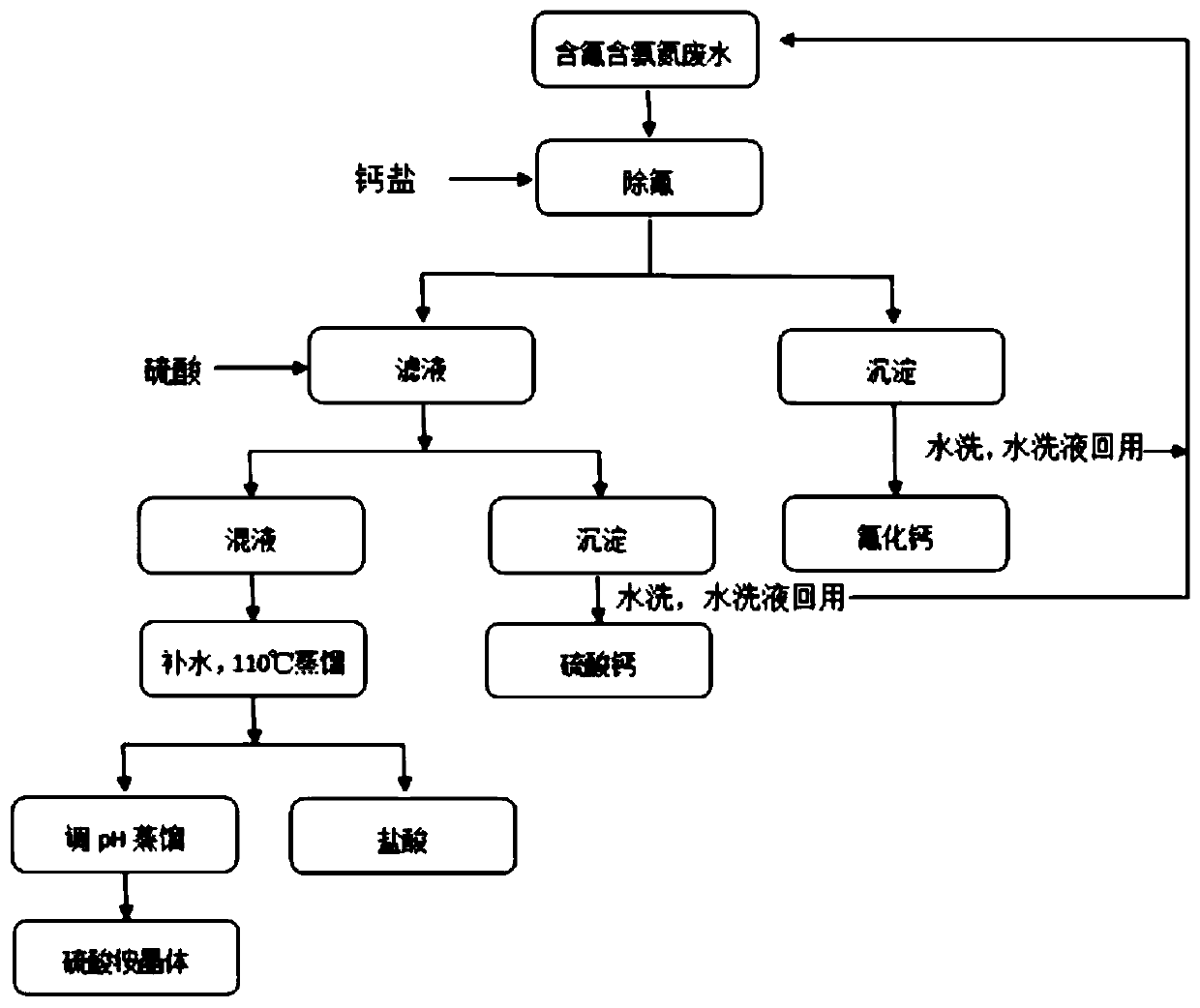

Water treatment method for fully utilizing resources in high-fluorine and high-ammonia nitrogen wastewater

A treatment method and high ammonia nitrogen technology, which is applied in the field of fluorine-containing and ammonia nitrogen wastewater treatment, can solve the problems of corrosiveness, influence on heat exchange efficiency, and decrease of dissolved oxygen in water, and achieve good fluoride removal effect and less residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] High-fluorine and high-ammonia nitrogen waste liquid, stock solution F 5412.785ppm, ammonia nitrogen 3846.45ppm, pH value about 6, add 12g of anhydrous calcium chloride and 8g of calcium hydroxide per liter of stock solution, stir for 2 hours, F drops below 30ppm, at this time the waste The calcium content in the waste liquid is 5341.24ppm; the waste liquid continues to add sulfuric acid to adjust the pH value to 2-3, there is precipitation, and it is filtered after stirring, and the calcium content in the waste liquid is reduced to 58.46ppm; Chloride ions in the medium drop to 26.49ppm; continue to add ammonia water to the waste liquid to adjust the pH value to 5-6, and obtain ammonium sulfate crystals and steam water that can be directly discharged after distillation.

Embodiment 2

[0024] Fluorine-containing ammonia-nitrogen wastewater, stock solution F 458ppm, ammonia nitrogen 2419.36ppm, pH 7, add 0.7g anhydrous calcium chloride and 0.5g calcium hydroxide to 1L stock solution, stir and filter, F content drops to 5.36ppm, calcium content is 200ppm , the chlorine content is 604.25ppm; after adding sulfuric acid to adjust the pH, a small amount of precipitation is obtained, and the calcium drops to 40ppm; at 110°C, the water is continuously replenished and distilled, and when the water output is about 80%, the chlorine content drops to 32.6ppm, and there is a small amount of precipitation in the mother liquor; After the mother liquor is filtered, the pH is adjusted, and the ammonium sulfate crystals and steam water are obtained by pressure distillation.

Embodiment 3

[0026] The BOE stock solution is 70g / L of medium F, add 195g anhydrous calcium chloride + 130g calcium hydroxide to 1L stock solution, stir for 2 hours and filter, repeat the above steps for the filtrate, add 195g anhydrous calcium chloride + 130g calcium hydroxide and stir for 2 Filter after 1 hour, F in the filtrate drops below 30ppm, and the calcium content in the filtrate is 1g / L; Add sulfuric acid to adjust the pH to about 1, a large amount of precipitation (calcium sulfate) occurs, and the calcium content in the detection solution after filtration is 506ppm; 110°C Distill under reduced pressure, add water continuously during the distillation process, the chlorine drops from about 2.8g / L to 56.36ppm, and there is precipitation in the mother liquor, at this time, the calcium content in the mother liquor is detected to drop below 50ppm; adjust the pH to 5.4 for distillation to a large number of ammonium sulfate crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com