Composite and multi-station full-die-cutting ultrahigh-frequency antenna processing device and method

A kind of processing equipment and ultra-high frequency technology, which is applied in the field of composite and multi-station full die-cutting ultra-high frequency antenna processing equipment, and can solve problems such as offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

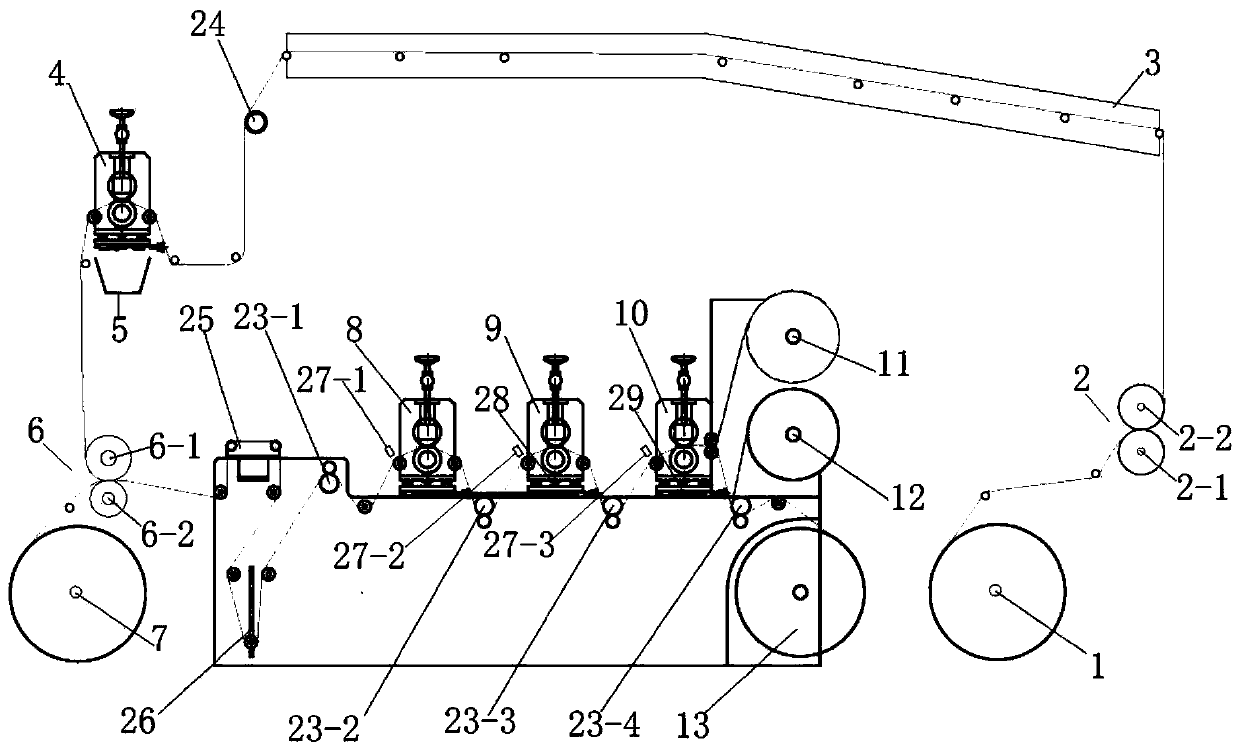

[0149] Specific embodiment 2, specific embodiment 2 is basically the same as this embodiment 1, the difference is: the registration described in a kind of composite and multi-station full die-cut UHF tag antenna processing equipment of specific embodiment 2 The mechanism is composed of three registration electric eyes, three longitudinal registration mechanisms 28, and three horizontal registration mechanisms 29, and each registration electric eye, one longitudinal registration mechanism 28, and one horizontal registration mechanism 29 form each set of registration units , the first flat die-cutting machine or the first circular knife die-cutting machine 8 corresponds to the first set of registration unit, the second flat-pressure die-cutting machine or the second circular knife die-cutting machine 9 corresponds to the second set of registration unit, the third flat The compression die cutting machine or the third circular knife die cutting machine 10 corresponds to the third s...

specific Embodiment 3

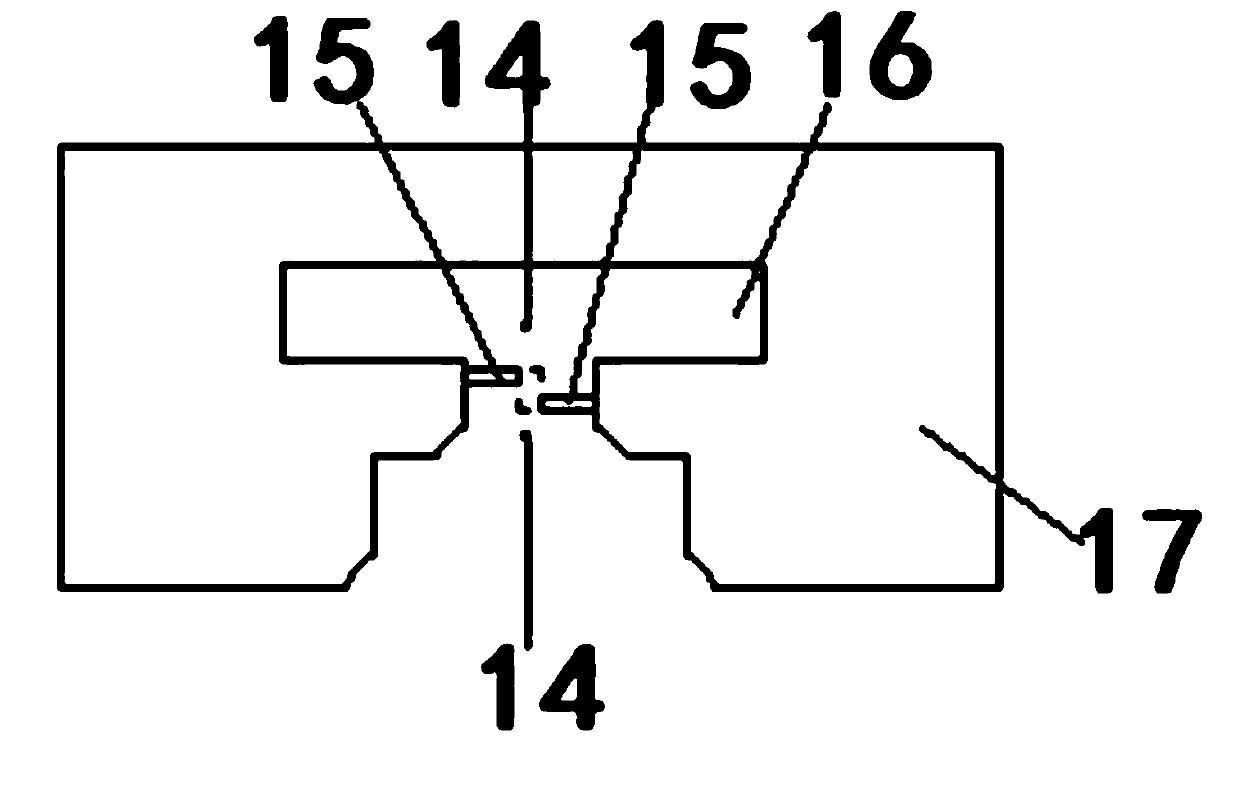

[0164] Specific embodiment 3, specific embodiment 3 is basically the same as this embodiment 1, the difference is: in specific embodiment 3, a composite and multi-station full die-cutting antenna processing equipment for UHF tags and the processing method No. The first die-cutting mechanism described in the nine steps is a die-cutting machine that performs flat die-cutting and / or circular knife die-cutting on the chip binding point 15 and the chip binding positioning point 14 at the same time, that is to say, the first die-cutting mechanism The flat die-cutting and / or circular knife die-cutting of the chip binding point 15 and the chip binding positioning point 14 are completed at one time, for example, all of them are replaced by a flat-press die-cutting machine with a circular knife die-cutting machine. The operation is similar to the antenna layer Carry out one-time flat die-cutting to form the chip binding point 15 and the chip binding positioning point 14, that is to say, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com