Baking-free bricks prepared through heavy-metal-polluted bottom mud

A technology for polluting sediment and burning-free bricks is applied in the field of preparation of building bricks or blocks, which can solve problems such as adverse effects on the human body of the land ecological environment, and achieve the effects of high cost performance, low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

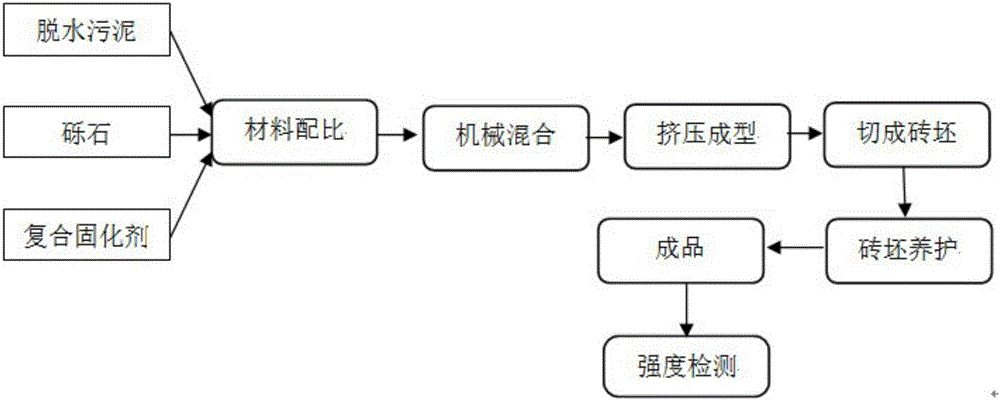

[0025] refer to figure 1 The process shown is to prepare unburned bricks, and the specific steps include:

[0026] (1) Add 3870g of heavy metal-contaminated bottom mud (water content 50%), 3870g of gravel (5-10mm in particle size), and 1935g of composite curing agent into the mixer, and mechanically stir evenly to obtain a premix;

[0027] (2) The premixed material processed in step (1) is sent into the brick making machine through the conveyor, extruded and formed, and on the blank cutting platform, the blank is cut to form a brick;

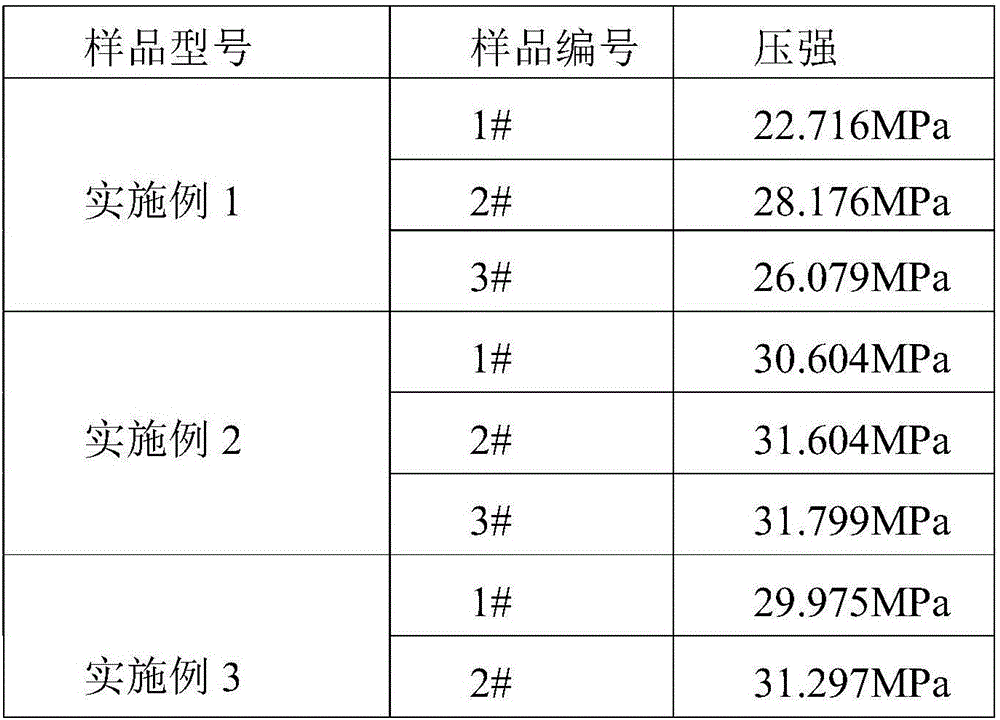

[0028] (3) The adobes are placed in the drying yard to dry naturally for 8 days. During the drying process, the adobes are watered and maintained with warm water at 40°C every morning. The strength and heavy metal leaching of the obtained unburned bricks are shown in Tables 1 and 2, respectively.

[0029] The composite curing agent is composed of Portland cement, modified fly ash, water reducer and chelating agent, wherein Portland cement 1800...

Embodiment 2

[0032] refer to figure 1 The process shown is to prepare unburned bricks, and the specific steps include:

[0033] (1) Add 2709g of heavy metal-contaminated bottom mud (water content 50%), 4063.5g of gravel (5-10mm in particle size), and 2257.5g of composite curing agent into the mixer, and mechanically stir evenly to obtain a premix;

[0034] (2) The premixed material processed in step (1) is sent into the brick making machine through the conveyor, extruded and formed, and on the blank cutting platform, the blank is cut to form a brick;

[0035] (3) The adobes are placed in the drying yard to dry naturally for 10 days. During the drying process, the adobes are watered and maintained with warm water at 30°C every morning. The strength of the unburned bricks obtained is shown in Table 1. The bricks were divided into 2, and heavy metal leaching was tested. The test results are shown in Table 3.

[0036] The composite curing agent is composed of Portland cement, modified fly a...

Embodiment 3

[0039] refer to figure 1 The process shown is to prepare unburned bricks, and the specific steps include:

[0040] (1) Add 3160.5g heavy metal contaminated bottom mud (water content 50%), 3612g aggregate, 2257.5g composite curing agent into the mixer, mechanically stir evenly, and prepare the premix;

[0041] (2) The premixed material processed in step (1) is sent into the brick making machine through the conveyor, extruded and formed, and on the blank cutting platform, the blank is cut to form a brick;

[0042] (3) The adobes are placed in the drying yard to dry naturally for 12 days. During the drying process, the adobes are watered and maintained with warm water at 20°C every morning. The strength of the unburned bricks obtained is shown in Table 1.

[0043] The composite curing agent is composed of Portland cement, modified fly ash, water reducing agent and chelating agent, wherein Portland cement is 2100g, modified fly ash is 105g, water reducing agent is 21g, and chela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com