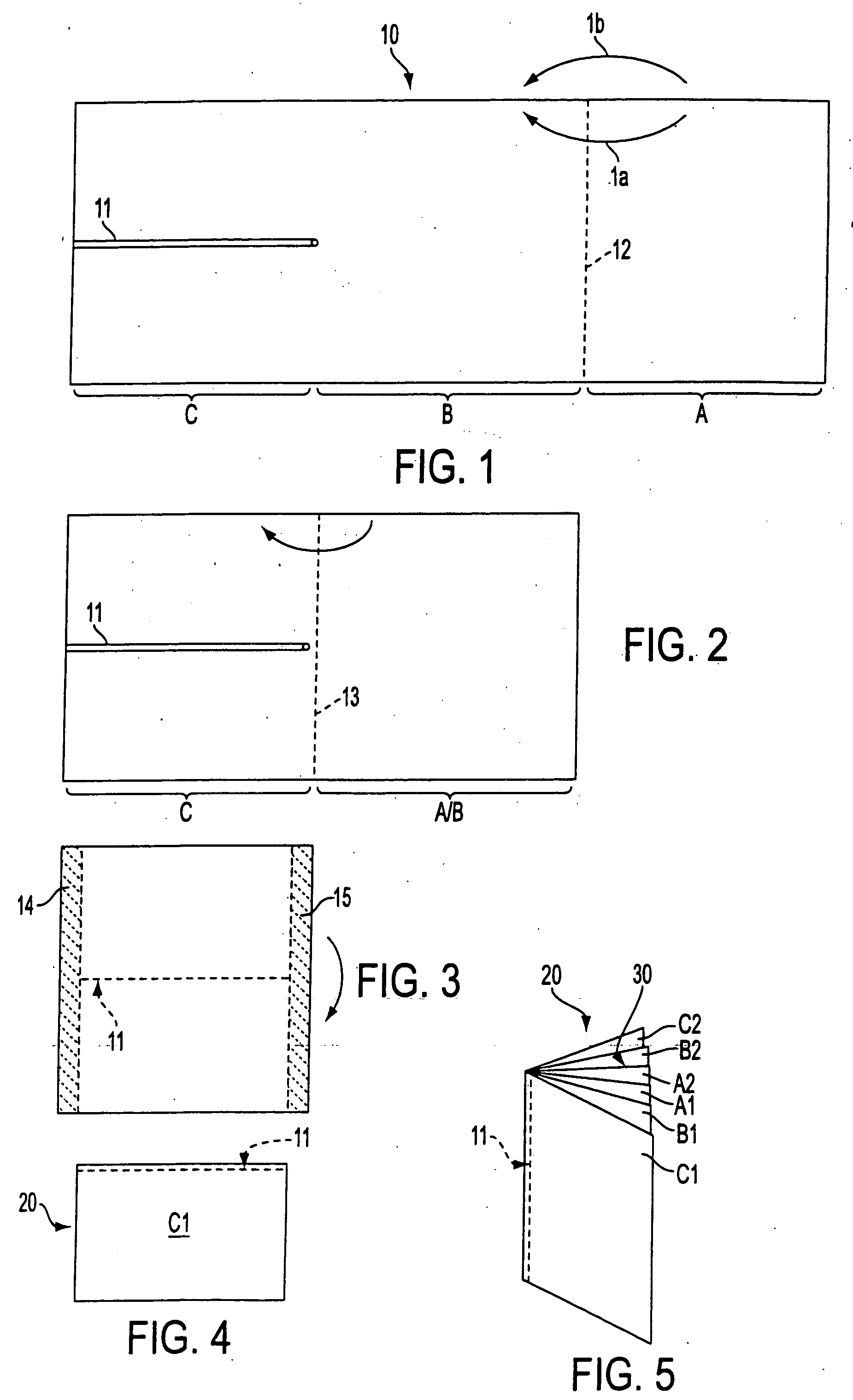

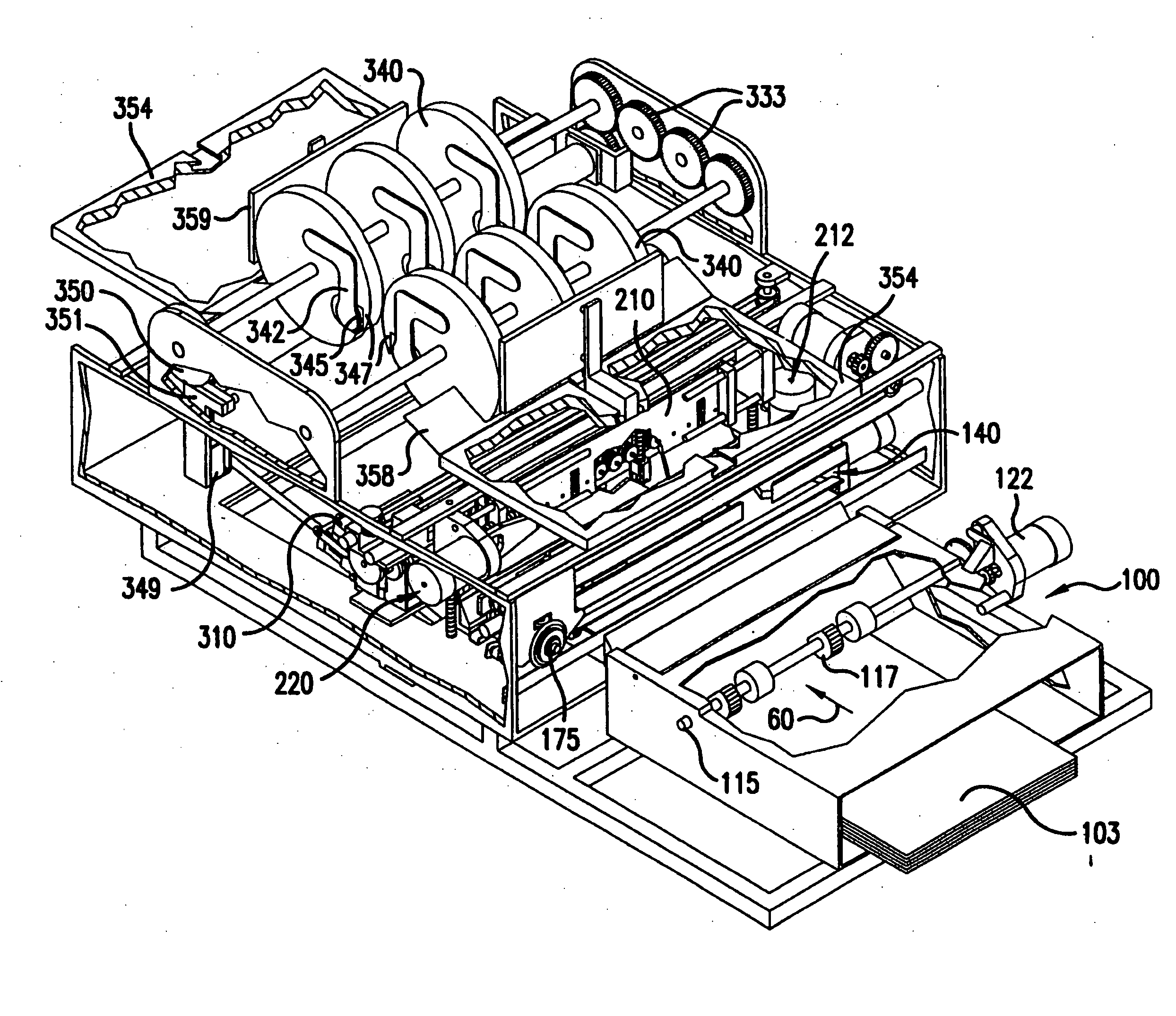

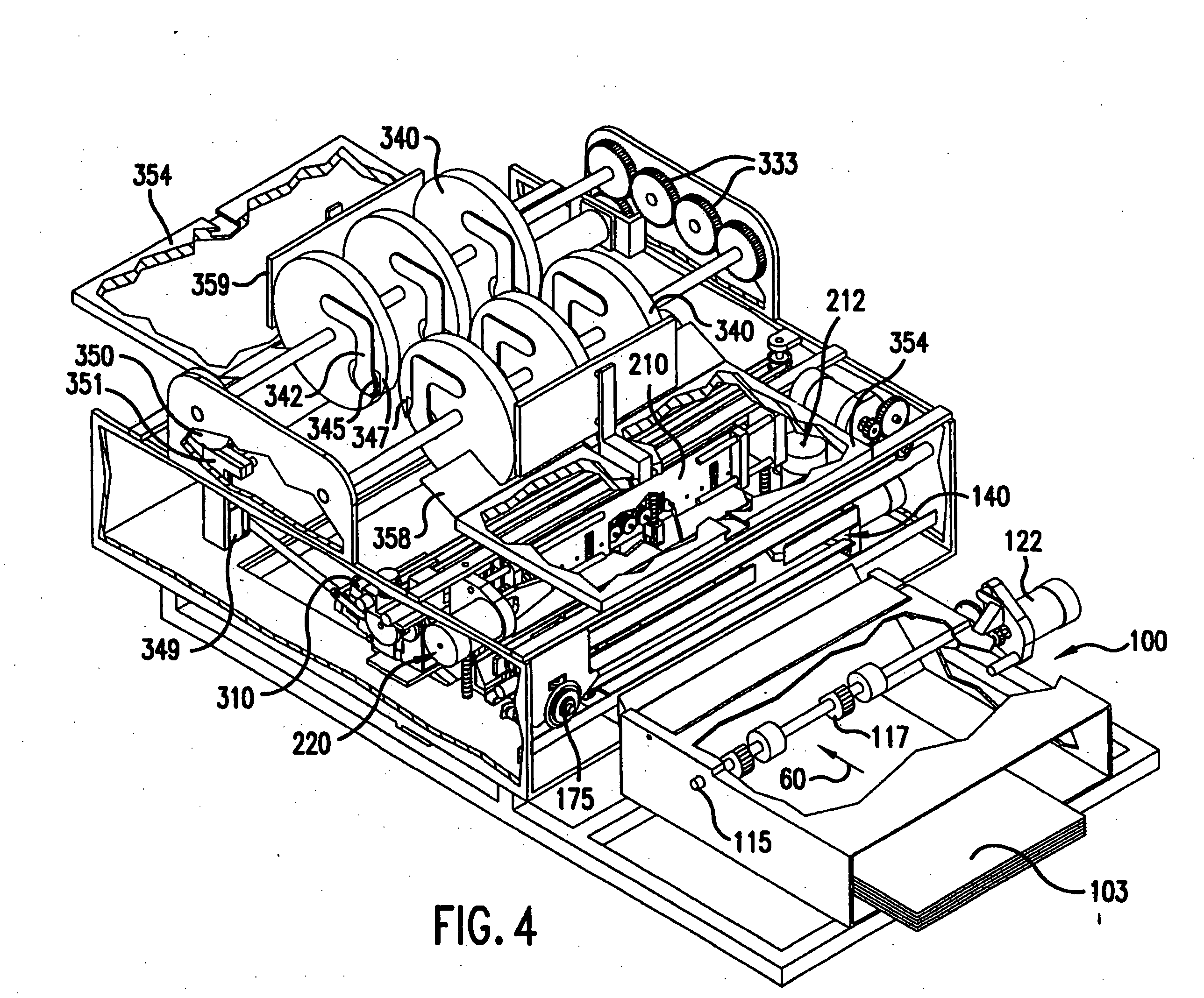

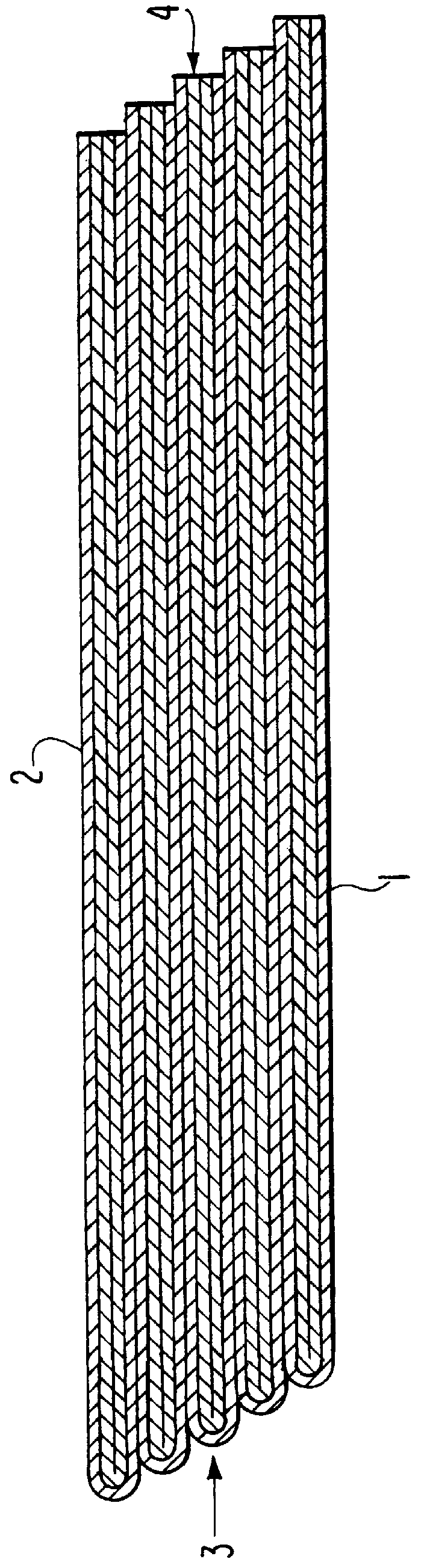

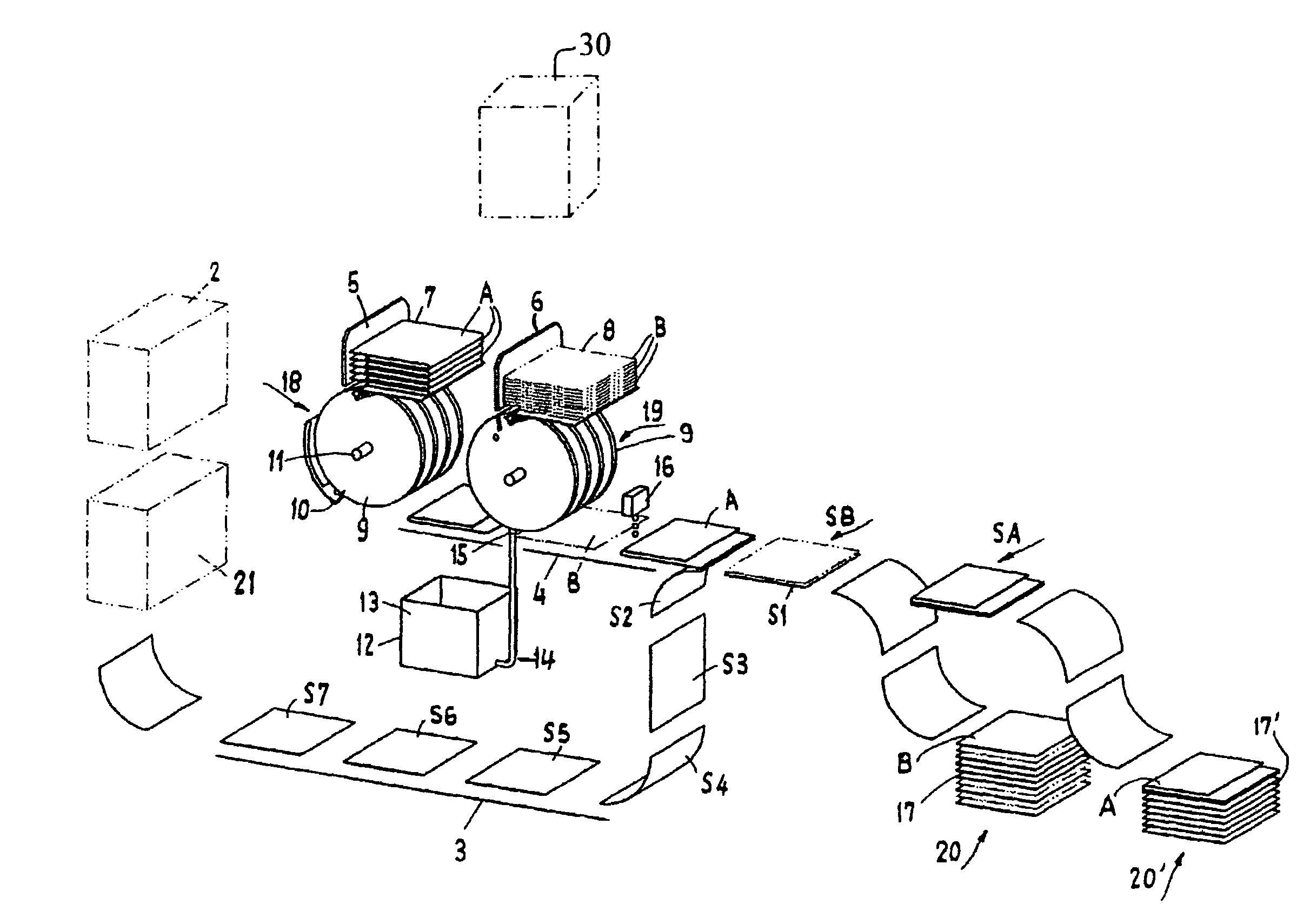

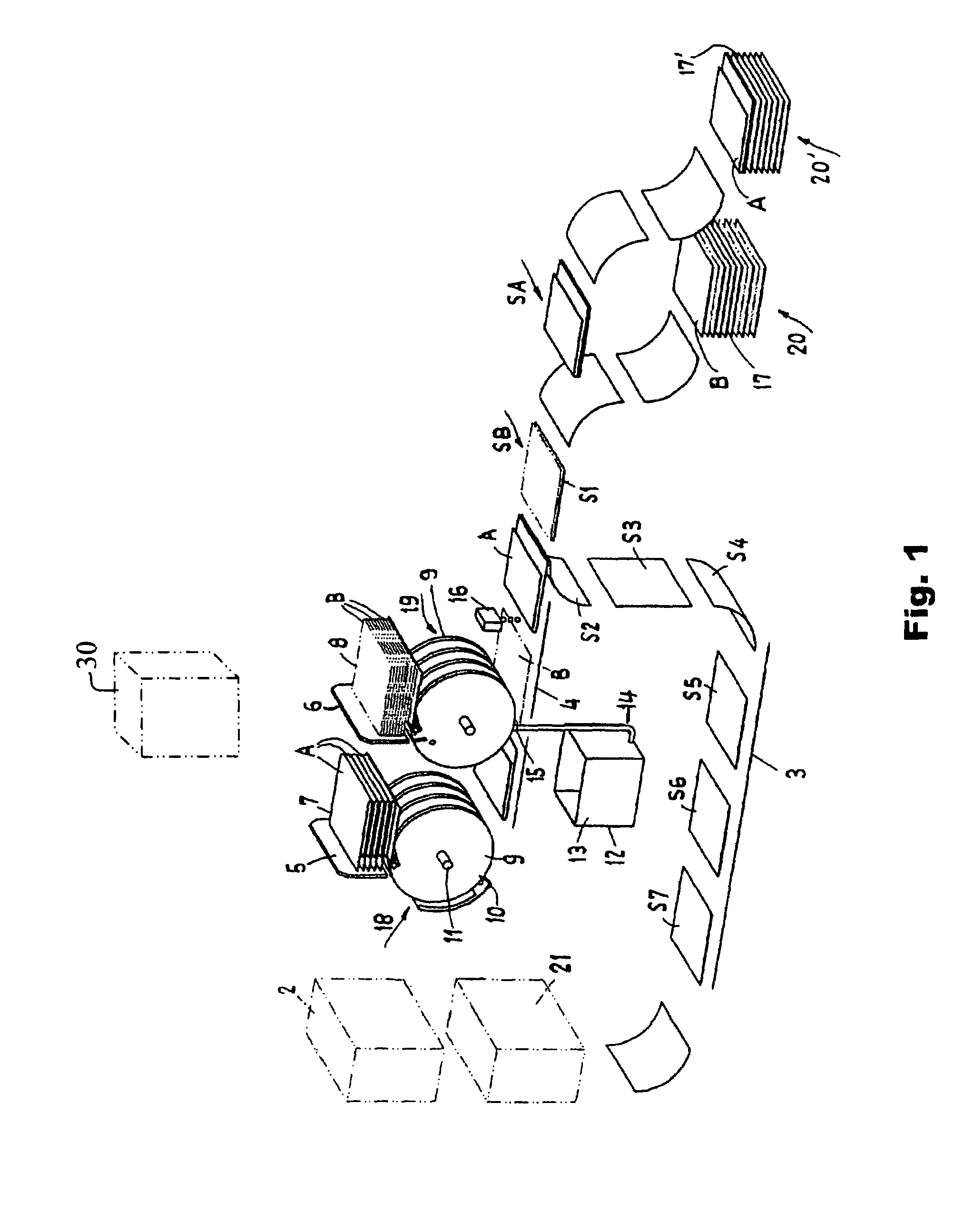

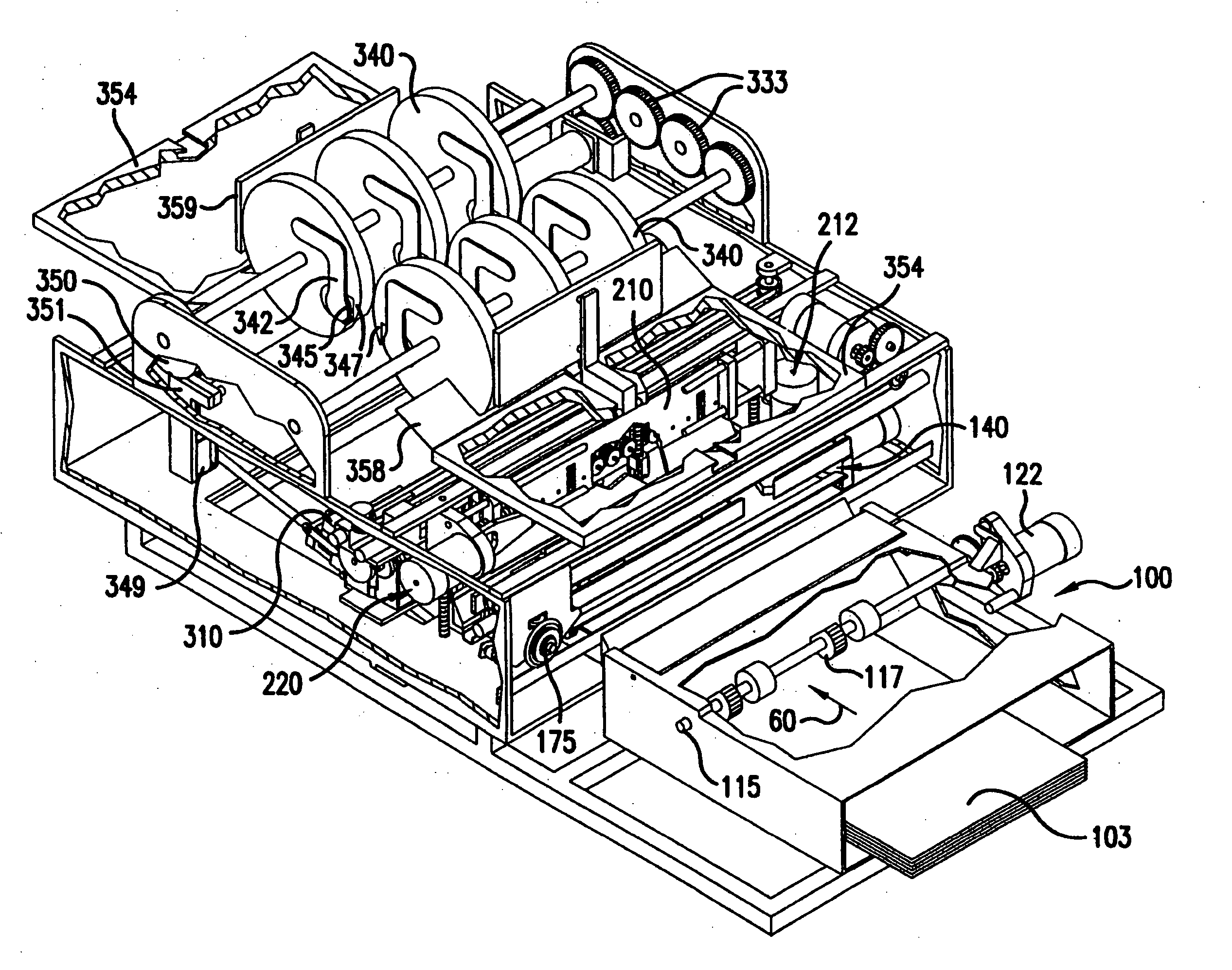

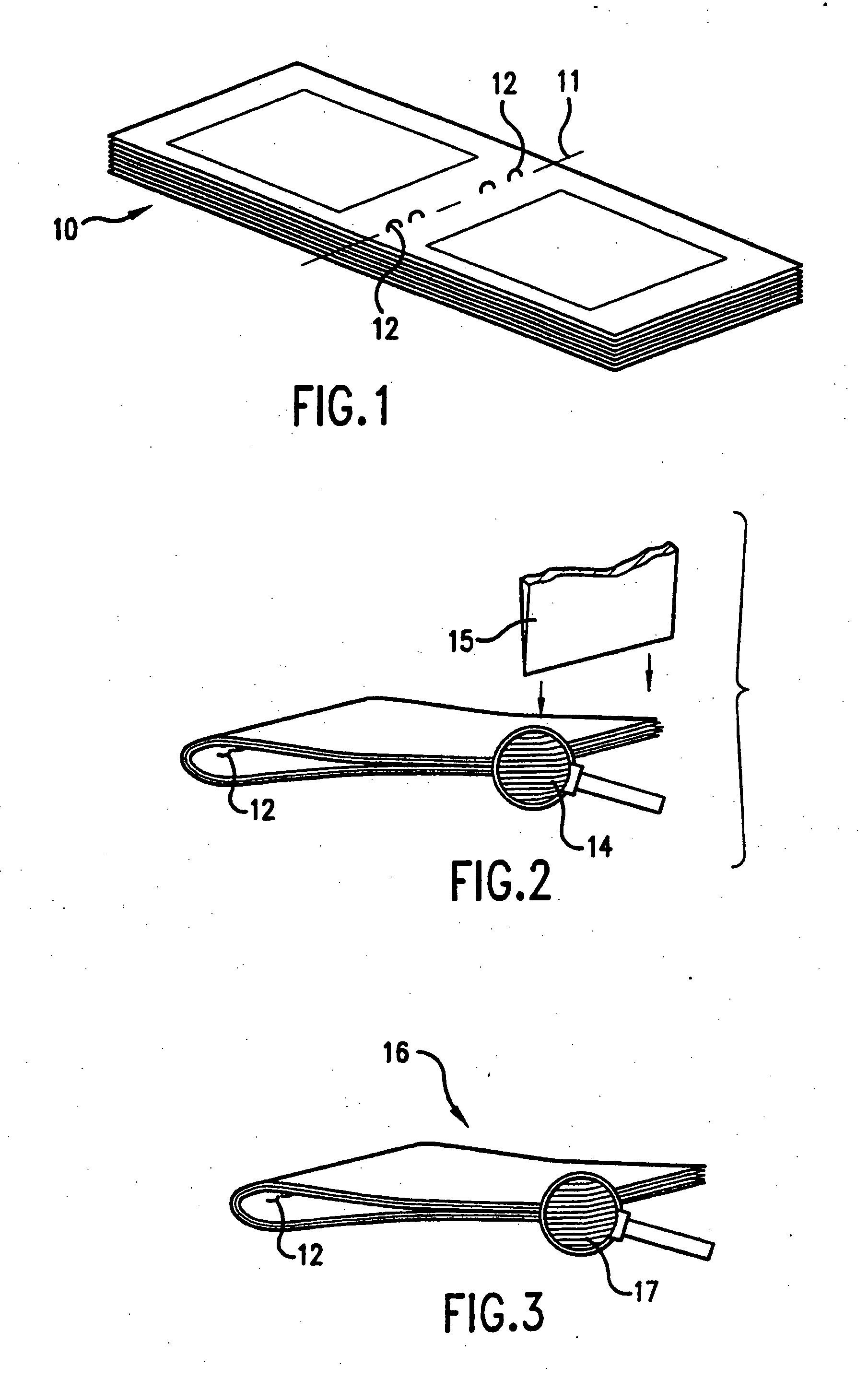

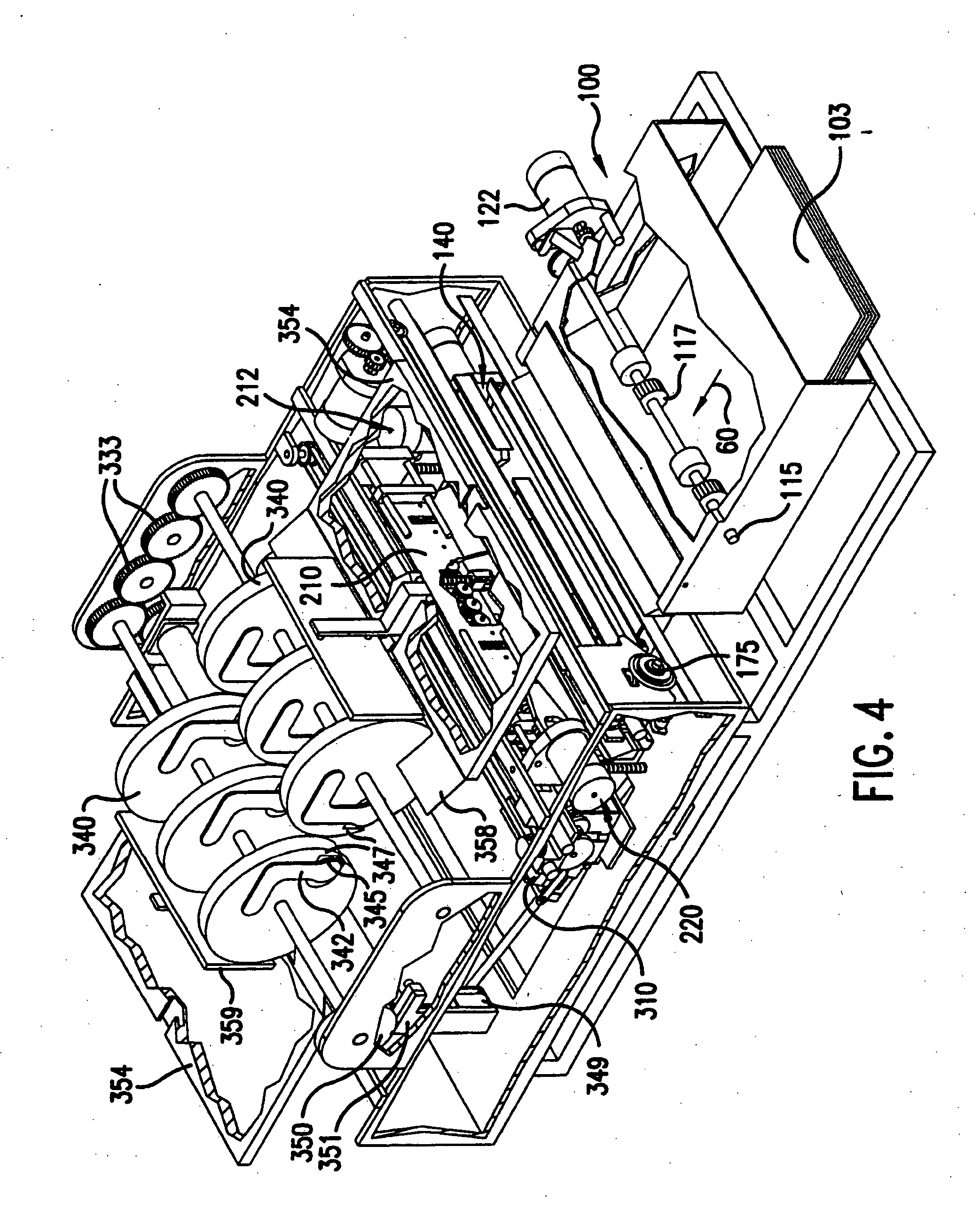

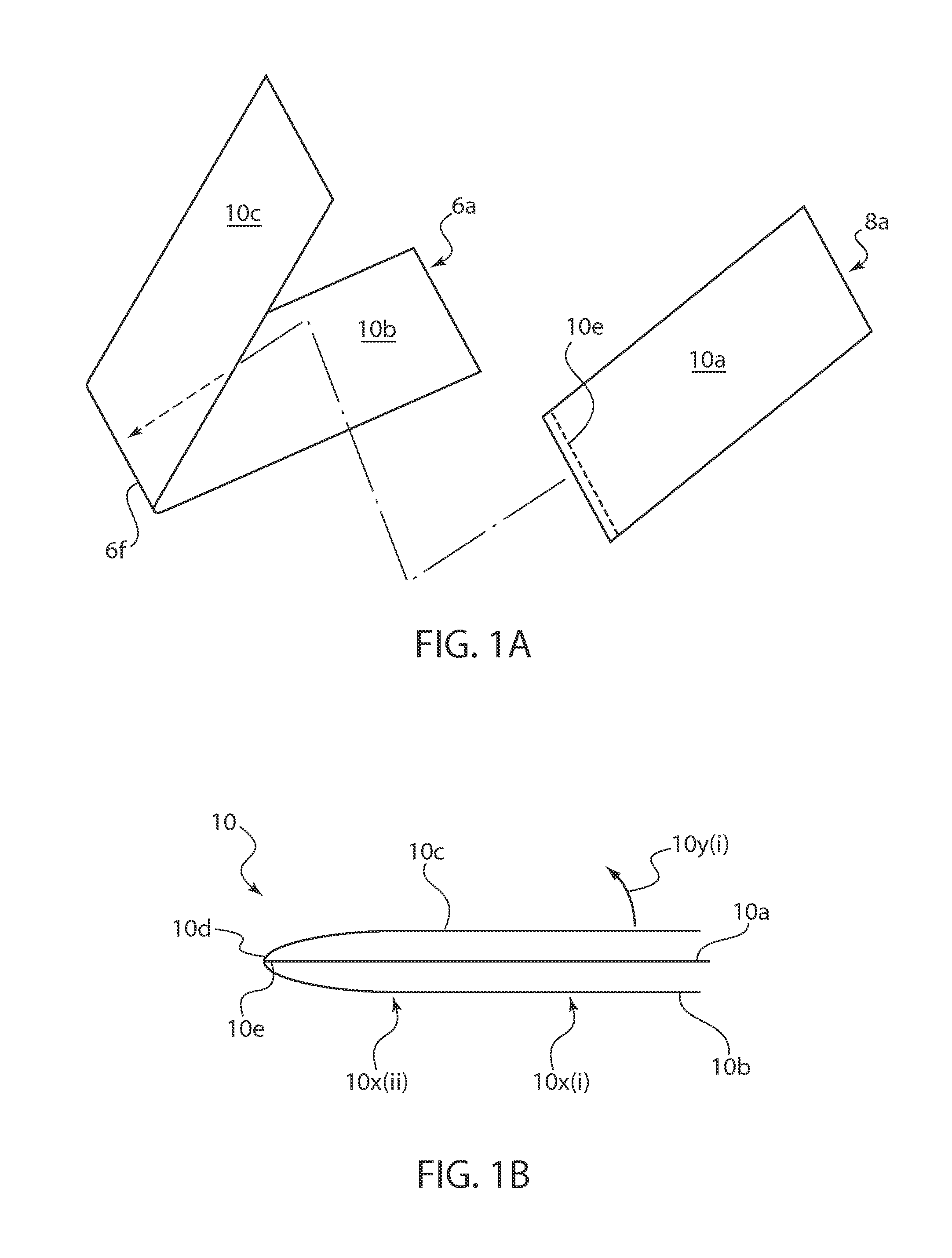

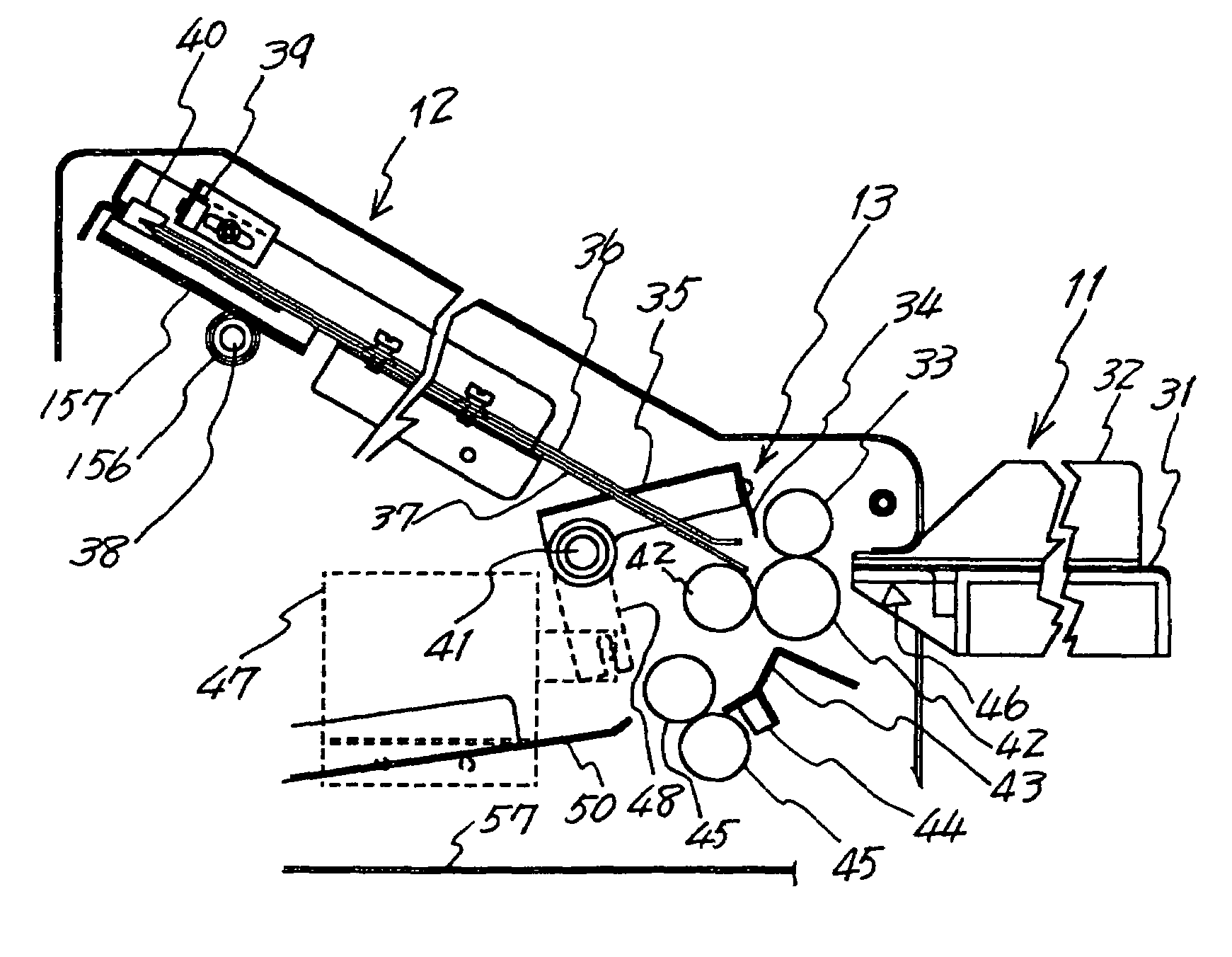

Method and apparatus for making booklets

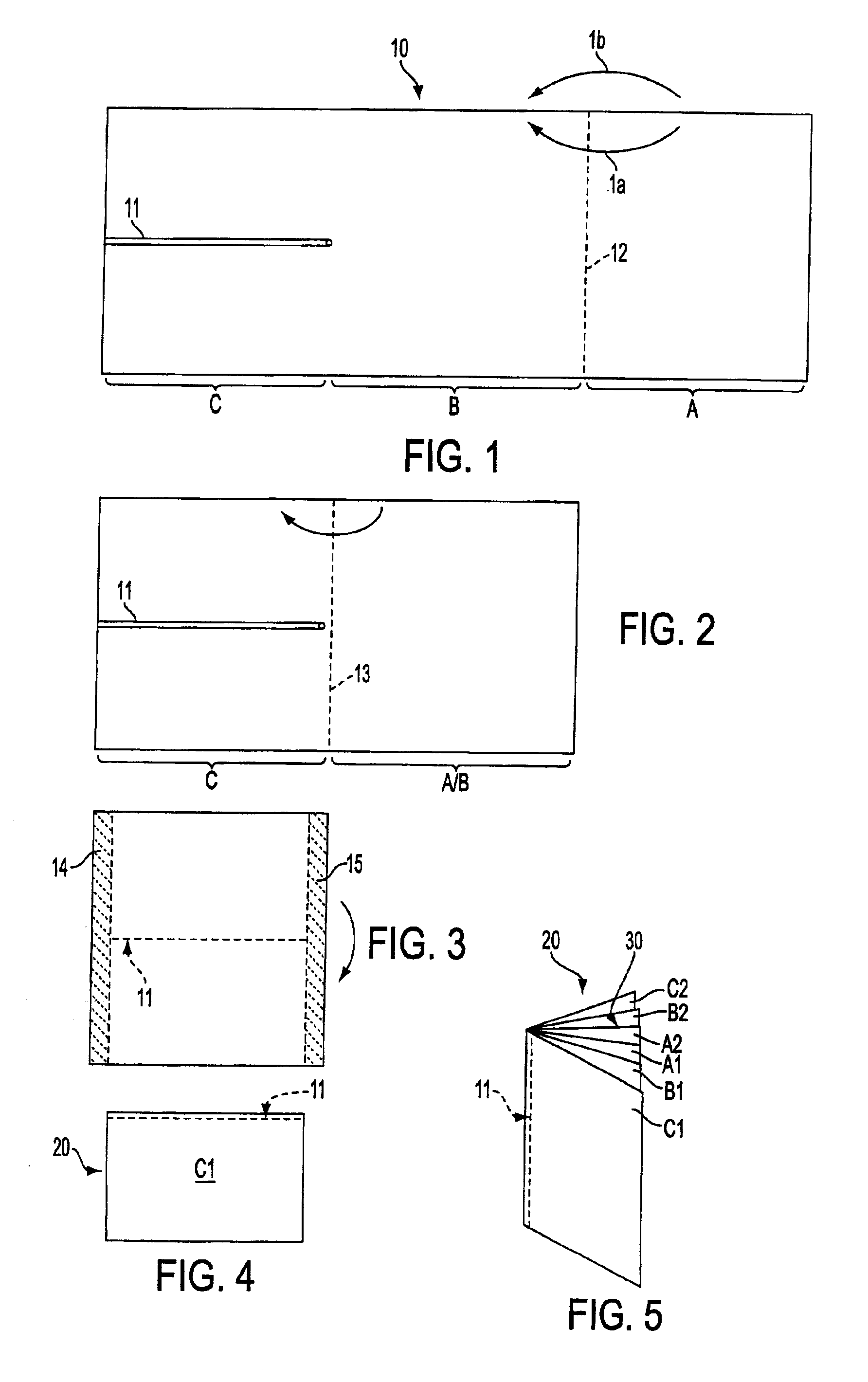

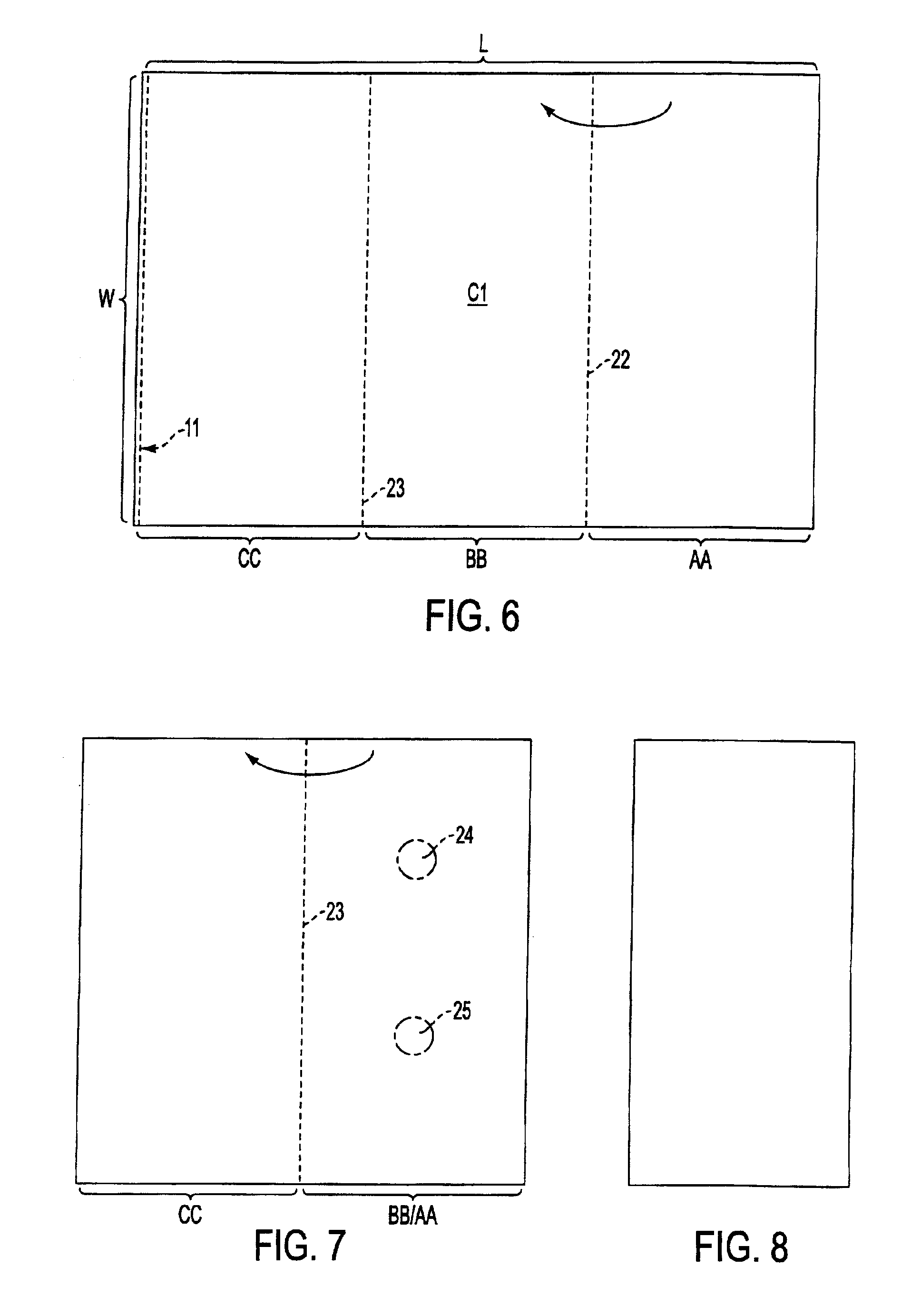

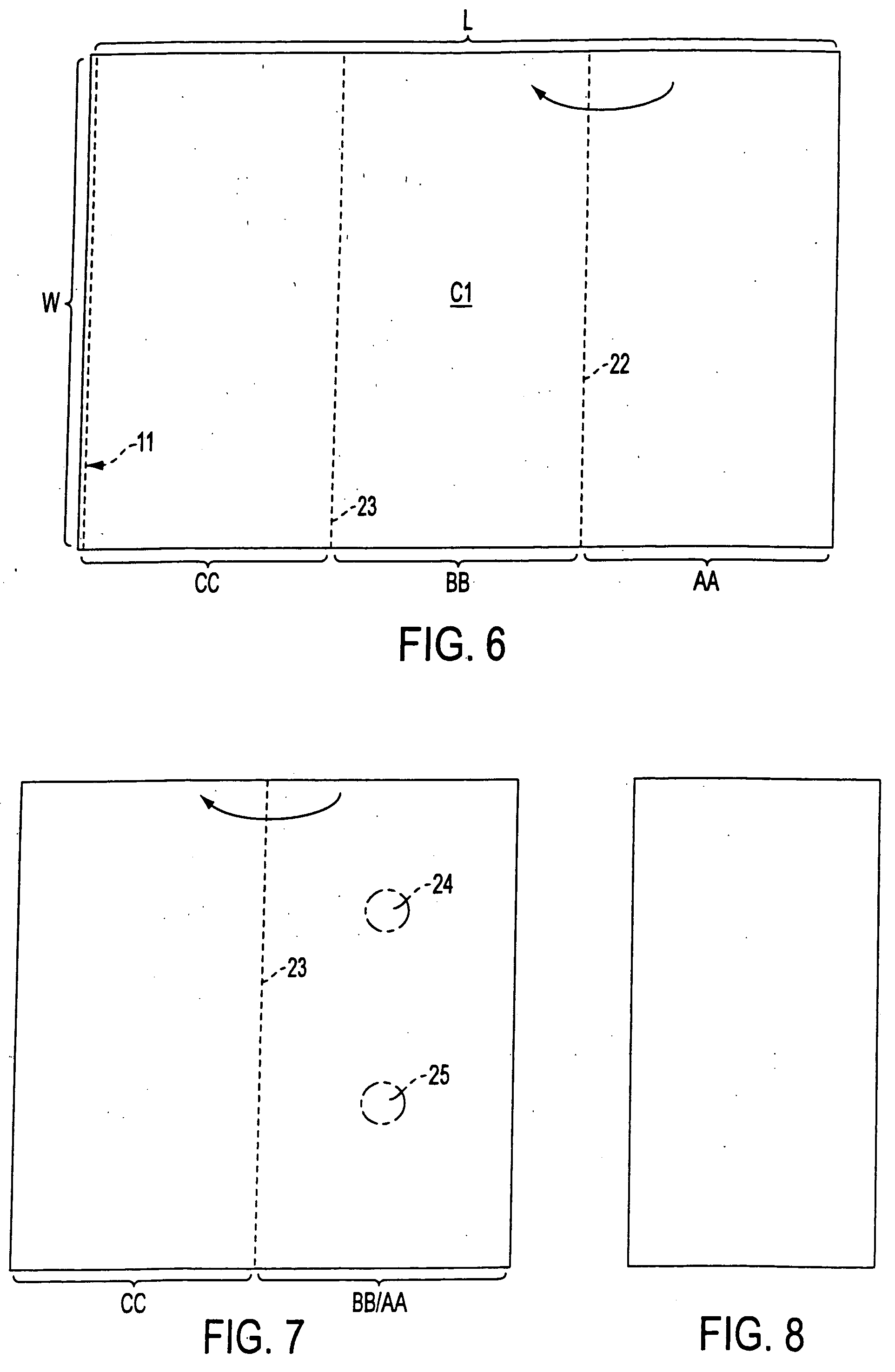

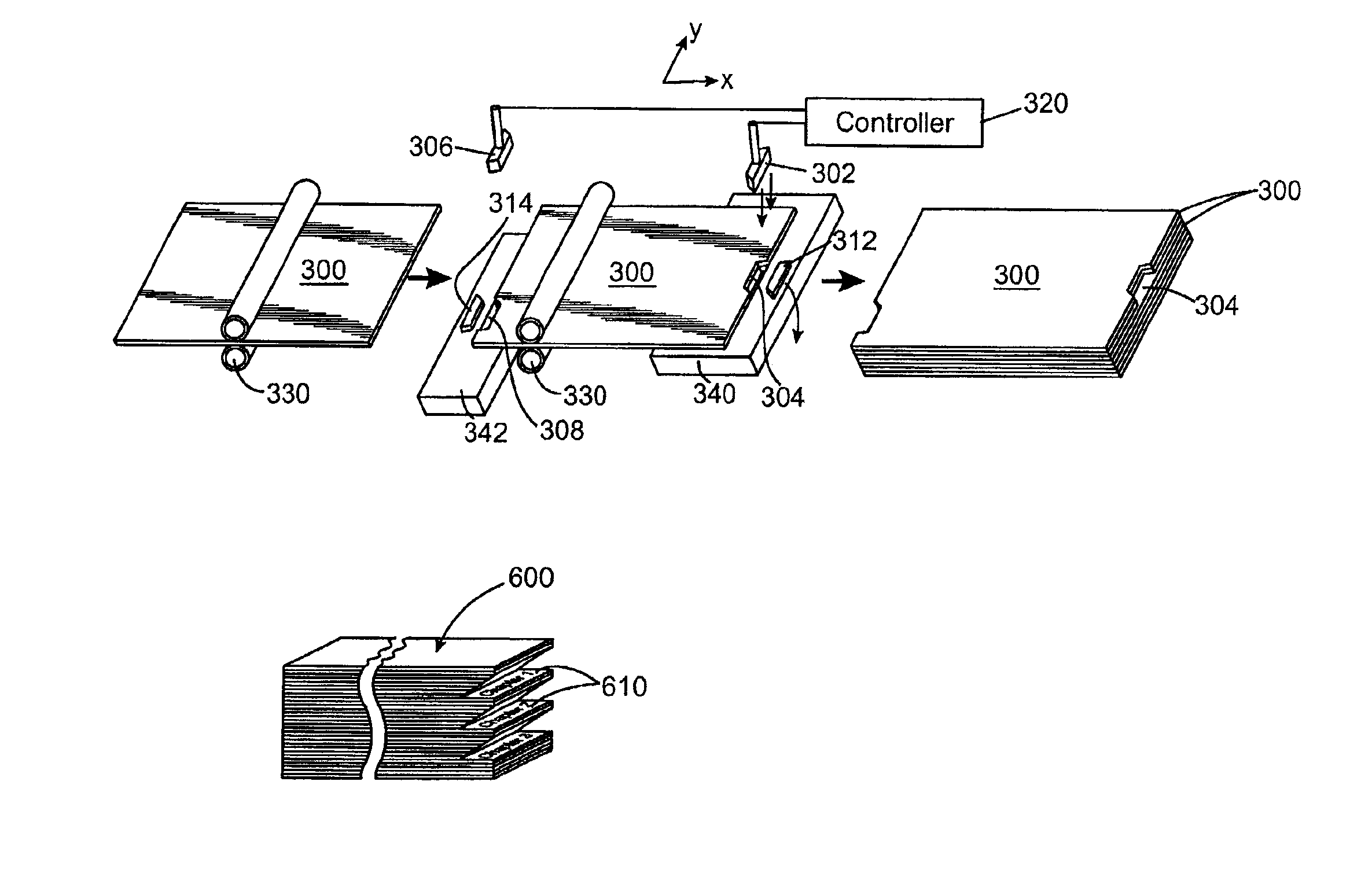

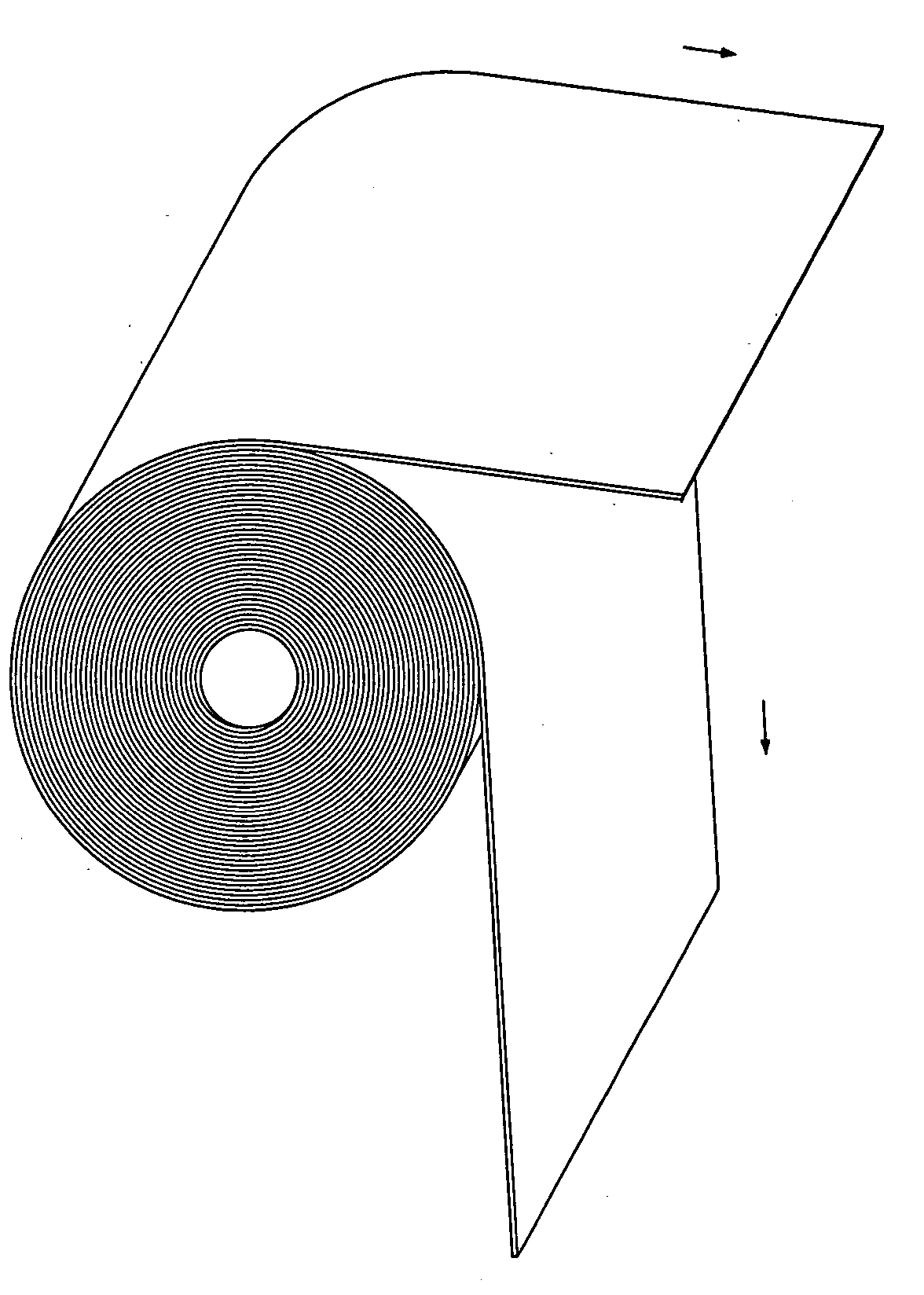

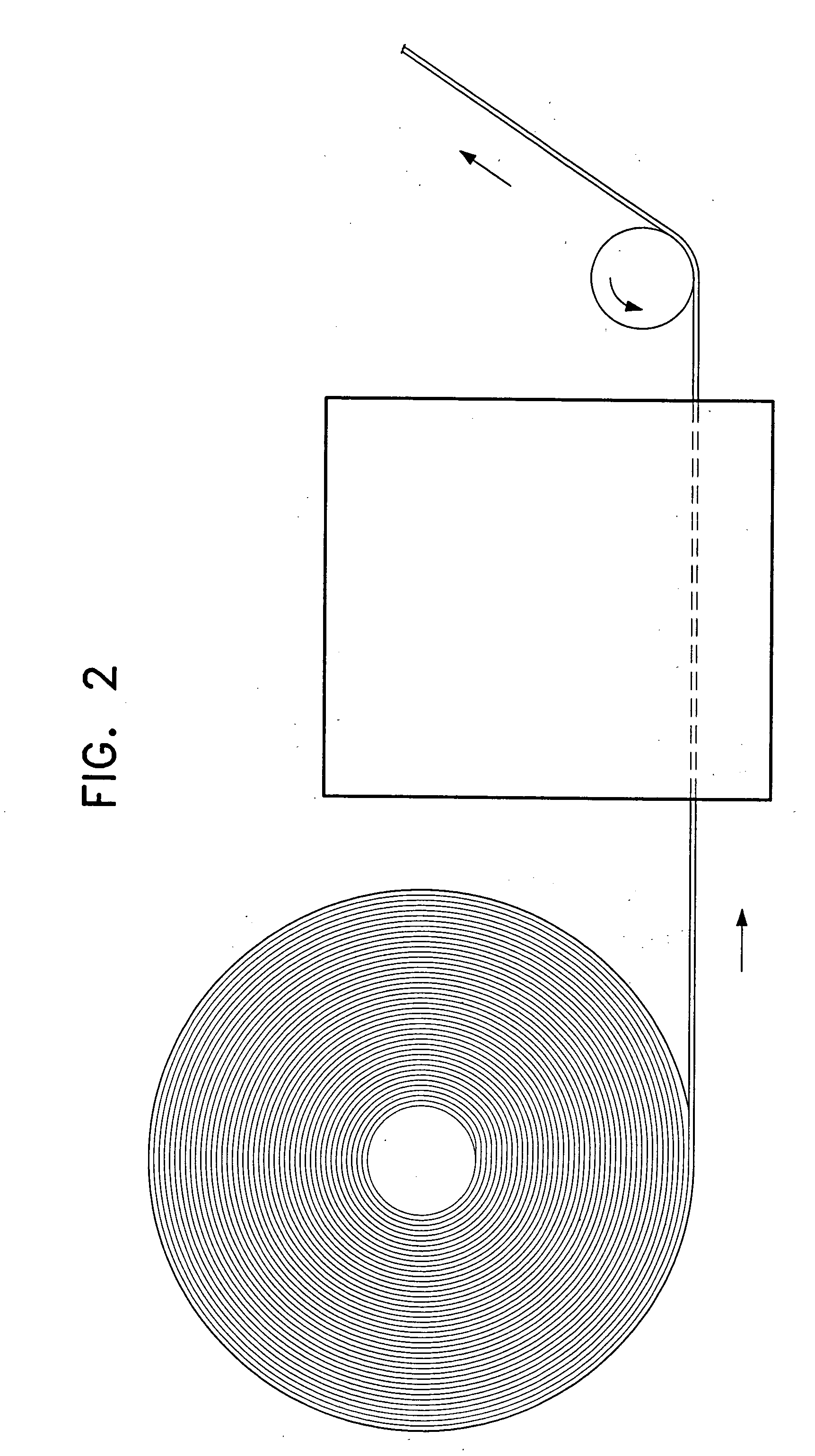

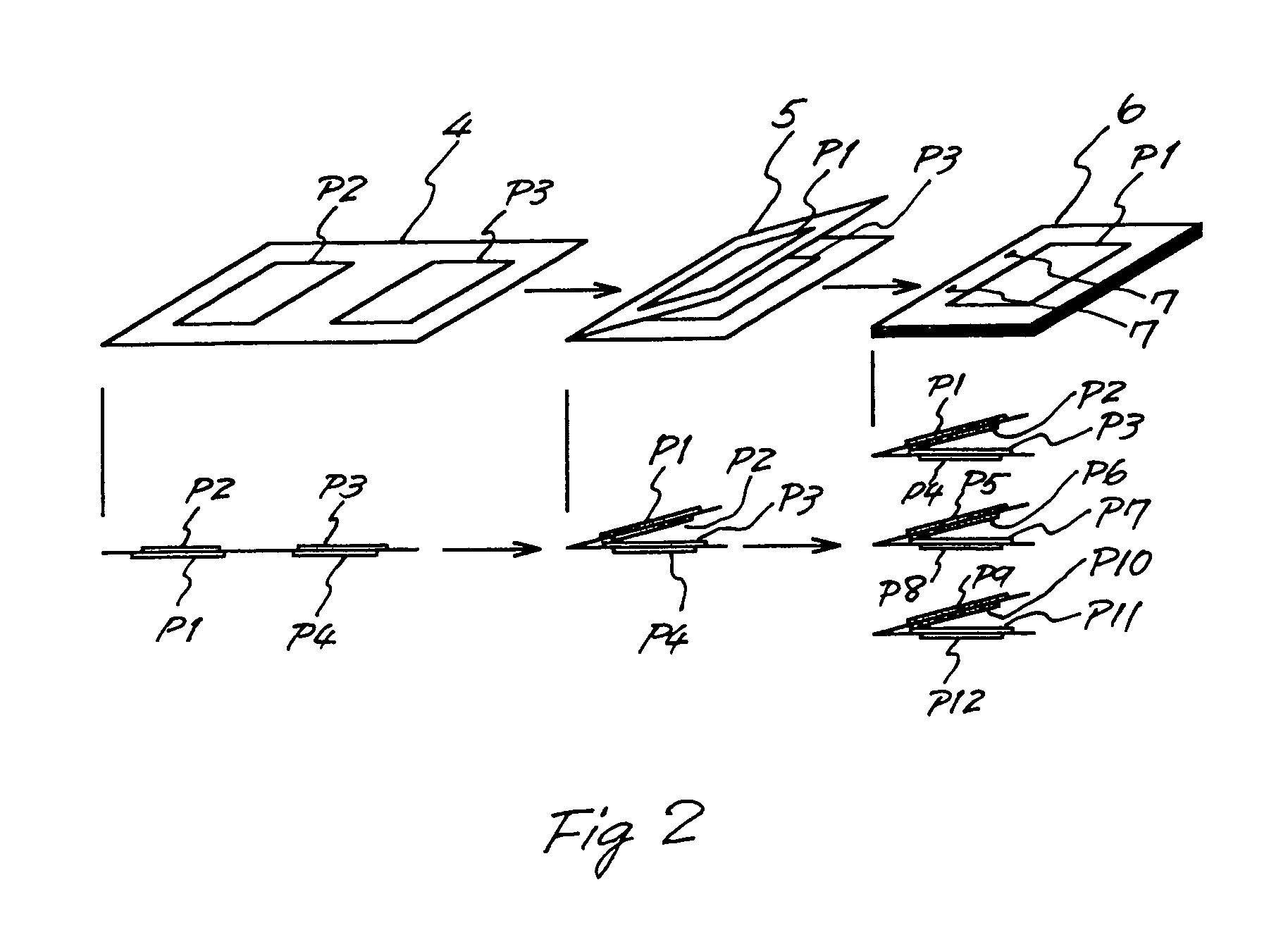

Method and apparatus for assembling sheets of printing media for booklets. In one aspect the sheets are folded, sheet-by-sheet, and in another aspect the sheets are collected, sheet-by-sheet, and registered on a fold in each sheet. In still another aspect printed sheets are loaded, sheet-by-sheet, into the apparatus. Each sheet is trimmed to a pre-determined width depending on the position of the sheet in the booklet being assembled. The sheets are thereafter folded, sheet-by-sheet, and collected into a stack. The method and apparatus have particular application in finishing duplex printed sheets of paper into saddle-stitched booklets.

Owner:HEWLETT PACKARD DEV CO LP

Sheet processing device and image forming device provided with the same

ActiveUS20160313687A1Reduce speedImprove productivityBookletsFunction indicatorsStackerAdhesive bonding

A sheet processing device includes: an adhesive-binding unit that applies an adhesive onto sheets stored in a stacker section one by one and adhesive-binds the sheets; a staple-binding unit that staple-binds sheets accumulated in the stacker section by means of staples; and a folding mechanism section having a folding roller that folds the adhesive-bound or staple-bound sheet bundle in two at a binding position of the adhesive-binding unit or staple-binding unit and a folding blade that pushes the bound sheet bundle into the folding roller. A folding speed of the folding mechanism section for the sheet bundle bound by the adhesive-binding unit is lower than a folding speed for the sheet bundle bound by the staple-binding unit; thereby, productivity of the folding processing is improved and occurrence of the peeling-off or break during the folding processing is reduced.

Owner:COPYER

Image formation processing system

ActiveUS20050265765A1Eliminate riskLong processing timeBookletsBook making processesAdhesiveImage formation

An image formation processing system is provided with an image formation portion, an adhesive applying portion which receives a plurality of sheets from the image formation portion, gathers the received sheets in the shape of a bundle to form a sheet bundle, and applies an adhesive to an end face of the sheet bundle, and a post-processing portion which receives a plurality of sheets from the image formation portion, gathers the received sheets in the shape of a bundle to form a sheet bundle, and performs predetermined post-processing on the sheet bundle, where the adhesive applying portion is disposed downstream of the image formation portion in the sheet transport, while the post-processing portion is disposed downstream of the adhesive applying portion in sheet transport.

Owner:COPYER +1

Method for manufacturing extended content booklet labels

A method for manufacturing an instructional booklet that folds away from a substrate. A multi-up book is provide having two or more booklets and a waste zone that share a common spine. The waste zone is adhered to a substrate that is larger than the booklets. An overlaminate is applied to secure the multi-up book to the substrate. The area between the booklets and the substrate is devoid of adhesive. Subsequently, the waste zone is die cut and removed along with the overlaminate and substrate leaving completed labels with booklets. The substrate can be adhered to a container without interference from the booklet. The booklet is held closed against the label by the overlaminate which extends beyond the substrate and booklet to adhere directly to the container.

Owner:MINIGRAPHICS

Sheet Processing Apparatus

A sheet processing apparatus includes: a holding portion which holds a booklet containing a two-folded sheet; and a pressing portion which presses a spine of a booklet into shapes during movement along the spine of the booklet held by the holding portion. The pressing portion can decrease, or release a pressing force to be applied to the booklet spine within a predetermined area of a moving range in which the pressing roller moves along the booklet spine.

Owner:CANON KK

Booklet Maker with Spaced Crease Rollers

Owner:XEROX CORP

Method for producing bound volumes

Owner:GOSS INT AMERICAS

Method and apparatus for making booklets

Method and apparatus for assembling sheets of printing media for booklets. In one aspect the sheets are folded, sheet-by-sheet, and in another aspect the sheets are collected, sheet-by-sheet, and registered on a fold in each sheet. In still another aspect printed sheets are loaded, sheet-by-sheet, into the apparatus. Each sheet is trimmed to a pre-determined width depending on the position of the sheet in the booklet being assembled. The sheets are thereafter folded, sheet-by-sheet, and collected into a stack. The method and apparatus have particular application in finishing duplex printed sheets of paper into saddle-stitched booklets.

Owner:TROVINGER STEVEN W +2

Method for manufacturing printed products such as books, brochures, magazines or the like

A method for manufacturing a printed product formed from a plurality of printed sheets which are printed sequentially for processing, wherein the printed products each comprise at least one printed sheet and an additional sheet which are stacked together in a stacking apparatus. The method includes feeding the additional sheet to the at least one printed sheet on a conveying path of a first conveying apparatus to the stacking apparatus.

Owner:MULLER MARTINI HLDG

Apparatus for making a booklet-like product

ActiveUS8353505B2Maintain processing efficiencyProduct planning can be facilitatedBookletsBook making processesNozzleEngineering

An apparatus for making a booklet-like product comprises a paper feeding part; a superposing part for superposing a plurality of continuous webs of paper fed to travel from the paper feeding part, whereby a layered continuous sheet of paper is prepared; a cutting part for cutting the layered continuous sheet into successive separate layered sheets of paper; a conveyance passage; and a stacking and ejection part for causing the separate layered sheets traveling along the conveyance passage to be piled every predetermined number thereof and to be ejected in the form of piles of sheets, each to form the booklet-like product. The superposing part is provided with a paste nozzle for applying paste to one of two adjacent such continuous webs of paper on its one side and a further paste nozzle for applying paste to the upper surface of the layered continuous sheet.

Owner:MIYAKOSHI PRINTING MACHINERY

Direct mail forms

InactiveUS20060182918A1Reduce downtimeImprove printing qualityStampsFlexible coversPulp and paper industrySilicone

A direct mail form having a bond paper layer extending across an entire width and length of the form. An adhesive label portion extends across a limited portion of the bond paper layer. The adhesive label portion of the bond paper layer is treated with a silicone release coating prior to application of the adhesive label portion to the bond paper layer. A bottom surface of the bond paper layer is printed prior to application of the silicone layer. The adhesive label portion and remaining free portion of the bond paper layer are subsequently printed with the bond paper layer also being printed prior to application of the silicone layer and adhesive layer portion so that upon removal of the adhesive label portion, printing is exposed.

Owner:HUB LABELS

Method and apparatus for making booklets

Method and apparatus for assembling sheets of printing media for booklets. In one aspect the sheets are folded, sheet-by-sheet, and in another aspect the sheets are collected, sheet-by-sheet, and registered on a fold in each sheet. In still another aspect printed sheets are loaded, sheet-by-sheet, into the apparatus. Each sheet is trimmed to a pre-determined width depending on the position of the sheet in the booklet being assembled. The sheets are thereafter folded, sheet-by-sheet, and collected into a stack. The method and apparatus have particular application in finishing duplex printed sheets of paper into saddle-stitched booklets.

Owner:HEWLETT PACKARD DEV CO LP

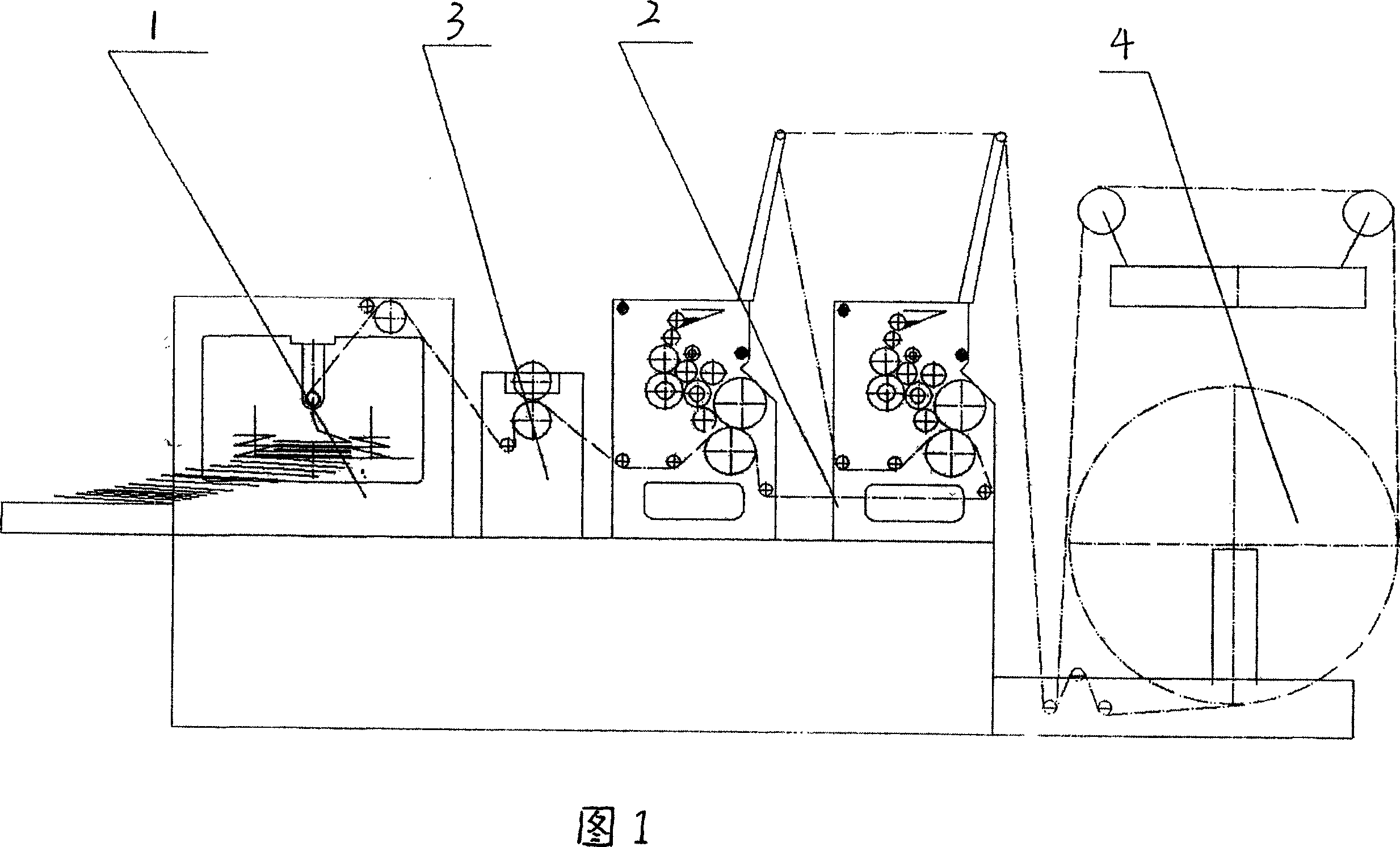

Method for producing inside pages of notebooks

InactiveCN101112842AEasy to writeThe printed lines on the inner pages are neat and clearBookletsBook keepingComputer sciencePaper sheet

The invention discloses a production method of the internal page of the tablet, aiming at solving the problems in the prior art of easy page losing, page dropping when rubberizing and the tablet which can not be opened in 180 DEG. The production method of the internal page of the tablet of the invention comprises a paper-mounting coiling part which conveys the web to the positive and reverse surface printing part with exact tension and force, a printing part carried out at least one color of printing to the web and conveys the web to the mounding line part, a mounding line part which punches the mounding line on the web, a folding-page marking part which folds the web at the mounding line position and marks the web after folded according to the page numbers stipulated in the tablet and conveys the web to the output part, and an output part which cuts the web at the folding position according to the marks. By adopting the method, the internal core of the tablet is firm without page loosening or dropping, the internal page printing line is tidy and clear, the tablet can be opened in 180 DEG, the processes such as page distribution and multi-time cutting, etc. are reduced, and the production efficiency is largely improved.

Owner:龚晓宏

Sheet processing apparatus and image forming apparatus

InactiveUS20080061489A1Good lookingOther printing matterBookletsBiomedical engineeringSheet material

A sheet processing apparatus configured to bind a sheet bundle includes a folding portion configured to fold the sheet bundle, a sheet processing portion provided upstream of the folding portion and configured to form a groove at a fold position of at least one sheet of the sheet bundle, and a controller configured to control an operation of the sheet processing portion. The controller controls an operation of the sheet processing portion such that a width of a groove formed on a sheet located on an outer side of the folded sheet bundle is larger than that of a groove formed on a sheet located on an inner side of the folded sheet bundle.

Owner:CANON KK

Method for manufacturing extended content booklet labels

ActiveUS20140083603A1Effective placementStampsPaper/cardboard articlesEngineeringMechanical engineering

A method of manufacturing an extended content booklet label. A multi-up book includes folds that are parallel to the book's spine. The multi-up book is disposed on the label web and held in place by an overlaminate. The overlaminate, book log and labels are all pre-trimmed in the longitudinal direction. The web is moved passed cutting elements to progressively slit the web and trim the major web into minor webs in which the overlaminate, booklets and labels are trimmed in the width direction to have a common edge.

Owner:MINIGRAPHICS

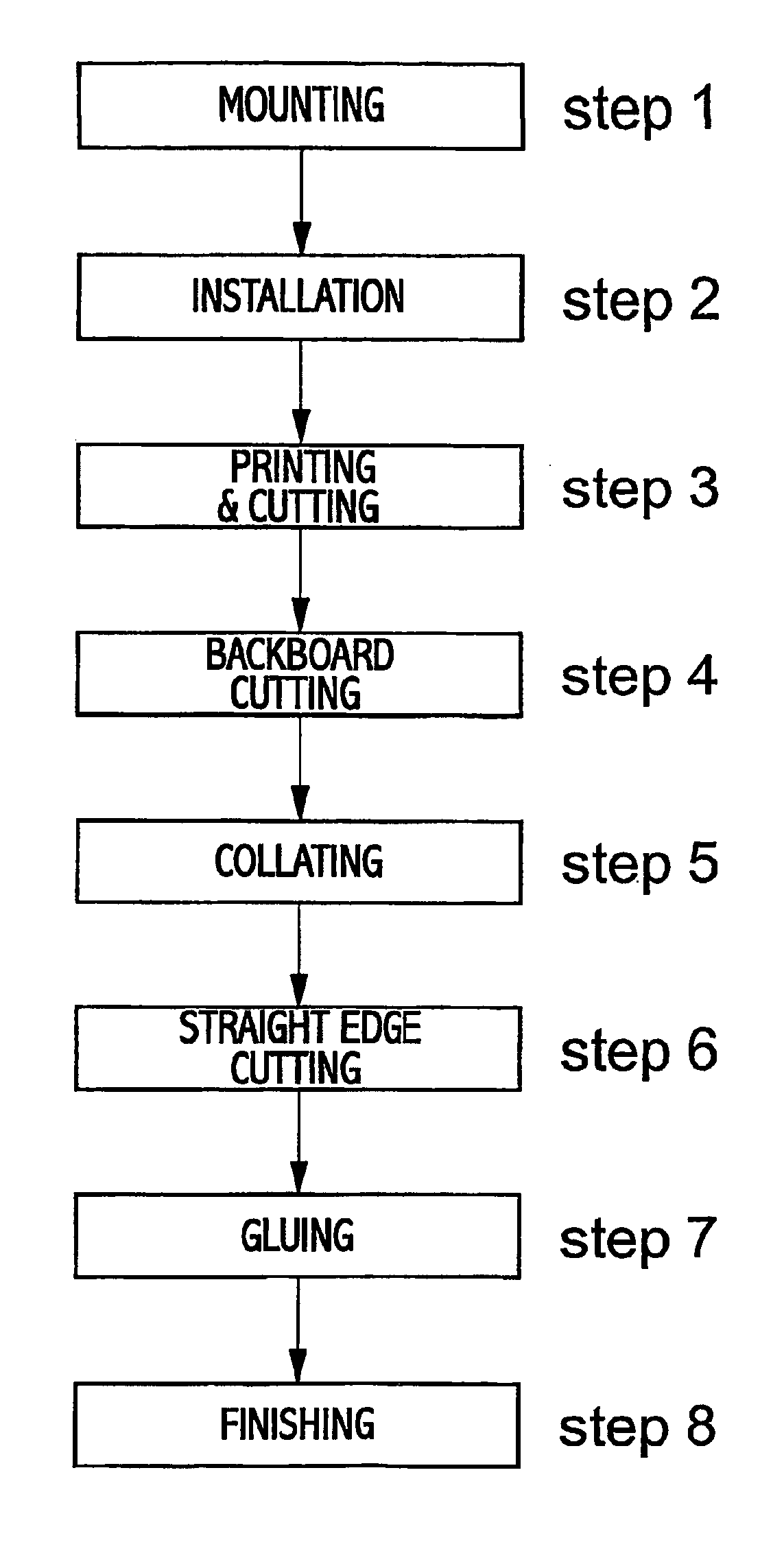

Notepad and process and apparatus for making same

InactiveUS6939426B2Lamination ancillary operationsManual label dispensersEngineeringMechanical engineering

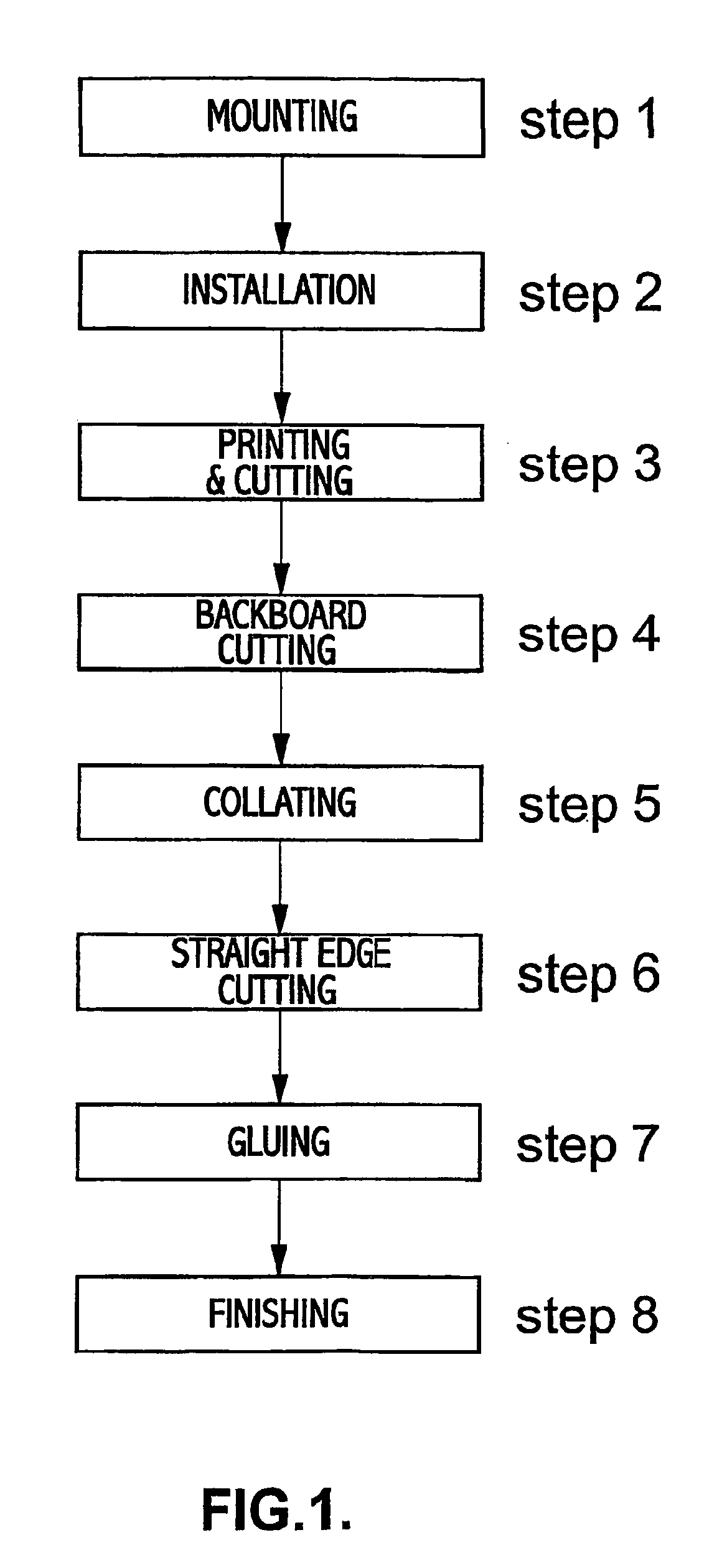

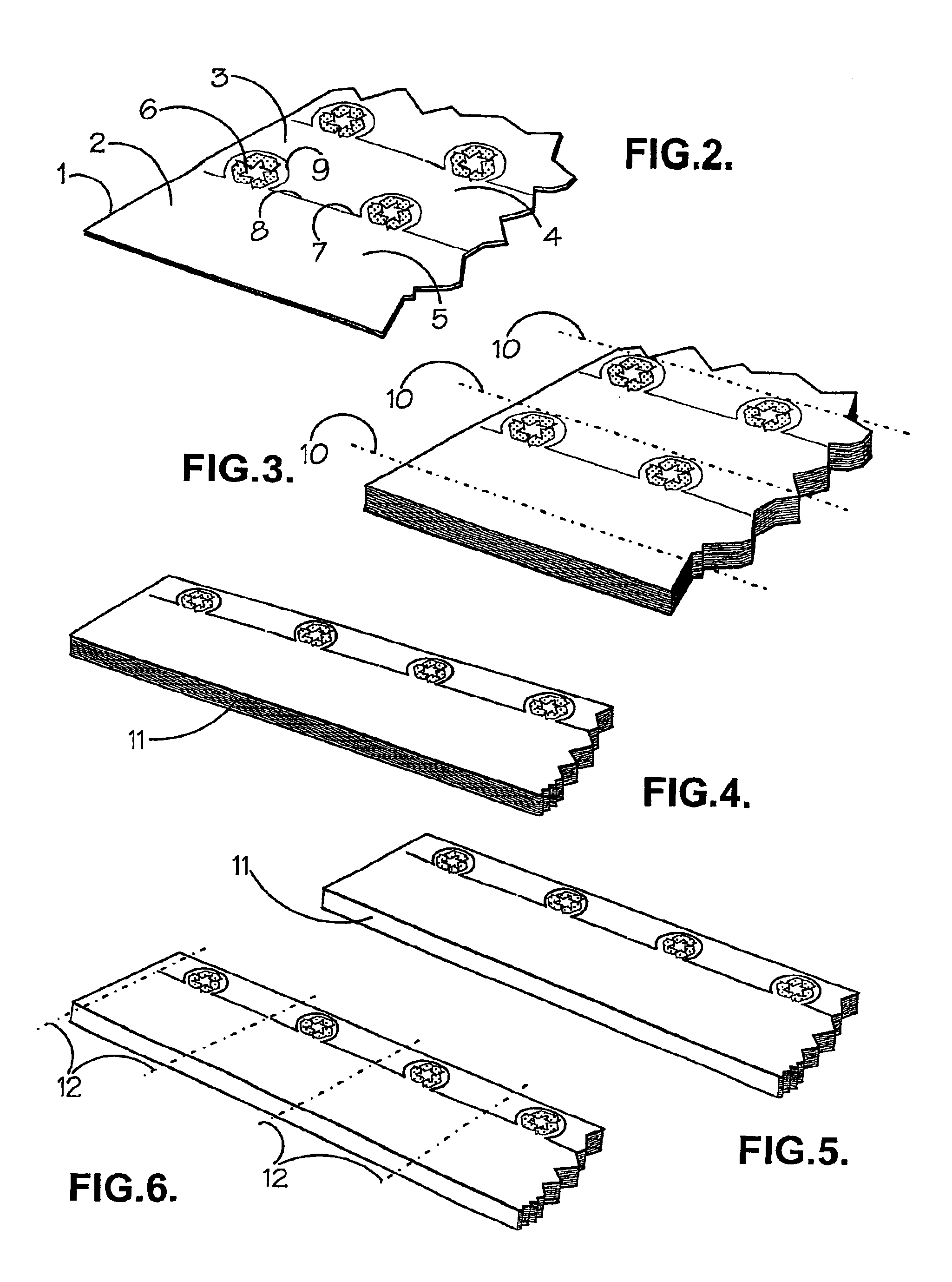

The invention relates to a notepad and to a process for manufacturing a notepad comprising providing a paper supply; sequentially feeding single pages from said paper supply to a printing and cutting station; printing on images on pad region of each single page; making at least one irregular cut at the edge of the pad region while leaving at least one straight edge of the pad region uncut; collating the printed and cut pages in a stack of desired quantity; cutting the collated stack along the at least one uncut straight edge of each pad region; and gluing the collated stack along the resulting cut straight edge.

Owner:PRAMIC

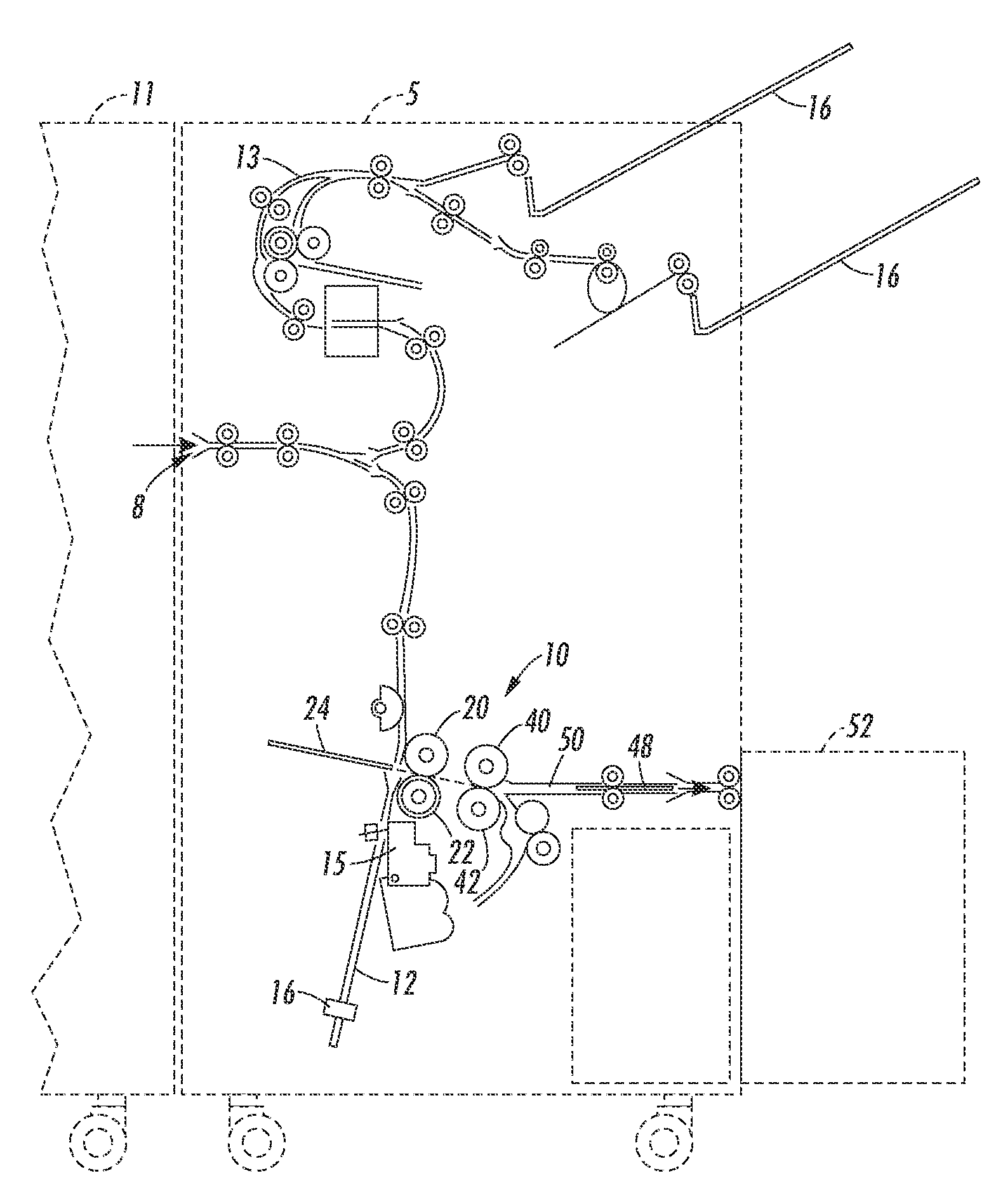

Sheet folding and binding apparatus and method

InactiveUS6983931B2Increase the areaSmall sizeMechanical working/deformationBookletsElectrical and Electronics engineeringSheet material

A binding apparatus includes a receiving device configured to receive a sheet from outside and convey the sheet, and a sheet folding device configured to fold the sheet, conveyed by the receiving device, in two at a center portion thereof in a direction the sheet is conveyed, so as to be a folded sheet, and convey the folded sheet with the folded portion thereof being a leading edge of the folded sheet. A jogging device includes a jogging table and is configured to receive and jog the folded sheet, conveyed by the sheet folding device, one after another, so as to be stacked into a stack of folded sheets on the jogging table. A binding device is configured to bind the stack of folded sheets stacked on the jogging table at an edge portion of the stack of folded sheets at the side where the folded portion of each folded sheet of the stack of folded sheets is located. A discharging device is configured to discharge the bound stack of folded sheets.

Owner:KANEKO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com