Synthetic method of palladium tetra-ammino sulfate

A technology of tetraammonium palladium sulfate and synthesis method, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., can solve the problem that product yield and quality are difficult to control, and the process flow is long. , excessive sulfuric acid and other problems, to achieve the effect of high product yield, good selectivity and large exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

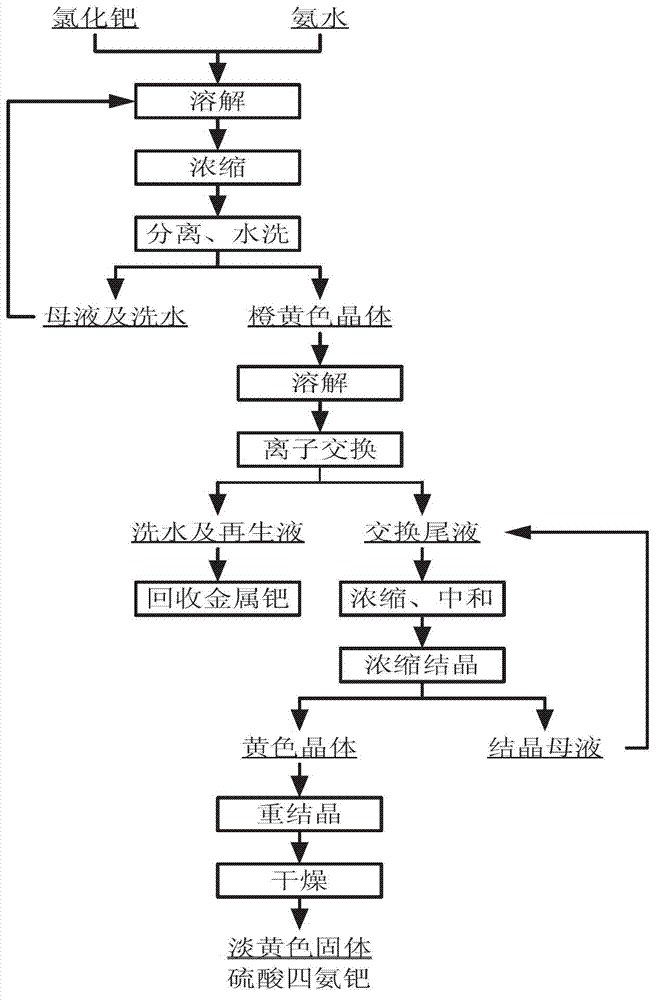

Image

Examples

example 1

[0024] Take 200 g of reagent palladium chloride in a flask, add 600 mL of reagent grade ammonia water, heat in a water bath, keep the temperature constant at 50°C, stir for 30 minutes, all the solids are dissolved, and a light yellow transparent solution is obtained. Adjust the temperature to 85°C and keep the temperature for 3 hours, a large amount of solids precipitated out in the flask. The solid was separated by filtration, washed with pure water, the filtrate and washing water were collected for treatment, the solid was transferred to an oven, the temperature was controlled at 100°C, and the temperature was kept constant for 2 hours to obtain an orange-yellow solid.

[0025] The solid was dissolved in water, and the concentration of palladium in the adjusted solution was 5 g / L. The ion exchange resin tube has a volume of 10L and is filled with about 7L of 201×7 anion exchange resin. The prepared solution flows through the resin slowly at a flow rate of 50mL / min. During th...

example 2

[0033] Take 200 g of reagent palladium chloride in a flask, add 500 mL of reagent grade ammonia water, heat in a water bath, keep the temperature constant at 50 ° C, stir for 30 minutes, all the solids are dissolved, and a light yellow transparent solution is obtained. Adjust the temperature to 85°C and keep the temperature for 3 hours, a large amount of solids precipitated out in the flask. The solid was separated by suction filtration, washed with a small amount of water, the filtrate and washing water were collected for treatment, the solid was transferred to an oven, the temperature was controlled at 100°C, and the temperature was kept constant for 2 hours to obtain an orange-yellow solid.

[0034] The solid was dissolved in water, and the concentration of palladium in the solution was adjusted to be 10 g / L. The volume of the ion exchange resin tube is 10L, and it is filled with about 7L of 201×7 anion exchange resin. The prepared solution flows through the resin slowly at...

example 3

[0042] Take 1000g of palladium chloride as a reagent in a flask, add 2000mL of reagent-grade ammonia water, heat in a water bath, keep the temperature constant at 60°C, stir for 30 minutes, all the solids are dissolved, and a light yellow transparent solution is obtained. Adjust the temperature to 85°C and keep the temperature for 5 hours, a large amount of solids precipitated out in the flask. The solid was separated by suction filtration, washed with water, the filtrate and washing water were collected for treatment, the solid was transferred to an oven, the temperature was controlled at 100°C, and the temperature was kept constant for 4 hours to obtain an orange-yellow solid.

[0043] The solid is dissolved in water, and the concentration of palladium in the solution is adjusted to be about 20 g / L. The volume of the ion exchange resin tube is 10L, and it is filled with about 7L of 201×7 anion exchange resin. The prepared solution flows through the resin slowly at a flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com