Titanium alloy anode oxidation technique based on ammonium tartrate system

A technology of anodic oxidation and ammonium tartrate, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of alloy hydrogen embrittlement, hazards, environmental pollution, etc., achieve good anti-contact corrosion performance, reduce pollution, composition simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Anodizing treatment of TB6 titanium alloy substrate

[0019] 1. Prepare alkaline corrosion solution

[0020] 25g / L sodium silicate, 25g / L sodium carbonate, 45g / L sodium hydroxide, 3g / L sodium lauryl sulfate, 5g / L triton and the rest of deionized water, stir well and set aside.

[0021] 2. Preparation of anodic oxidation treatment solution

[0022] 3g / L ammonium tartrate and the balance of deionized water, stir evenly, set aside.

[0023] 3. Anodizing treatment

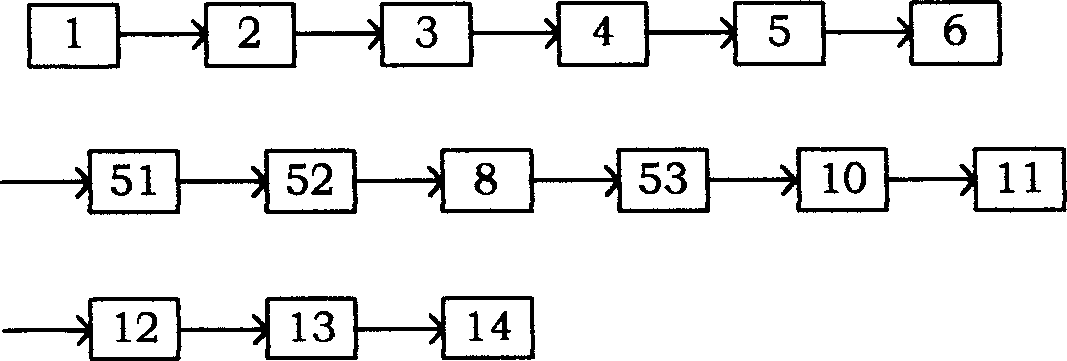

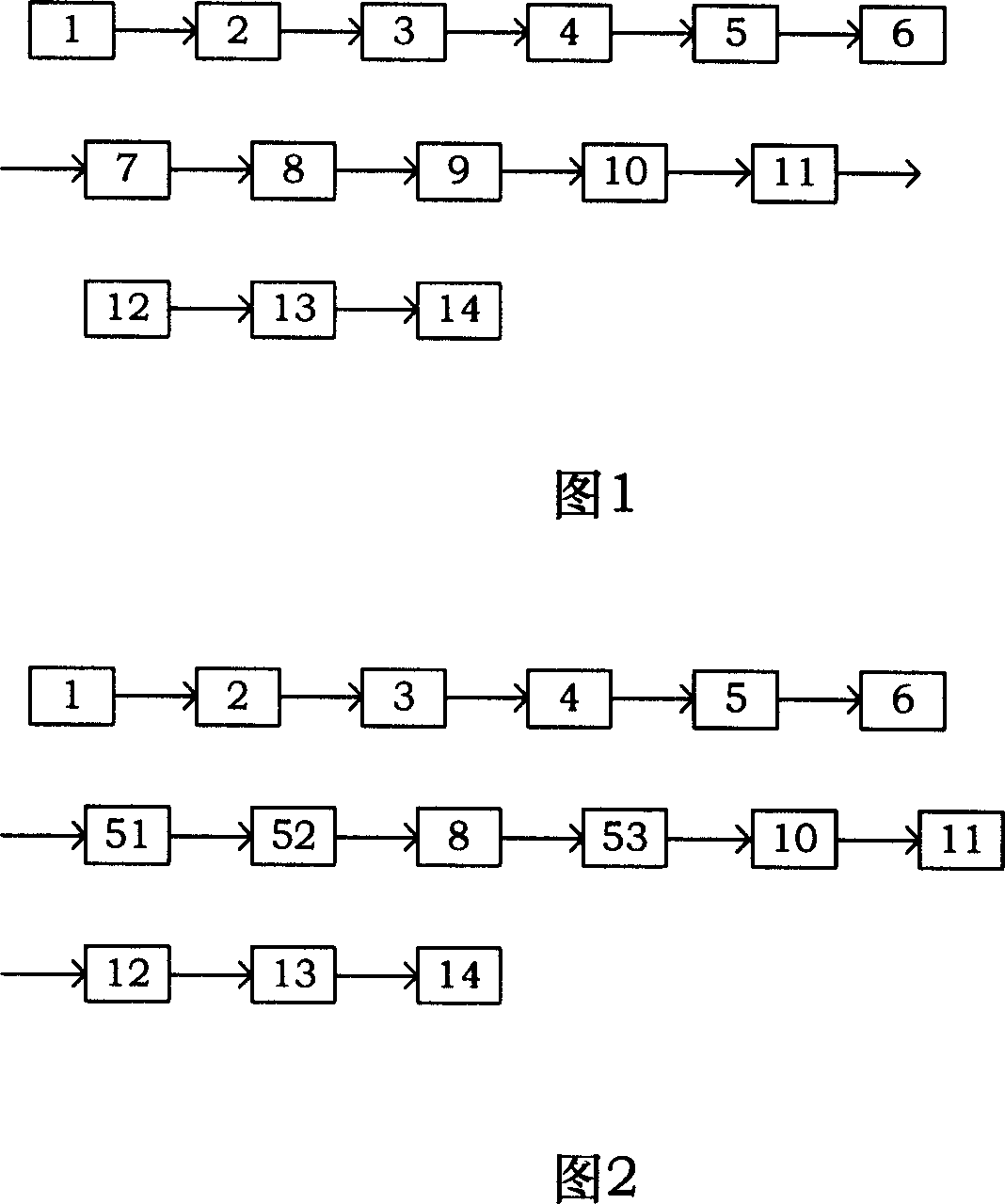

[0024] The TB6 titanium alloy substrate is sequentially subjected to anodic oxidation acceptance step 1-→organic solvent or water-based cleaning agent degreasing step 2-→mounting step 3-→degreasing step 4-→first flowing hot water washing step 5-→ After the conventional treatment of the first flowing cold water washing step 6, put it into the corrosion solution at 50±1°C for 30 minutes to complete the alkali corrosion step 51; then wash at the flowing water temperature of 40±1°C for 2 minutes to co...

Embodiment 2

[0039] Example 2: Anodizing treatment of TC18 titanium alloy substrate

[0040] 1. Prepare alkaline corrosion solution

[0041] 20g / L sodium silicate, 25g / L sodium carbonate, 40g / L sodium hydroxide, 3g / L sodium lauryl sulfate, 8g / L Tween 80 and the rest of deionized water, stir well and set aside.

[0042] 2. Preparation of anodic oxidation treatment solution

[0043] 3g / L ammonium tartrate and the balance of deionized water, stir evenly, set aside.

[0044] 3. Anodizing treatment

[0045] The TC18 titanium alloy substrate is sequentially subjected to anodic oxidation pre-acceptance step 1-→organic solvent or water-based cleaning agent degreasing step 2-→installation step 3-→degreasing step 4-→first flowing hot water washing step 5-→ After the conventional treatment of the first flowing cold water washing step 6, put it into the corrosion solution at 55±1°C for 40 minutes to complete the alkali corrosion step 51; then wash at the flowing water temperature of 45±1°C for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com