Health care vinegar and brewing process thereof

A technology of health-care vinegar and process, which is applied in the field of health-care vinegar and its brewing process, can solve the problems of unstable vinegar, decreased vinegar component concentration, single health-care effect, etc., and achieves improved raw material utilization, good health-care function, The effect of adapting to a wide range of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

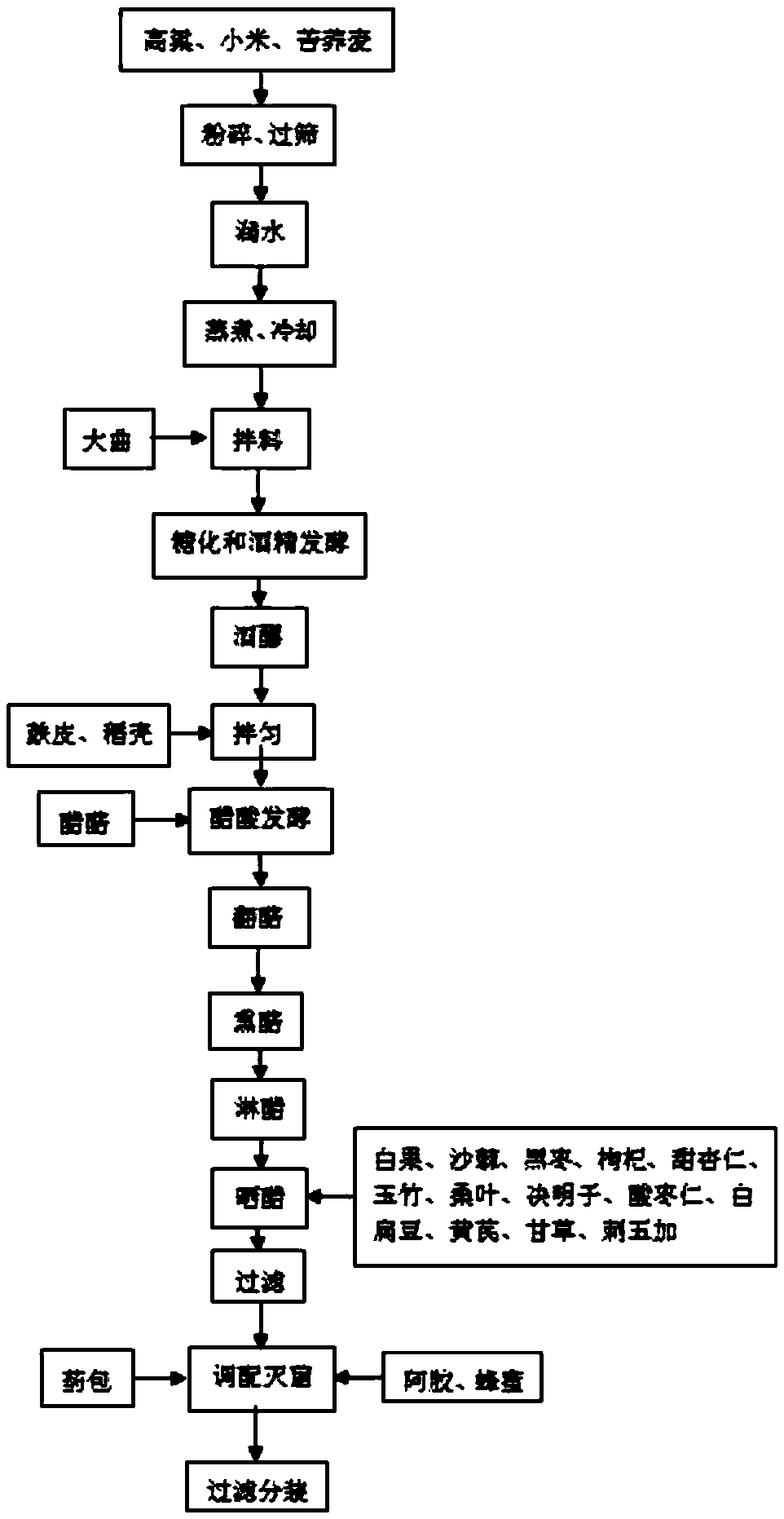

[0033] A brewing process of health-care vinegar, the concrete steps are as follows:

[0034] Raw material input amount is 500kg, and raw material weight ratio is sorghum: millet: tartary buckwheat=63:25:12; According to finally making health-care vinegar and raw material input ratio is 5:1, promptly finally makes health-care vinegar 2500kg;

[0035] 1. Steaming process

[0036] According to the ratio of raw materials, the raw materials are conveyed to the hammer-based pulverizer by the conveying auger, and then crushed through a φ9mm sieve, and sent to the spiral steamer for raw material moistening. The moistening ratio is 50%, and the moistening time is 1h. , and then heated and steamed in a spiral pressure steamer, after steaming, add water at 70-80°C, the water ratio is 225%, and finally cool quickly to 25-26°C in a spiral steamer, then add Daqu and mix Evenly, the amount of Daqu is 63% of the raw material;

[0037] 2. Saccharification and Alcoholic Fermentation Process ...

Embodiment 2

[0053] A brewing process of health-care vinegar, the concrete steps are as follows:

[0054] Raw material input is 500kg, and the raw material weight ratio is sorghum: millet: tartary buckwheat=65:25:10; According to finally made health-care vinegar and raw material input ratio is 5:1, promptly finally made health-care vinegar 2500kg;

[0055] 1. Steaming process

[0056] According to the ratio of raw materials, the raw materials are conveyed to the hammer-based pulverizer by the conveying auger, and then crushed through a φ9mm sieve, and sent to the spiral steamer for raw material moistening. The moistening ratio is 50%, and the moistening time is 1h. , and then heated and steamed in a spiral pressure steamer, after steaming, add water at 70-80°C, the water ratio is 225%, and finally cool quickly to 25-26°C in a spiral steamer, then add Daqu and mix Evenly, the amount of Daqu is 65% of the raw material;

[0057] 2. Saccharification and Alcoholic Fermentation Process

[005...

Embodiment 3

[0073] A brewing process of health-care vinegar, the concrete steps are as follows:

[0074] Raw material input amount is 500kg, and raw material weight ratio is sorghum: millet: tartary buckwheat=65:20:15; According to finally making health-care vinegar and raw material input ratio is 5:1, promptly finally makes health-care vinegar 2500kg;

[0075] 1. Steaming process

[0076] According to the ratio of raw materials, the raw materials are conveyed to the hammer-based pulverizer by the conveying auger, and then crushed through a φ9mm sieve, and sent to the spiral steamer for raw material moistening. The moistening ratio is 50%, and the moistening time is 1h. , and then heated and steamed in a spiral pressure steamer, after steaming, add water at 70-80°C, the water ratio is 225%, and finally cool quickly to 25-26°C in a spiral steamer, then add Daqu and mix Evenly, the amount of Daqu is 55% of the raw material;

[0077] 2. Saccharification and Alcoholic Fermentation Process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com