A kind of inclined flattening trademark machine

A trademark machine and oblique pressing technology, used in printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as poor die-cutting quality, and achieve the effect of smooth lifting, improving efficiency and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

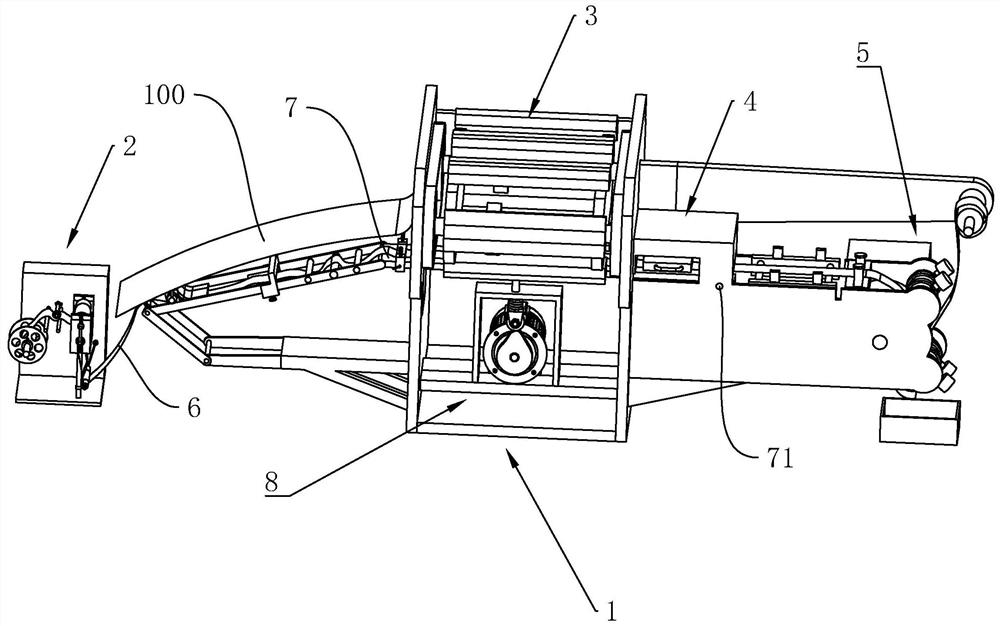

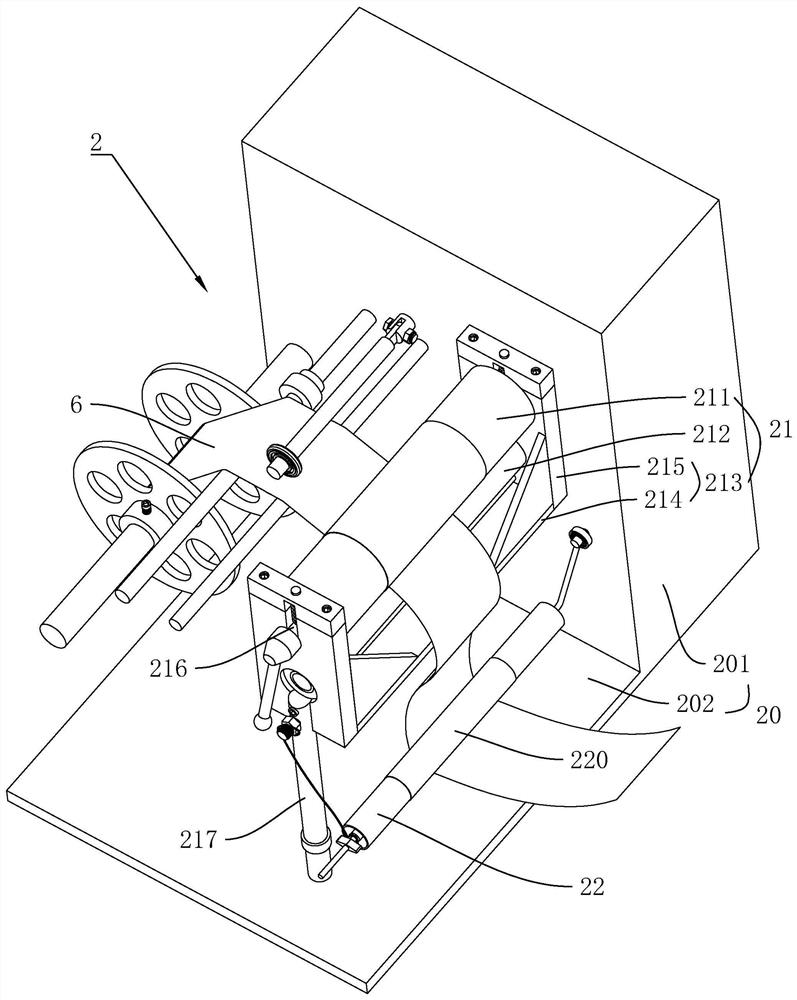

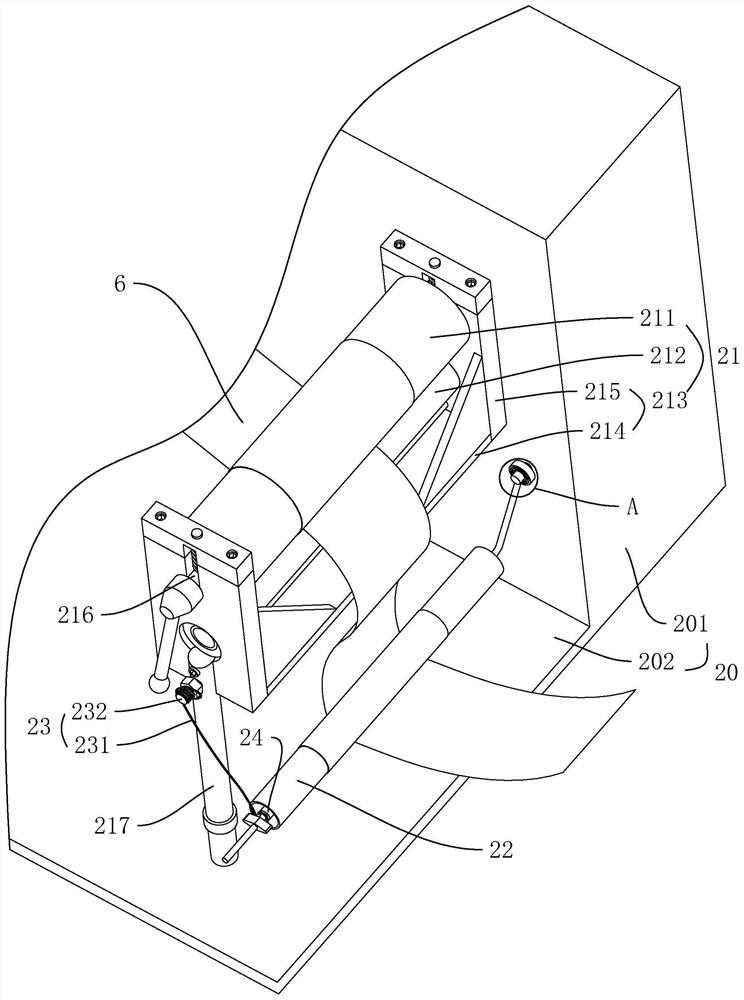

[0043] A kind of inclined flattening trademark machine, such as figure 1 As shown, it includes frame 1, feeding mechanism 2, printing mechanism 3, die-cutting mechanism 4, oblique pressing plate 7, driving mechanism 8 and paper pulling mechanism 5, printing mechanism 3, die-cutting mechanism 4, and paper pulling mechanism 5 According to the transmission direction of the self-adhesive label tape 6, it is sequentially installed on the frame 1. The oblique pressing flat rocker 7 is obliquely hinged on the frame 1, and is directly below the printing mechanism 3 and the die-cutting mechanism 4. The driving mechanism 8 It is arranged below the frame 1, and is used to drive the inclined downward end of the oblique pressure level seesaw 7 to perform lifting motion.

[0044] Such as figure 1 As shown, the feeding mechanism 2 is installed next to the frame 1, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com