Support rod for outdoor tent and production process

A production process and technology of support rods, applied in the field of tents, can solve the problems of ineffective protection of metal support rods, unfavorable storage and use of support rods, and easy corrosion of metal support rods, so as to increase corrosion resistance and light resistance And weather resistance, the effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

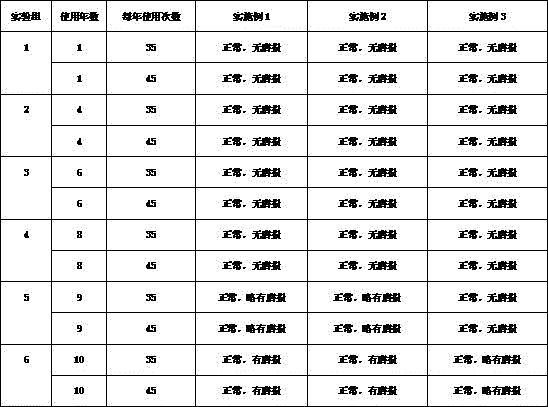

Examples

Embodiment 1

[0019] A support rod for an outdoor tent, the support rod for the outdoor tent includes a metal support rod and a support rod coating arranged on the outside of the metal support rod, the mass fraction of each component in the metal support rod includes 4 parts C, 2.5 parts of Cu, 5 parts of Mn, 3 parts of Ti, 60 parts of Fe, 2.5 parts of Cr, 3 parts of Al, 5 parts of Co, 1.7 parts of Si, 2.5 parts of Sn, 1 part of Ni, 2 parts of Pb, the support rod coating The parts by mass of each component include 45 parts of epoxy resin, 1.5 parts of pigment, 20 parts of solvent, 0.15 part of defoamer, 0.5 part of dispersant, 0.1 part of curing agent, 0.33 part of wetting agent, 0.12 part of anti-settling agent , 0.2 parts of leveling agent, 0.1 parts of rust inhibitor, 0.6 parts of drier, 0.3 parts of plasticizer, 0.4 parts of matting agent, 0.2 parts of flame retardant, 0.17 parts of antifouling agent, 0.2 part of anti-skinning agent, 13 part filler.

[0020] The metal support rod also ...

Embodiment 2

[0031] A support rod for an outdoor tent, the support rod for the outdoor tent includes a metal support rod and a support rod coating arranged on the outside of the metal support rod, the mass fraction of each component in the metal support rod includes 5 parts C, 1 part of Cu, 8 parts of Mn, 1 part of Ti, 63 parts of Fe, 1 part of Cr, 4 parts of Al, 3 parts of Co, 3.7 parts of Si, 1.5 parts of Sn, 3 parts of Ni, 1 part of Pb, the support rod coating The parts by mass of each component include 30 parts of epoxy resin, 3.5 parts of pigment, 13 parts of solvent, 1.3 parts of defoamer, 0.2 part of dispersant, 0.4 part of curing agent, 0.14 part of wetting agent, 0.5 part of anti-settling agent , 0.13 parts of leveling agent, 0.3 parts of rust inhibitor, 0.2 parts of drier, 0.5 parts of plasticizer, 0.1 part of matting agent, 0.5 parts of flame retardant, 0.13 parts of antifouling agent, 0.5 part of anti-skinning agent, 11 part filler.

[0032] The metal support rod also includes...

Embodiment 3

[0043] A support rod for an outdoor tent, the support rod for the outdoor tent includes a metal support rod and a support rod coating arranged on the outside of the metal support rod, the mass fraction of each component in the metal support rod includes 4 parts C, 2 parts of Cu, 7 parts of Mn, 2 parts of Ti, 60 parts of Fe, 2.5 parts of Cr, 4 parts of Al, 4 parts of Co, 2 parts of Si, 2 parts of Sn, 1 part of Ni, 2 parts of Pb, the support rod coating The parts by mass of each component include 40 parts of epoxy resin, 3.5 parts of pigment, 13 parts of solvent, 1.3 parts of defoamer, 0.4 part of dispersant, 0.2 part of curing agent, 0.14 part of wetting agent, 0.5 part of anti-settling agent , 0.13 parts of leveling agent, 0.2 parts of rust inhibitor, 0.4 parts of drier, 0.4 parts of plasticizer, 0.1 parts of matting agent, 0.5 parts of flame retardant, 0.13 parts of antifouling agent, 0.2 parts of anti-skinning agent, 11 part filler.

[0044] The metal support rod also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com