Dividing wall rotary kiln device for flue gas dehydration

A rotary kiln and flue gas technology, applied in the direction of rotary drum furnaces, furnaces, separation methods, etc., can solve problems such as limited industrial flue gas processing capacity, achieve the effects of reducing acid rain and air pollution, reducing energy consumption, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

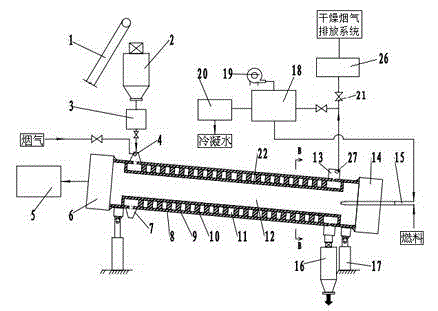

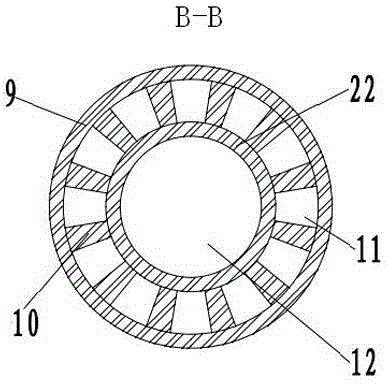

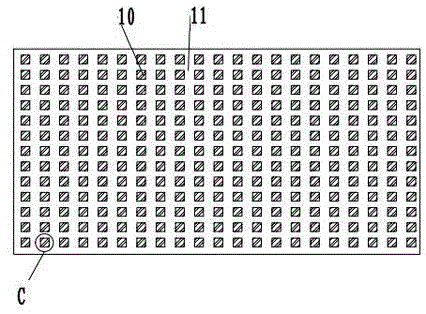

[0017] The partition wall rotary kiln device for flue gas dehydration of the present invention is as figure 1 As shown, it includes feeding equipment 1, feeding bin 2, conveyor 3, rotary kiln 8, waste heat power generation equipment 5, spare unloading bin 16, heat exchanger 18, blower 19, condenser 20, desulfurization and denitrification equipment 26 and drying Smoke exhaust system. Such as figure 2 As shown, the rotary kiln is a partition wall rotary kiln, which is composed of an outer ring 9 and an inner ring 22 installed coaxially. There is an annular material channel 11 between the inner ring and the outer ring. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com