A gift box and its manufacturing process

A gift box and lower box technology, which is applied in the field of cartons, can solve the problems that affect the stability of beauty and full blooming, and the unevenness of gifts, so as to achieve the effect of stably displaying products, preventing products from being scattered, and improving interest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

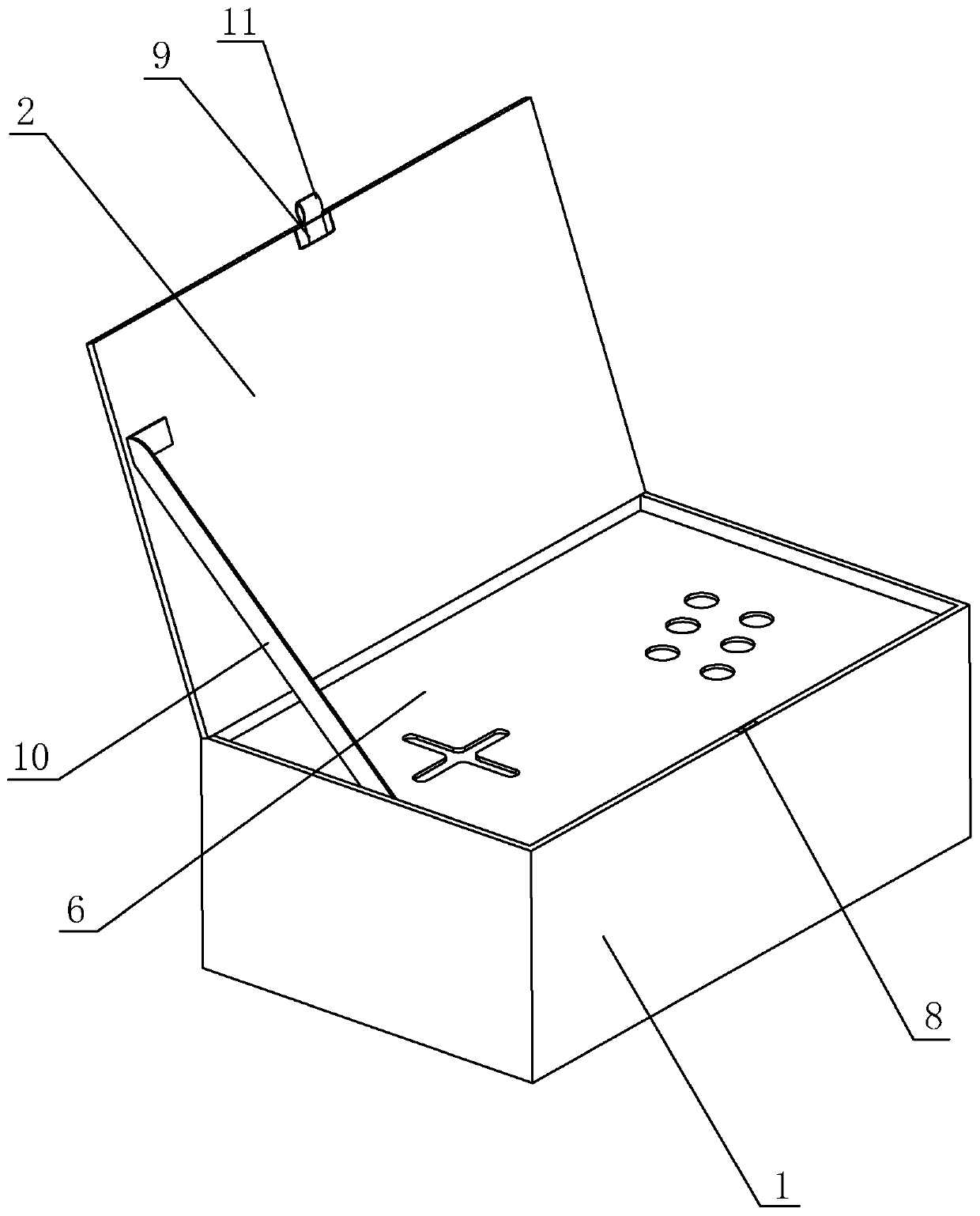

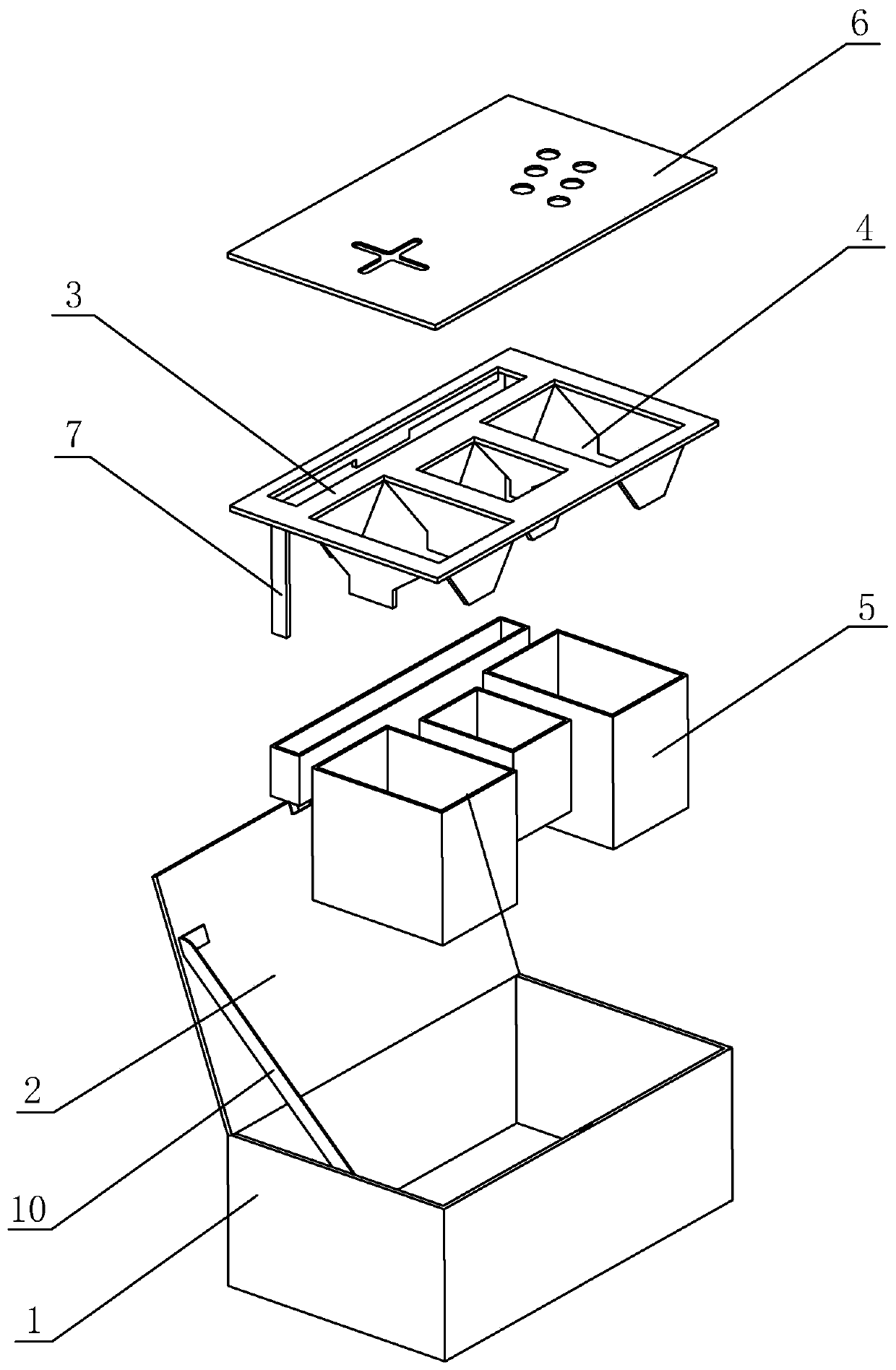

[0049] A gift box, see figure 1 and image 3 , including the lower box 1 and the cover plate 2. The lower box 1 is die-cut from a 2.5mm gray board. The surface of the gray board is dug with multiple V grooves and folded according to the V grooves to form the lower box 1. The upper end of the lower box 1 is The opening structure is set and lined with cardboard inside. The lined cardboard is 2.5mm gray board. The outer wall of the lower box 1 is wrapped with the lower box face paper, which is printed in four colors and covered with a glossy film, and then processed by bronzing and wrinkle leather, and then die-cut and wrapped on the outer wall of the lower box 1. The surface paper of the lower box can improve the aesthetics of the lower box 1, with better hand feeling and more prominent graphic display.

[0050] The cover plate 2 is die-cut from a 2.5mm gray board, and a V groove is dug on the side of the gray board. The opening of the box 1 is covered. The side of the cover...

Embodiment 2

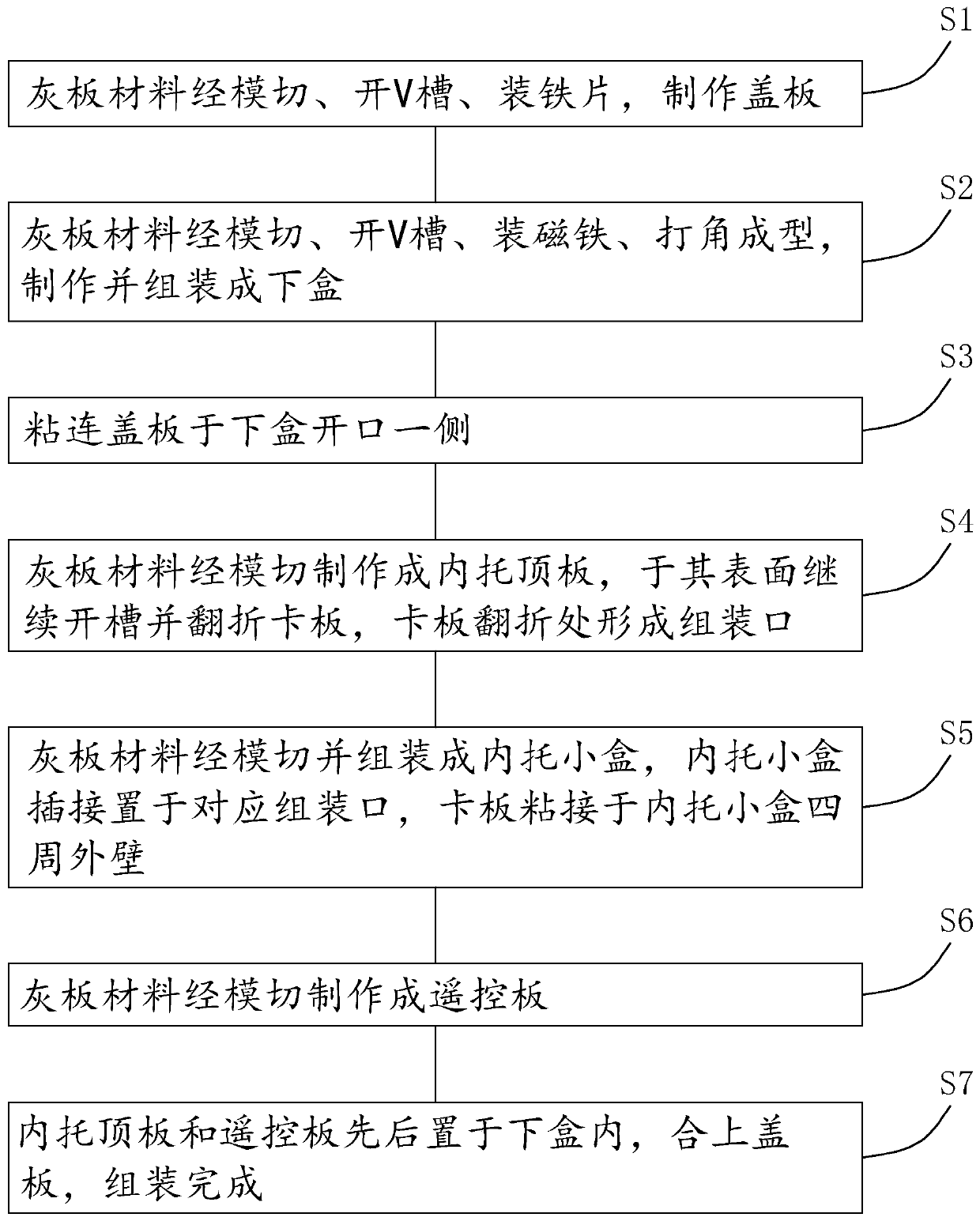

[0056] A manufacturing process of a gift box, refer to image 3 and Figure 4 , including the following steps:

[0057] Step 1: Die-cut the gray board material, open a V groove, install the iron sheet 9, and make the cover plate 2;

[0058] Step 2: The gray board material is die-cut, V-grooved, fitted with magnets 8, cornered and formed, and assembled into a lower box 1;

[0059] Step 3: Glue the cover plate 2 to the opening side of the lower box 1;

[0060] Step 4: Die-cut the gray board material to make the inner support top plate 3, continue to groove on its surface and fold over the clamping plate 7, and the folded position of the clamping plate 7 forms the assembly port 4;

[0061] Step 5: The gray board material is die-cut and assembled into a small inner support box 5, the inner support small box 5 is plugged and placed in the corresponding assembly port 4, and the clamping plate 7 is bonded to the outer wall around the inner support small box 5;

[0062] Step 6: Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com