Blue-green algae solid moulded fuel and preparation method thereof

A solid molding fuel and blue-green algae technology, applied in the direction of solid fuel, fuel, biofuel, etc., can solve the problems of difficulty in popularization and transportation, difficulty in collecting hydrogen, difficulty in large-scale utilization, etc., to achieve large-scale industrial production, wide application range, Fast processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the cyanobacteria solid briquette fuel of the present embodiment, comprises the following steps:

[0035] 1. Drying: Dry the blue-green algae to reduce the water content of the blue-green algae to 10%.

[0036] 2. Crush: crush and sieve the cyanobacteria to obtain the cyanobacteria raw material, and the particle size of the cyanobacteria raw material is ≤5mm.

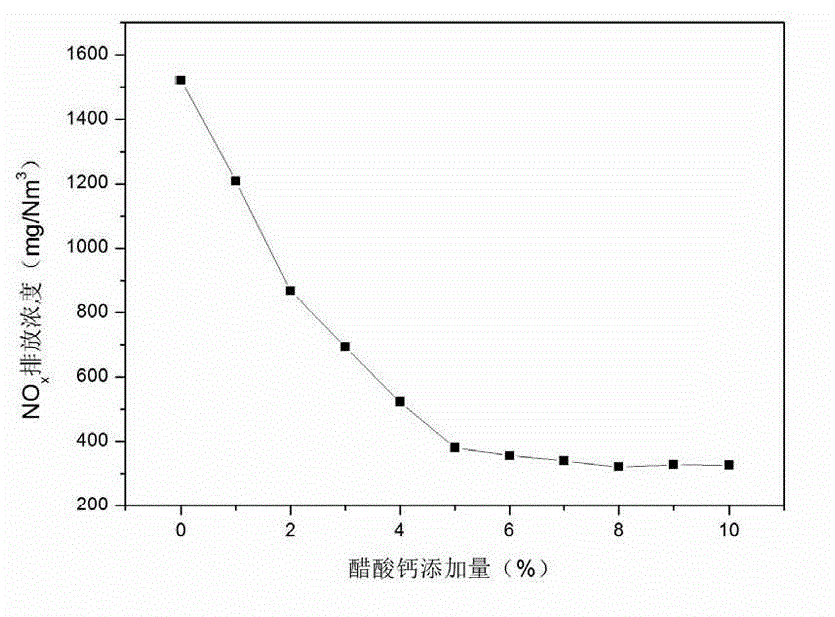

[0037] 3. Add denitrification and antifungal agents: add calcium propionate according to 8% of the mass of blue-green algae raw materials, and stir evenly to obtain dried blue-green algae raw materials.

[0038] 4. Molding: Under the conditions of molding pressure of 60MPa and molding temperature of 80°C, the dried cyanobacteria raw material is mechanically extruded by a molding machine to become a solid fuel.

[0039] 5. Cooling: Sieve out the unformed fines of the high-temperature solid fuel on a vibrating sieve, and use it to lower the temperature to below 10°C higher than room tempe...

Embodiment 2

[0050] The preparation method of the cyanobacteria solid briquette fuel of the present embodiment, comprises the following steps:

[0051] 1. Drying: Dry the blue-green algae to reduce the water content of the blue-green algae to 12%.

[0052] 2. Crush: crush and sieve the blue-green algae to obtain the blue-green algae raw material, the particle size of the blue-green algae raw material is ≤3mm.

[0053] 3. Add denitrification and antifungal agents: add calcium formate according to 6% of the mass of blue-green algae raw materials, and stir evenly to obtain dried blue-green algae raw materials.

[0054] 4. Molding: Under the conditions of molding pressure of 65MPa and molding temperature of 85°C, the dried cyanobacteria raw material is mechanically extruded by a molding machine to become a solid fuel.

[0055] 5. Cooling: Sieve out the unformed fines of the high-temperature solid fuel on a vibrating sieve, and use it to lower the temperature to below 10°C higher than room tem...

Embodiment 3

[0058] The preparation method of the cyanobacteria solid briquette fuel of the present embodiment, comprises the following steps:

[0059] 1. Drying: Dry the blue-green algae to reduce the water content of the blue-green algae to 8%.

[0060] 2. Crush: crush and sieve the blue-green algae to obtain the blue-green algae raw material, and the particle size of the blue-green algae raw material is ≤4mm.

[0061] 3. Add denitration and antifungal agents: add calcium benzoate according to 5% of the mass of the blue-green algae raw material, and stir evenly to obtain the dried blue-green algae raw material.

[0062] 4. Molding: Under the conditions of molding pressure of 30MPa and molding temperature of 70°C, the dried cyanobacteria raw material is mechanically extruded by a molding machine to become a solid fuel.

[0063] 5. Cooling: Sieve out the unformed fines of the high-temperature solid fuel on a vibrating sieve, and use it to lower the temperature to below 10°C higher than ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com