Die cutting equipment for aluminum foil circuit board processing

A circuit board and aluminum foil technology, which is applied in the field of die-cutting equipment for aluminum foil circuit board processing, can solve problems such as finished product errors, and achieve the effects of reducing errors, improving flexibility, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

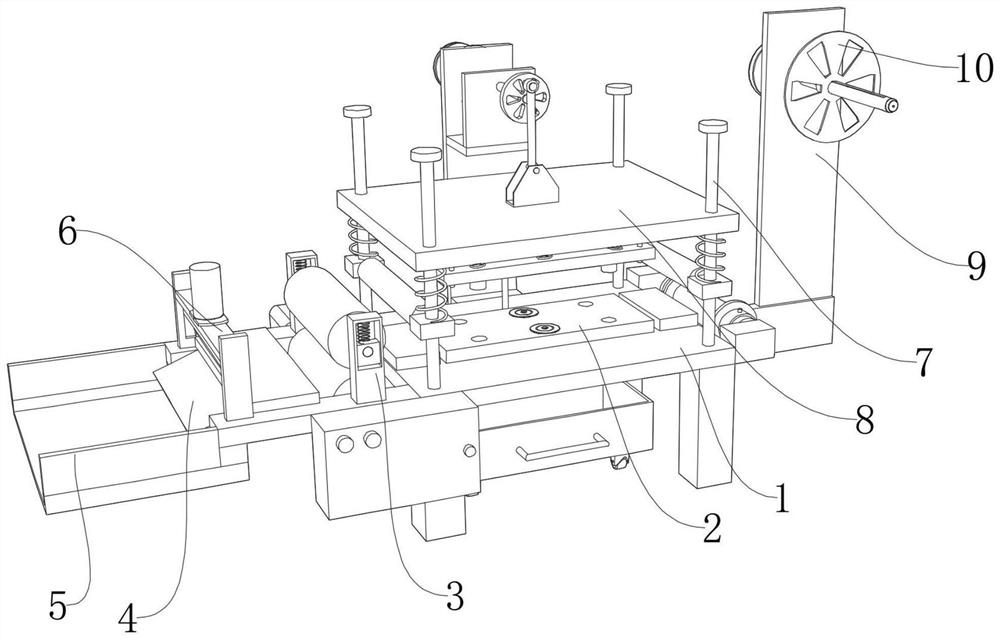

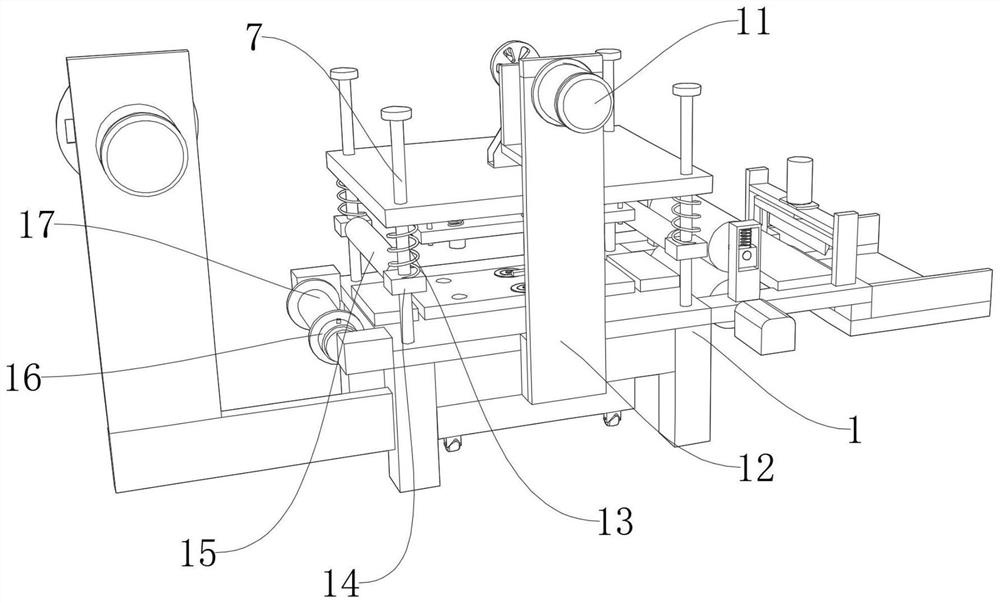

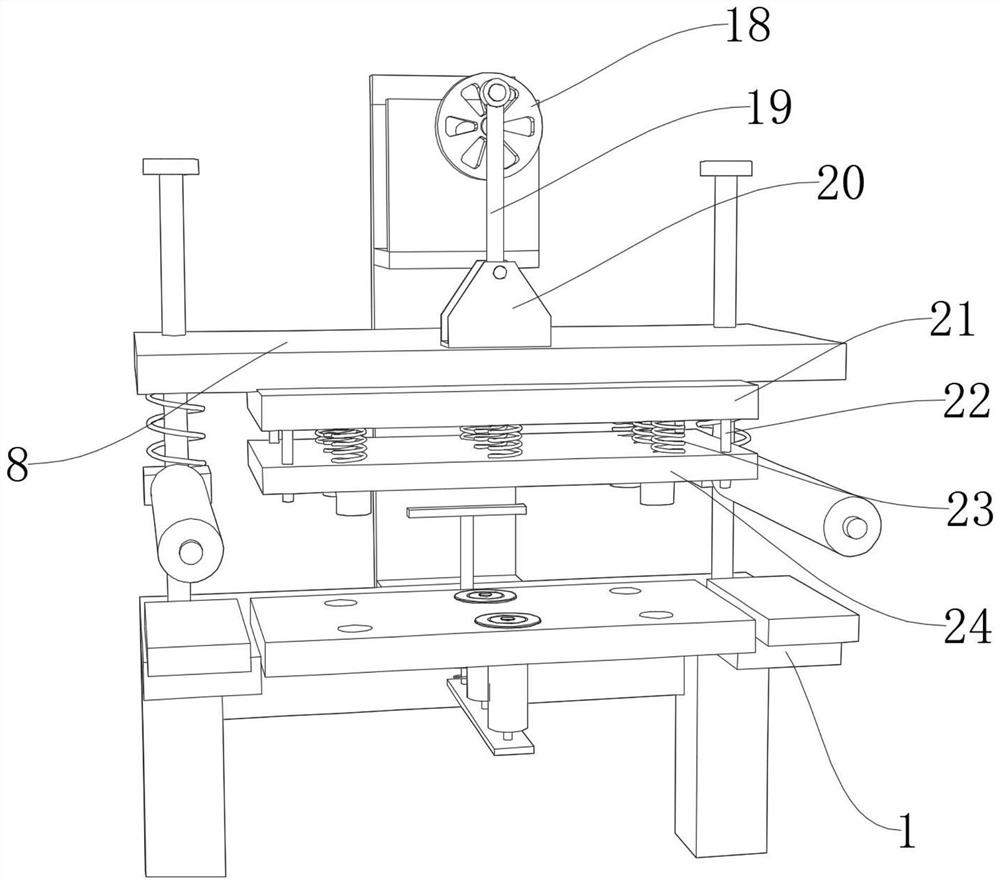

[0038] like Figure 1-Figure 9 As shown, a die-cutting equipment for aluminum foil circuit board processing includes a frame 1, the upper surface of the frame 1 is fixed with four guide columns 7 by bolts, and a sliding plate 8 is slidably connected between the four guide columns 7, and the sliding plate 8 The top of the frame 1 is fixed with a connecting seat 20 by bolts, one side of the frame 1 is fixed with a mounting frame 12 by bolts, one side of the mounting frame 12 is fixed with a first motor 11 by bolts, and one end of the output shaft of the first motor 11 is fixed by bolts There is a turntable 18, one side of the turntable 18 is rotatably connected with an eccentrically arranged push rod 19, and the bottom of the push rod 19 is rotatably connected with the turntable 18, the bottom of the slide plate 8 is fixed with an upper template 21 by bolts, and the bottom of the upper template 21 is fixed with bolts A plurality of second springs 23 are fixed, the bottom of the ...

Embodiment 2

[0040] refer to Figure 1-Figure 9 , the present invention provides a new technical solution, a die-cutting equipment for aluminum foil circuit board processing, including a frame 1, the upper surface of the frame 1 is fixed with four guide columns 7 by bolts, and between the four guide columns 7 A sliding plate 8 is slidably connected, a connecting seat 20 is fixed on the top of the sliding plate 8 by bolts, a mounting frame 12 is fixed on one side of the frame 1 by bolts, a collection box is arranged at the bottom of the frame 1, and the bottom outer wall of the collection box is fixed by bolts There are a plurality of universal wheels, and the collection box is located below the installation port. The collection box is convenient for collecting scraps. One side of the installation frame 12 is fixed with the first motor 11 by bolts, and one end of the output shaft of the first motor 11 is bolted. A turntable 18 is fixed, one side of the turntable 18 is rotatably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com