Preparation of zirconium-doped hydrotalcite-like adsorbent and application of zirconium-doped hydrotalcite-like adsorbent in treatment of phosphorus-containing wastewater

A hydrotalcite and adsorbent technology, which is applied in the direction of adsorption of water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor regeneration effect and small adsorption capacity, and achieve fast adsorption speed, The effect of large adsorption capacity and large economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

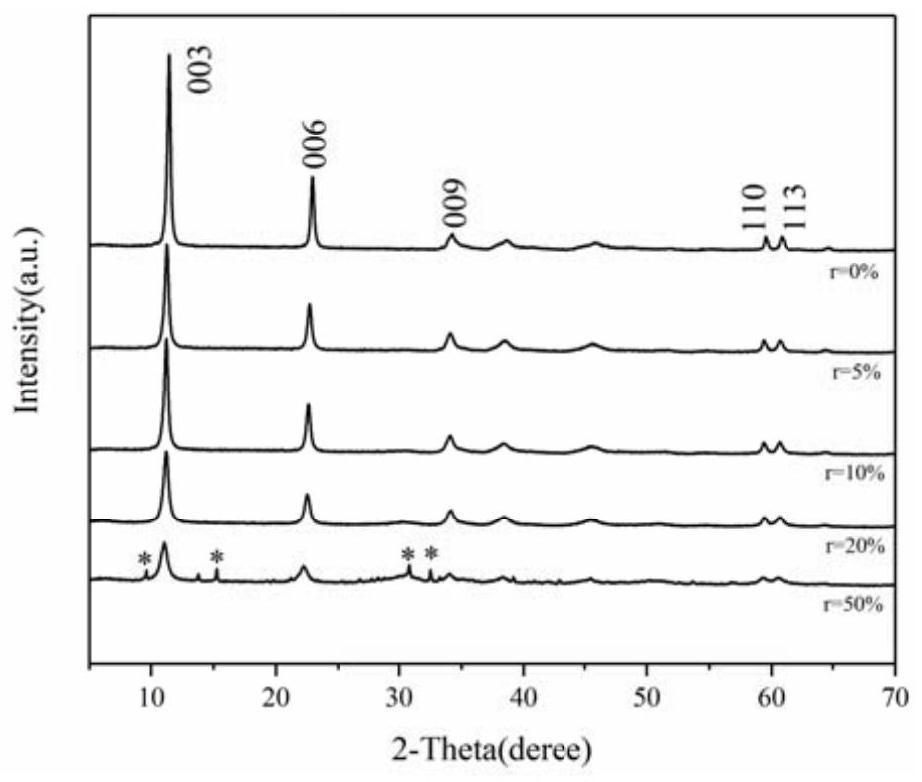

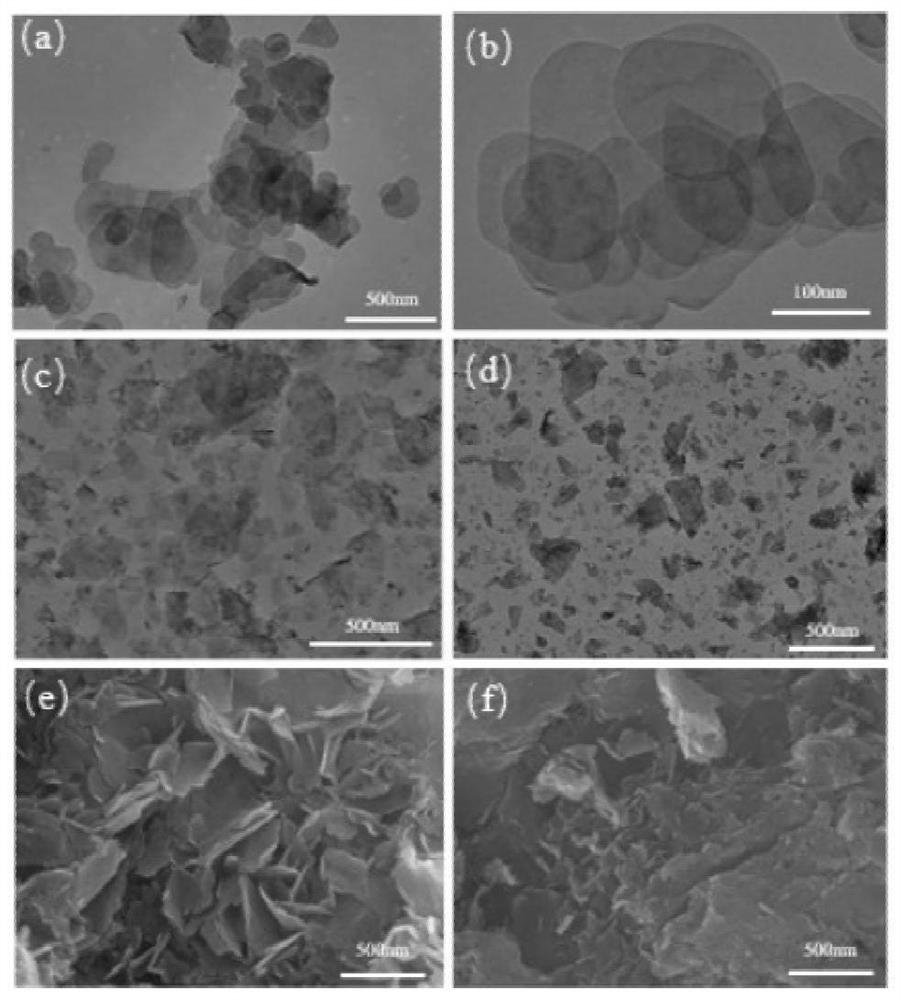

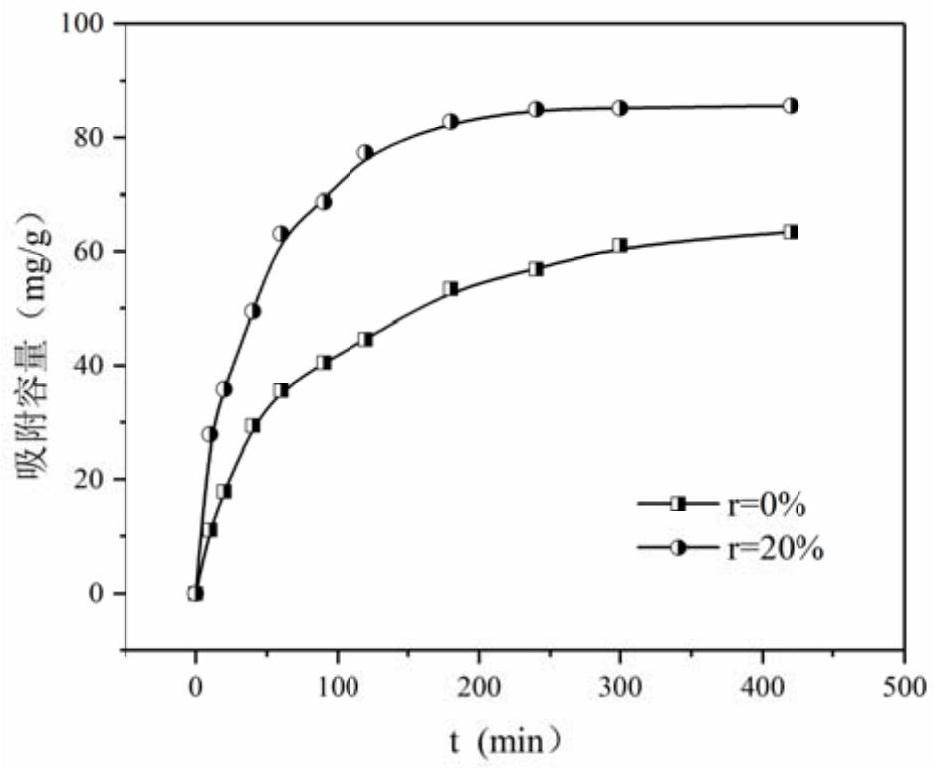

Embodiment 1

[0026] Step 1) 10.165g MgCl 2 ·6H 2 O and 4.5 g FeCl 3 ·6H 2 O was dissolved in 50mL deionized water to form a mixed metal solution, and 5.34g NaOH and 3.5g Na 2 CO 3 Dissolve in 50mL deionized water to make mixed lye. In the state of stirring, the two mixed solutions were slowly added dropwise to a three-necked flask containing 50 mL of deionized water with a peristaltic pump, and the pH of the reaction system was monitored with a pH meter. The pH of the solution was maintained at about 10 by controlling the rate of addition. make it happen co-precipitation reaction. After the reaction was completed, the slurry was transferred to a tetrafluoroethylene-lined hydrothermal kettle and heated at 120°C for 12 hours. Centrifugal washing until the pH is about 7, drying at 80°C, grinding through a 100-mesh sieve to obtain hydrotalcite-like powder, and roasting in a muffle furnace at 400°C for 2 hours to obtain an adsorbent material. The adsorption capacity is 41.65mg / g.

[00...

Embodiment 2

[0029] Step 1) 10.165g MgCl 2 ·6H 2 O, 4.05g FeCl 3 ·6H 2 O and 0.537 ZrOCl 2 ·8H 2 O was dissolved in 50mL deionized water to form a mixed metal solution, and 5.34g NaOH and 3.5g Na 2 CO 3 Dissolve in 50mL deionized water to make mixed lye. Slowly drop the two mixed solutions into a three-necked flask containing 50mL of deionized water with a peristaltic pump while stirring, monitor the change in the pH of the reaction system with a pH meter, and maintain the pH of the solution at around 10 by controlling the dropping rate. make it happen co-precipitation reaction. After the reaction was completed, the slurry was transferred to a tetrafluoroethylene-lined hydrothermal kettle and heated at 120°C for 12 hours. Centrifugal washing until the pH is around 7, drying at 80°C, grinding through a 100-mesh sieve to obtain hydrotalcite-like powder, and roasting at 500°C in a muffle furnace for 4 hours to obtain an adsorbent material with an adsorption capacity of 64.40mg / g.

[...

Embodiment 3

[0032] Step 1) 10.165g MgCl 2 ·6H 2 O, 3.6g FeCl 3 ·6H 2 O and 1.074 ZrOCl 2 ·8H 2 O was dissolved in 50mL deionized water to form a mixed metal solution, and 5.34g NaOH and 3.5g Na 2 CO 3 Dissolve in 50mL deionized water to make mixed lye. Slowly drop the two mixed solutions into a three-necked flask containing 50mL of deionized water with a peristaltic pump while stirring, monitor the change in the pH of the reaction system with a pH meter, and maintain the pH of the solution at around 10 by controlling the dropping rate. make it happen co-precipitation reaction. After the reaction was completed, the slurry was transferred to a tetrafluoroethylene-lined hydrothermal kettle and heated at 120°C for 12 hours. Centrifugal washing until the pH is around 7, drying at 80°C, grinding through a 100-mesh sieve to obtain hydrotalcite-like powder, and roasting at 400°C in a muffle furnace for 2 hours to obtain an adsorbent material with an adsorption capacity of 77.38 mg / g.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com