Method for improving stability of gasoline by decoloring by using activated carbon fiber

A technology of activated carbon fiber and stability, which is applied in the field of using activated carbon fiber to decolorize and improve the stability of gasoline. It can solve the problems of low adsorption efficiency and complicated regeneration process, and achieve the effect of simple regeneration method, good color and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

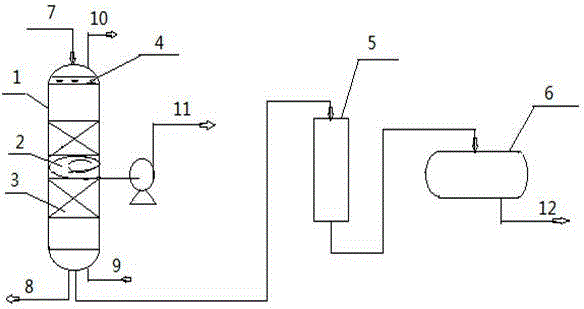

[0017] 1. Adsorption process.

[0018] (1) Gasoline below 40°C from the device enters the adsorber from the top, and is evenly sprayed onto the activated carbon fiber packing layer through the feed distributor at the top of the adsorber. The adsorption process of activated carbon fibers is an exothermic process, and low temperature is conducive to Physical adsorption, the heat generated during the adsorption process is taken away by the ring coil (circulating water as the refrigerant) arranged in the packing layer, a temperature sensor is installed between the packing layers, and the temperature of the adsorption packing layer is controlled below 70°C to ensure better the adsorption effect.

[0019] (2) After the gasoline passes through the adsorber, it enters the filter under self-pressure to remove the fine activated carbon fibers carried out. The gasoline filtered by the filter enters the buffer tank and is pumped into the tank area.

[0020] 2. Regeneration process.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com