Catalytic conversion method for preducing more propylene

A catalytic conversion method and propylene technology, which are applied in chemical recovery, organic chemistry, bulk chemical production, etc., can solve the problems of increasing the propylene selectivity and yield limitations of catalytic cracking units, and achieve the effect of continuous regeneration operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

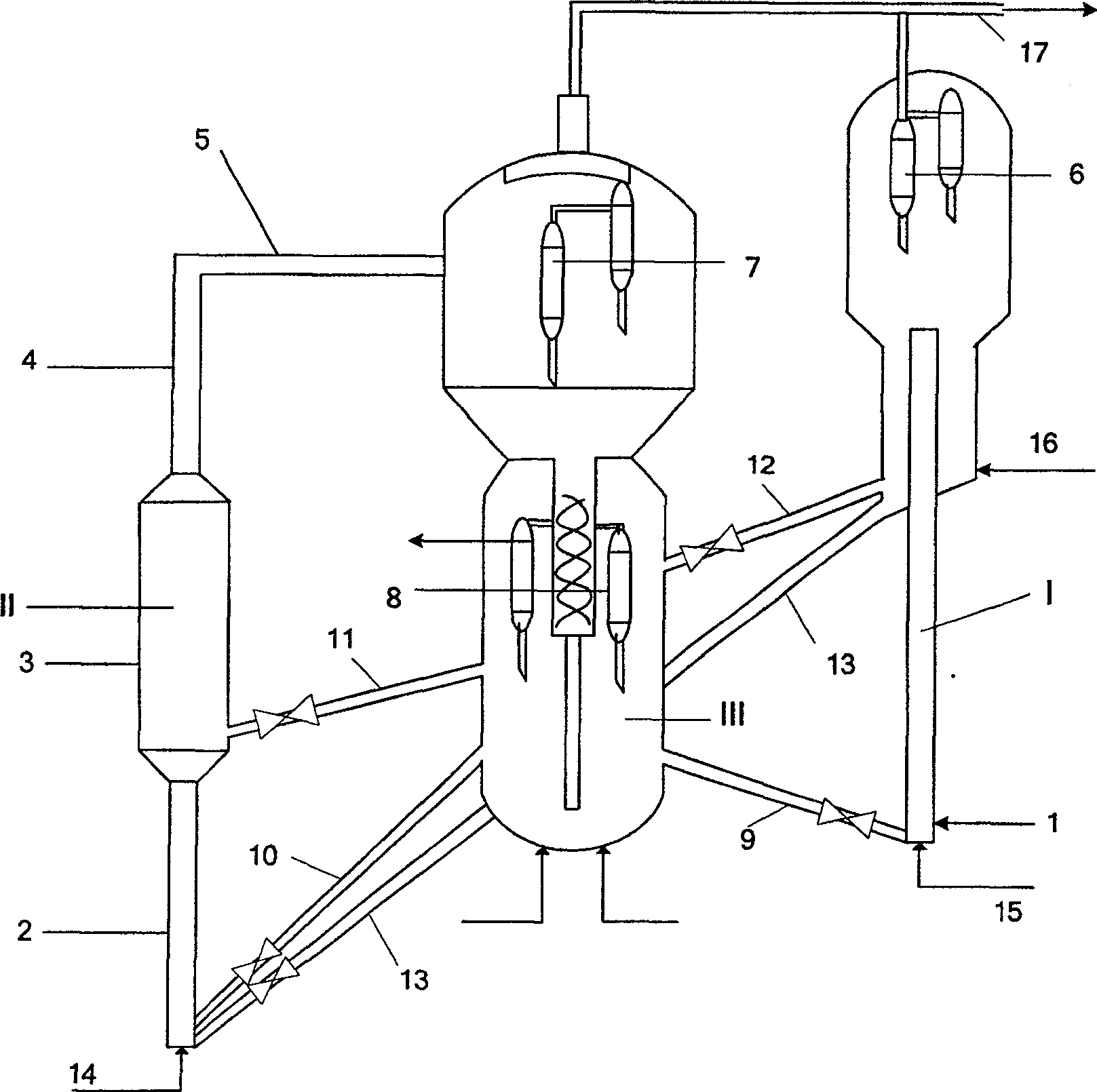

[0052] This example illustrates the catalytic conversion process of hydrocarbon oil using Catalyst A containing Y-type zeolite on the medium-scale double riser reaction regeneration system provided by the present invention.

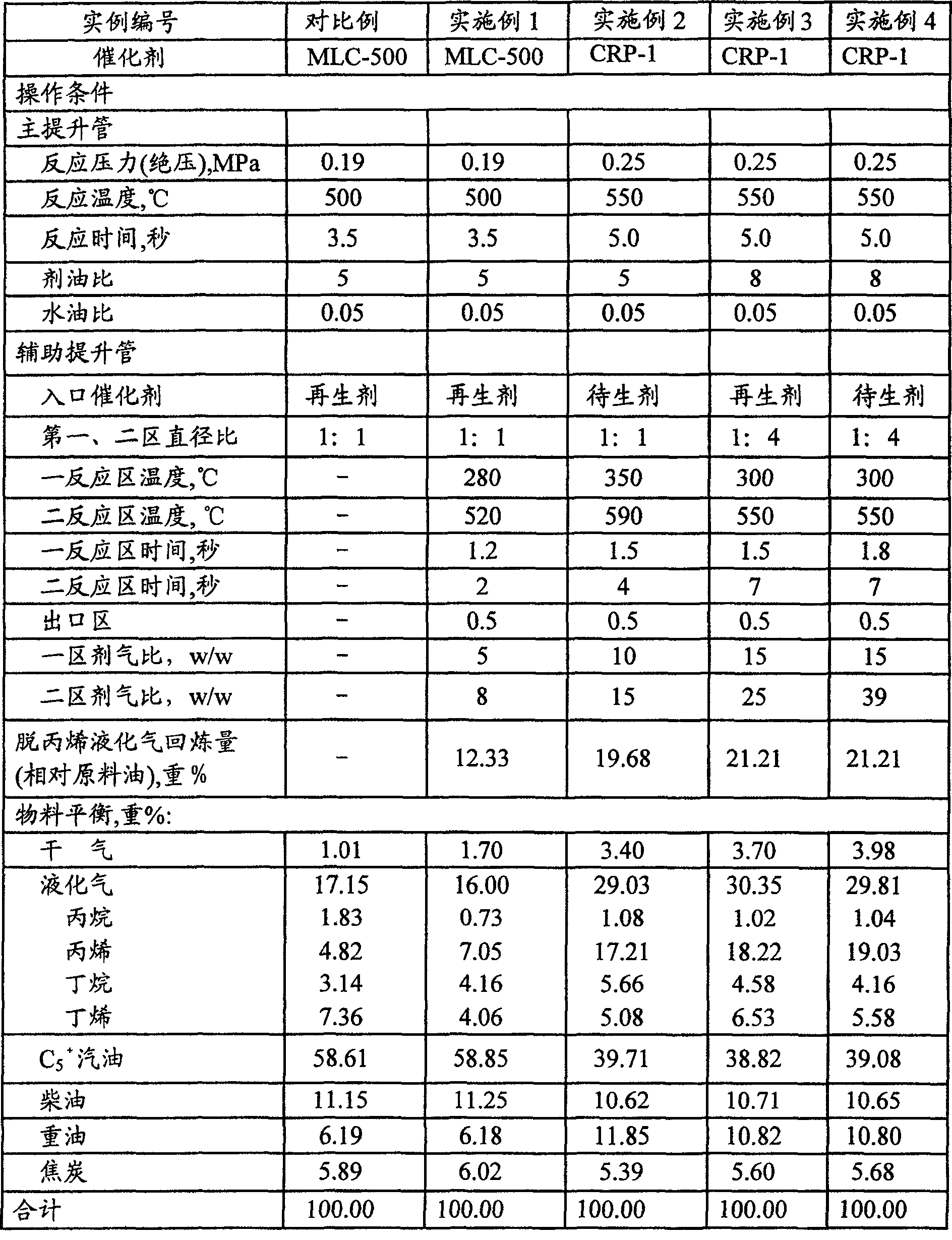

[0053] The total height of the main riser reactor of the reaction regeneration system is 15 meters, and the diameter is 0.25 meters; the total height of the auxiliary riser reactor is 12 meters, and the diameter is 0.25 meters. The heights are 4.4 meters, 5.2 meters and 2.4 meters respectively. The main operating conditions and product distribution are listed in Table 3, and the properties of gasoline are listed in Table 4.

[0054] It can be seen from the data in Table 3 that the yield of liquefied gas is 16.00% by weight, and the yield of propylene is 7.05% by weight.

Embodiment 2

[0056] This example illustrates the process of catalytic conversion of hydrocarbon oil using the cracking catalyst B containing both Y-type zeolite and ZSM-5 zeolite active components on the medium-scale double-riser reaction regeneration system provided by the present invention.

[0057] The total height of the main riser reactor of the reaction regeneration system is 15 meters, and the diameter is 0.25 meters; the total height of the auxiliary riser reactor is 12 meters, and the diameter is 0.25 meters. The heights are 4.4 meters, 5.2 meters and 2.4 meters respectively. The main operating conditions and product distribution are listed in Table 3, and the properties of gasoline are listed in Table 4.

[0058] It can be seen from the data in Table 3 that the propylene yield was 17.21% by weight.

Embodiment 3

[0060] This example illustrates the process of catalytic conversion of hydrocarbon oil using Catalyst B containing both Y-type zeolite and ZSM-5 zeolite on the medium-scale novel double riser reaction regeneration system provided by the present invention.

[0061] The main reactor of the reaction regeneration system has a total height of 15 meters and a diameter of 0.25 meters; the total height of the auxiliary riser reactor is 12 meters, the diameter of the first reaction zone is 0.25 meters, and its height is 4.4 meters; the diameter of the second reaction zone The diameter of the outlet area is 0.25 meters, and its height is 2.4 meters. The main operating conditions and product distribution are listed in Table 3, and the properties of gasoline are listed in Table 4.

[0062] It can be seen from the data in Table 3 that the yield of propylene was 18.22% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

| motor octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com