Large-size and low-cost double-deck structured airship pod made of composite material has and having no mechanical connection

A composite material and large-scale technology, applied in the direction of rigid airships, etc., can solve the problems of affecting the flight of airships and increasing the weight of airships, and achieve the effects of reducing structural weight, overall light weight, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

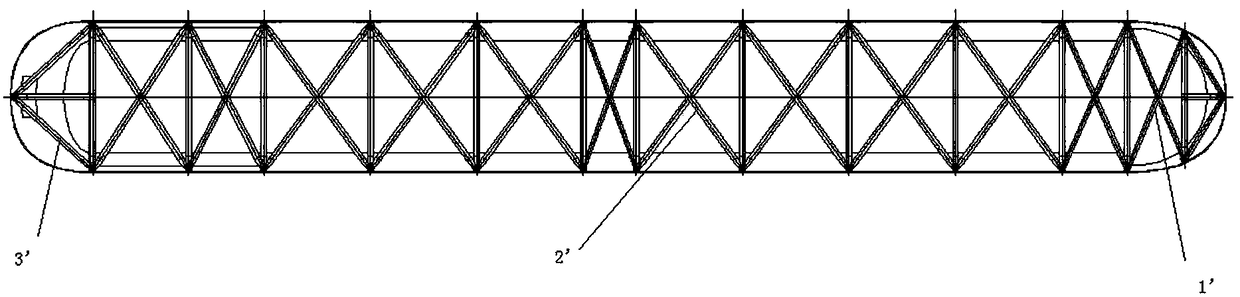

[0046] The invention provides an airship pod with large size and low-cost double-layer wall plate structure without mechanical connection. The structural design of composite materials takes into account its mechanical properties and comprehensively considers the highest and lowest service temperature of the material, and the performance caused by humidity / heat. Due to factors such as degradation, damage tolerance requirements, and material manufacturability, the overall appearance is simple, and full composite materials can be realized without mechanical connections, and are light in weight and low in cost.

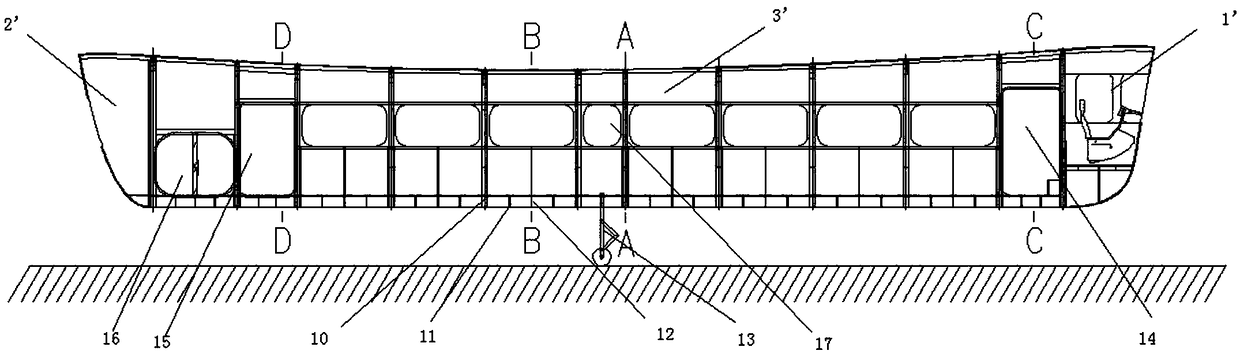

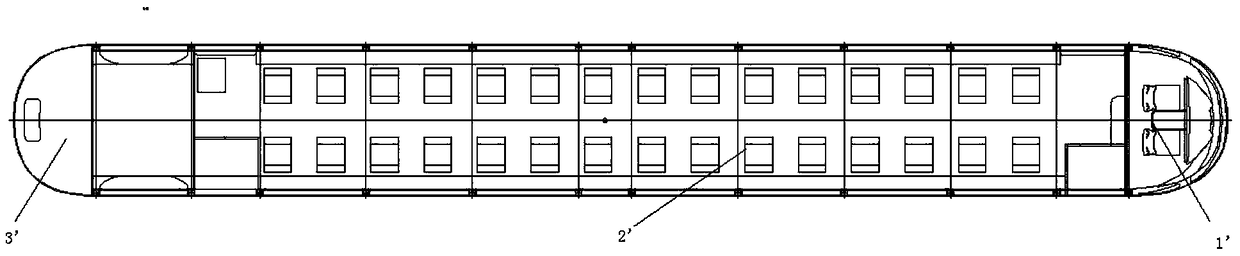

[0047] As an embodiment of the present invention, the present invention provides such as Figure 1-7 Composite materials without mechanical connection large-scale low-cost double-wall structure airship pod, including front cabin 1', rear ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com