Process for manufacturing hot plate in chemical industry

A manufacturing process and hot plate technology, which is applied in the field of improvement of the current hot plate processing and manufacturing process, can solve the problems of unfavorable hot plate temperature uniformity, high processing requirements, and large damage to processing equipment, and is conducive to generalization. And the effect of popularization, low processing equipment requirements, and enhanced temperature rise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings.

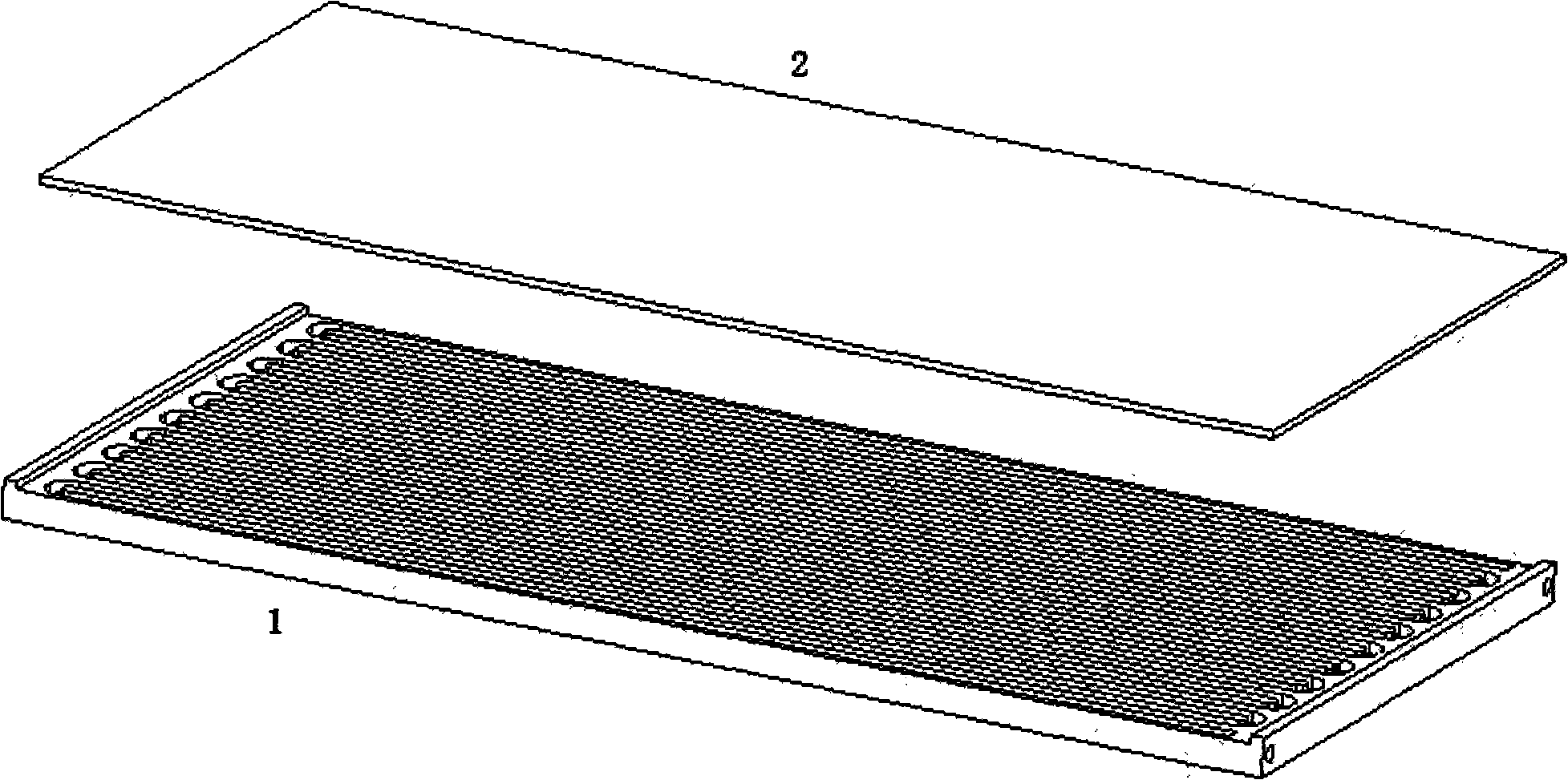

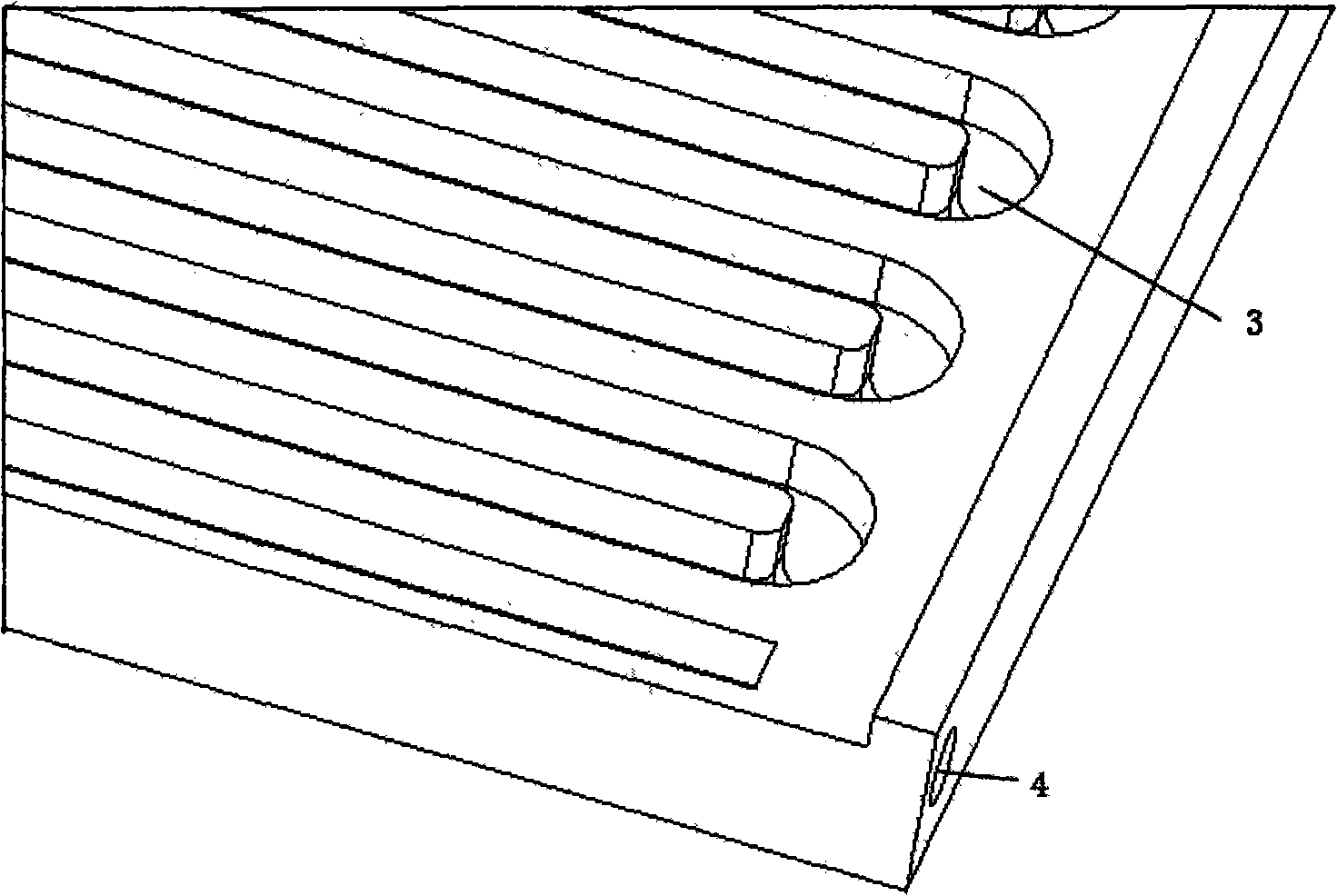

[0014] As shown in the figure, the hot plate of the present invention includes a hot plate base material 1 , a cover plate 2 , a heating steam inlet and outlet 3 and a heating steam circulation channel 4 . The heating steam inlet and outlet 3 and the heating steam circulation channel 4 are processed on the base material 1 of the heating plate, and the cover plate 2 is covered on the base material 1 of the heating plate.

[0015] The processing process is as follows: use a milling cutter to mill out the heating steam circulation channel 4 on the hot plate base material 1, the heating steam circulation channel is just the circulation path of steam in the hot plate, and the heating steam inlet and outlet 2 are processed by ordinary drilling machine, The heating steam circulation channel in the same plate forms a complete steam circulation path. The cover plate 2 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com