Preparation method and application of fold hydrosulphonyl functionalized graphene oxide material

A graphene and functionalization technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of high cost, easy aging of macroporous ion exchange fibers, etc., and achieve low cost, simple regeneration method, and acid resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

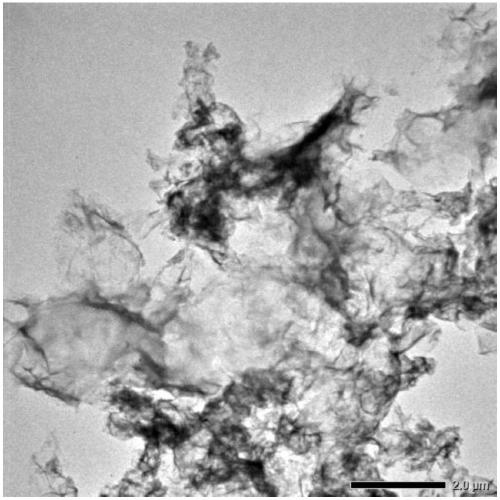

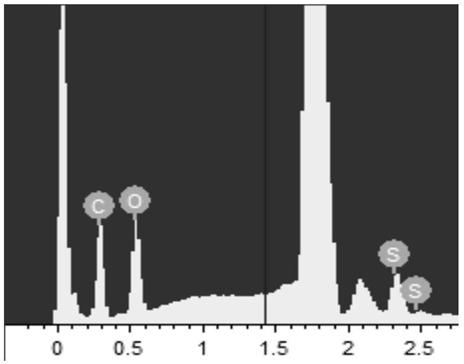

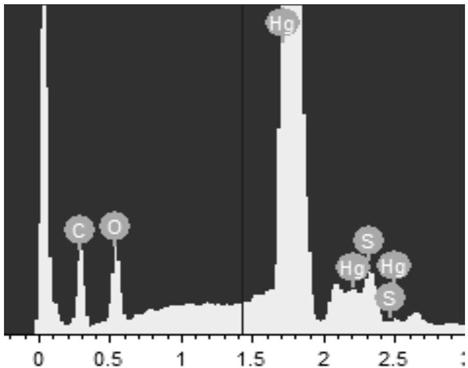

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: The preparation method of the wrinkled sulfhydryl-functionalized graphene oxide material of the present embodiment is carried out according to the following steps:

[0019] 1. Preparation of graphene oxide;

[0020] (1) 1.0~1.5g graphene is dispersed in 25ml of concentrated sulfuric acid, ultrasonicated for 2~4 hours, transferred to the ice-water mixture below 10℃, slowly added 0.5~0.8g of sodium nitrate, under the condition of magnetic stirring Add 3~4g potassium permanganate, react for 3~5 hours;

[0021] (2) After the completion of the reaction, transfer to a water bath at 35 to 40 °C and stir for 30 to 60 minutes, add 45 to 60 ml of distilled water, then transfer to a water bath at 80 to 85 °C for 15 to 30 minutes, and then add 80 to 100 mL of water , keep still for 2 to 6 minutes, remove the water bath, add 10% H 2 O 2 Until the color is golden yellow, then centrifugal washing, first washing with 5% hydrochloric acid three times, then washing with ...

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the drying in step 1 (2) is freeze drying, the drying temperature is -60 to -40°C, and the drying time is 12 to 14 hours. Others are also implemented. The same way.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of graphene oxide in the mixture in step 2 is 1-2 g / L; other embodiments are also the same as Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com