In situ load preparation of catalyst and catalytic ozonation drinking water deep purification method thereof

A technology of ozone oxidation and deep purification, applied in the direction of catalyst activation/preparation, catalyst regeneration/reactivation, chemical instruments and methods, etc., can solve problems such as not being widely promoted and applied, affecting large-scale applications, and complex reactors, etc. Achieving the effect of good catalytic ozonation oxidation to degrade refractory pollutants in water, excellent catalytic ozonation process ability, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

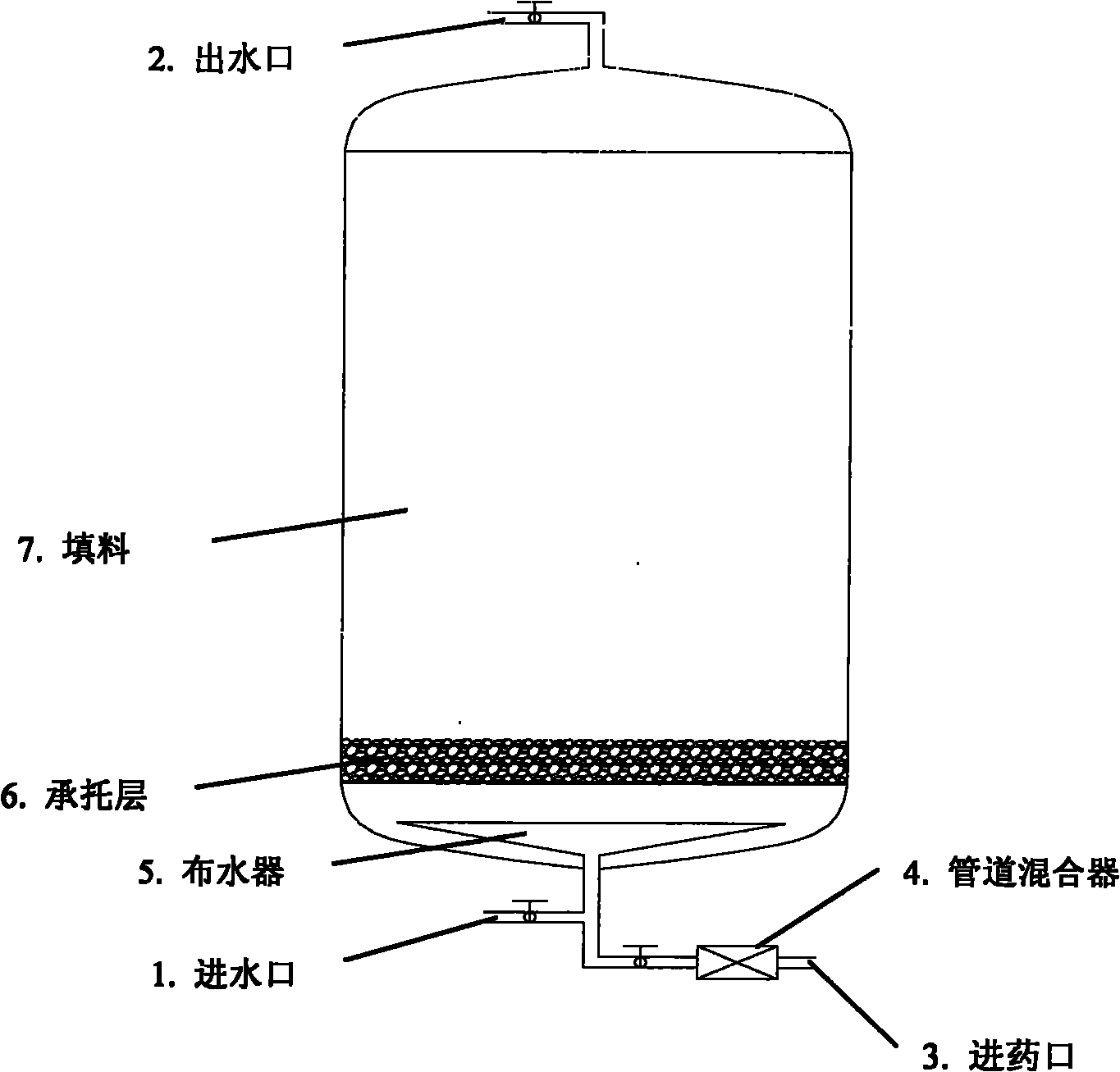

[0028] Preparation of iron-manganese composite oxide / support matrix catalytic material: fill the columnar reactor with diatomaceous earth as the support matrix; prepare 15g / L FeSO 4 ·7H 2 O and 4g / L KMnO 4 Reserve solution, add appropriate amount of lye to make the pH value of permanganate solution between 9.0-11.0; pump FeSO 4 Solution pumped in figure 1 In the shown reactor, stop the pump until the load matrix is submerged, and release the medicinal solution after immersion for 15 minutes; the permanganate solution added with lye is pumped into the reactor ( figure 1 ), stop the pump until the loaded substrate is submerged, let the solution flow out after immersion for 20 minutes, and let it stand for 60 minutes intermittently. Repeat the above method 3 times. Pump clean water into the reactor and let it flow out slowly until the concentration of iron and manganese in the effluent is lower than the national drinking water quality standard.

Embodiment 2

[0030] Preparation of iron-manganese composite oxide / support matrix catalytic material: fill the columnar reactor with diatomaceous earth as the support matrix; prepare 8g / L FeSO 4 ·7H 2 O with 10g / L FeCl 3 ·6H 2 Mixed stock solution of O; prepare 2g / L KMnO 4 reserve solution, and add an appropriate amount of lye to make the pH value of the permanganate solution between 9.0-11.0; pump FeSO 4 with FeCl 3 The mixed solution is pumped into figure 1 In the shown reactor, stop the pump until the load matrix is submerged, and release the medicinal solution after immersion for 30 minutes; the permanganate solution added with lye is pumped into the reactor ( figure 1 ), stop the pump until the loaded substrate is submerged, let the solution flow out after immersion for 30 minutes, and let stand for 30 minutes intermittently. Repeat the above method 3 times. Pump clean water into the reactor and let it flow out slowly until the concentration of iron and manganese in the efflue...

Embodiment 3

[0032] Preparation of iron-manganese composite oxide / support matrix catalytic material: fill the columnar reactor with ceramsite as the support matrix; prepare 8g / L FeSO 4 ·7H 2 O, 8g / L MnCl 2 4H 2 O with 10g / L FeCl 3 ·6H 2 Mixed stock solution of O; prepare 15g / L KMnO 4 stock solution, and add an appropriate amount of lye to make the pH value of the permanganate solution between 10-11; use a pump to pump the mixed solution figure 1 The shown reactor stops the pump until the load matrix is submerged, and releases the medicinal solution after 60 minutes of immersion; the permanganate solution added with lye is pumped into the reactor ( figure 1 ), stop the pump until the loaded matrix is submerged, let the solution flow out after 60 minutes of immersion, and let stand for 60 minutes intermittently. Repeat the above method 5 times. Pump clean water into the reactor and let it flow out slowly until the concentration of iron and manganese in the effluent is lower than t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com