Sound insulation glass with liquid sound insulation layer structure

A technology of sound-insulating glass and sound-insulating layer, which is applied in the direction of sound-emitting devices and instruments, and can solve problems such as difficulty in adapting to changes in internal and external temperature differences, difficulty in vacuum degree, and high leakage rate, and achieve simple and practical production methods, reduced energy consumption, and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The accompanying drawings and the present invention are further analyzed below in conjunction with the embodiments.

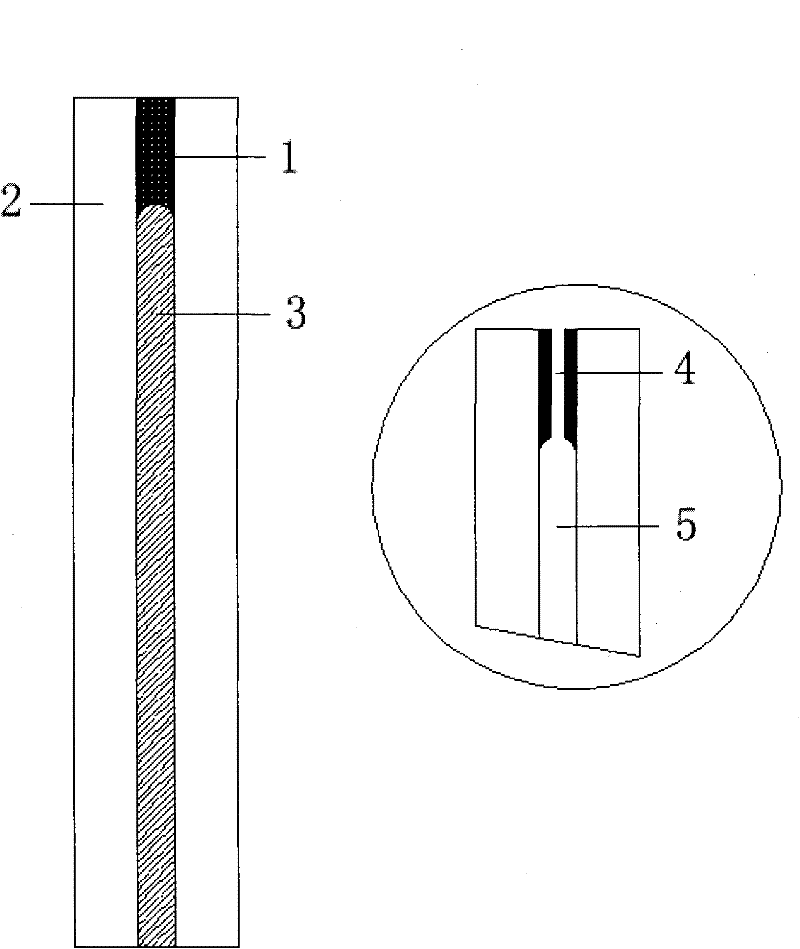

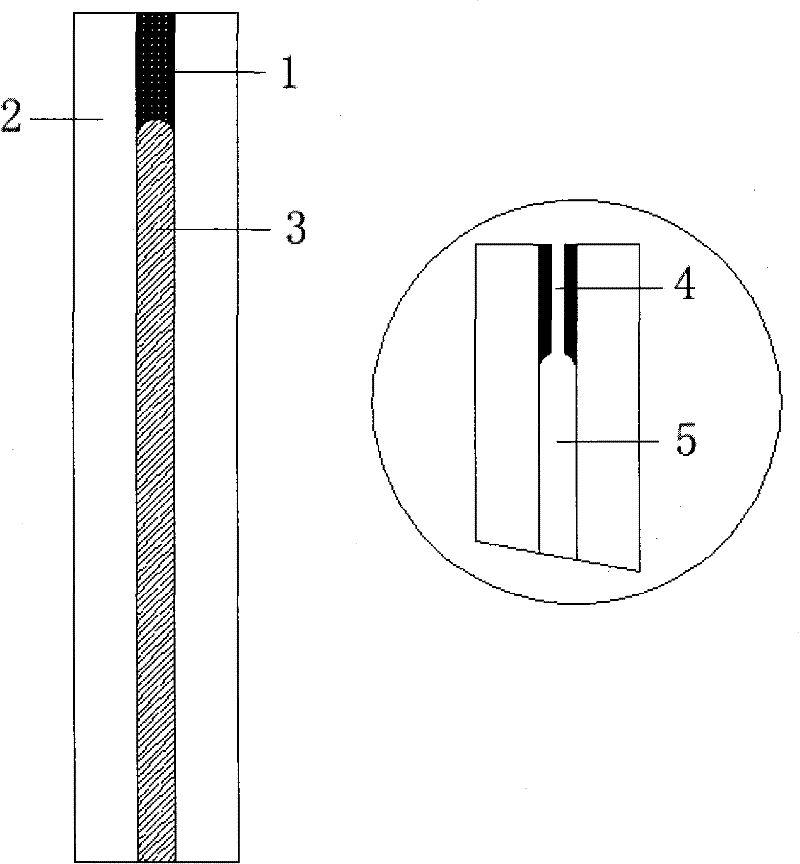

[0011] Depend on figure 1 It can be seen that the present invention contains at least two flat or curved glass 2 with the same peripheral shape, and the edges of the adjacent glasses are bonded and sealed with a sealing material 1 to form a cavity 5, and the cavity 5 is reserved while the cavity 5 is formed. The liquid hole 4 connects the liquid injection hole 4 with the cavity 5, and injects liquid into the cavity 5 through the liquid injection hole 4 to form the required liquid sound insulation layer 3. After the liquid injection is completed, the liquid injection hole 4 is sealed, so far Acoustic glazing with a liquid sound-insulating layer is completed.

[0012] In this embodiment, the original glass is flat toughened glass, the sealing material is silicone sealant, and the injected liquid is antifreeze for automobiles. It is determined through exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com