Preparation method of sludge ceramsite used for medium and low concentration ammonia nitrogen wastewater treatment

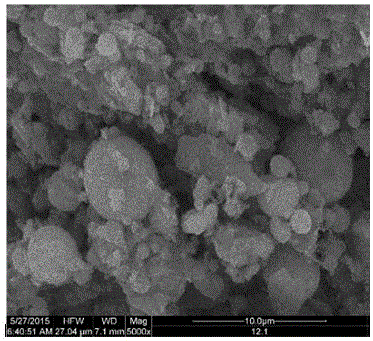

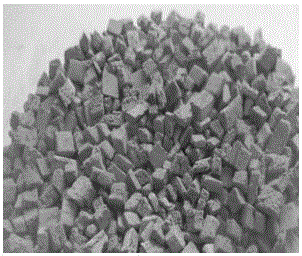

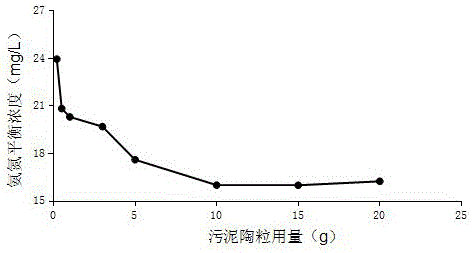

A low-concentration ammonia nitrogen and sludge ceramsite technology, which is applied in ceramic products, applications, clay products, etc., can solve secondary pollution and other problems, achieve low cost, facilitate adsorption, and increase the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1) Pretreatment of raw materials: Soak the fly ash at 25°C for 3 days with 5% NaOH solution by mass percentage, wash it with deionized water, and dry it at 105°C in an electric constant temperature drying oven; The remaining sludge in the dehydration workshop of the factory is dried at 105°C; the clay is dried at 105°C; the above three raw materials are dried and pulverized by a pulverizer, and passed through a 100-mesh sieve for later use;

[0057] 2) Mixing of raw materials: take pretreated fly ash, 60% residual sludge, and 10% clay in a mass ratio of 30% and fully mix to obtain a dry material;

[0058] 3) Granulation: add an appropriate amount of deionized water to the above dry material and stir evenly to make a 1-3mm billet, and place it on a tray and dry it in an oven at 110°C until the surface is free of moisture;

[0059] 4) Firing: Put the dried billet into the muffle furnace and heat it to 350°C, preheat for 30 minutes, then heat up to 800°C and fire for 10 mi...

Embodiment 2

[0068] 1) Pretreatment of raw materials: Soak the fly ash at 25°C for 3 days with 5% NaOH solution by mass percentage, wash it with deionized water, and dry it at 105°C in an electric constant temperature drying oven; The remaining sludge in the dehydration workshop of the factory is dried at 105°C; the clay is dried at 105°C; the above three raw materials are dried and pulverized by a pulverizer, and passed through a 100-mesh sieve for later use;

[0069] 2) Mixing of raw materials: taking pretreated fly ash, 40% of excess sludge and 10% of clay in a mass ratio of 50% and fully mixing to obtain a dry material;

[0070] 3) Granulation: add an appropriate amount of deionized water to the above dry material and stir evenly to make a 1-3mm billet, and place it on a tray and dry it in an oven at 110°C until there is no moisture on the surface;

[0071] 4) Firing: Put the dried billet into a muffle furnace and heat it to 450°C, preheat for 40 minutes, then heat up to 800°C and fire...

Embodiment 3

[0074] 1) Pretreatment of raw materials: Soak the fly ash at 25°C for 3 days with 5% NaOH solution by mass percentage, wash it with deionized water, and dry it at 105°C in an electric constant temperature drying oven; The remaining sludge in the dehydration workshop of the factory is dried at 105°C; the clay is dried at 105°C; the above three raw materials are dried and pulverized by a pulverizer, and passed through a 100-mesh sieve for later use;

[0075] 2) Mixing of raw materials: take pretreated fly ash, 30% residual sludge, and 10% clay in a mass ratio of 60% and fully mix to obtain a dry material;

[0076] 3) Granulation: add an appropriate amount of deionized water to the above dry material and stir evenly to make a 1-3mm billet, and place it on a tray and dry it in an oven at 110°C until there is no moisture on the surface;

[0077] 4) Firing: Put the dried billet into a muffle furnace and heat it to 500°C, preheat it for 10 minutes, then raise the temperature to 1100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com