Multi-stage absorption, regeneration and purification method of polysilicon tail gas

A technology of polysilicon and exhaust gas, which is applied in the direction of chemical instruments and methods, separation methods, polycrystalline material growth, etc., can solve the problems of increased difficulty in equipment processing, large amount of adsorbent, and high energy consumption, so as to save investment in power equipment and shorten Adsorption cycle, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

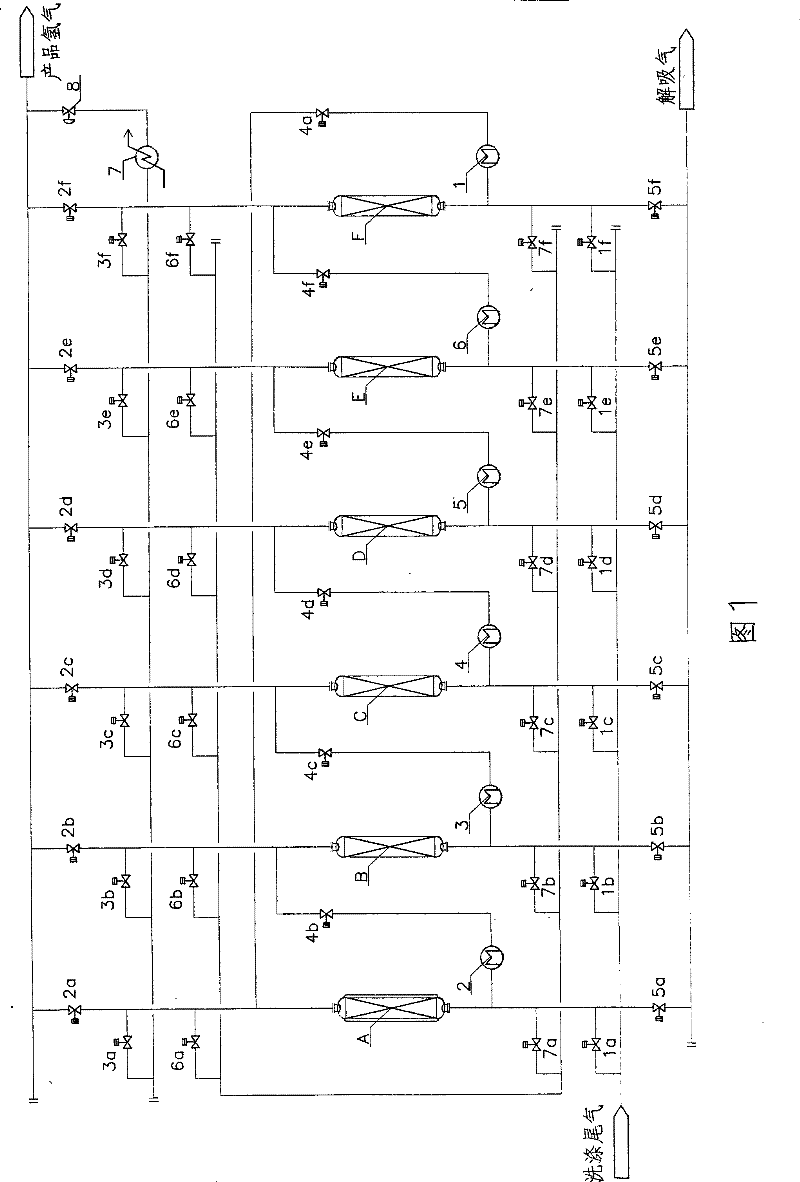

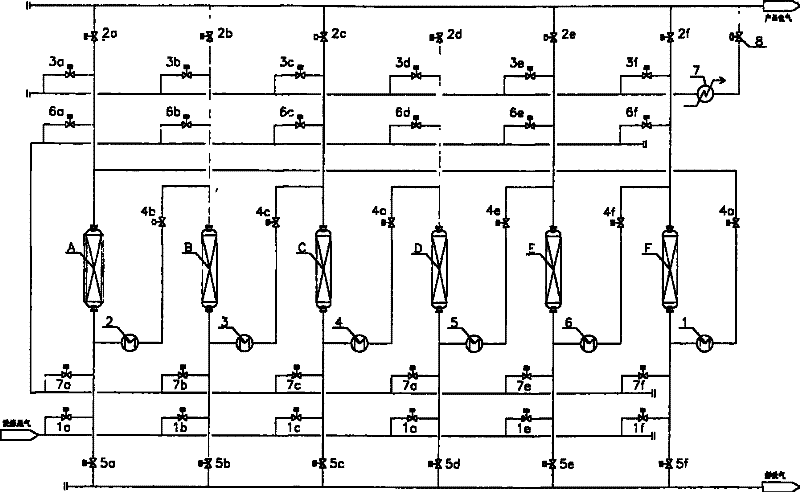

[0019] see figure 1 , for convenience of description, the present invention will be illustrated below with six adsorption towers of A, B, C, D, E, and F as examples. Among them, tower A and tower B are in the adsorption process, tower C is in the preparation process, tower D is in the first stage heating regeneration process, tower E is in the second stage heating regeneration process, and tower F is in the third stage heating regeneration process.

[0020] Adsorption process

[0021] This embodiment adopts double-tower series adsorption, that is, at any time, two towers are in the simultaneous adsorption step, and the feeding time of the two towers is controlled by time delay. That is, column B lags behind column A for half an adsorption cycle to feed.

[0022] The polysilicon tail gas after washing and separation enters from the bottom of tower A through valve 1a, comes out from the top of tower A through valves 6a and 7b, and enters tower B from the bottom of tower B. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com