Booklet Maker with Spaced Crease Rollers

a booklet maker and crease roller technology, applied in the field of automatic booklet makers, can solve the problems of affecting the booklet making process, affecting the quality of the booklet,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

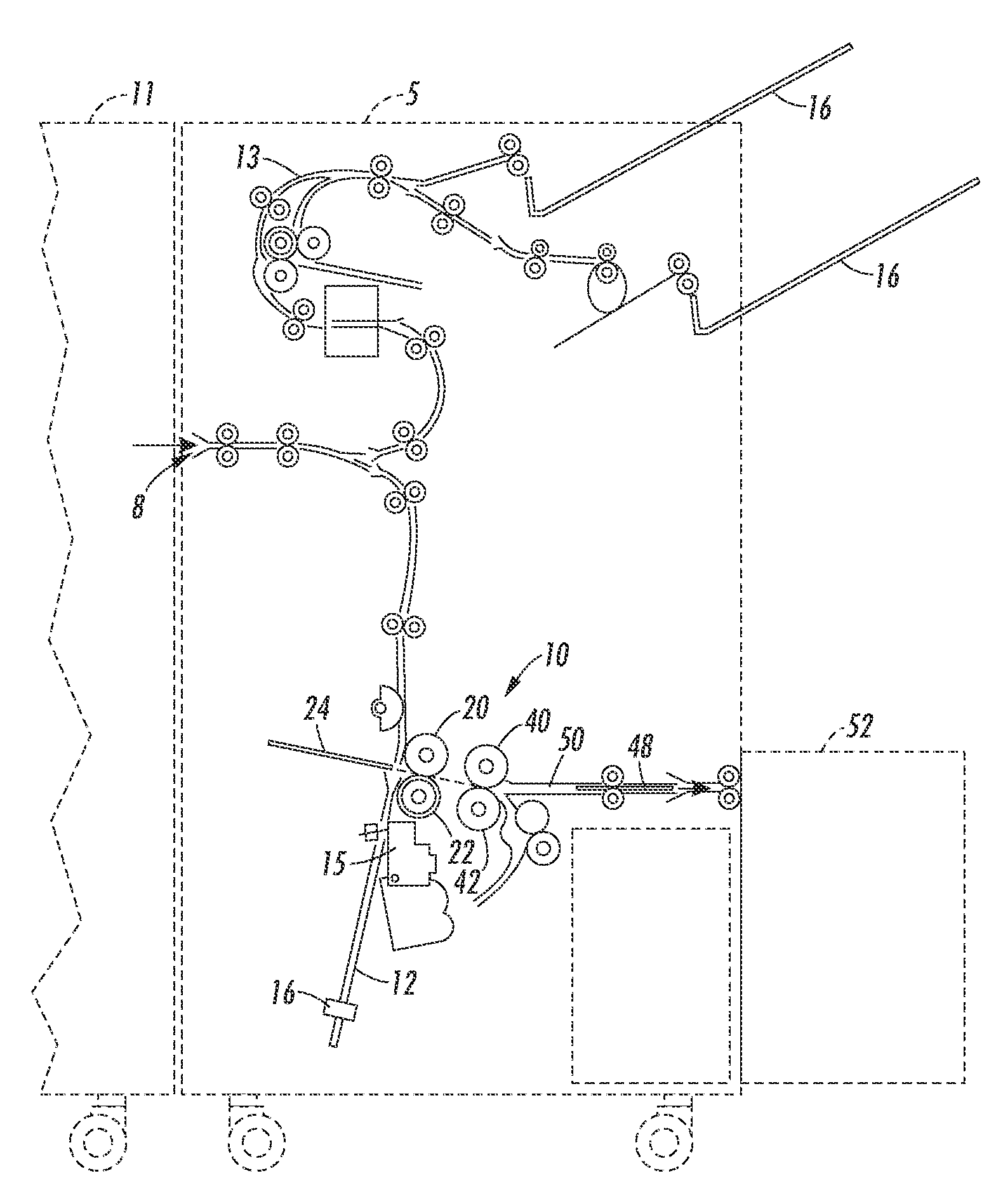

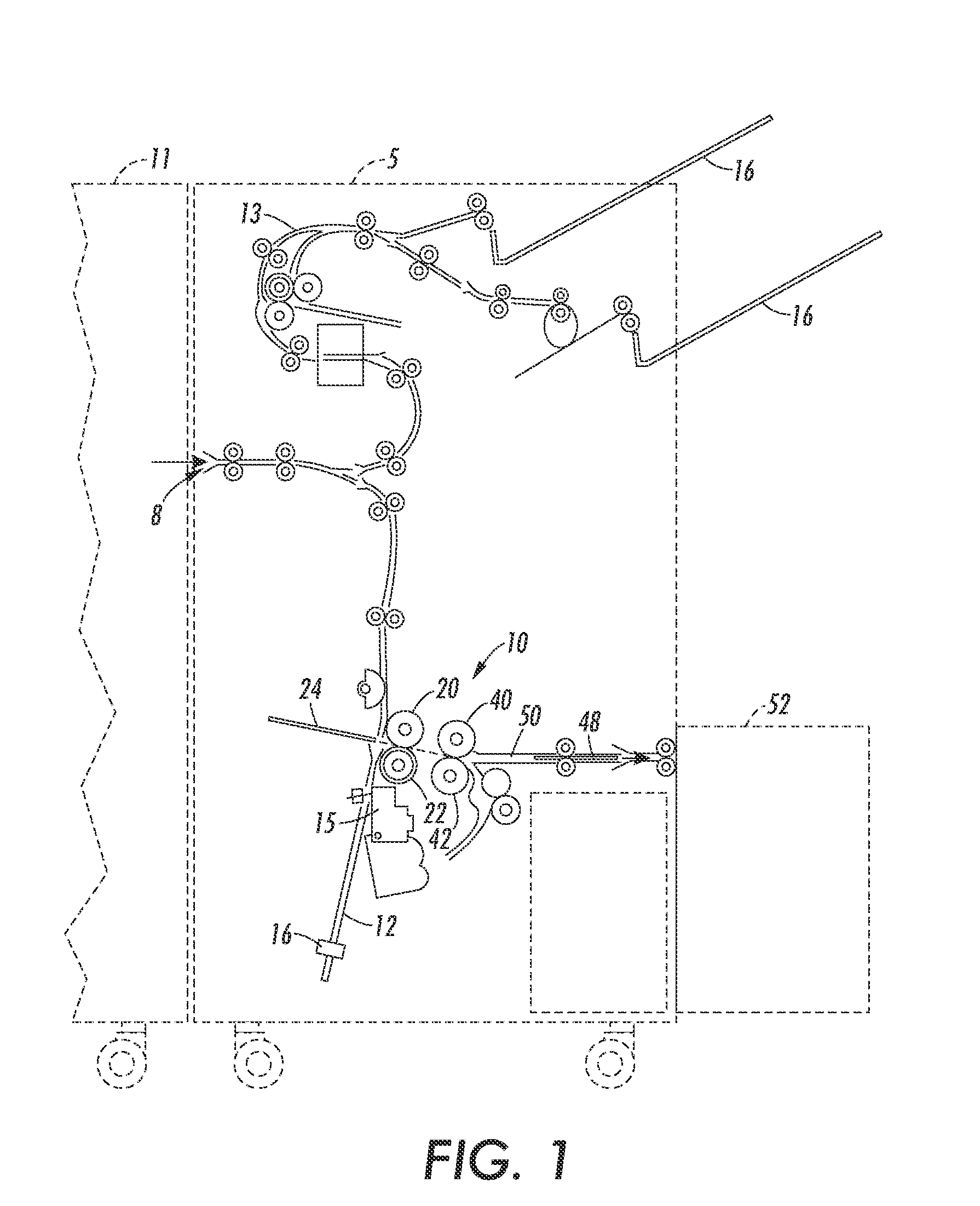

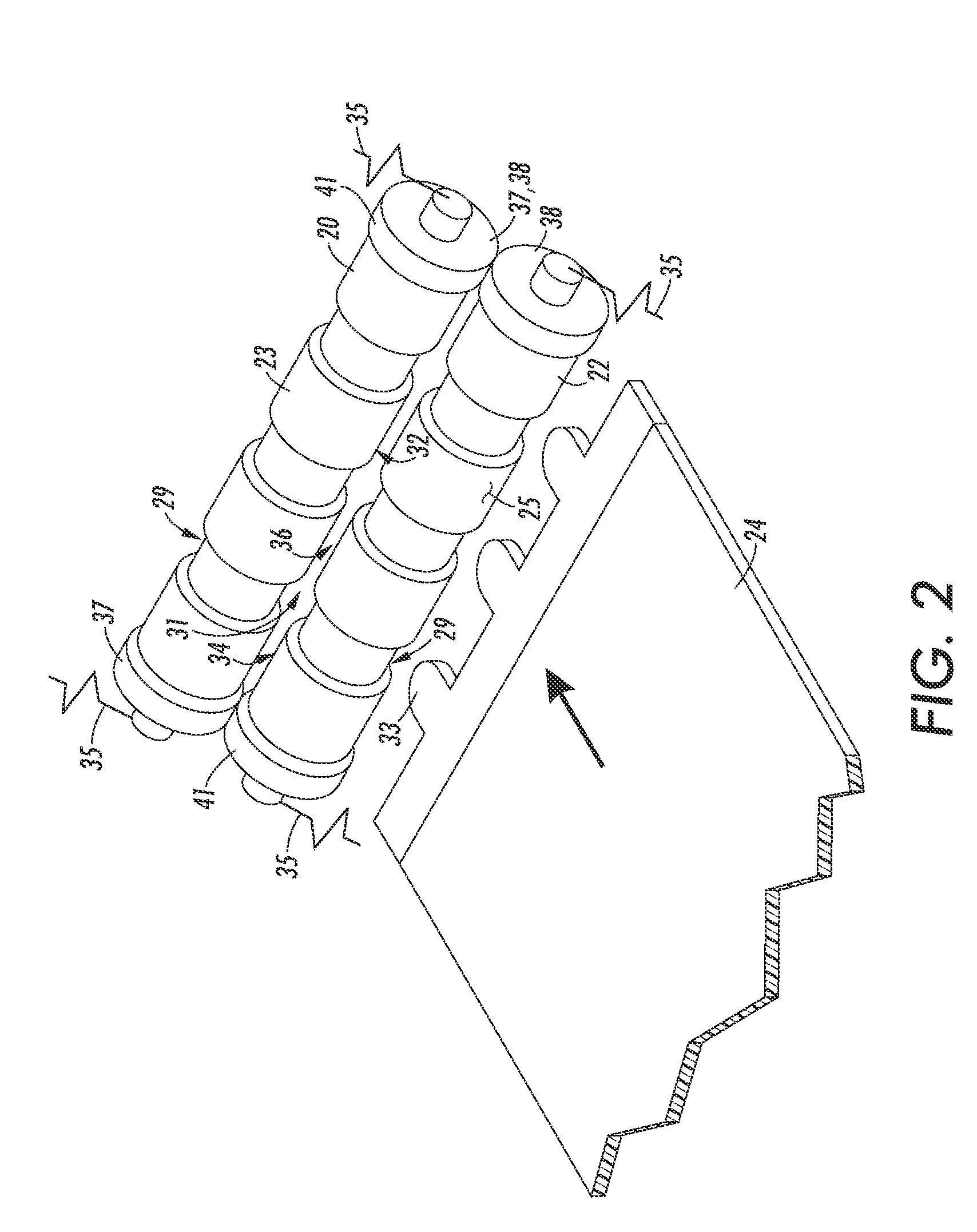

[0020]Exemplary embodiments include a booklet maker including crease rollers for forming booklets. The booklet maker can include a movable crease blade positioned adjacent a pair of crease rollers for forming a crease in processed sheets. The crease rollers can be spaced from each other to permit the entry of the sheets therebetween.

[0021]As used herein, “booklet maker” refers to a device that operates on substrate media such as sheets of paper to form a booklet of folded sheets secured together.

[0022]As used herein, “crease roller” refers to a rotating longitudinally extending device for engaging substrate media to form a bend therein.

[0023]As used herein, “crease blade” refers to a member engagable with substrate media to assist in forming a bend therein.

[0024]As used herein, “spacing device” refers to a member for maintaining a space between components such as crease rollers.

[0025]As used herein, “nip space” refers to the space or opening between rollers.

[0026]As used herein, “pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spring tension | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com