Covalent organic framework film material for removing triclosan in environmental water as well as preparation method and application of same

A technology of covalent organic framework and thin film materials, applied in chemical instruments and methods, inorganic chemistry, water pollutants, etc., can solve the problems of affecting TCS adsorption, no selectivity of adsorption, unfavorable repeated use, etc., and achieve low cost and high efficiency Absorptive capacity, not easily broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

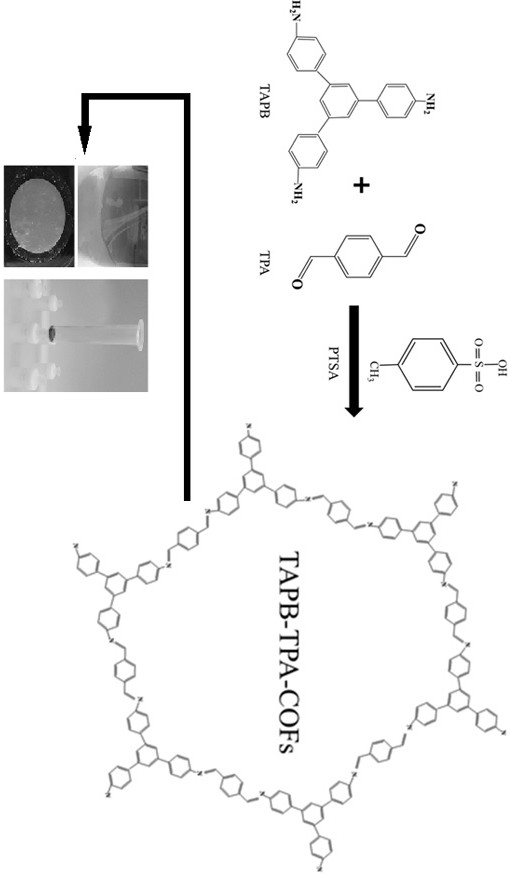

[0058] Preparation of TAPB-TPA-COFs membrane:

[0059] 1) 0.799mol PTSA and 0.267mol TAPB were dissolved in 100 mL of acetonitrile aqueous solution (V MeCN :V H2O =3:7), ultrasonic waves were added to disperse and dissolve to obtain a TAPB / PTSA solution, and pipette 50 mL of the TAPB / PTSA solution into a 250 mL beaker.

[0060] 2) Dissolve 0.267mol TPA in 100 mL ethyl acetate solution, pipette 50 mL of TPA mixture and slowly add it on top of TAPB / PTSA solution, and form an organic phase / aqueous phase interface.

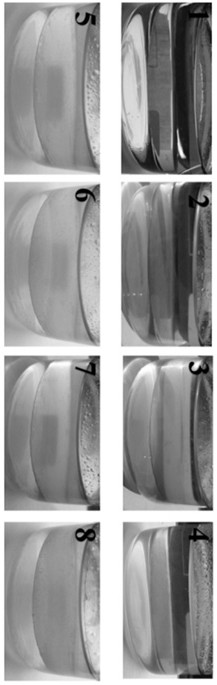

[0061] 3) Seal the beaker with parafilm and let it stand under light for 1-8 days. The growth process is as follows: figure 2 As shown, with the increase of the growth days, the color of the TAPB-TPA-COFs solution gradually deepened to orange-yellow, and the thickness of the film also gradually increased.

[0062] 4) When the TAPB-TPA-COFs film grows out and has a certain thickness, remove the upper organic phase solution, and take out the TAPB-TPA-COFs film into ...

Embodiment 2

[0065] Performance characterization of TAPB-TPA-COFs film under natural light and sunlight:

[0066] 1) 0.799mol PTSA and 0.267mol TAPB were dissolved in 100 mL of acetonitrile aqueous solution (V MeCN :V H2O =3:7), ultrasonic waves were added to disperse and dissolve to obtain a TAPB / PTSA solution, and pipette 50 mL of the TAPB / PTSA solution into a 250 mL beaker.

[0067] 2) Dissolve 0.267 mol of TPA in 100 mL of ethyl acetate solution, pipette 50 mL of TPA mixture and add it slowly on top of TAPB / PTSA solution to form an organic phase / aqueous phase interface.

[0068] 3) Seal the beaker with parafilm, and let it stand for 8 days under natural light indoors and sunlight outdoors.

[0069] 4) When the TAPB-TPA-COFs film grows out and has a certain thickness, remove the upper organic phase solution, and take out the TAPB-TPA-COFs film into a petri dish as a support with an aqueous phase filter paper.

[0070] 5) successively use acetonitrile aqueous solution (V MeCN :V H2O...

Embodiment 3

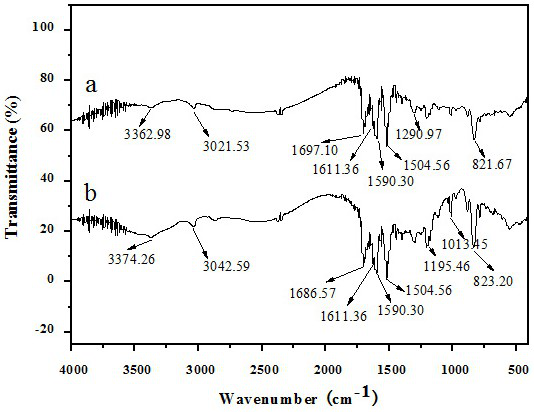

[0073] According to the steps of Example 2, in step 3, the illumination conditions were changed, and the grown TAPB-TPA-COFs film was subjected to X-ray under the irradiation of 365nm ultraviolet light (5W), indoor natural light, outdoor sunlight, and incandescent lamp (30W). Diffraction (XRD) analysis, the results are as follows Figure 4 shown.

[0074] Depend on Figure 4 It can be seen that COFs films of a certain crystal form can be formed under the four light conditions, and the samples obtained under natural light and sunlight show a sharper peak at [100], indicating that the prepared material has better crystallinity and a more structured crystal form. The TAPB-TPA-COFs film has an obvious strong diffraction peak at 2θ=2.3° in the small angle region, corresponding to the (100) diffraction crystal plane. This result indicates that the material has better crystallinity on the (100) crystal plane. This is consistent with most reported COFs materials. The spacing of CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com