Method for die cutting of wine labels on embossed aluminum-coated paper

A technology for aluminum-coated paper and wine labels, applied in metal processing, etc., can solve the problems of only replacing the die-cutter, increasing costs, and wear of the die-cutting blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A process for die-cutting wine labels on embossed aluminized paper, comprising the following steps:

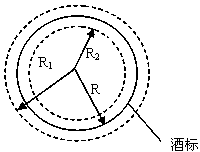

[0030] The border of the wine label to be die-cut is circular.

[0031] First, measure the radius R of the circular wine label;

[0032] Second, add about 1mm to the radius of the wine label as the outer radius R 1 , minus about 1mm from the radius of the wine label as the radius R of the inner circle 2 , to get a ring, then the width of the ring is about 2mm;

[0033] Third, according to the ring size obtained in step 2, cut out the corresponding ring on the discarded old blanket to obtain the rubber printing plate of the ring;

[0034] Fourth, install the ring rubber printing plate obtained in step 3 on the corresponding coating roller of the glazing machine, and fix it with double-sided tape;

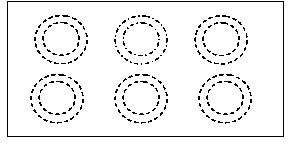

[0035] In addition, in the case of arranging several wine labels on large-format paper such as full-open or folio paper, multiple wine label rings can also be pasted on th...

Embodiment 2

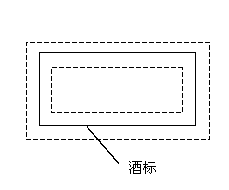

[0041] The boundary of the wine label to be die-cut is rectangular.

[0042] First, measure the length and width of the rectangular wine label;

[0043] Second, add about 1.5mm to the length and width of the wine label as the outermost boundary, and subtract about 1.5mm from the length and width of the wine label as the innermost boundary to obtain a rectangular border with a width of about 3mm;

[0044] Thirdly, according to the size of the rectangular frame obtained in step 2, cut out the corresponding rectangular frame ring on the discarded old blanket to obtain the rubber printing plate of the rectangular frame;

[0045] Fourth, install the rubber printing plate with a rectangular frame obtained in step 3 on the plate cylinder of any unit of the printing machine, and can be installed in the idle unit when printing any job, and be coated online while printing other jobs. Cloth, the rubber printing plate with a rectangular frame can be fixed with double-sided tape;

[0046...

Embodiment 3

[0051] A method for die-cutting wine labels on embossed aluminized paper, comprising the following steps:

[0052] First, first measure the outer boundary size of the wine label to be die-cut;

[0053] Second, add 2 mm to the measured outer border size of the wine label as the outermost border size of the new graphic, and subtract 2 mm from the outer border size as the innermost border size of the new graphic to obtain a wine label shape frame with a width of 4 mm;

[0054] Third, obtain the outer boundary, inner boundary, and width of the wine label shape frame according to step 2, cut out one or more corresponding wine label shape frames on the discarded old rubber cloth, and dig out the rubber cloth inside the inner boundary Empty, to get a new rubber plate;

[0055] The 4th, the new rubber plate that step 3 obtains is installed on the cylinder of the equipment that has embossing mechanism;

[0056] In addition, in the case of arranging several wine labels on large-format...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com