Method for degrading atrazine in water by activating potassium peroxymonosulfate through iron-aluminum mud

A technology of potassium hydrogen persulfate and atrazine, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as resource consumption and adverse effects, and achieve The effect of wide distribution, low cost and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Use iron-aluminum mud from a water supply plant in Beijing as raw material, air-dried, crushed, and ground through a 100-mesh sieve for use. The obtained iron-aluminum slime was analyzed, and the results of pH, organic matter and main element composition are shown in Table 1.

[0034] Step 2: Add 200ml of 10μM atrazine solution into a 250ml Erlenmeyer flask. Accurately take 0.1g iron-aluminum slime sample in the conical flask of 250ml, add the potassium hydrogen persulfate solution 5ml of certain concentration simultaneously in conical flask, make the mol ratio of persulfate and atrazine be 20: 1.

[0035] Step 3: Place the Erlenmeyer flask on a magnetic stirrer and perform magnetic stirring at a speed of 200 r / min. Samples were taken at 0.5h, 1h, 2h, 3h, 4h, 5h, and 6h respectively, and after the samples were filtered through a 0.22 μm membrane filter, the concentration of atrazine was determined by liquid chromatography. According to the difference between ...

Embodiment 2

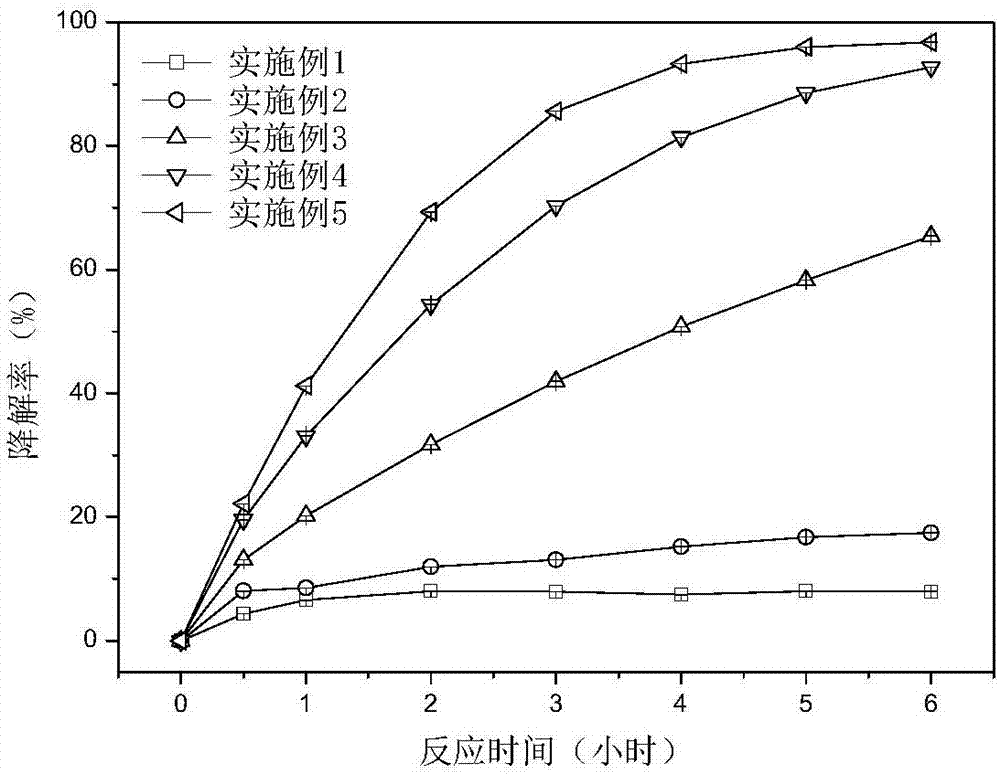

[0039] Except that the mol ratio of persulfate and atrazine is 50:1 in the second step, other implementation steps are all the same as in Example 1. For experimental results, see figure 1 .

Embodiment 3

[0041] Except that the mol ratio of persulfate and atrazine is 100:1 in the second step, other implementation steps are all the same as in Example 1. For experimental results, see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com