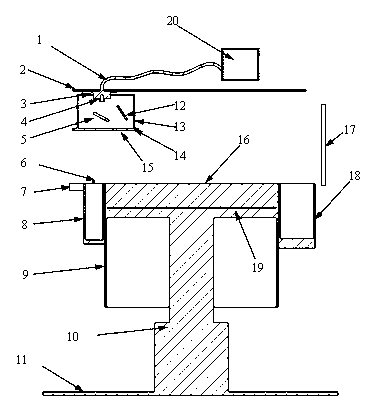

Mobile galvanometer selective laser melting (SLM) forming device

A technology of laser melting and forming equipment, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of poor forming accuracy, difficult to increase forming size, deformation of light spot, etc., and achieve long life, high positioning accuracy, ability to strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below by specific embodiment:

[0025] As shown in the accompanying drawings, the mobile galvanometer selective laser melting SLM forming equipment includes a numerical control system 15 connected with an X-axis linear motor 2 with a horizontal guide rail group and a Y-axis linear motor 3 with a longitudinal guide rail group through a communication line 1 , the communication line 1 is an optical fiber, the X-axis linear motor 2 and the Y-axis linear motor 3 constitute a scanning drive structure, and the scanning drive structure is drivingly connected with the laser beam expander and collimator mirror group 4, and the bottom of the laser beam expander collimator mirror group 4 Snap into the vibrating mirror unit, a forming working component is arranged under the vibrating mirror unit, and an inert gas curtain 17 is set between the forming working component and the vibrating mirror unit. The forming working assembly includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com