Method for producing inside pages of notebooks

A production method and notebook technology, which is applied in bookkeeping, book binding, printing, etc., and can solve the problems of easy-to-drop web pages, low process efficiency, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

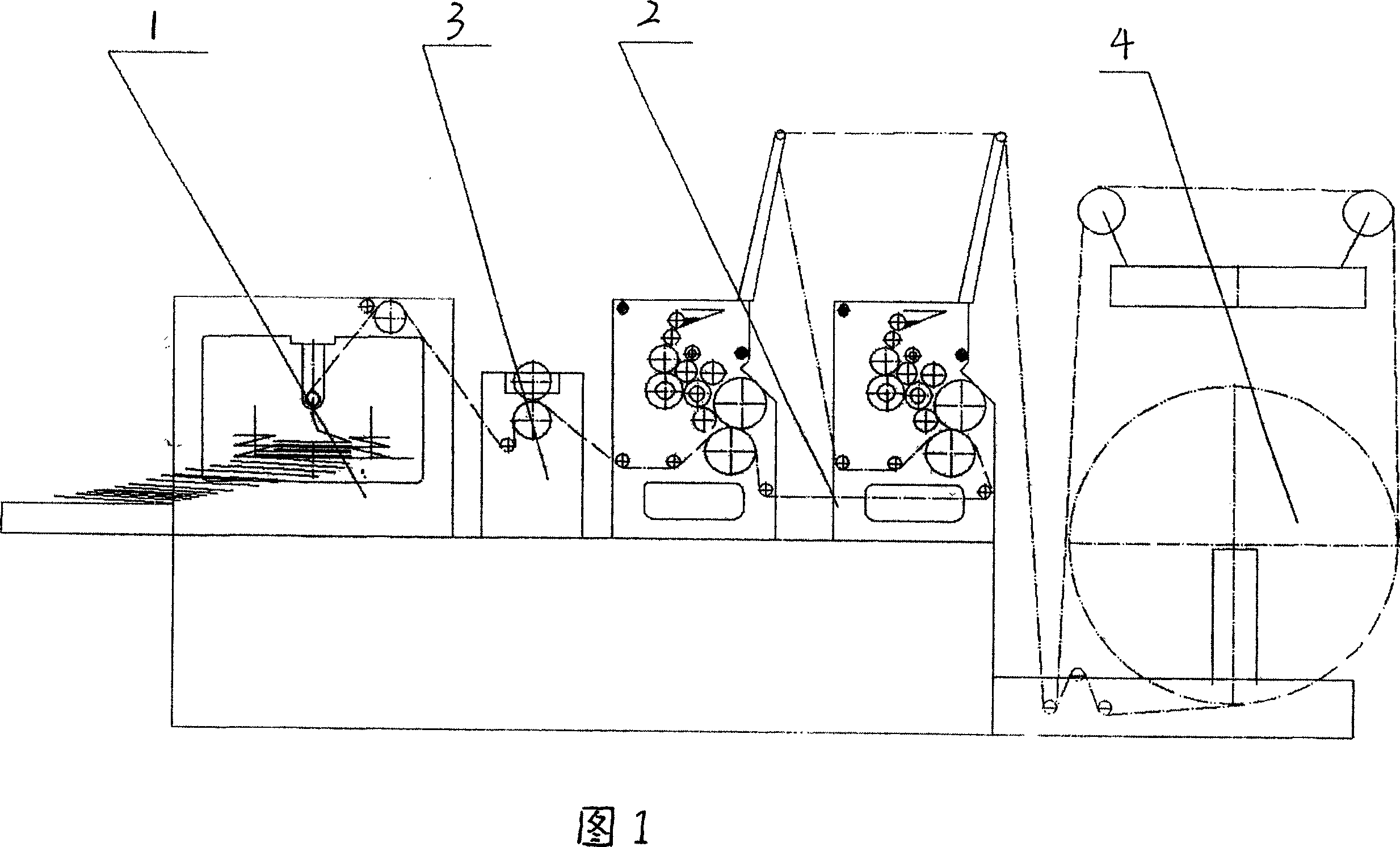

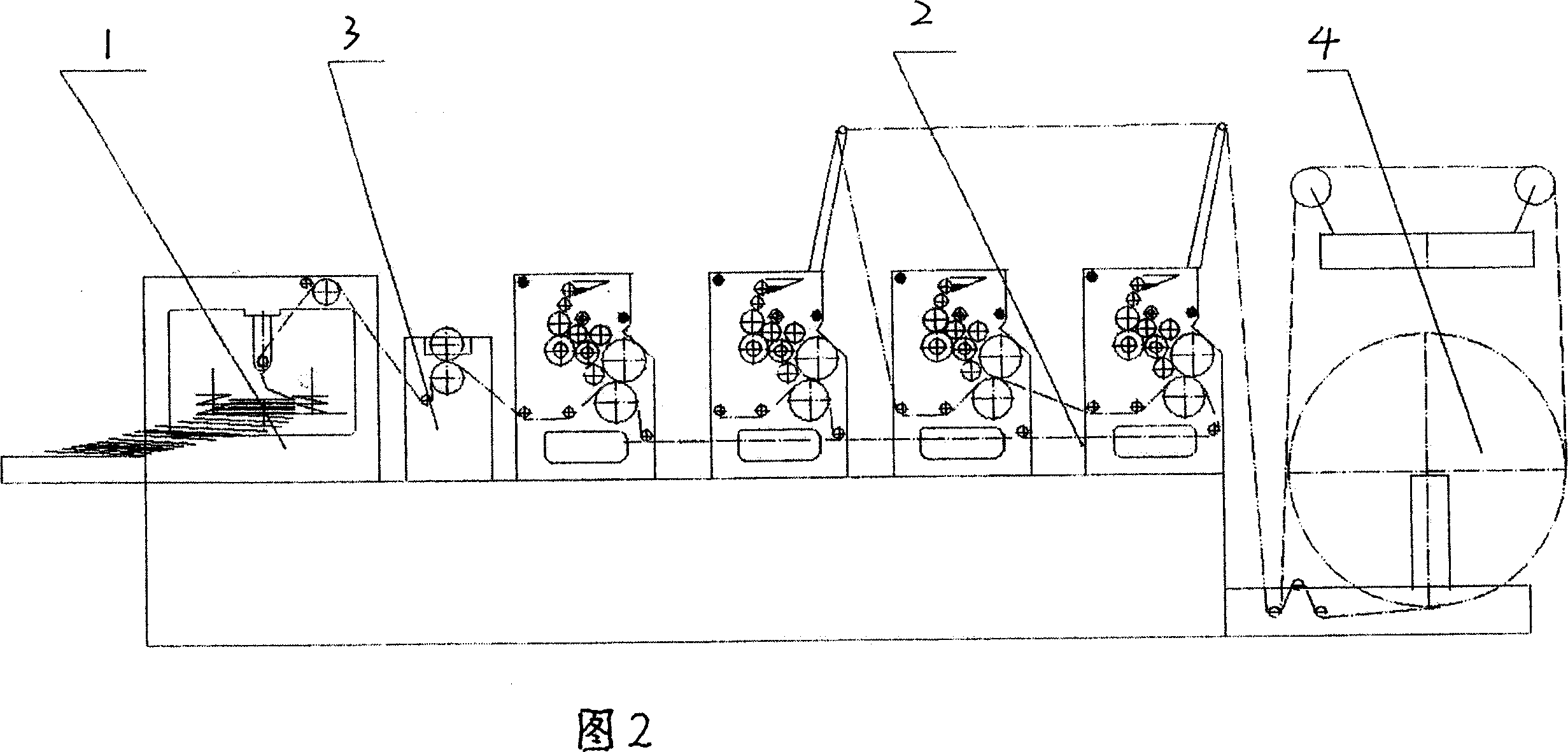

[0023] As shown in Figure 1 and Figure 2, the device for producing the inner pages of the notebook includes a folding mark output section 1, a front and back printing section 2, a ridge line section 3, and a paper unwinding section 4; the folding mark output section 1 Including Z-folding machine, counting and marking system and output system. The folding marking output unit 1 can make the printed paper fold and output continuously at the ridge line, and at the same time mark the specified number of each book, and output the The paper is cut in the middle of the two fold lines, and the core is taken out according to the mark. The front and back printing section 2 includes a front printing press and a back printing press (as shown in FIG. 1), or two front printing presses and two back printing presses (as shown in FIG. 2), front and back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com