Anti-static high-temperature-resistant adhesive tape

A high-temperature, anti-static technology, used in adhesives, film/sheet release coatings, etc., to solve problems such as poor heat resistance and aging resistance, general heat resistance, and single structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

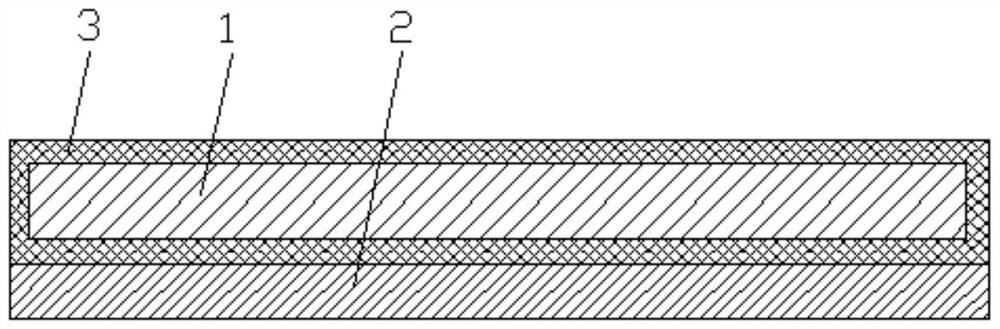

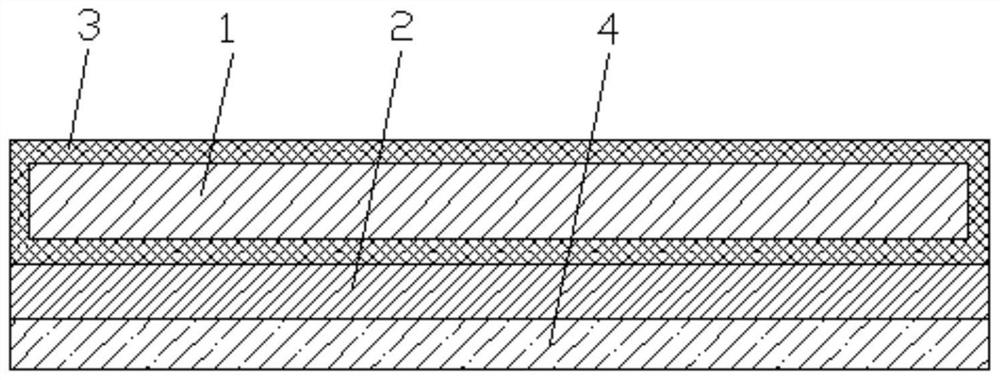

[0034] On the basis of the above structure, in this embodiment, the surface of the substrate 1 is coated with an antistatic layer 3, which is easy to prepare and can effectively improve the antistatic performance of the adhesive tape, thereby quickly releasing the static electricity released by the electronic components, effectively Protect electronic components.

Embodiment 2

[0036] On the basis of Embodiment 1, in this embodiment, the antistatic layer 3 is prepared from an antistatic agent, and the substrate 1 can obtain good antistatic performance by using the antistatic agent.

[0037] The above-mentioned antistatic layer 3 is usually directly coated with an antistatic agent on the substrate 1, and the antistatic agent adopts an existing antistatic agent. Mixed two types.

[0038] The externally-coated antistatic agent refers to a type of antistatic agent used for coating on the surface of polymer materials, that is, the antistatic layer 3 involved in this embodiment. Generally, it is formulated into a solution with a mass fraction of 0.5% to 2.0% with water or ethanol before use, and then it is attached to the surface of the polymer material by coating, spraying or dipping, and then dried at room temperature or hot air. Forms an antistatic coating. Most of these are cationic antistatic agents, and some are amphoteric and anionic antistatic ag...

Embodiment 3

[0041] On the basis of the above structure, in this embodiment, the adhesive layer 2 is silica gel. Silicone has the function of high temperature resistance, so the tape can avoid failure when used in a high temperature environment, and effectively maintain the high temperature resistance of the tape.

[0042] In addition, the thickness of the adhesive layer 2 is 0.02-0.04mm, which is suitable, which can not only satisfy various properties of the adhesive tape, but also save costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com