Graphene-copper composite heat dissipation film and its preparation method and application

A technology of composite heat dissipation film and graphene film, applied in the direction of graphene, applications, other household appliances, etc., can solve the problems of poor thermal conductivity and flexibility of macroscopic materials, and many defects, and is conducive to machine repair, prolong life, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 proposes a kind of graphene-copper composite cooling film, and its preparation method comprises the steps:

[0016] S101: first pretreating natural graphite, and then sequentially undergoing high-speed shearing, ultrasonic stripping and emulsification to obtain graphene.

[0017] S102: The graphene obtained in the step S101 is mixed, then prepared into a film and dried to obtain a graphene film, and then the graphene film is heated at a temperature of 2900° C. The micro-airbags were rolled to produce micro-folds.

[0018] S103: Compacting the graphene film treated in step S102 with the copper foil, and then pasting the thermally conductive black film on the other side of the copper foil to obtain a graphene-copper composite heat dissipation film with a thickness of 25 μm.

Embodiment 2

[0020] Embodiment 2 proposes a kind of graphene-copper composite cooling film, and its preparation method comprises the steps:

[0021] S101: first pretreating natural graphite, and then sequentially undergoing high-speed shearing, ultrasonic stripping and emulsification to obtain graphene.

[0022] S102: Mix the graphene obtained in the step S101, then prepare a film and dry it to obtain a graphene film, then heat the graphene film at a temperature of 3100° C. The micro-airbags were rolled to produce micro-folds.

[0023] S103: compacting the graphene film treated in step S102 with the copper foil, and then pasting the thermally conductive black film on the other side of the copper foil to obtain a graphene-copper composite heat dissipation film with a thickness of 150 μm.

Embodiment 3

[0025] Embodiment 3 proposes a kind of graphene-copper composite cooling film, and its preparation method comprises the steps:

[0026] S101: first pretreating natural graphite, and then sequentially undergoing high-speed shearing, ultrasonic stripping and emulsification to obtain graphene.

[0027] S102: Mix the graphene obtained in the step S101, then prepare a film and dry it to obtain a graphene film, then heat the graphene film at a temperature of 3000° C. The micro-airbags were rolled to produce micro-folds.

[0028] S103: Compacting the graphene film treated in step S102 with the copper foil, and then pasting the thermally conductive black film on the other side of the copper foil to obtain a graphene-copper composite heat dissipation film with a thickness of 80 μm.

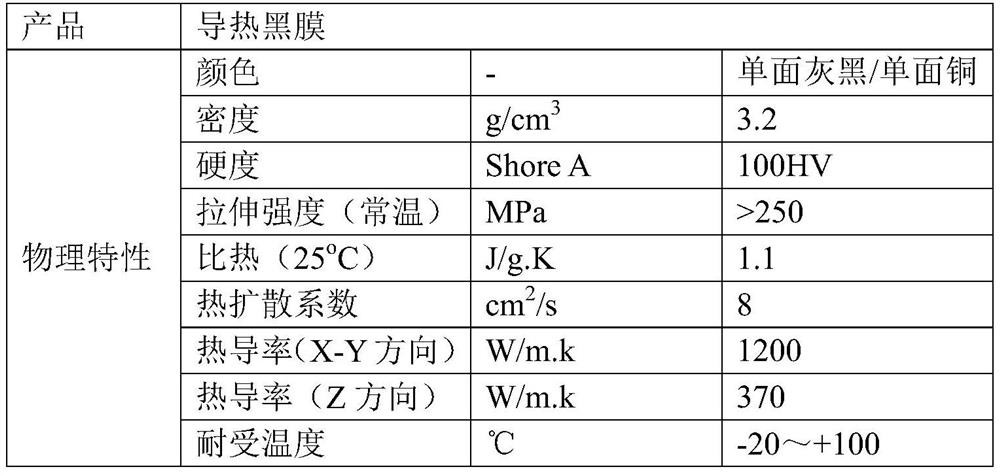

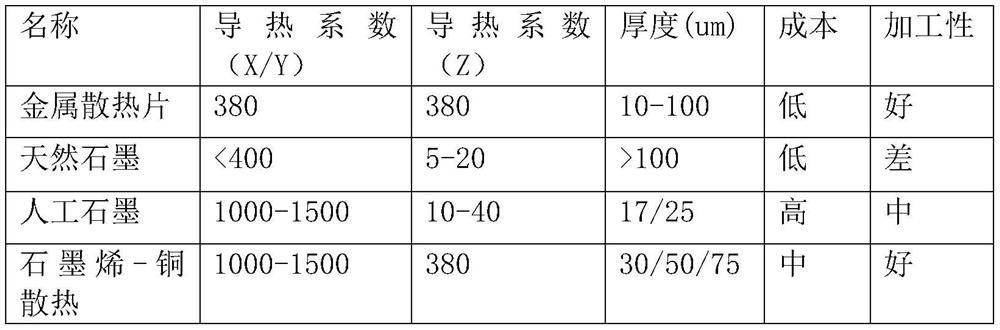

[0029] Table 1: Parameters of thermally conductive black film

[0030]

[0031] In the new material laboratory of the Yangpu District Entrepreneurship Base in Shanghai, the OPPO prototype was tested w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com